Oil collector for hydraulic oil tank of roll bending hydraulic station

A technology of hydraulic oil tank and oil collecting device, which is applied in the direction of oil supply oil tank device, metal rolling, metal rolling rack, etc. It can solve the problems of flowing to the ground and the difficulty of hydraulic oil in the oil tank getting into the oil barrel, etc., and achieves relief The workload, the structure is simple, and the effect of avoiding oil accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

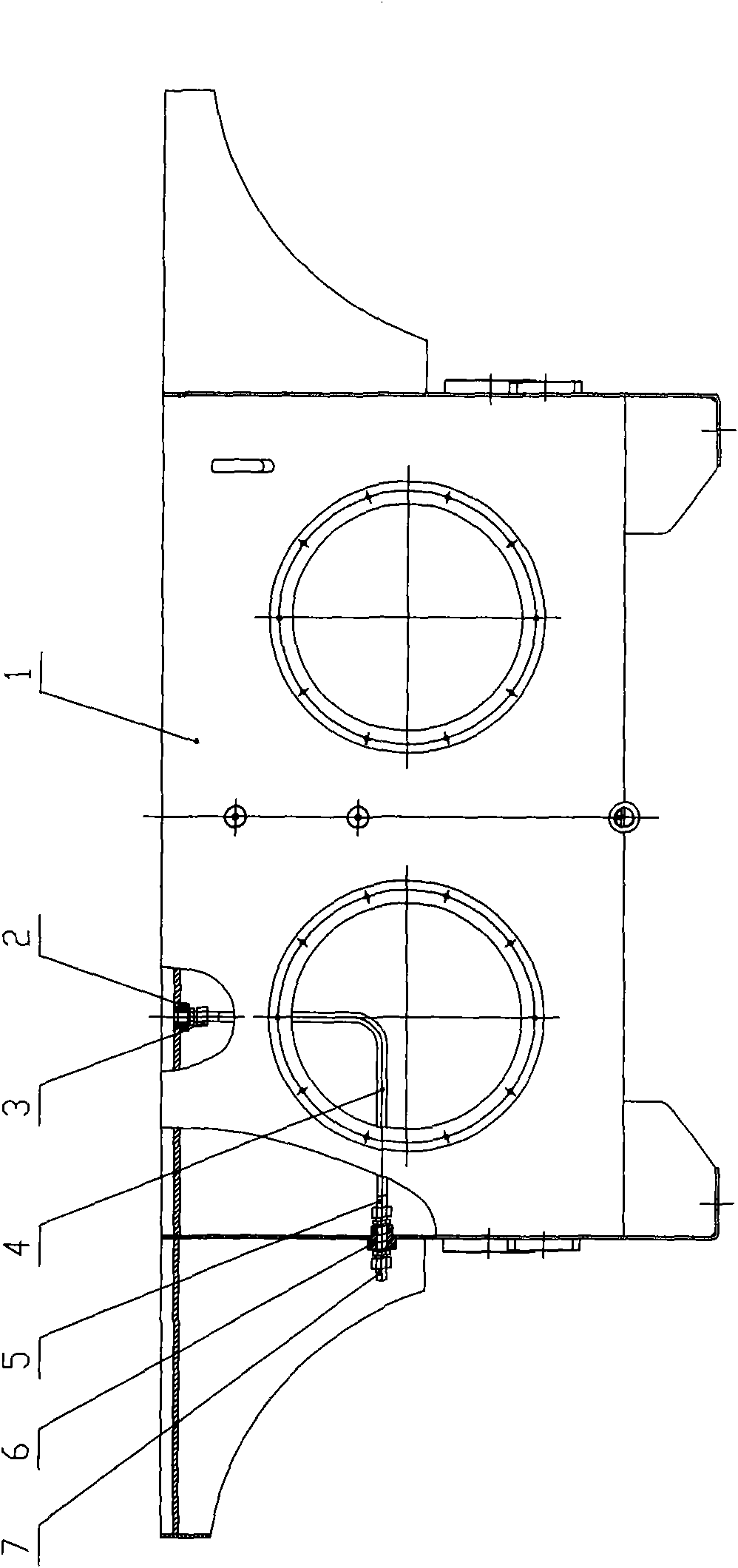

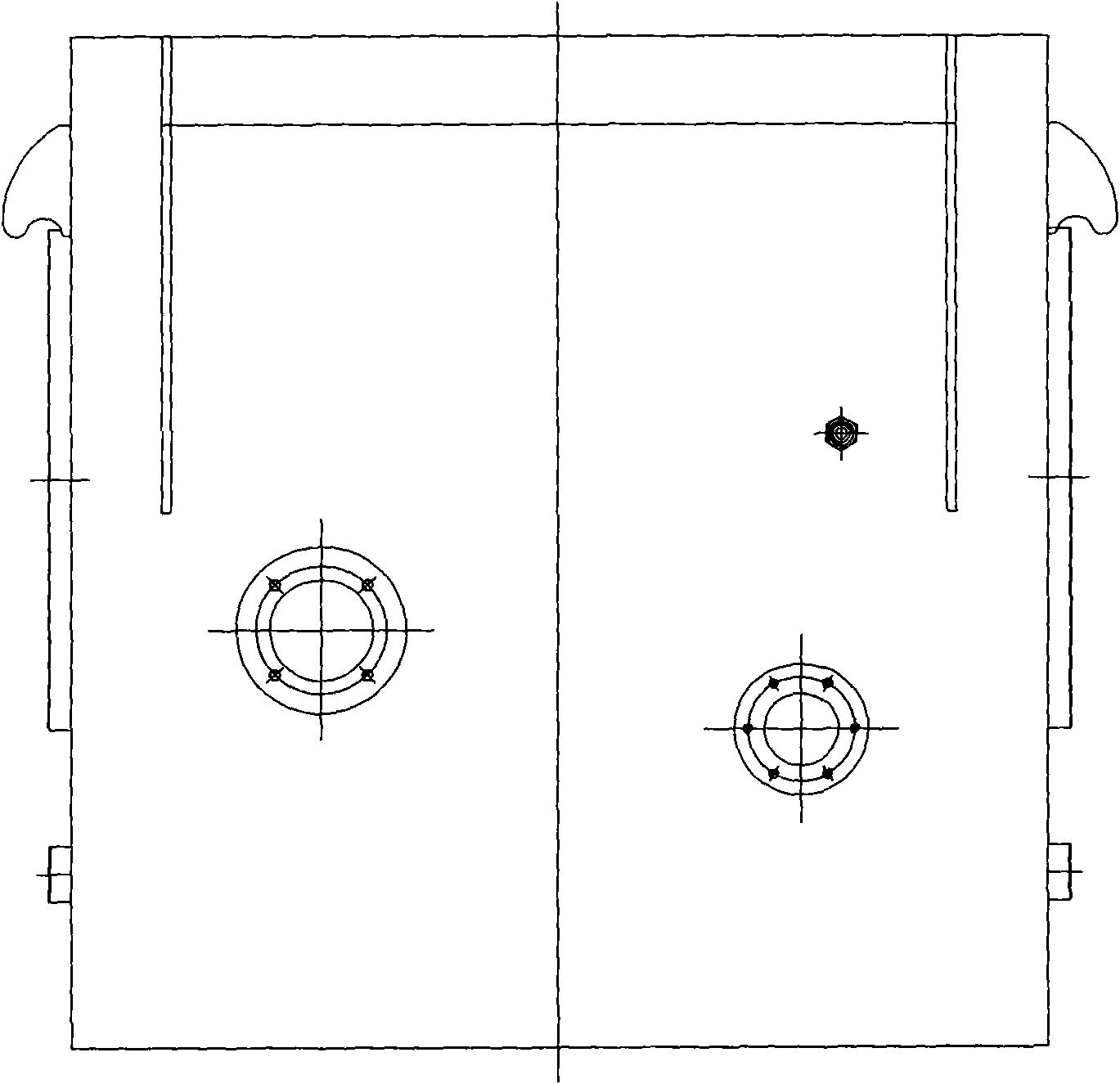

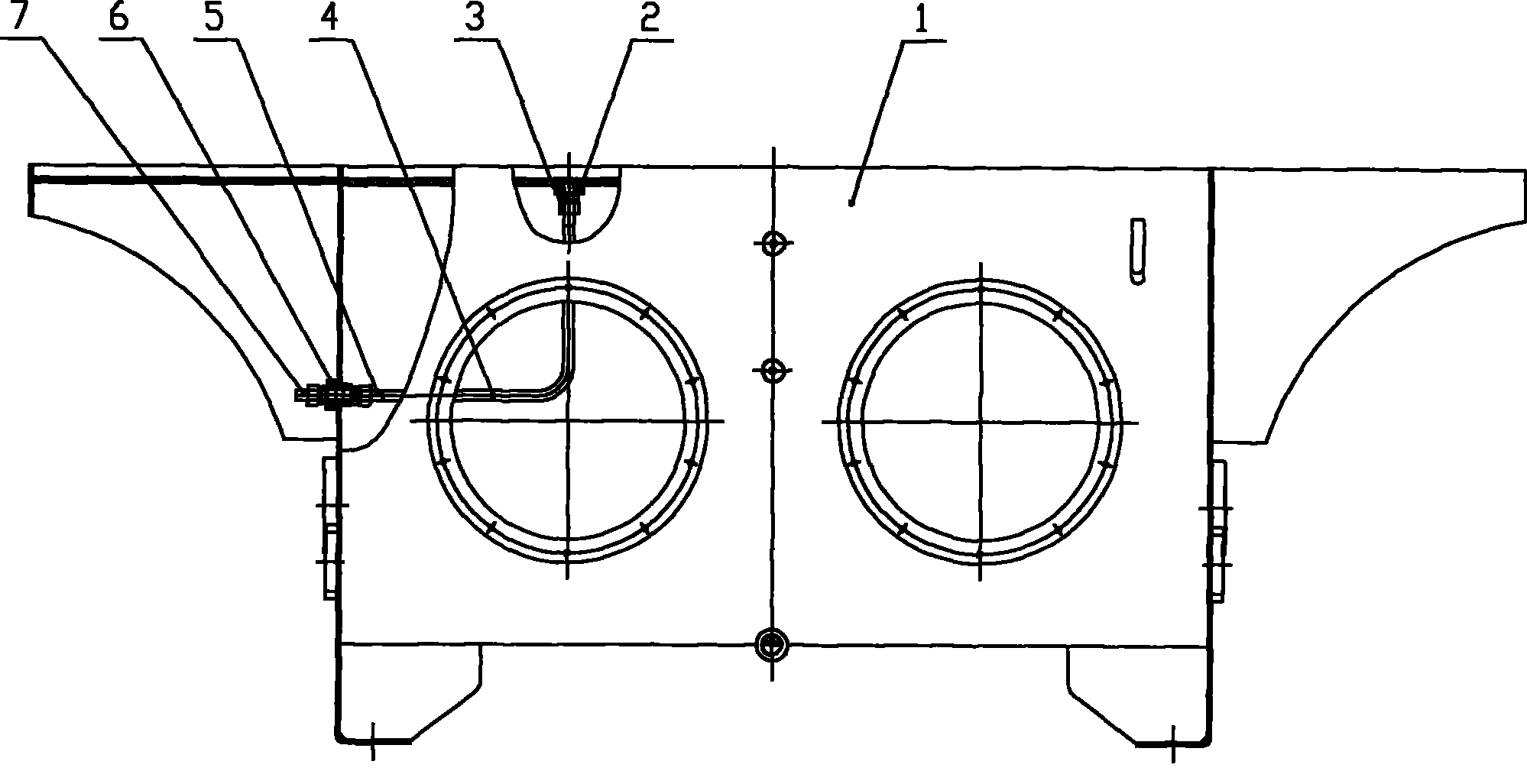

[0011] Such as Figure 1 ~ Figure 2 As shown, it includes a hydraulic oil tank 1 , an internal thread joint 2 , a first straight joint 3 , a steel pipe 4 , a second straight joint 5 , a joint body 6 and a third straight joint 7 .

[0012] The present invention adopts the hole of drilling a φ 35 on the lower left side of the hydraulic oil tank 1 top plate; As shown in the left view, also drill a φ 35 hole in the right side middle part of this view. Weld an internal thread joint 2 on the top of the hydraulic oil tank 1 and weld a joint body 6 on the side of the hydraulic oil tank 1 to facilitate the installation of hydraulic pipe joints; the steel pipe 4 Bend to 90 degrees, weld the first straight joint 3 and the second straight joint 5 on both sides of the steel pipe 4 respectively, the first straight joint 3 and the second straight joint 5 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com