Multi-way valve for tractor hydraulic lifter

A technology for hydraulic lifters and tractors, applied in the field of multi-way valves, can solve problems such as inconvenient operation, achieve the effects of convenient operation, improve stability and safety, and prevent uncontrolled self-dropping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

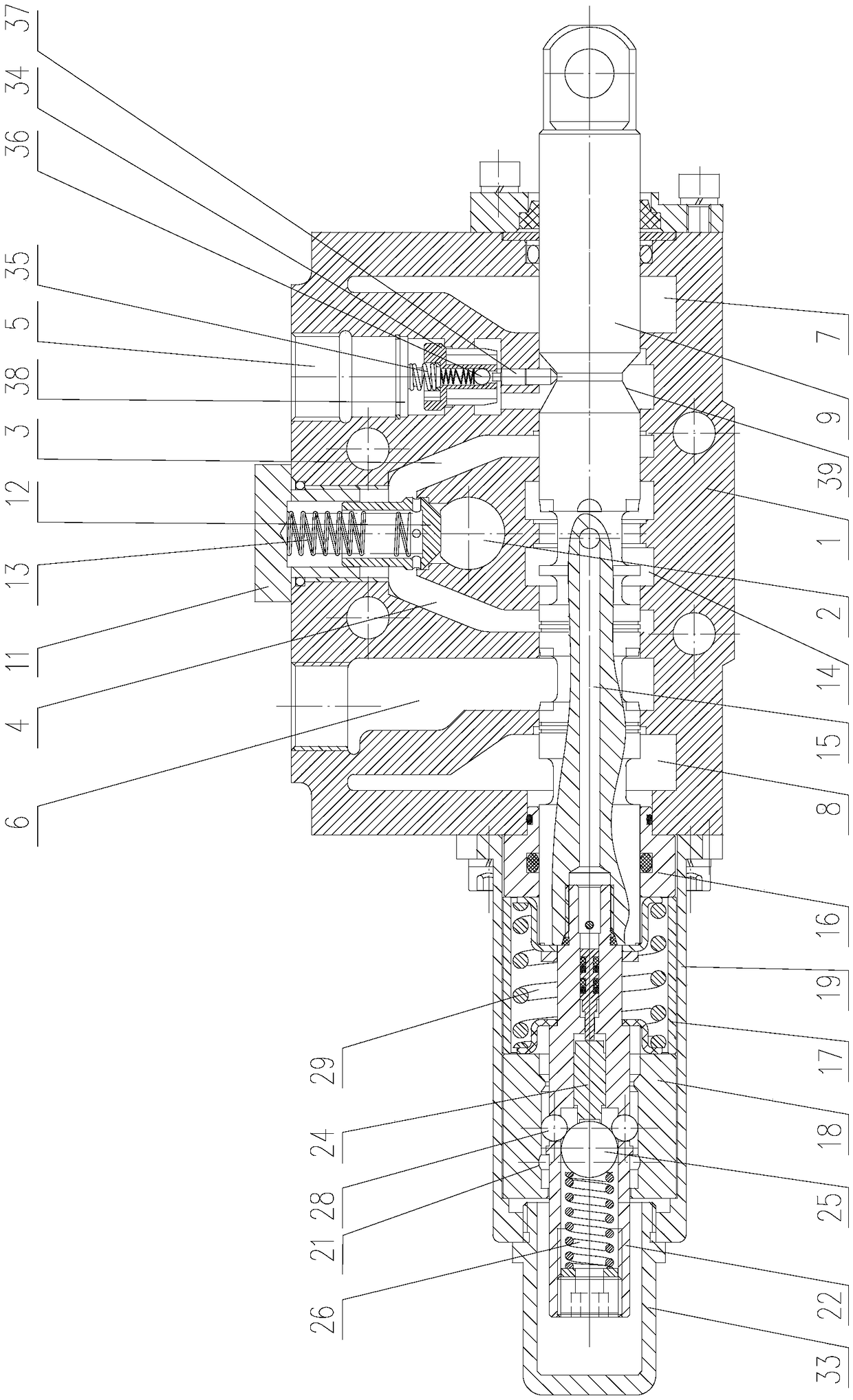

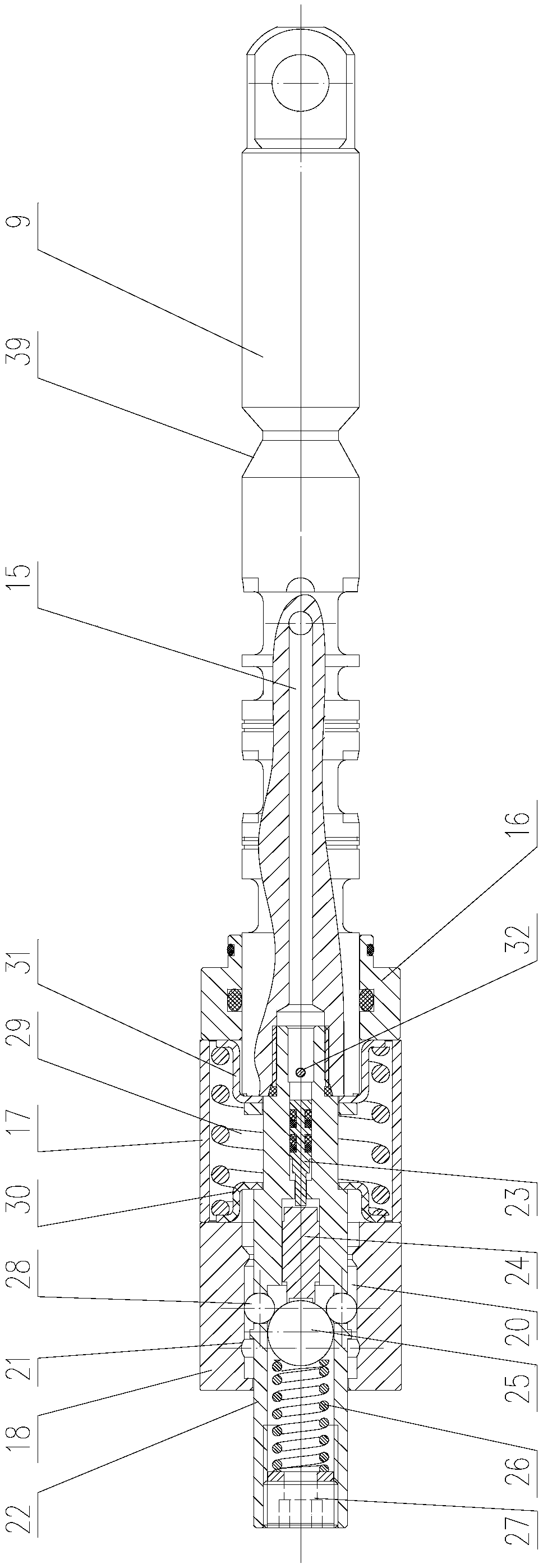

[0017] Such as figure 1 and figure 2 As shown, the multi-way valve for tractor hydraulic lifter of the present invention comprises valve body 1, and valve body 1 is provided with oil inlet chamber 2, oil passage A 3, oil passage B 4, oil outlet chamber A 5, oil outlet Chamber B 6, oil return chamber A 7, oil return chamber B 8 and valve stem 9, valve stem 9 is airtight and slidingly connected with valve body 1, installed at the intersection of oil inlet chamber 2, oil passage A 3 and oil passage B 4 There is a one-way valve, and the one-way valve includes a one-way valve seat 11, a conical valve body 12 and a one-way valve spring 13, and the one-way valve spring 13 is assembled in the valve body 1 through the one-way valve seat 11, and the one-way valve The valve seat 11 and the valve body 1 are sealed with a sealing ring; the valve stem 9 is equipped with oil passage A 3, oil passage B 4, oil outlet chamber A 5, oil outlet chamber B 6, oil return chamber A 7 and The ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com