Downhole injection device being able to change polymer viscosity

An injection device, polymer technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve problems such as different polymer viscosity requirements, affecting polymer utilization efficiency, changing polymer viscosity, etc., to reduce Operational cost, effect of increasing injection efficiency and utilization efficiency, increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

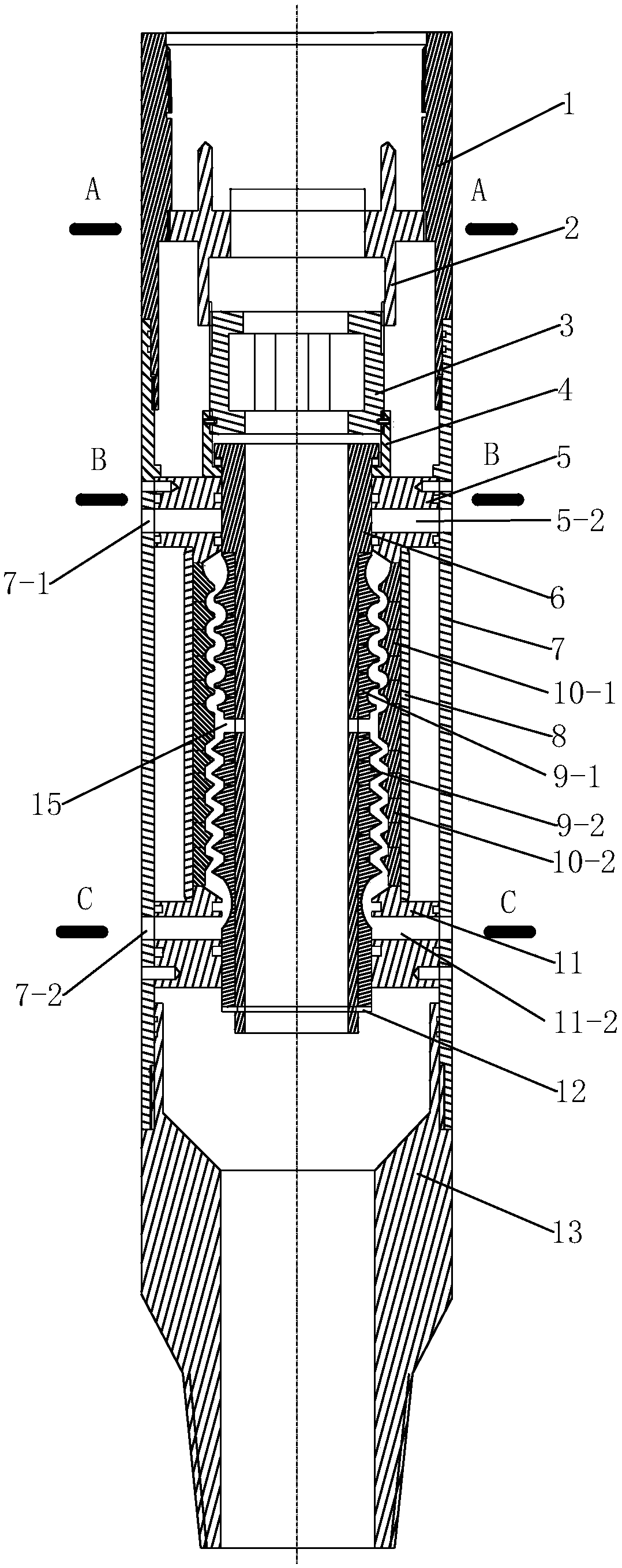

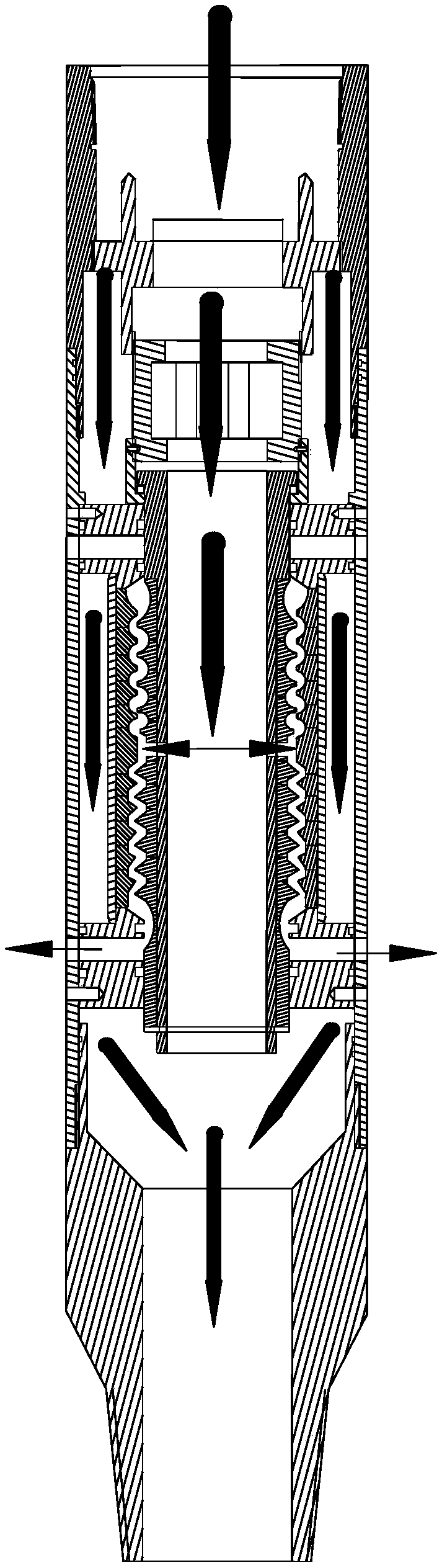

[0020] see Figure 1 to Figure 7 , a downhole injection device capable of changing polymer viscosity, comprising an upper joint 1, an outer casing 7 and a lower joint 13 sequentially connected from top to bottom, and a viscosity-preserving liquid outlet is provided on the side wall of the outer casing 7 7-1 and viscosity reducing liquid outlet 7-2.

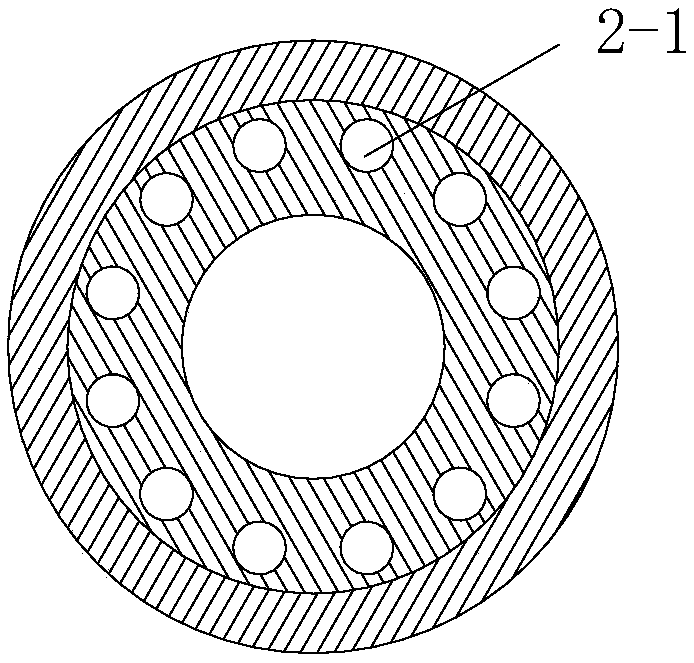

[0021] A guiding and positioning component 2 is fixedly connected inside the upper joint 1 , and the guiding and positioning component 2 is provided with an introduction pen tip structure and a positioning structure.

[0022] Inside the outer casing 7, there is a dispensing adjustment mechanism integrating the functions of maintaining viscosity and reducing viscosity. The dispensing adjustment m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com