Inertial rotor detection tooling

A technology for testing tooling and rotors, applied in the field of testing, can solve problems such as not easy measurement, not easy to clamp, no clamping support surface to press the fixed surface, etc., to increase the effective measurement range, ensure accuracy, and clamp Small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is further described:

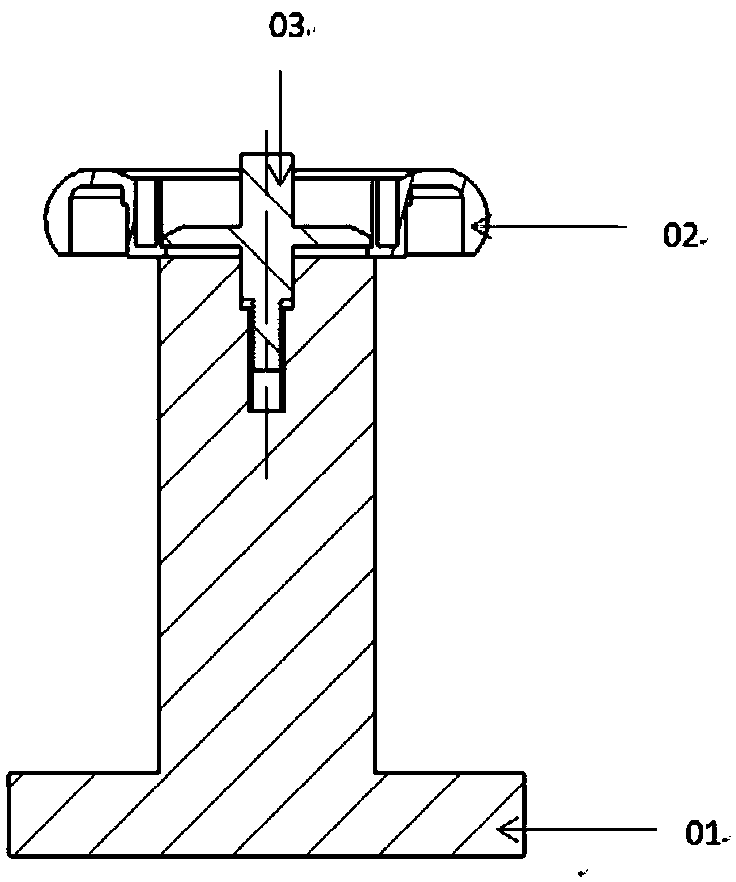

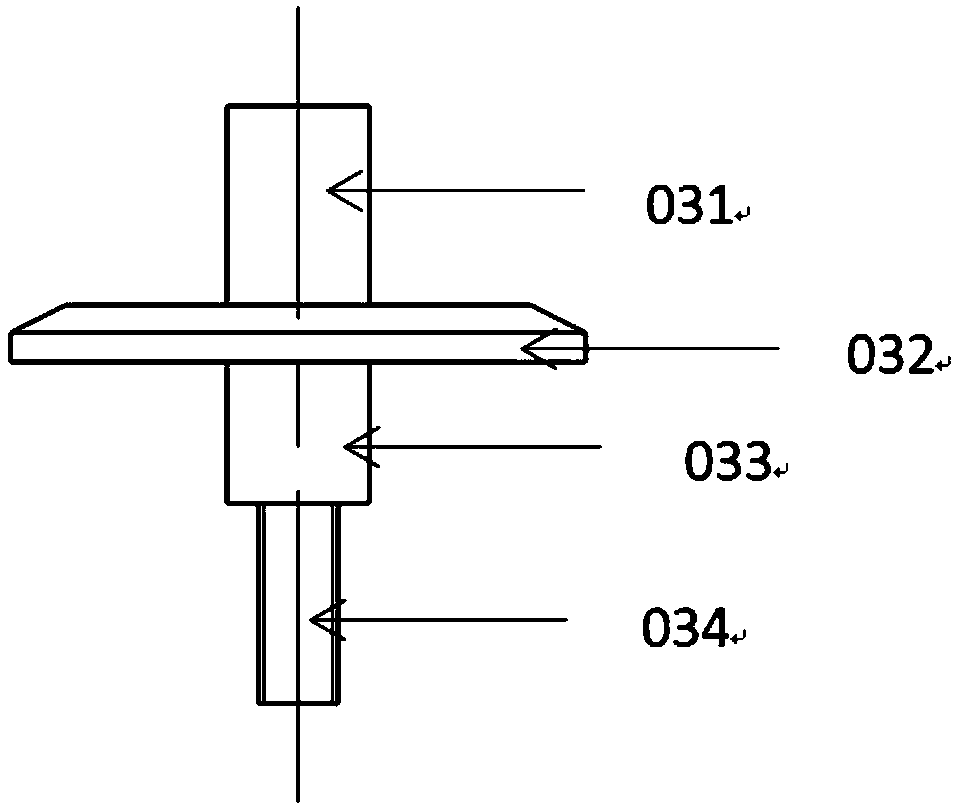

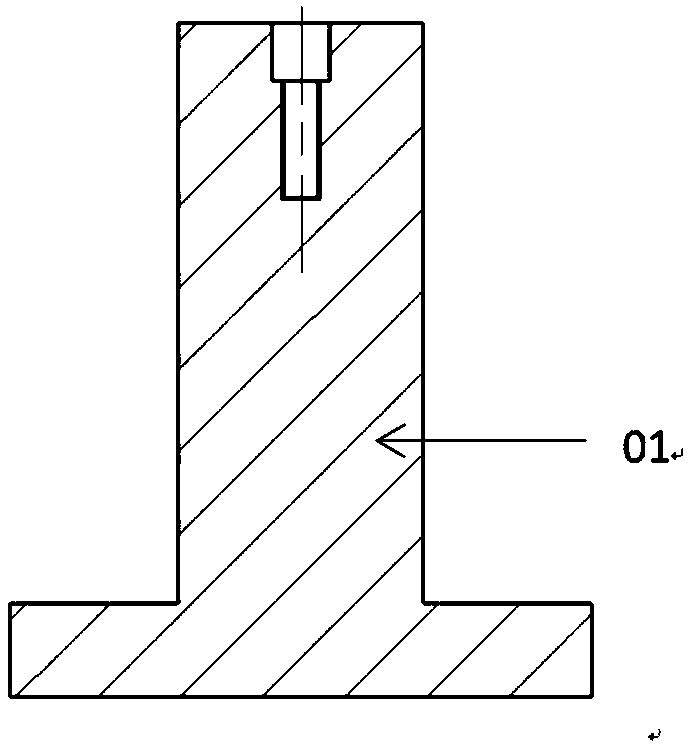

[0014] like Figure 1 to Figure 4 As shown, an inertial rotor detection tool is characterized in that it includes a main body 01 of the tooling and a compression cap 03; the main body 01 is a stepped cylinder, the lower end is a chassis, and the center of the upper end is provided with a second-level stepped hole, and the second-level stepped hole and The main body 01 is coaxial with the step cylinder, the small diameter part of the step hole is provided with threads, and the upper end surface is parallel to the lower chassis plane; the compression cap 03 includes the knob rod 031, the disc 032, the precision guide column 033, the threaded rod 034, and the compression cap 03 is installed in the upper end step hole of the main body 01, the threaded rod 034 is threaded with the small diameter part of the step hole, the bottom surface of the disc 032 is attached to the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com