Navigation device in orthopedics department and preparation method of navigation device

A navigation device and orthopedic technology, applied in the field of medical equipment, can solve problems such as insufficient connection of orthopedic surgery, scattered overall structure, heavy medical equipment, etc., and achieve the effects of good system compatibility, good molding and processing performance, and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

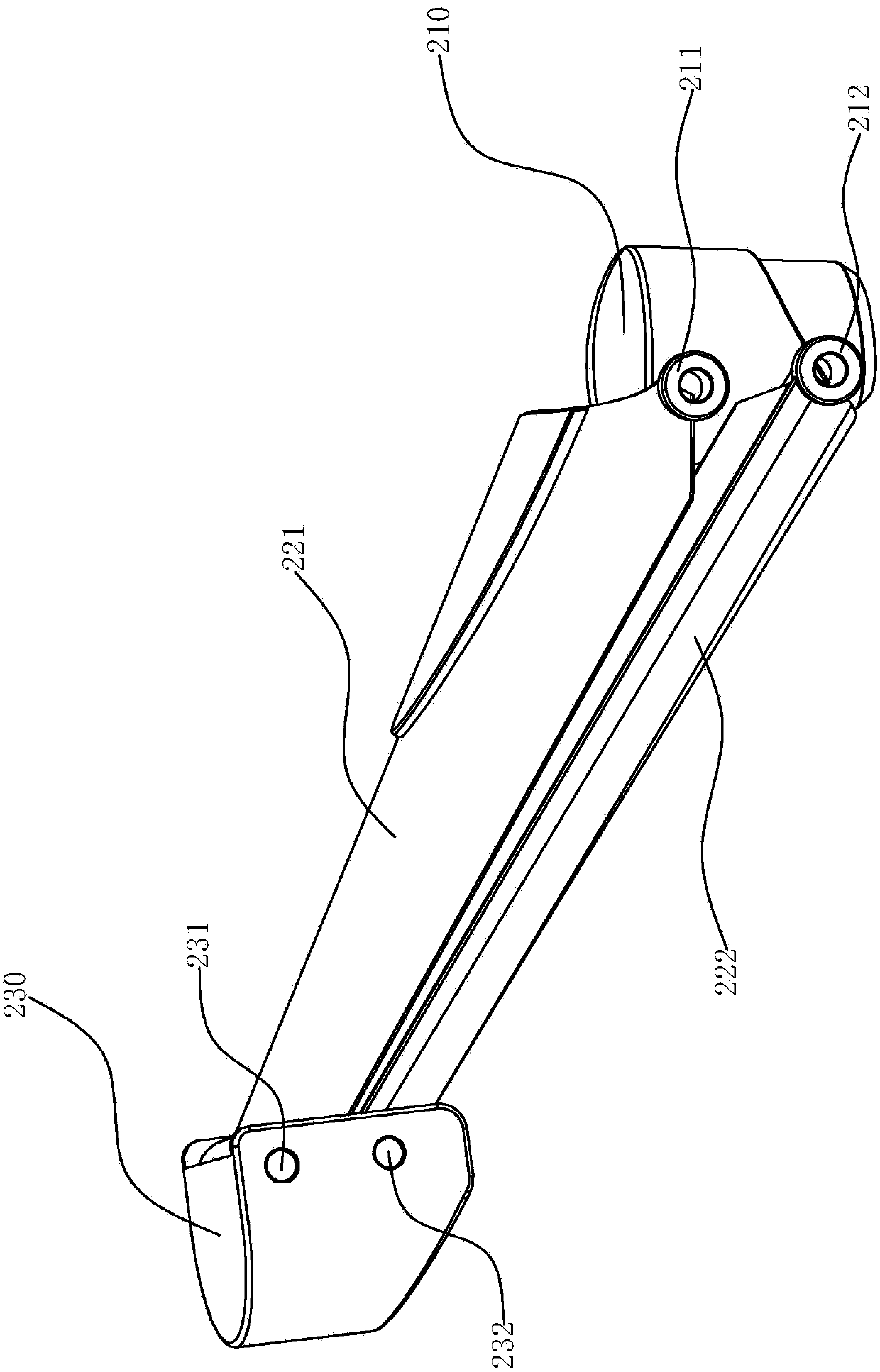

[0054] Weigh the raw materials according to the composition and weight parts of the modified polyphenylene ether plastic material of the first movable arm and the second movable arm of Example 1 in Table 1, and place the polyphenylene ether, polybutene and HIPS at a temperature of Blow dry at 80°C for 3 hours. At the same time, the barrel in the high-speed injection molding machine was heated to 170 ° C, and then the LDPE, titanium dioxide, interface modifier, toughening modifier, glass fiber, antioxidant, toner and dried polymer were weighed above. Phenyl ether, polybutene, and HIPS are thoroughly mixed and added to the barrel, and heated to a molten state. The nozzle passing through the hot runner with a temperature of 260°C is injected into the molds of the first movable arm and the second movable arm with a temperature of 60°C in two times, wherein the first injection pressure is 100MPa, and the second injection pressure is 100MPa. Then, the first movable arm and the seco...

Embodiment 2

[0056] Weigh the raw materials according to the composition and parts by weight of the modified polyphenylene ether plastic materials of the first movable arm and the second movable arm of Example 2 in Table 1, and place the polyphenylene ether, polybutene and HIPS at a temperature of Blow dry at 95°C for 2 hours. At the same time, the barrel in the high-speed injection molding machine was heated to 185°C, and then the LDPE, titanium dioxide, interface modifier, toughening modifier, glass fiber, antioxidant, toner and dried polymer were weighed above. Phenyl ether, polybutene, and HIPS are thoroughly mixed and added to the barrel, and heated to a molten state. The nozzles passing through the hot runner with a temperature of 275°C are injected into the molds of the first movable arm and the second movable arm at a temperature of 75°C in two times, wherein the first injection pressure is 110 MPa, and the second injection pressure is 85 MPa. Then, the first movable arm and the s...

Embodiment 3

[0058] Weigh the raw materials according to the composition and parts by weight of the modified polyphenylene ether plastics of the first movable arm and the second movable arm of Example 3 in Table 1, and place the polyphenylene ether, polybutene and HIPS at a temperature of Blow dry at 110°C for 1 hour. At the same time, the barrel in the high-speed injection molding machine was heated to 190 ° C, and then the LDPE, titanium dioxide, interface modifier, toughening modifier, glass fiber, antioxidant, toner and dried polymer that were weighed above were mixed. Phenyl ether, polybutene, and HIPS are thoroughly mixed and added to the barrel, and heated to a molten state. The nozzles passing through the hot runner with a temperature of 285°C are injected into the molds of the first movable arm and the second movable arm with a temperature of 75°C in two times, wherein the first injection pressure is 120 MPa, and the second injection pressure is 70 MPa. Then, the first movable ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com