Automatic bagging machine

A bagging machine, automatic technology, applied in garbage collection, household utensils, applications, etc., can solve problems such as fear of dirt, achieve the effect of solving fear of dirt, convenient and quick use, and maintaining a hygienic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

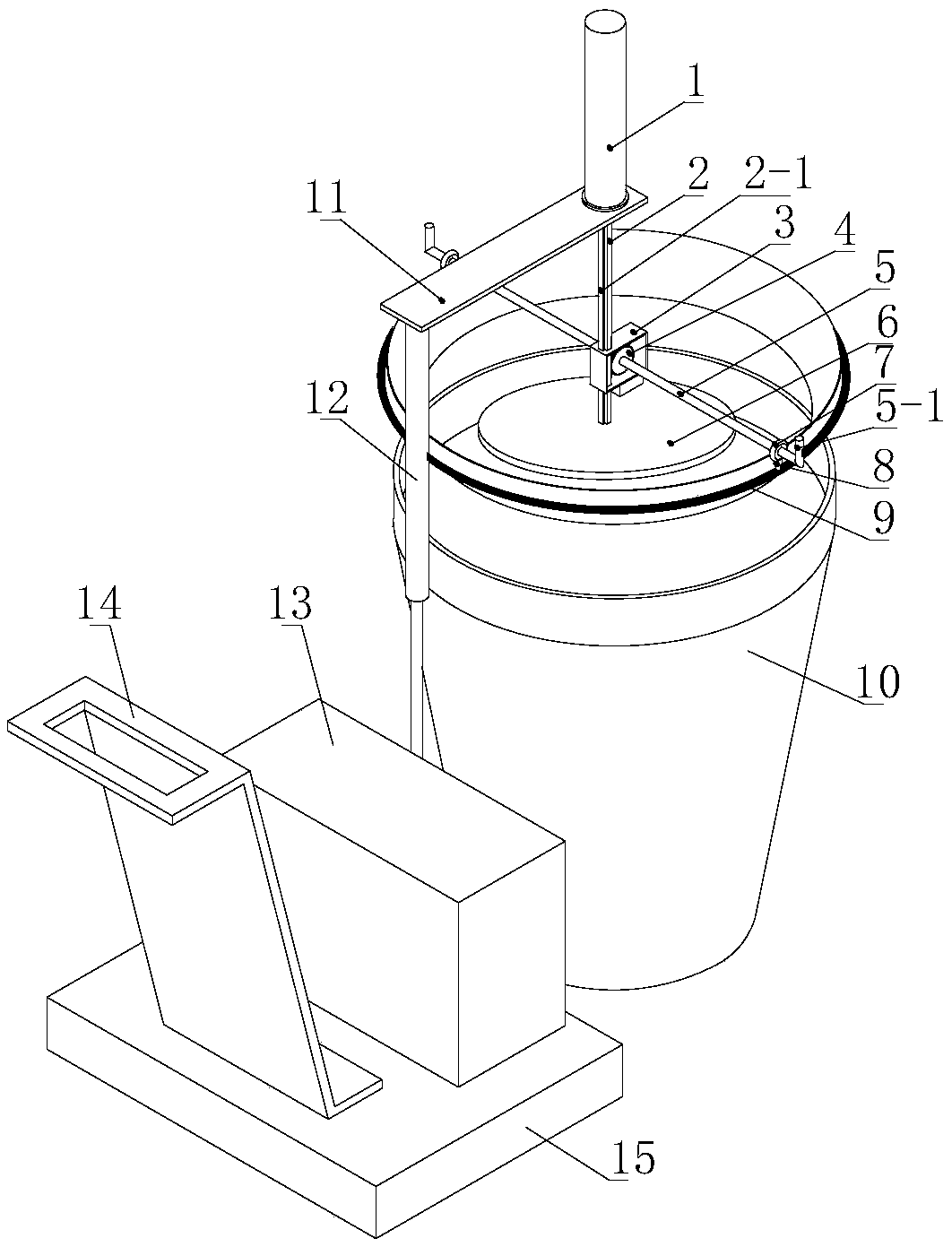

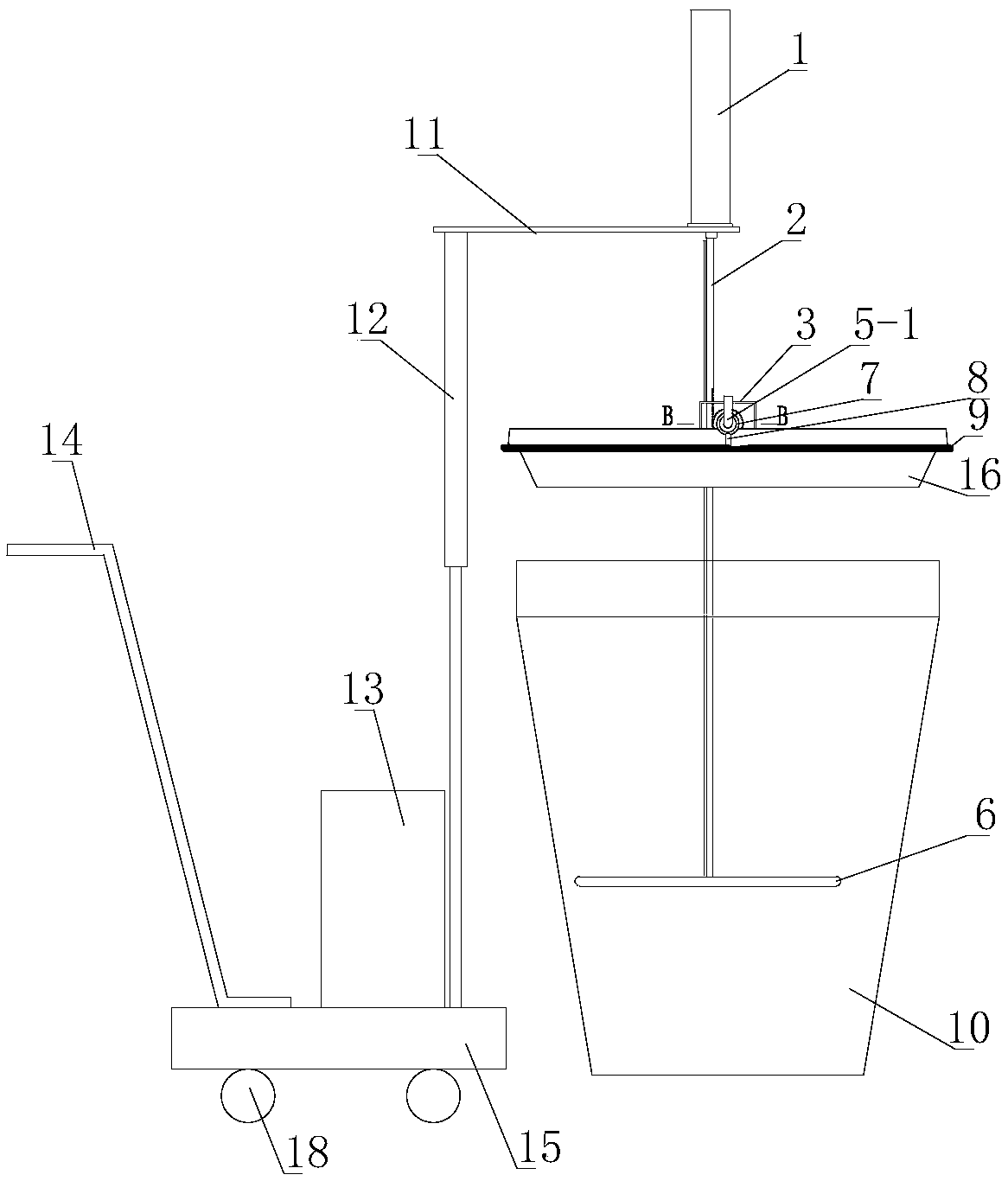

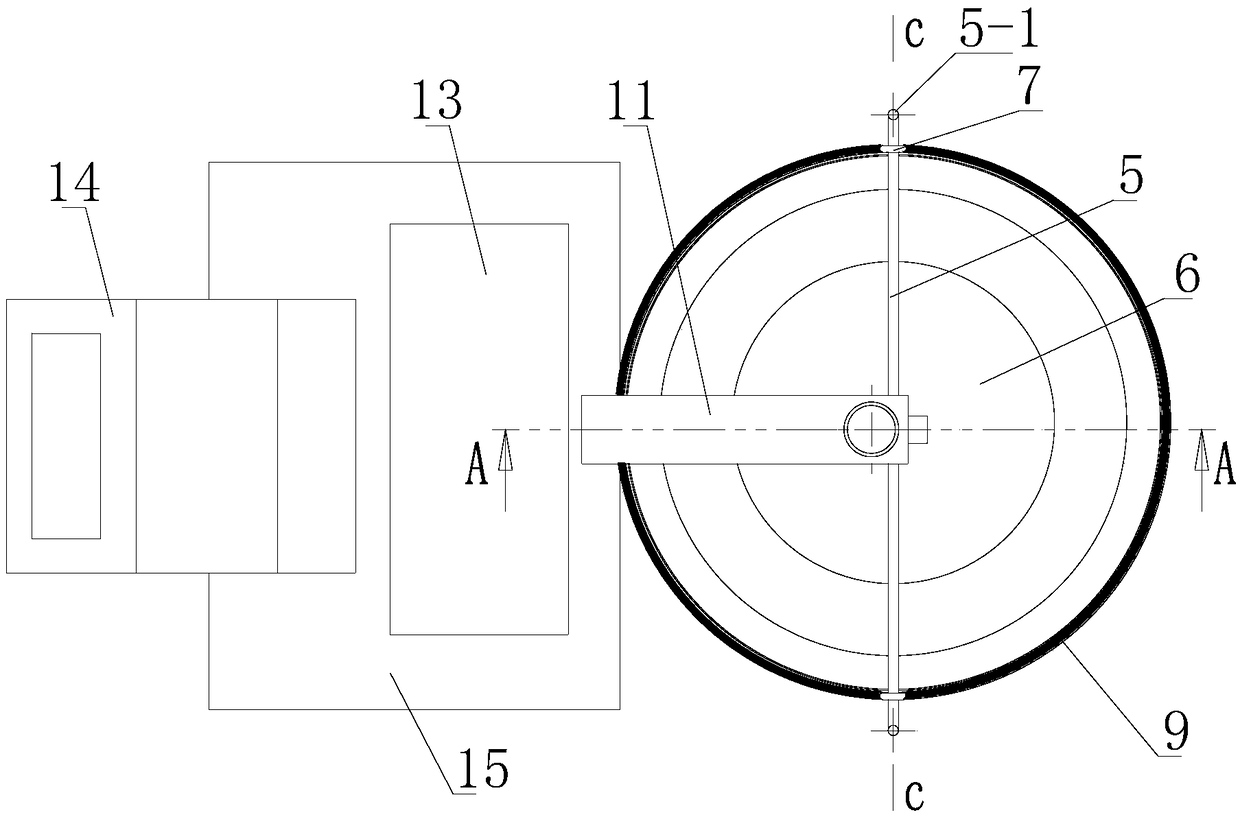

[0031] An automatic bagging machine, including a telescopic device, a bag removing device and a support plate, the telescopic device includes a cylinder 1, an operating rod 2 and an operating box 3, the cylinder 1 is connected to the top end of the operating rod 2, and the operating rod 2 Through the operation box 3, the bottom end of the operation rod 2 is installed with a support plate 6, the gear 4 is arranged in the operation box 3, the side of the operation rod 2 is provided with teeth, the number of teeth is equal to half of the number of teeth of the gear 4, and the teeth can be Engaging with the gear 4, the inner wall of the operation box 3 is provided with a T-shaped chute 3-1, and the operating rod 2 is provided with a T-shaped slider 2-1 that slides in cooperation with the T-shaped chute 3-1, and the bag removal The device includes a rotating rod 5 and a ferrule 9, the two ends of the rotating rod 5 are connected to the hook 5-1, the middle part of the rotating rod 5...

Embodiment 2

[0038] An automatic bagging machine, including a telescopic device, a bag removing device and a support plate, the telescopic device includes a cylinder 1, an operating rod 2 and an operating box 3, the cylinder 1 is connected to the top end of the operating rod 2, and the operating rod 2 Through the operation box 3, the bottom end of the operation rod 2 is installed with a support plate 6, the gear 4 is arranged in the operation box 3, the side of the operation rod 2 is provided with teeth, the number of teeth is equal to half of the number of teeth of the gear 4, and the teeth can be Engaging with the gear 4, the inner wall of the operation box 3 is provided with a T-shaped chute 3-1, and the operating rod 2 is provided with a T-shaped slider 2-1 that slides in cooperation with the T-shaped chute 3-1, and the bag removal The device includes a rotating rod 5 and a ferrule 9, the two ends of the rotating rod 5 are connected to the hook 5-1, the middle part of the rotating rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com