Cooling water angle adjustable crystallizer for aluminium alloy casting

A technology of aluminum alloy and cooling water, applied in the field of semi-continuous casting of aluminum alloy, which can solve the problems of limited adjustment range and immutability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

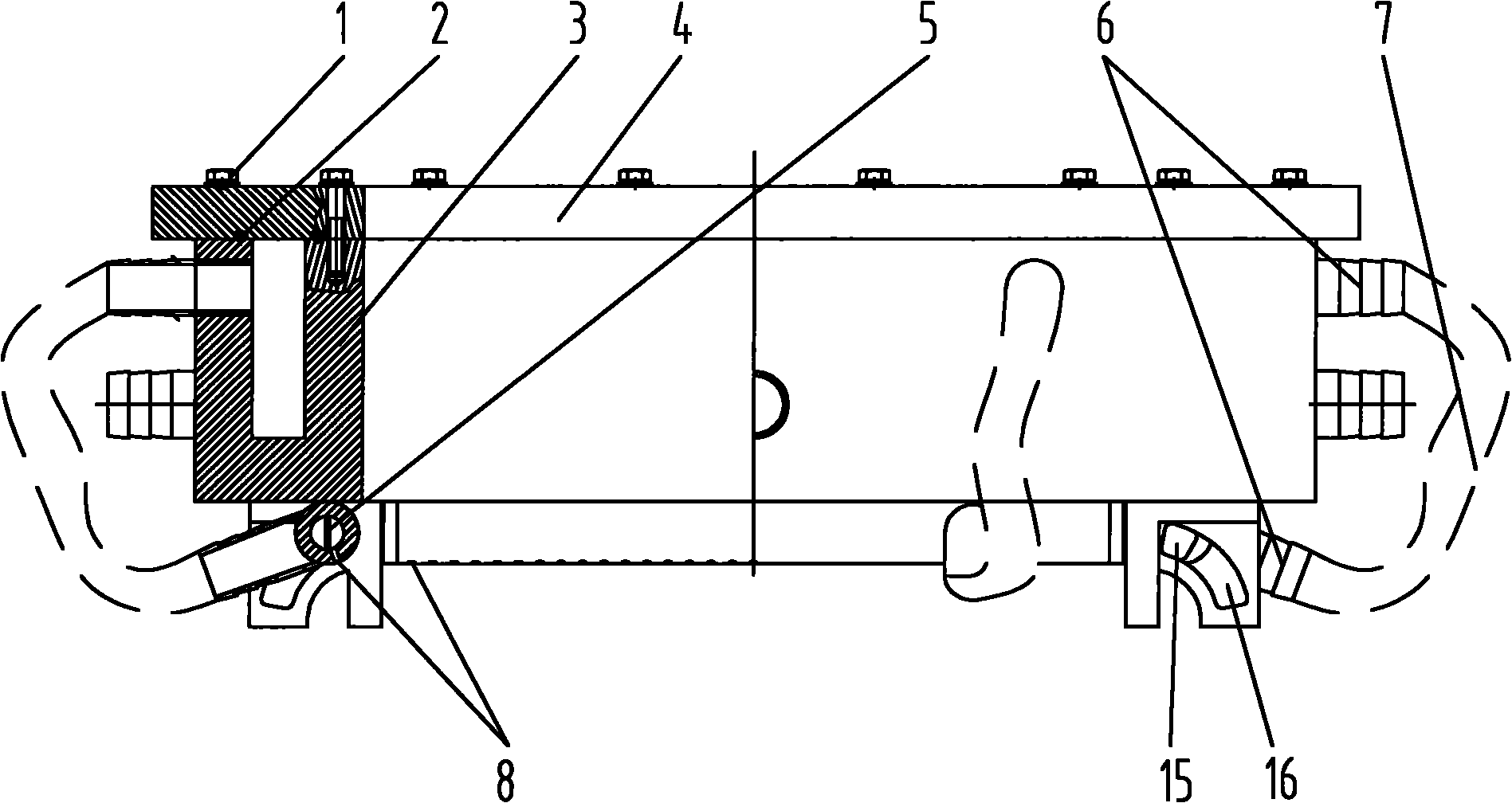

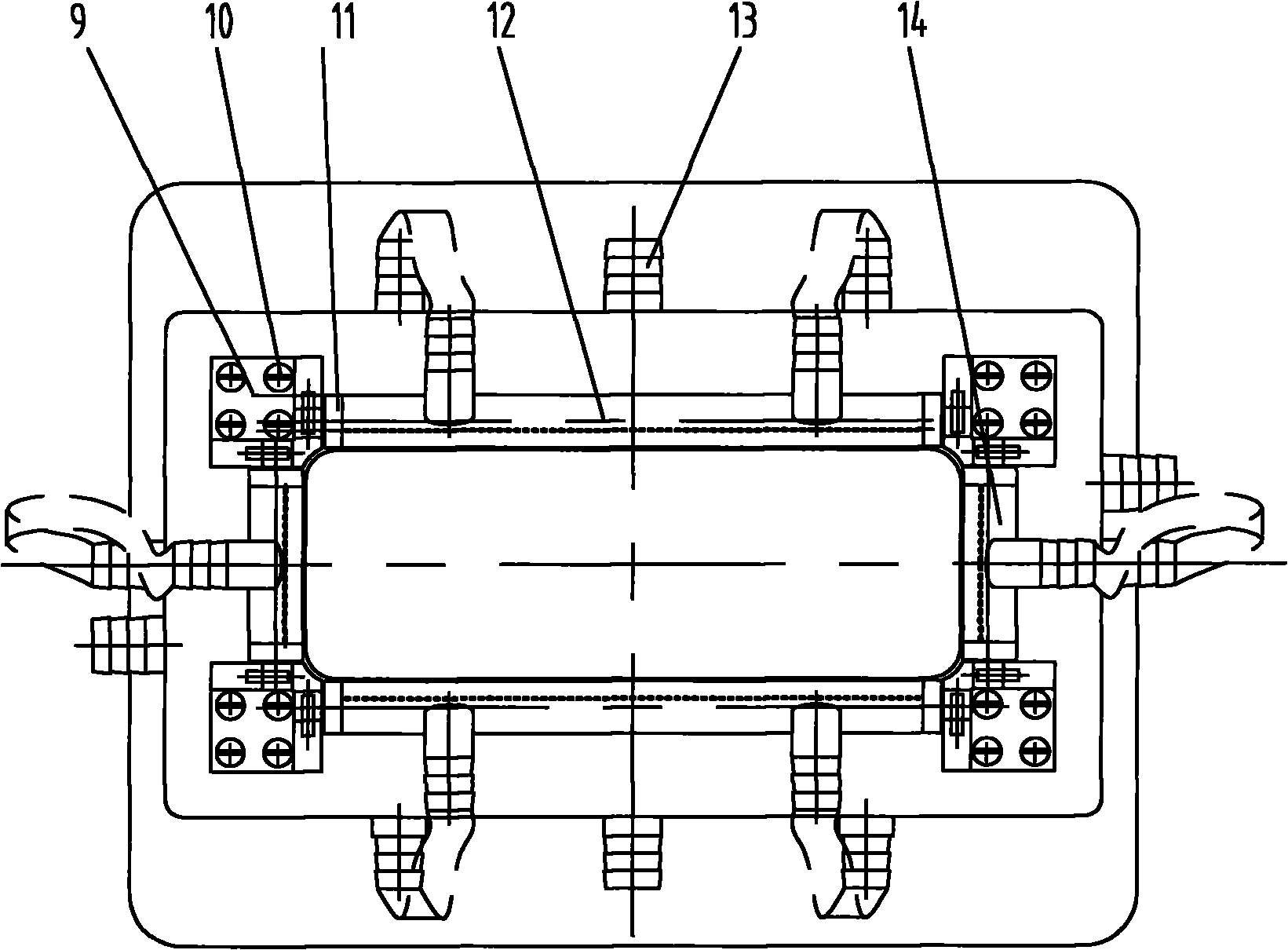

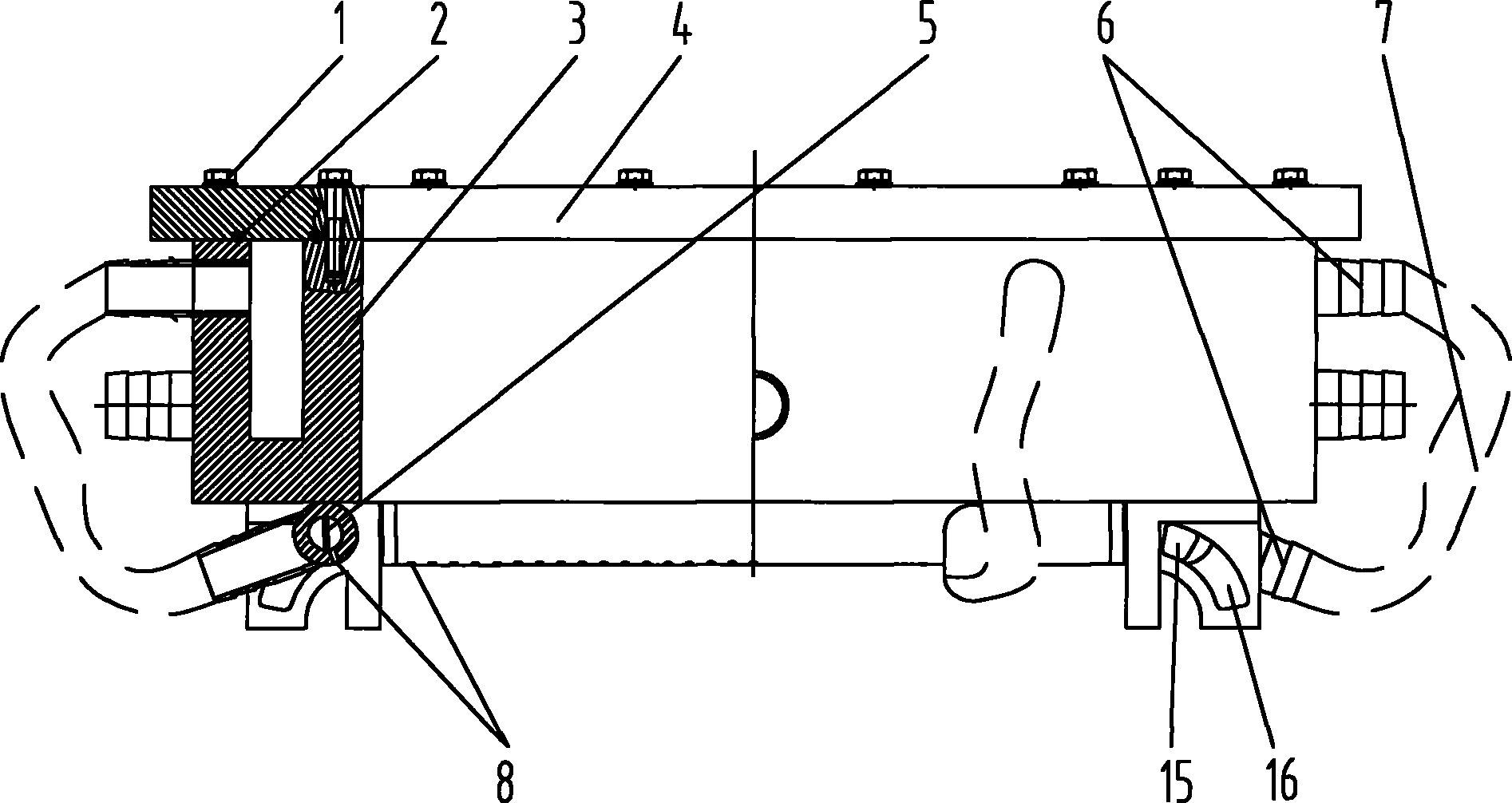

[0018] Such as figure 1 , figure 2 As shown, the crystallizer with adjustable cooling water angle for aluminum alloy casting includes a main body 3 and an upper cover 4. The upper cover 4 is connected to the main body 3 by bolts 1 and sealed by a sealing strip 2. The main body is provided with a cooling water cavity. Rolling surface cooling pipes 12 are respectively installed on the front and rear rolling surfaces of the cooling water chamber, and the rolling surface cooling pipes 12 are connected with the rolling surface cooling water chamber. 14 communicates with the cooling water cavity of the narrow surface, the four corners of the bottom surface of the main body are respectively fixed with fixed blocks 9 by bolts 10, the two ends of the front and rear rolling surface cooling pipes 12 and the two ends of the left and right narrow surface cooling pipes 14 are respectively passed through the sliding blocks 11 is movably connected with the corresponding fixed block 9, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com