Button sewing machine and operating method thereof

An operation method and button sewing machine technology, which is applied in the field of button sewing machines, can solve the problems of not being able to fix clothes, not being able to clean fabric fibers in time, and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

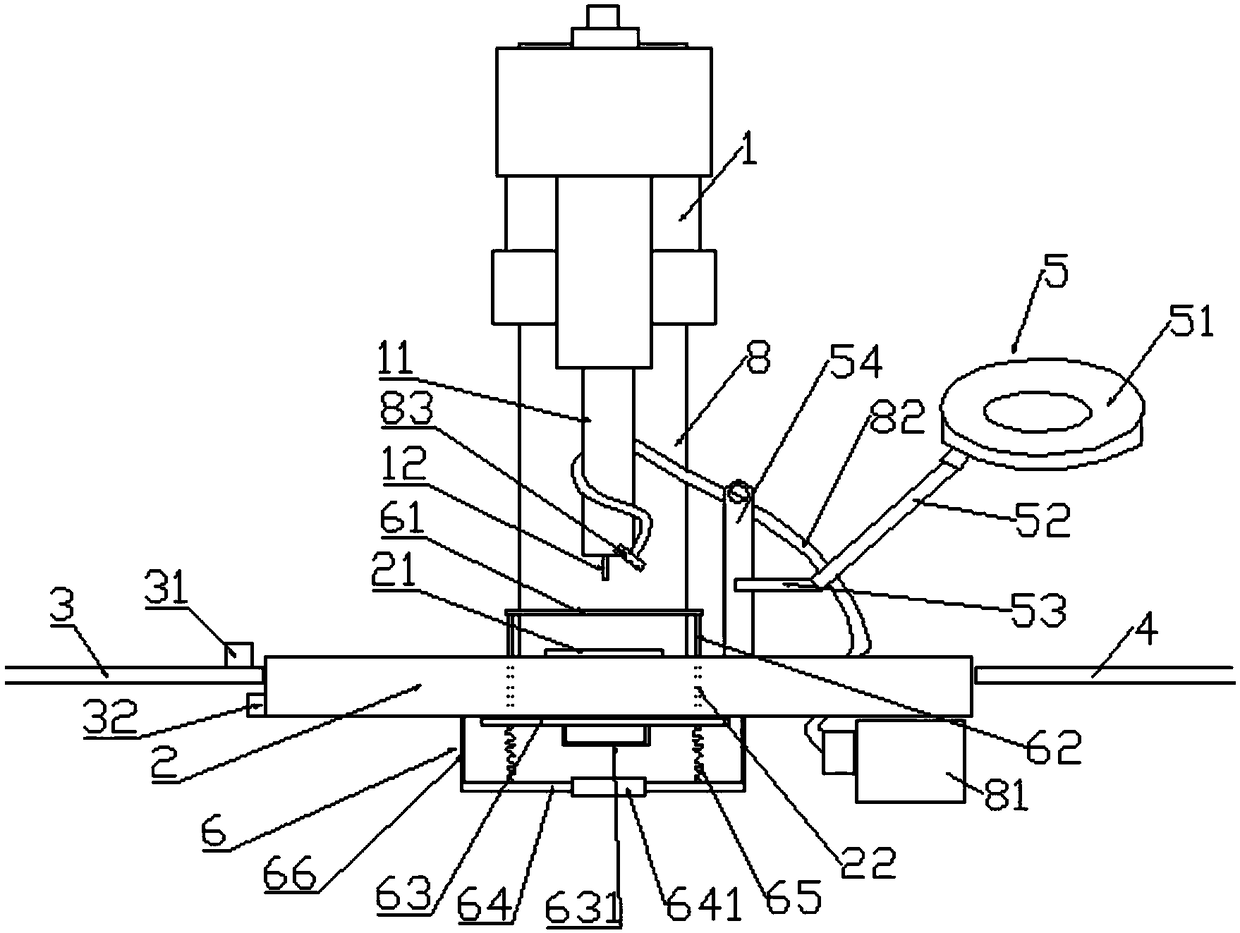

[0028] Such as figure 1 As shown, a button sewing machine includes a button sewing machine body 1, an operating table 2, a first conveyor belt 3, a second conveyor belt 4, a button feeding mechanism 5, a clothing fixing mechanism 6 and a dust blowing mechanism 8, and the button sewing machine body 1 is fixed on the operating table 2, the button sewing machine body 1 includes a button sewing head 11 and a button sewing needle 12 arranged on the button sewing head 11, and the first conveyor belt 3 and the second conveyor belt 4 are respectively located on two sides of the operating console 2. On the side, the button feeding mechanism 5 is located on one side of the button sewing machine body 1, the clothing fixing mechanism 6 is located on the operating table 2, the dust blowing mechanism 8 is located above the operating table 2, and the surface of the operating table 2 is fixed with the position of the button sewing needle 12. Matching button draw-in slot 21, clothing firm pres...

Embodiment 2

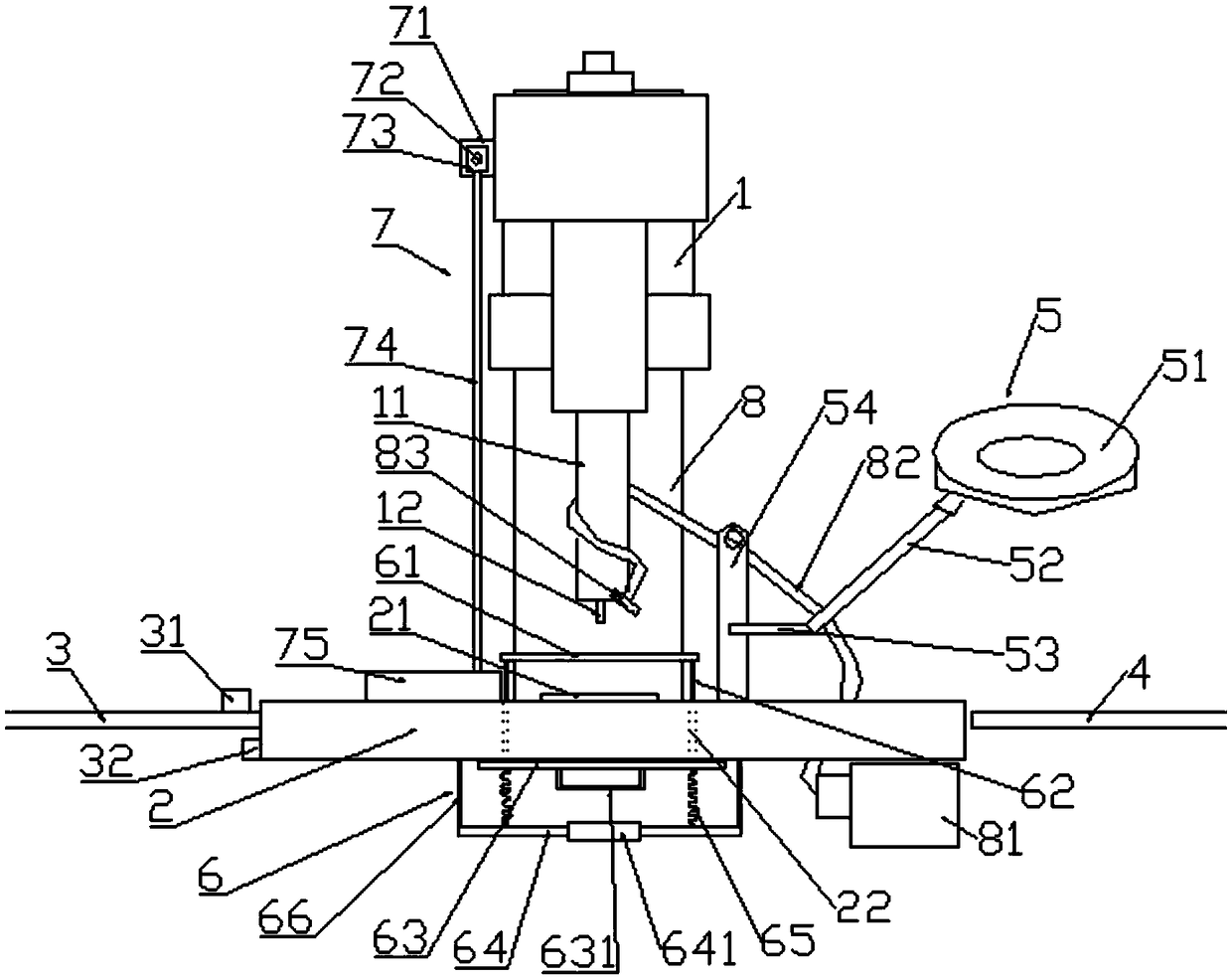

[0037] Such as figure 2 Shown, a kind of button sewing machine, on the basis of embodiment 1, the button sewing machine body 1 is also provided with a dust cleaning mechanism 7, and the dust cleaning mechanism 7 includes a motor 71 fixed on the button sewing machine body 1, and a motor The screw mandrel 72 that 71 links to each other, the slide block 73 that is enclosed within on the screw mandrel 72, the vertical bar 74 that is fixed on the slide block 73 and the cleaning brush 75 that is fixed on the bottom end of the vertical bar 74, cleaning brush 75 and 2 operating desks Face to face contact.

[0038] The operation method of this button sewing machine comprises the steps:

[0039] S1. The first conveyor belt 3 transports the garment to the side of the console 2, and stops the first conveyor belt 3 by waving at the infrared detector 31, and the worker puts the place where the garment needs to be buttoned to the button slot 21 on the console 2 Then use the clothing press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap