Manufacturing method of injection mold and 3D printing injection mold

A production method and injection mold technology, applied in the field of 3D printing, can solve problems such as long printing time, and achieve the effect of reducing raw materials, ensuring heat dissipation performance, and ensuring cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of manufacturing method of injection mold, described following steps:

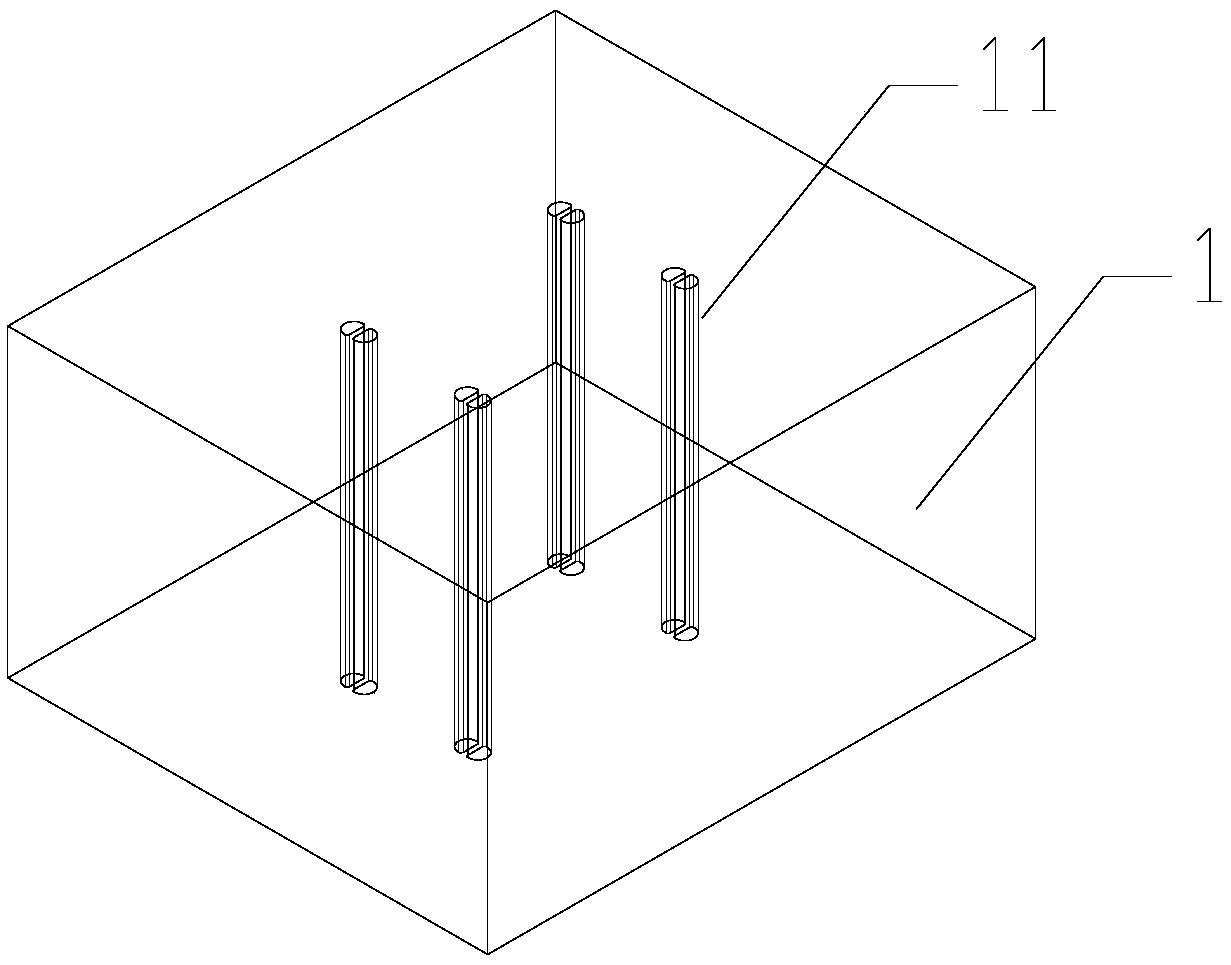

[0030] Select a piece of beryllium copper base, and process a straight waterway inside the beryllium copper part. In this step, if figure 2 As shown in , set four through holes consistent with the distribution of the final beryllium copper part on the beryllium copper base to form a straight waterway. In this step, the straight waterway can be directly processed by CNC technology.

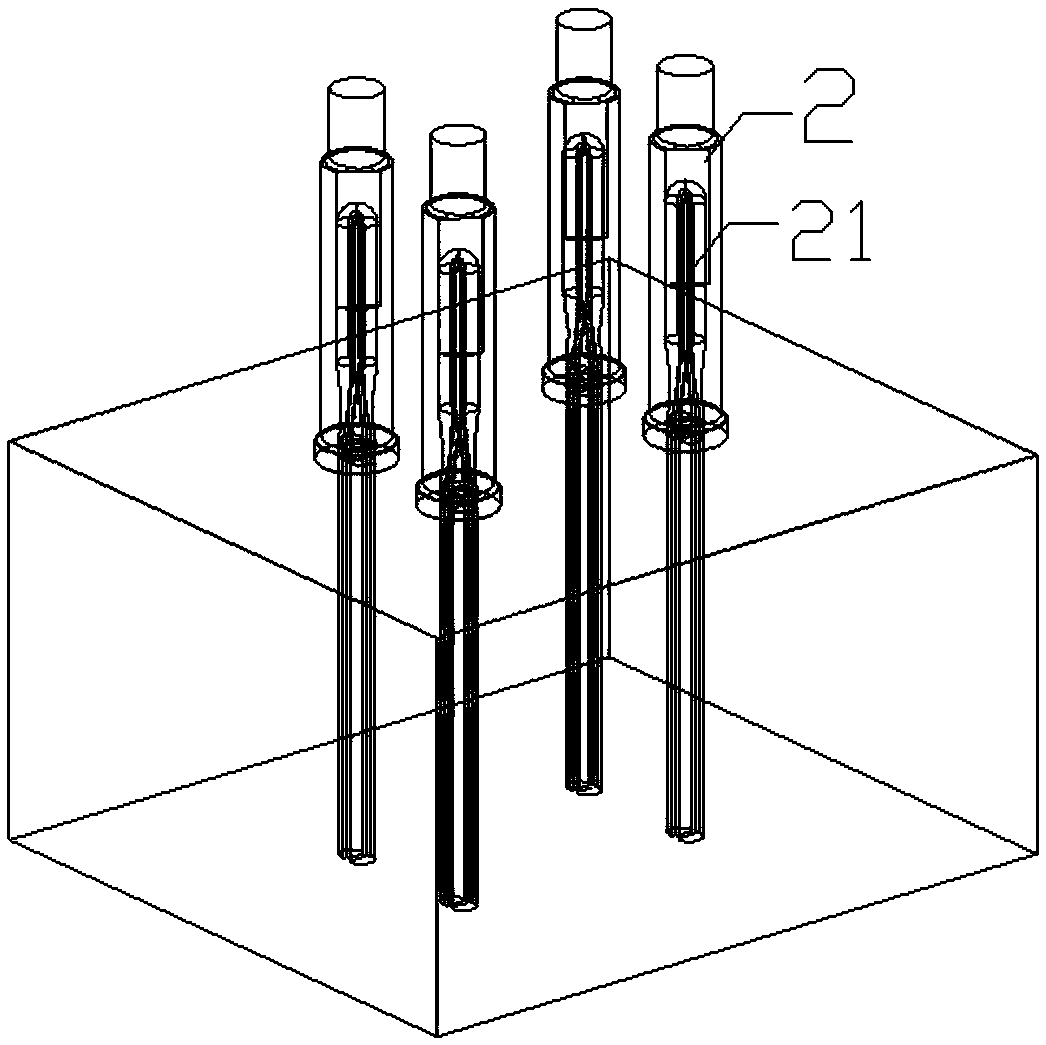

[0031] Immediately afterwards, as image 3 As shown, a steel part is processed by 3D printing technology above the beryllium copper part, and a conformal waterway is arranged inside the steel part, and the conformal waterway is connected with the linear waterway. In this step, the conformal waterway needs to be involved in advance as needed.

[0032] Through the above two steps, the body of the injection mold has been obtained. Since the lower part of the injection mold is still...

Embodiment 2

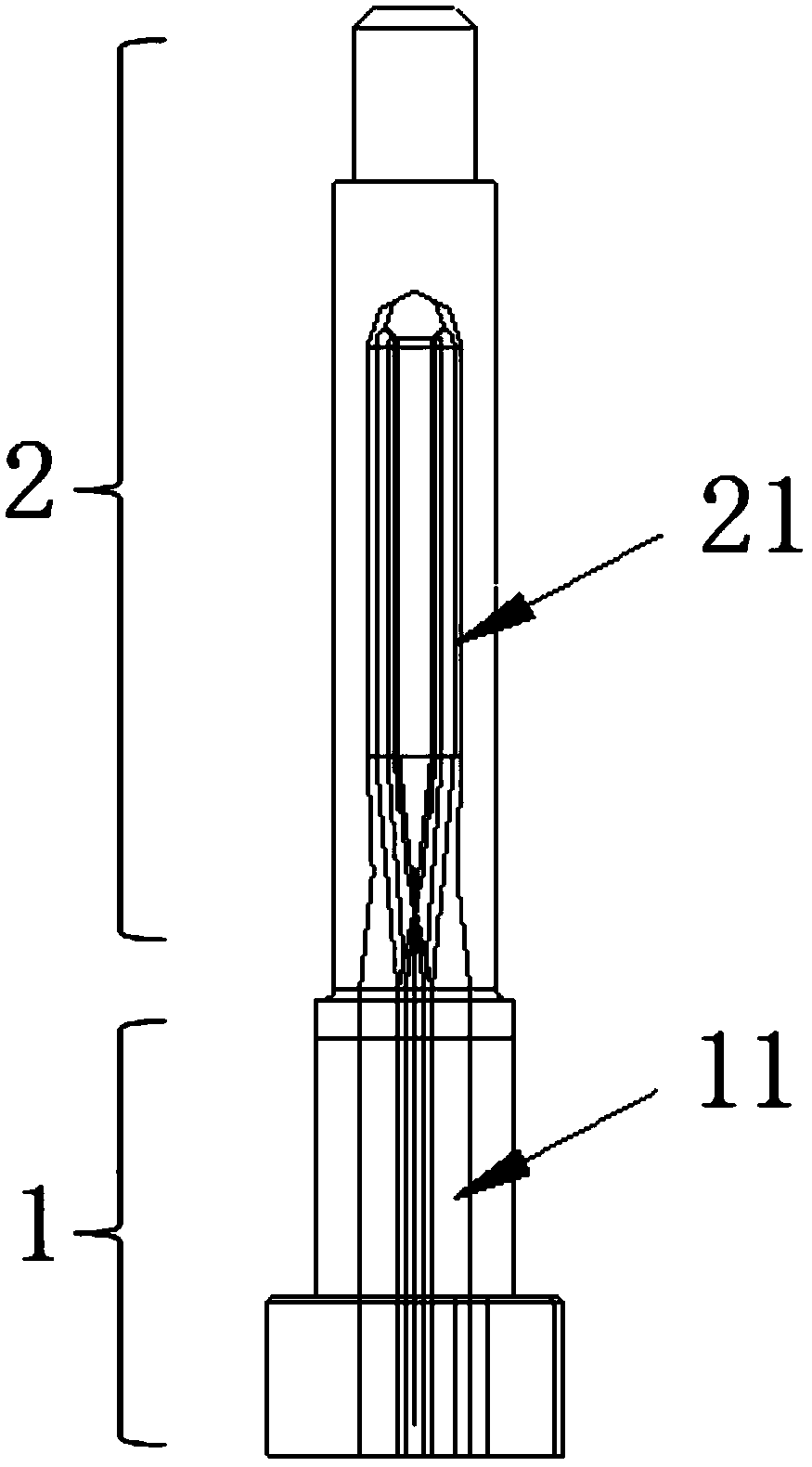

[0037] This embodiment provides a 3D printing injection mold, which is made by the manufacturing method provided in Embodiment 1, such as figure 1 As shown, the entire 3D printing injection mold includes: a beryllium copper part, which is provided with a linear waterway inside; The straight line waterway is connected.

[0038] In this embodiment, the steel part is made of MS1 material, which has high hardness; at the same time, the thermal conductivity of beryllium copper is better. Finally, the entire injection mold combines the high hardness and wear resistance of MS1 material and the fast cooling performance of beryllium copper. , by adopting the 3D graft printing method, the two metals are grafted and printed as a whole, so that the mold parts have the characteristics of high hardness, wear resistance and efficient cooling at the same time.

[0039] In this example, if figure 1 As shown, the shape of the injection mold is a linear tubular structure. However, the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com