A storage device for self-rotating replacement of drill rods of breakers

A storage device and breaker technology, applied in mechanically driven excavators/dredgers, etc., can solve the problem of time-consuming and laborious replacement methods, and achieve the effect of fast replacement, convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

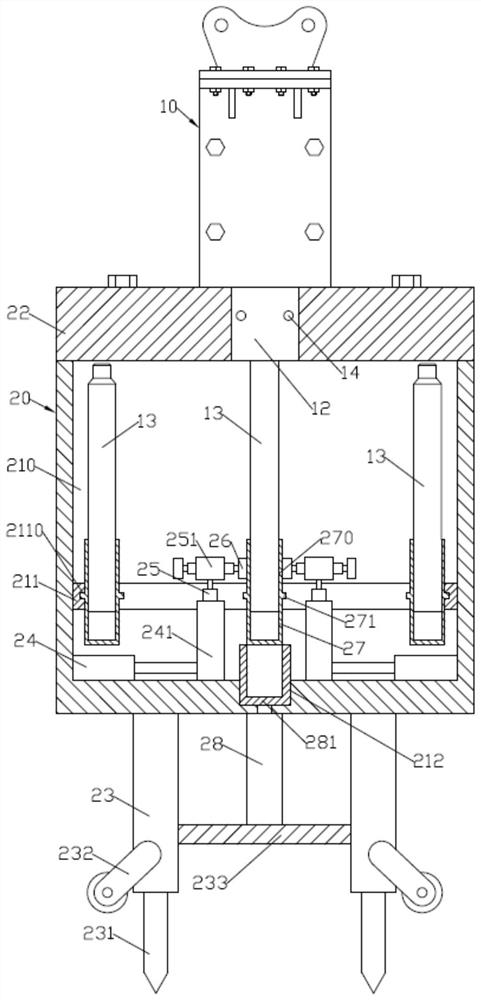

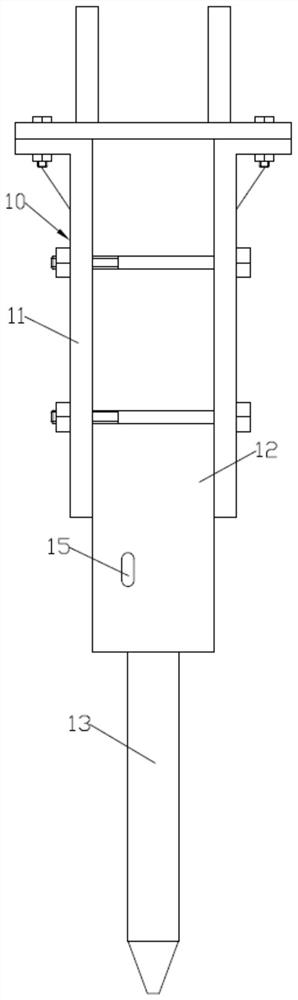

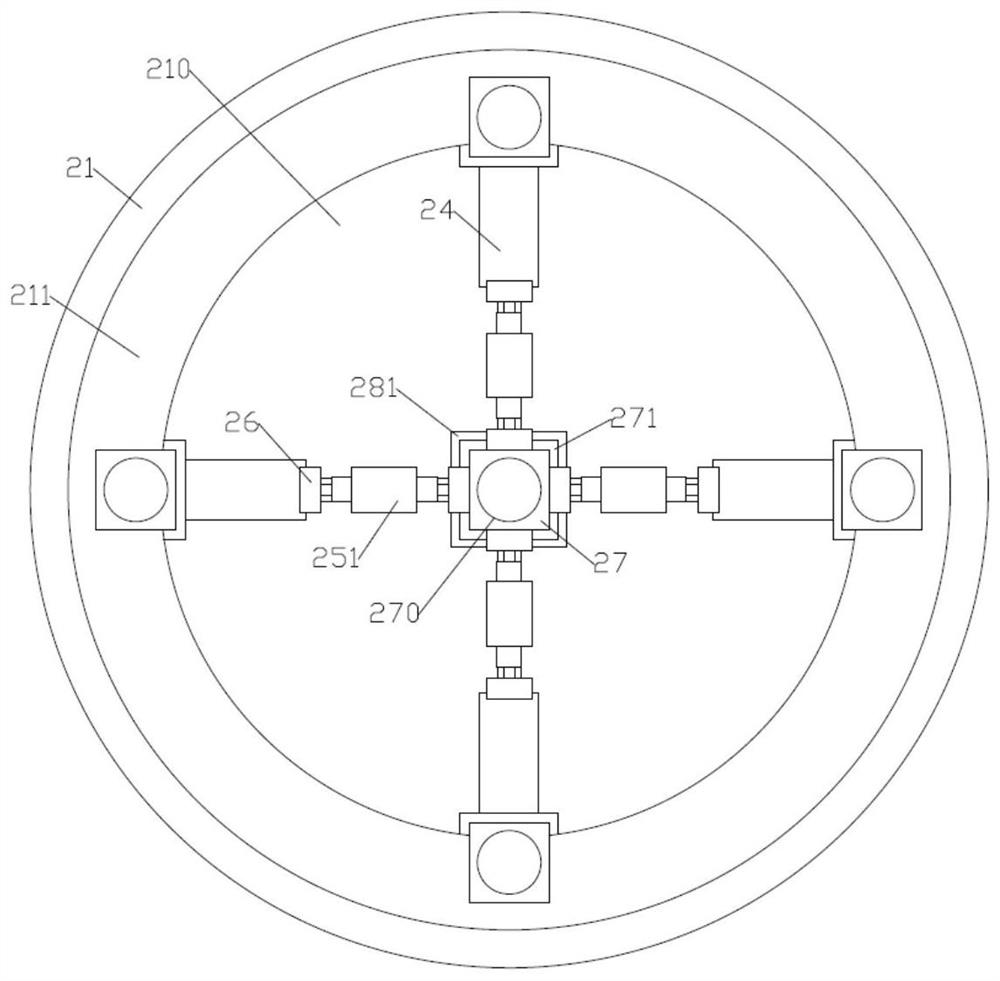

[0018] Such as Figure 1 ~ Figure 4 As shown, a storage device for the self-rotating replacement of the drill rod of the breaker includes a breaker 10 and a storage device 20; the breaker 10 includes a frame 11, a cylinder 12 and a drill rod 13; the frame 11 includes a pair of front and rear symmetrically arranged The limit plate; the cylinder 12 is arranged between a pair of limit plates; the cylinder 12 is inserted with a flat pin 15 in the left and right direction; the drill rod 13 is detachably installed on the lower end of the cylinder 12 through the flat pin 15; the cylinder 12. A pair of left-right symmetrical cylindrical round pins 14 are inserted in the front and rear direction; a pair of round pins 14 pass through the flat pin 15 horizontally and frontally; Box 21; the upper end surface of storage box 21 is fixed with cover plate 22 by several bolts; Four uniform storage and holding grooves 2110 on the circumference; a cuboid-shaped storage support block 27 is inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com