A detection method for an inertial rotor

A detection method and rotor technology, applied in the detection field, can solve problems such as easy pressure deviation, difficult measurement, and difficult clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

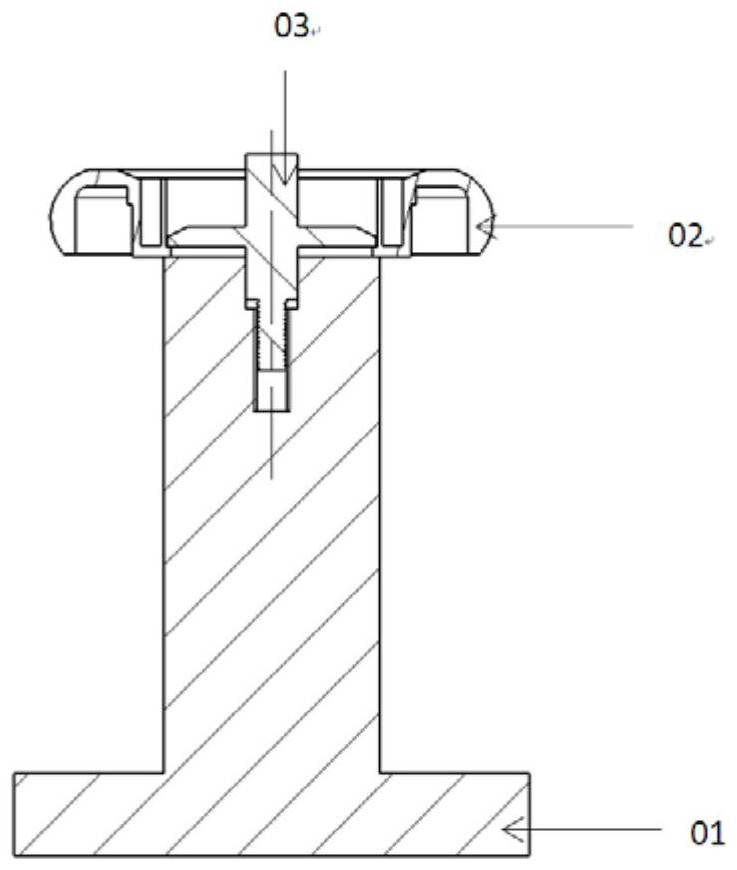

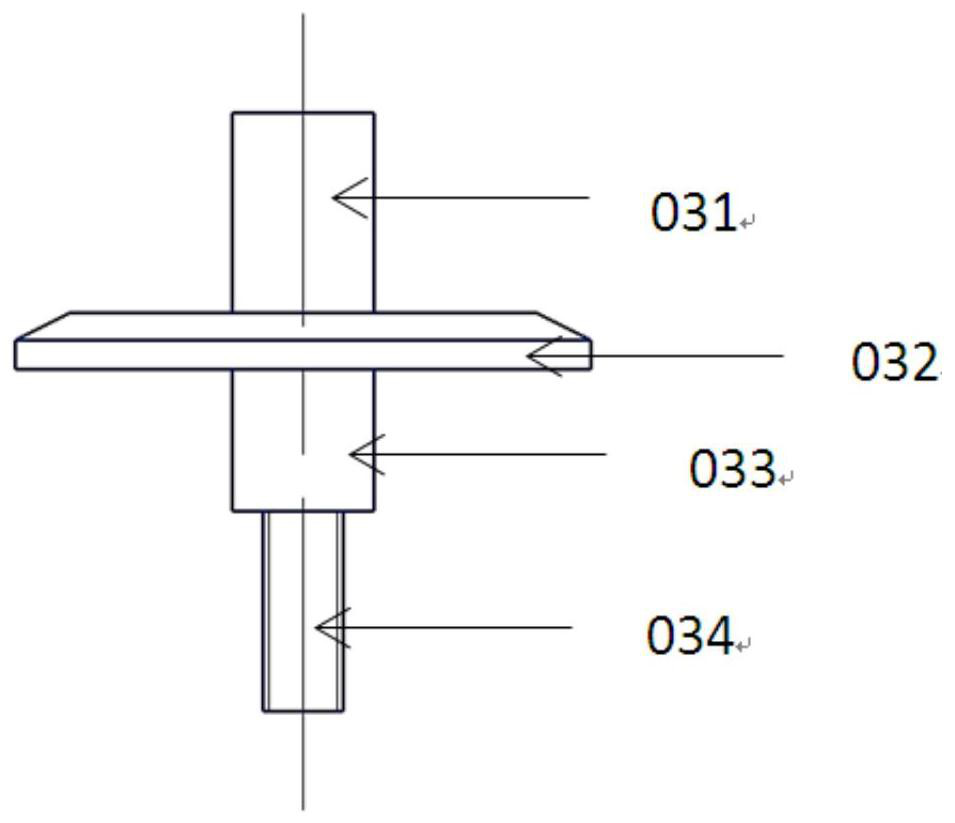

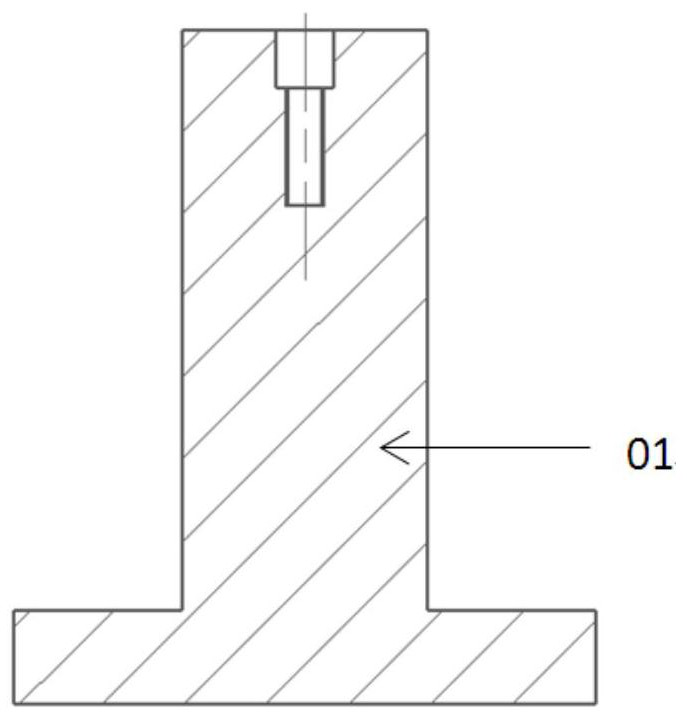

[0014] Below in conjunction with accompanying drawing, the present invention is further described:

[0015] A method for detecting an inertial rotor, which is characterized in that the lower surface of the inertial rotor is placed in a self-made inertial rotor detection tool, the large hole in the center step hole of the inertial rotor is centered, and the end face of the small hole in the center step hole of the inertial rotor is pressed tightly to increase the The effective measurement range of the center step hole and the large hole, the pressing force is balanced, the measuring needle of the three-coordinate measuring machine is moved to any position in the center step hole of the inertial rotor except the upper and lower edges, and the operating lever of the three-seat meter measuring machine is manually operated. Collect points on the circumference of any position except the upper and lower edges on the big hole in the center step hole of the inertial rotor, read the valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com