Pneumatic crawler-type forklift and method

A crawler and forklift technology, applied in the direction of lifting devices, etc., can solve the problems of manual transportation of parts such as high labor intensity, and achieve the effects of reliable braking, strong climbing ability, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

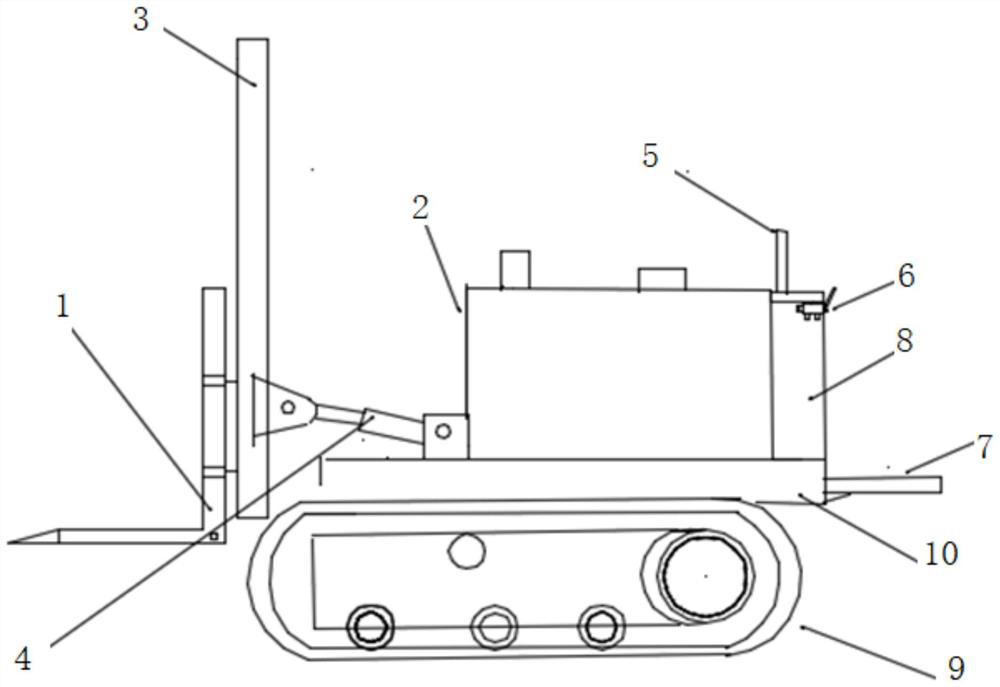

[0057] An embodiment of the present invention provides a pneumatic crawler forklift with a width of less than 1 meter, a track length of less than 1.3 meters, and a small turning radius, which is suitable for operations in narrow tunnels and limited spaces in mines.

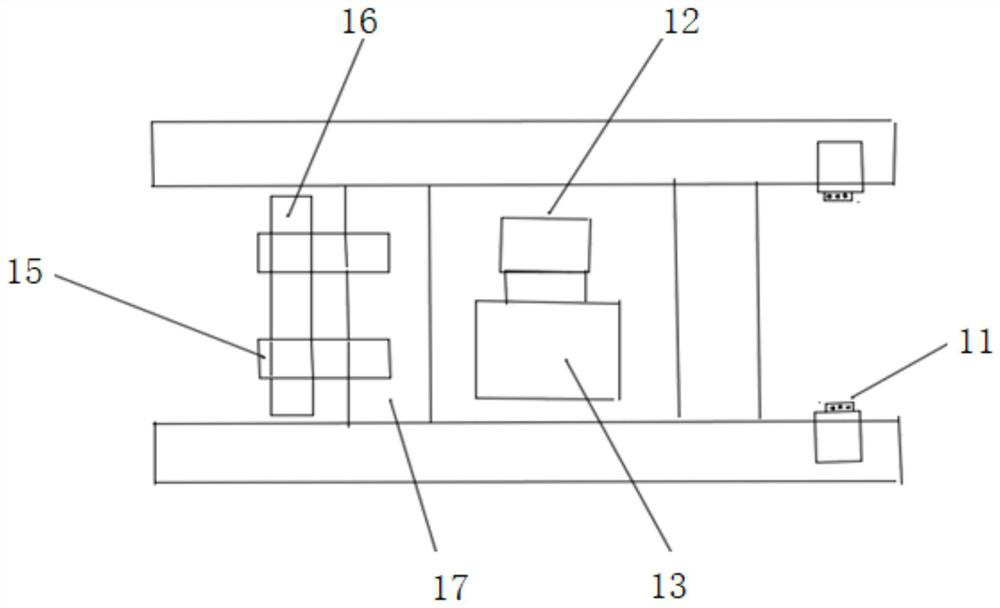

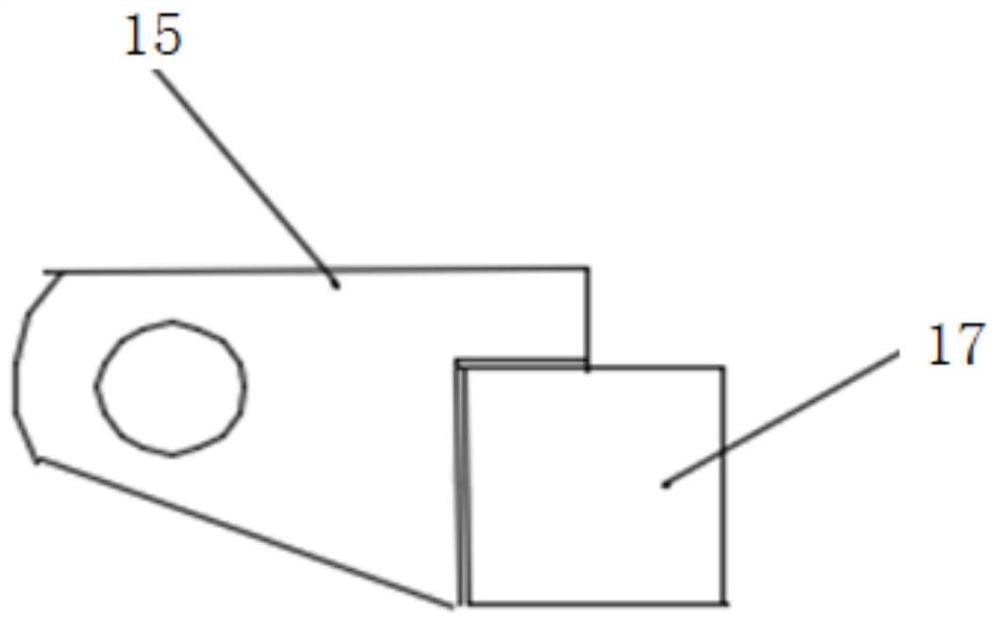

[0058] like Figure 1~5 As shown, the forklift includes: an operating platform 8, a walking track assembly 9, a vehicle chassis 10, a forklift mast assembly, a power assembly 20, and a hydraulic oil tank assembly 2; The front beam 17 of the assembly and the two crawlers are respectively installed on the left and right sides of the main body walking bracket, and the crawler belt assembly front beam 17 is installed on the front side of the main body walking bracket; the vehicle chassis 10 is installed on the main body walking bracket; the forklift mast assembly includes the door Frame 3, fork frame, fork head 1, lifting cylinder 25 and tilting cylinder 4; the bottom end of the door frame 3 is installed on the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com