A maintenance device for high-altitude special equipment

A technology for overhauling devices and special equipment, which is applied to switchgear, workbenches, electrical components, etc. It can solve problems such as inconvenient use, high energy consumption, and non-adjustability, and achieves the effects of easy use, low operation difficulty, and reduced self-gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

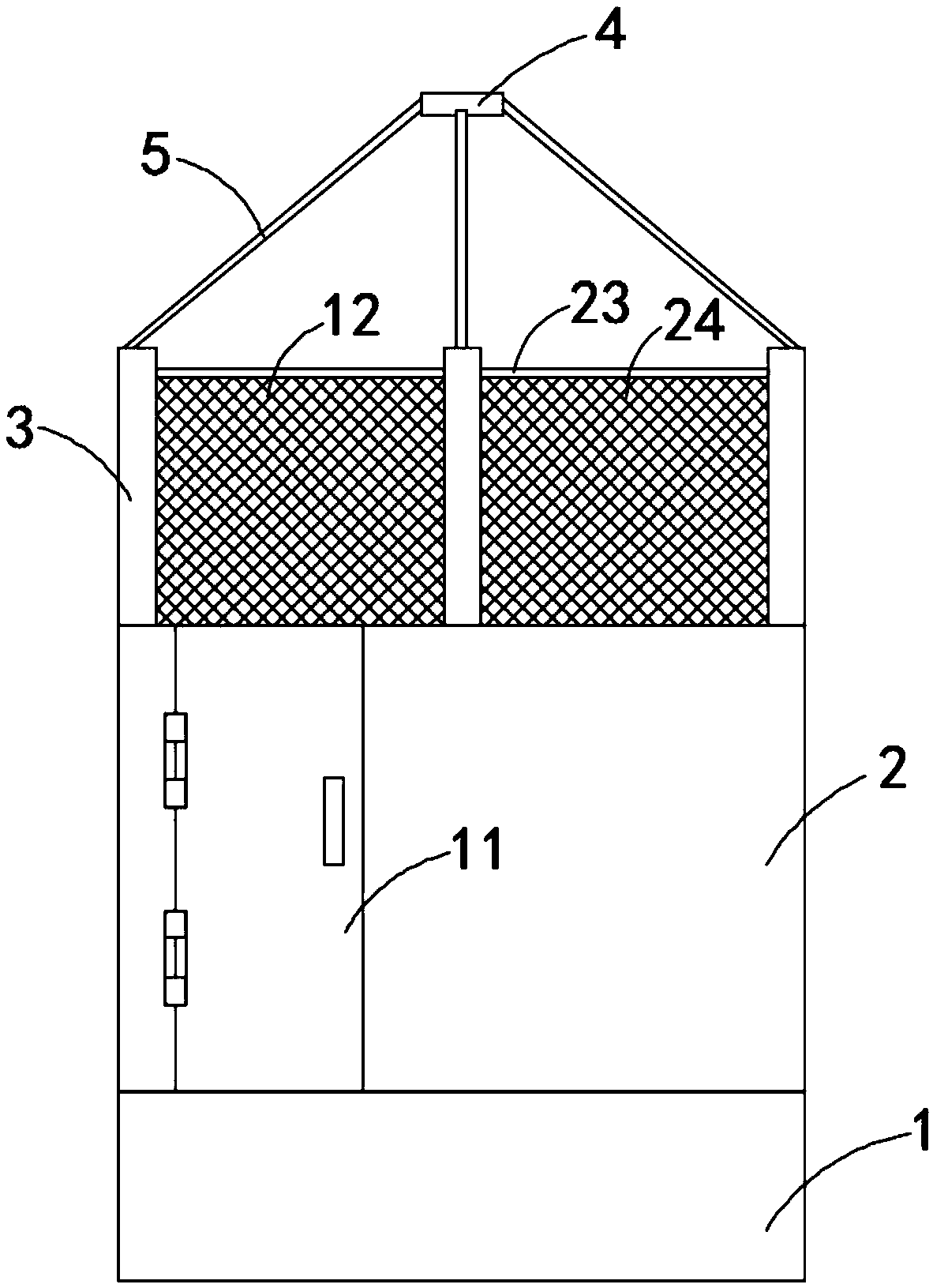

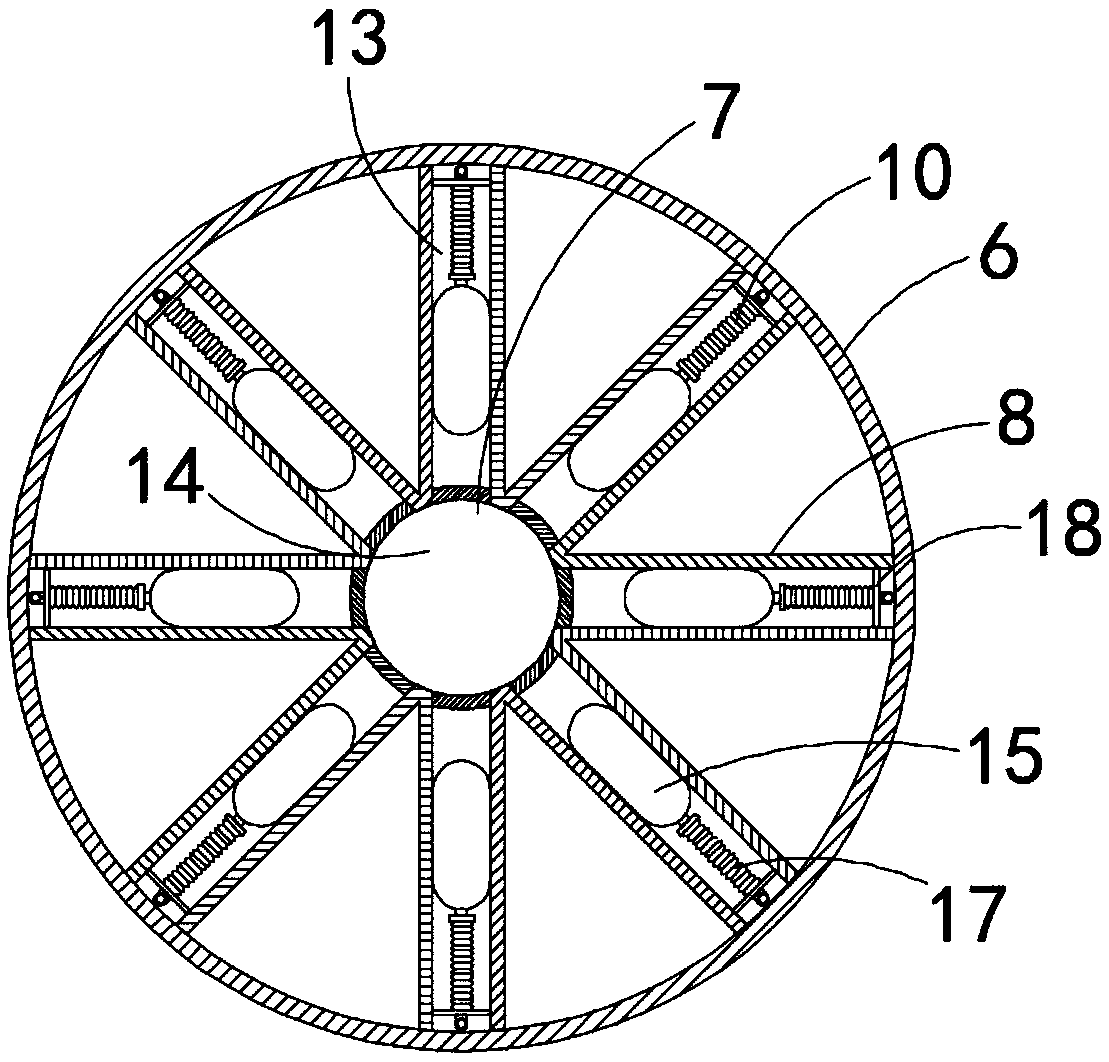

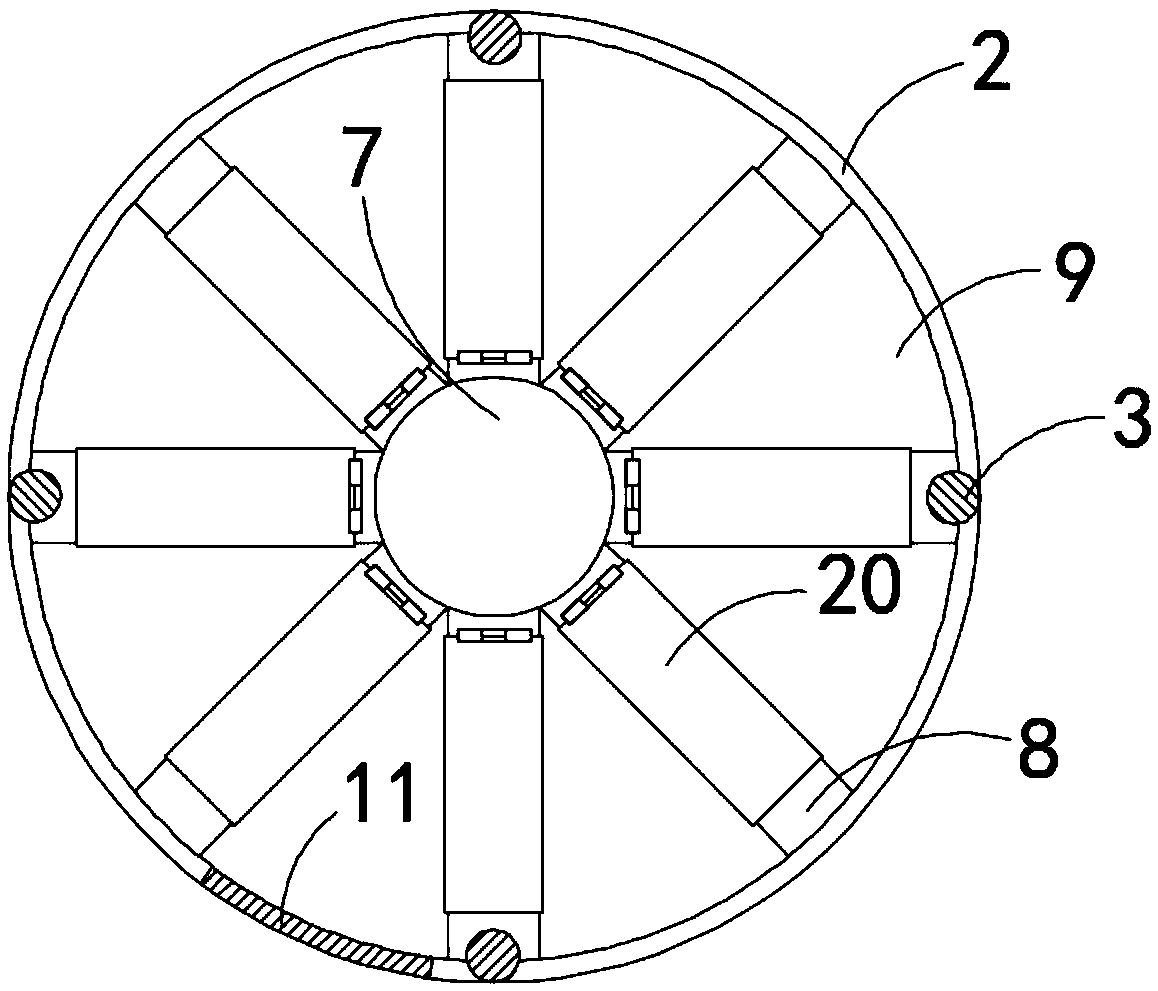

[0028] like Figure 1-8 As shown, a maintenance device for high-altitude special equipment includes a cylindrical base 1, the upper end of the base 1 is fixedly connected with an annular protective plate 2, and the upper end of the annular protective plate 2 is evenly and fixedly connected with a plurality of fixed columns 3, and the annular protective plate 2 is provided with a fixed block 4, the upper end of the fixed column 3 is fixedly connected with the fixed block 4 by a rope 5, the base 1 includes an annular shell 6, and the center of the shell 6 is provided with a cylindrical center seat 7, The side wall of the central base body 7 is fixedly connected with many horizontally arranged support columns 8, the number of support columns 8 is preferably 8, and the plurality of support columns 8 are evenly distributed around the central base body 7, and the support columns 8 are far away from the central base body One end of 7 is fixedly connected to the inner side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com