A Calculation Method of Automatic Production Line Equipment Fault Shutdown Rate

An automatic production line and equipment failure technology, applied in the field of failure rate calculation, can solve the problems of different influences on the production line and the inability to truly reflect the operation status of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

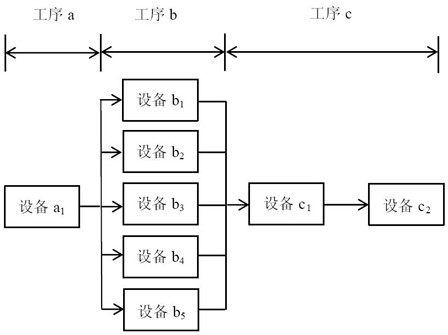

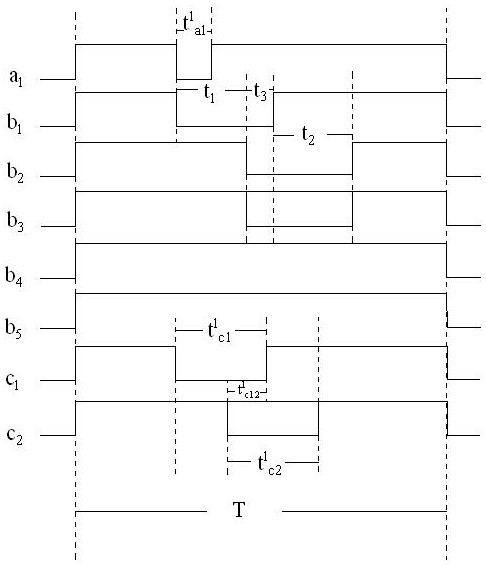

[0027] Such as figure 1 As shown, in this embodiment, the schematic diagram of the process of the automated production line is as follows figure 2 As shown, the automated production line includes three processes a, b, and c, and process a includes a 1 One piece of equipment; process b is a parallel equipment process, including b 1 , b 2 , b 3 , b 4 and b 5 Five parallel equipment; process c is a serial equipment process, including c 1 and c 2 Two devices in series; device a 1 , equipment b 1 , b 2 , b 3 , b 4 and b 5 , equipment c 1 and c 2 downtime of image 3 shown;

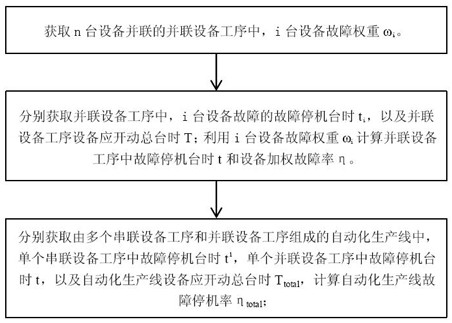

[0028] The calculation method of automatic production line equipment failure shutdown rate includes the following steps:

[0029] Step 1: Obtain the failure weight ω of i equipment in the process of parallel equipment with n equipment connected in parallel i ;

[0030] ω i Indicates the influence degree of i equipment failure on the process of parallel equipment, 0≤i≤n, and i is an integer;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com