Automatic fine sand separation and recovery device

A technology of separation and recovery, fine sand, applied in solid separation, chemical instruments and methods, filter screens, etc., can solve the problems of lack of safety buffer devices, inability to adjust the height of conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

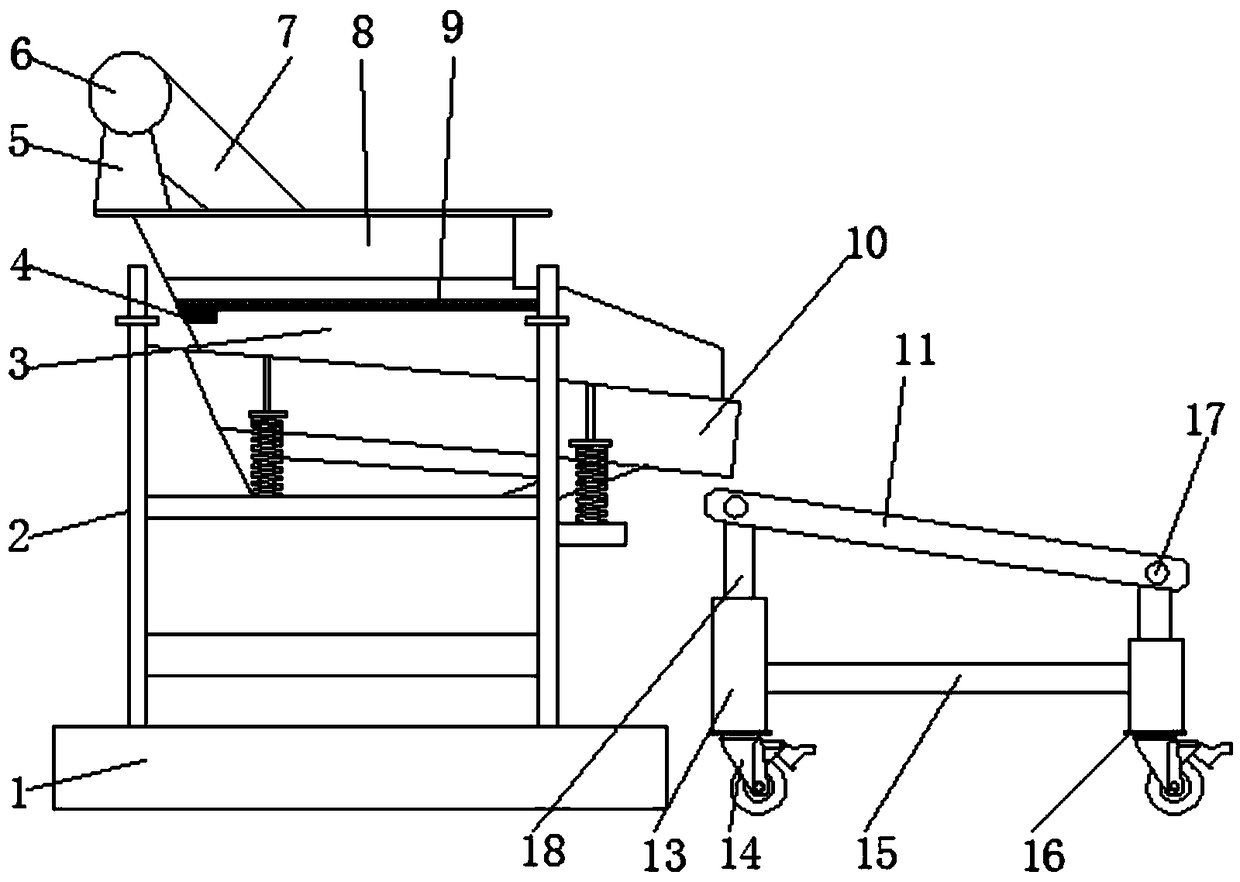

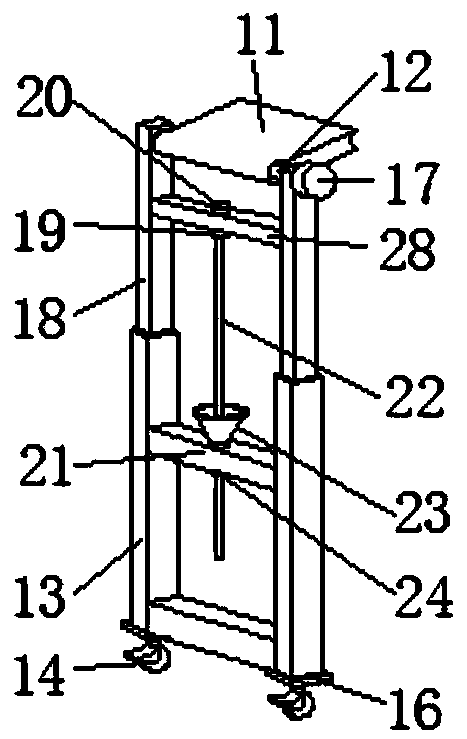

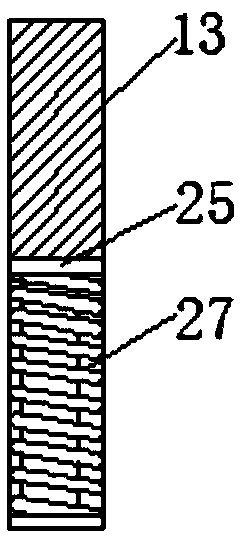

[0021] see Figure 1-4 , this embodiment provides an automatic fine sand separation and recovery device, including a base 1, a support rod 13 and a connecting rod 15, the supporting rod 13 is arranged on one side of the base 1, and the connecting rod 15 is arranged between the two supporting rods 13 , the number of connecting rods 15 is set to three, the upper end surface of the base 1 is connected with a bottom shell 2, the inner cavity of the bottom shell 2 is equipped with a fine sand separation shell 3, and the upper end surface of the fine sand separation shell 3 is provided with a feed port 8 , the interior of the fine sand separation shell 3 is provided with a filter screen 9, the lower end surface of the filter screen 9 is connected with a vibrator 4, the upper end face side of the fine sand separation shell 3 is equipped with a connecting seat 5, and the upper end face of the connecting seat 5 is provided with Blast device 6, one side of the blast device 6 is connecte...

Embodiment 2

[0024] see figure 1 On the basis of Embodiment 1, a further improvement has been made: the bottom end surface of the support rod 13 is welded with a fixed seat 16, and the lower end surface of the fixed seat 16 is provided with a universal wheel 14, and the universal wheel 14 is added to facilitate the movement of the transmission device .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com