Keel separation wall and mounting method thereof

A keel and ground keel technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of slow fixing speed and narrow space, and achieve the effect of fast and convenient fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

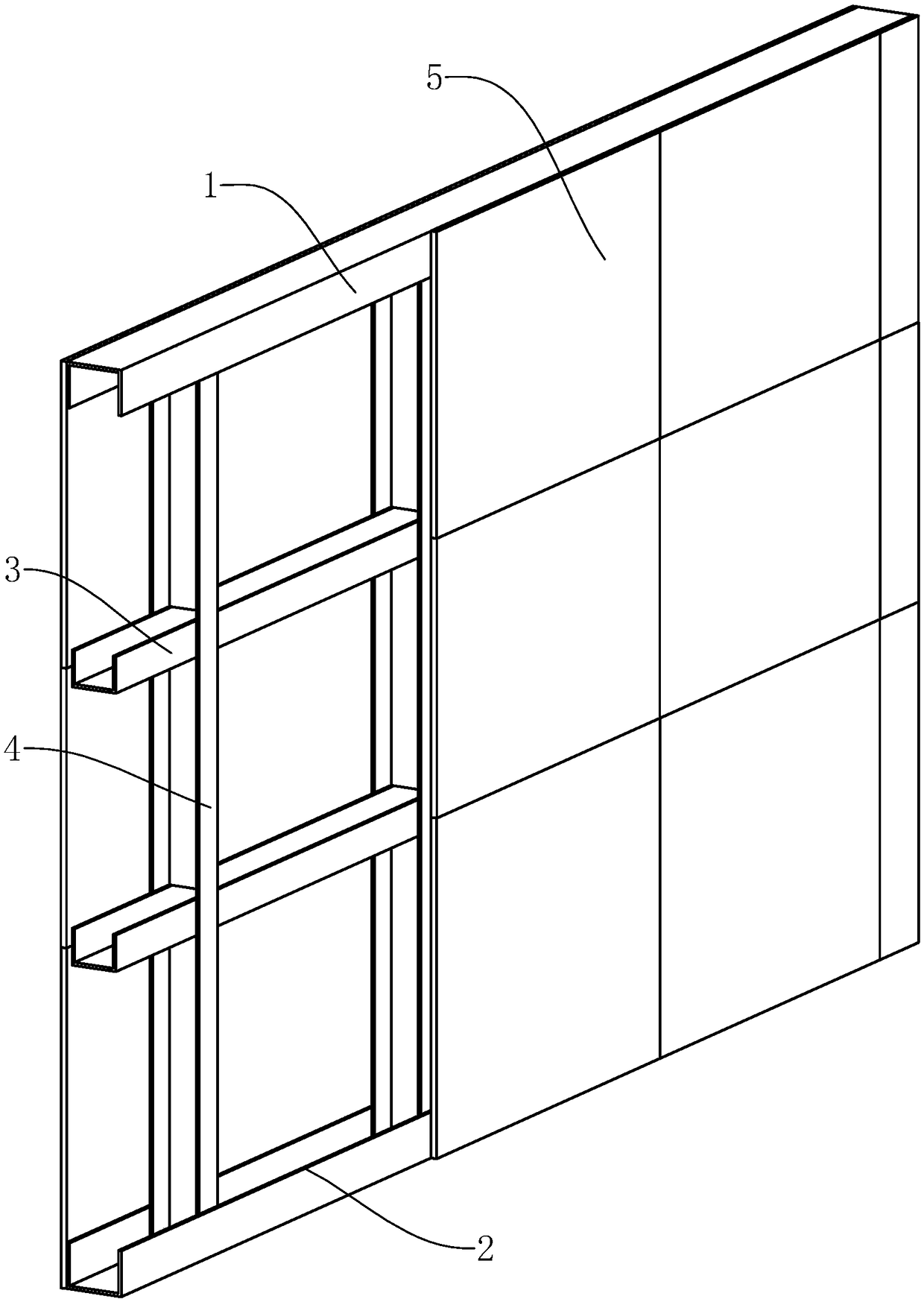

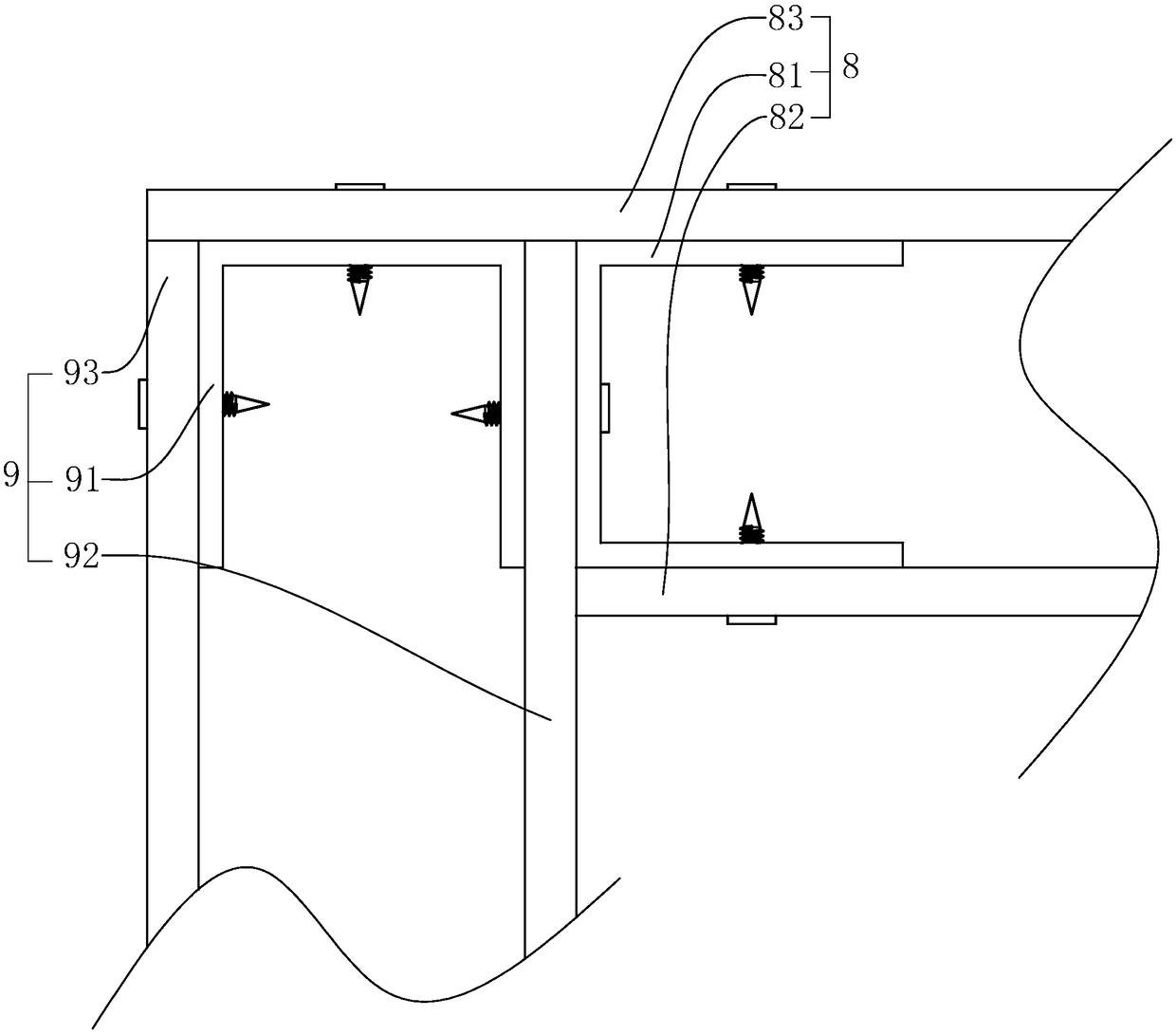

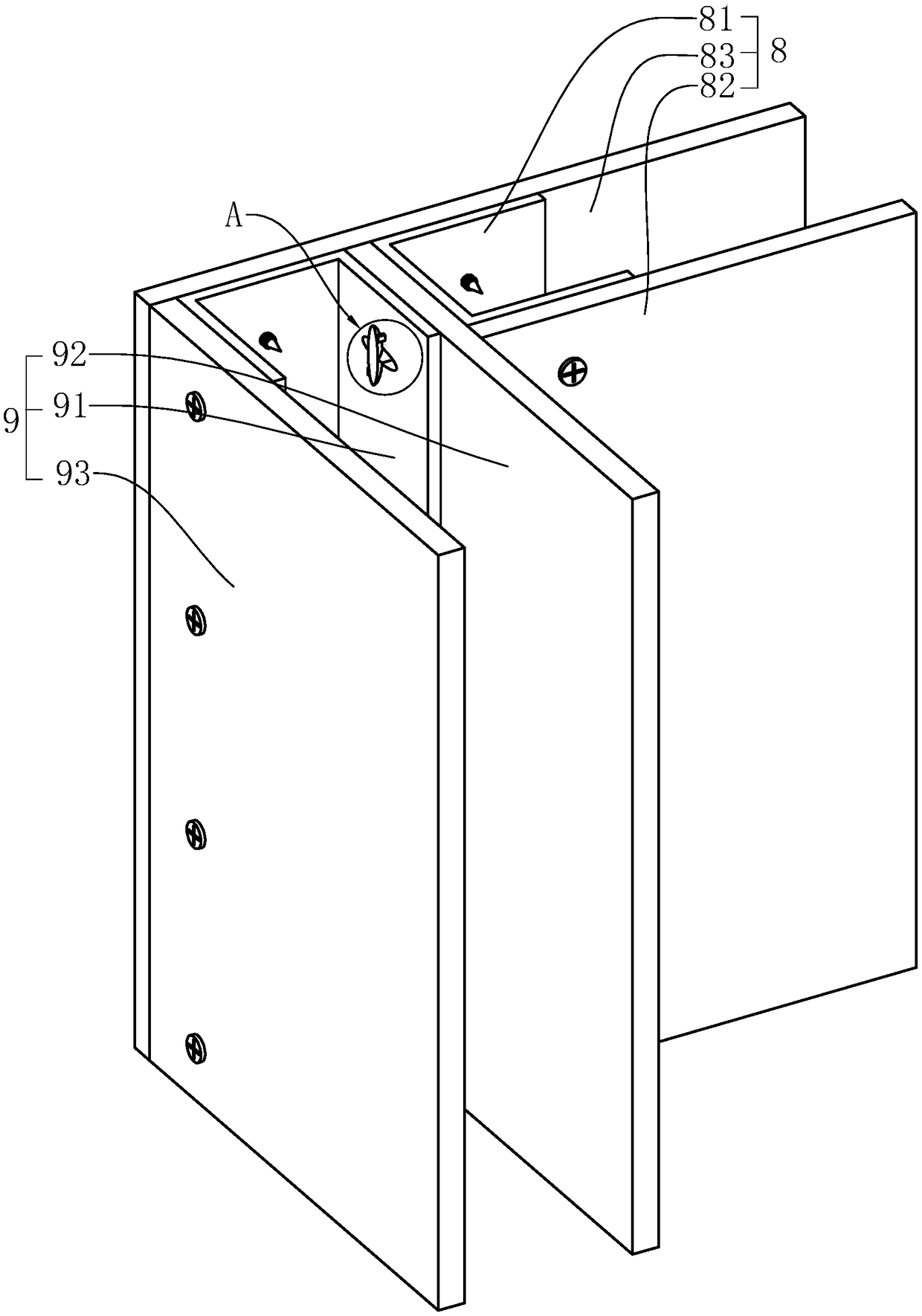

[0034] Such as figure 1 As shown, a keel partition wall includes multiple partition walls. The partition wall includes a top keel, a ground keel 2, a horizontal brace keel 3, a vertical keel 4 and a decorative panel 5. The top keel 1 and the ground keel 2 and the cross-bracing keel 3 are arranged horizontally and in parallel in the same partition wall, the vertical keel 4 is arranged vertically and fixedly connected with the top joist 1, the ground joist 2 and the cross-bracing joist 3 respectively, and the decorative panels are pasted Merged and fixed on both sides of the keel formed by the top keel 1, the ground keel 2 and the cross brace keel 3.

[0035] In the process of setting the keel of the partition wall, firstly, according to the designed wall position, the wall position line is released on the ground, and the line is led to the ceiling and side walls; The keel 2 is generally fixed to the ceiling and the ground respectively by nailing the top keel 1 and the ground k...

Embodiment 2

[0050] A method for installing a keel partition wall, comprising the following steps:

[0051] S1. Wall position setting: according to the wall position determined by the design, lay out the wall position line on the ground, and lead the line to the ceiling and side walls, so that the top keel 1, ground keel 2 and edge keel 2 can be easily positioned through the wall position line. The vertical keel 4 at the free end of the wall avoids misalignment when the keel of the partition wall is installed.

[0052] S2. Install the keel: install the top keel 1 and the ground keel 2 according to the position of the wall line, insert the vertical keel 4 between the top keel 1 and the ground keel 2, and connect the vertical keel 4 and the top keel 1 and along the keel 2 are fixed, horizontally fix the horizontal support keel 3 on the vertical keel 4, the specific steps are as follows:

[0053]S21. Check the smoothness of the ceiling, ground and wall that fit the roof joist 1, the ground j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com