Oil displacing microemulsified acid system for acidizing plugging removal and preparation method of system

A micro-lactic acid and system technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of affecting water injection pressure and injection volume, yet to find oil-displacing micro-lactic acid, prone to strong adsorption, etc., and reduce water injection. The effect of pressure, excellent oil displacement performance, and good dissolving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

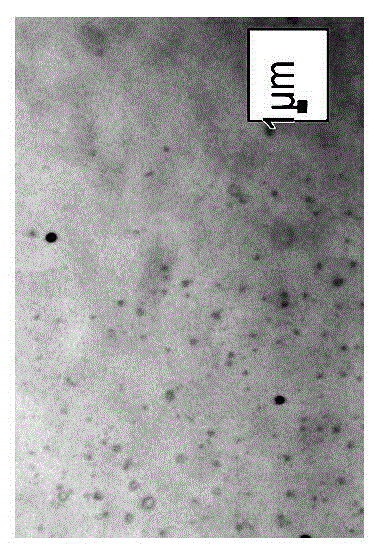

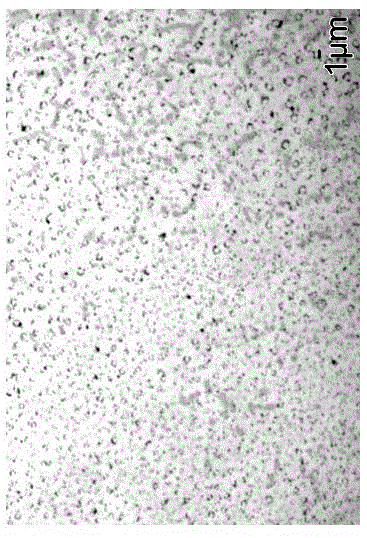

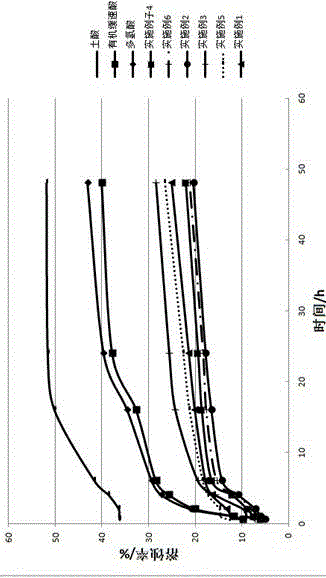

Image

Examples

Embodiment 1

[0030] Add 45g of polyhydric acid into a 400ml plastic beaker, heat it in a 60°C water bath to 50-60°C, add 12g of C16 / C18 fatty aminohydroxypropyl sulfonate and 4g of coconut amine polyoxyethylene ether phosphoric acid under stirring After fully dissolving the ester, add 19g of 10% hydrochloric acid, then add 20g of No. 0 diesel oil, and stir for 0.5h to obtain light yellow and transparent oil-displacing microlactic acid.

Embodiment 2

[0032] Add 45g of organic tartaric acid into a 400ml plastic beaker, heat it in a 60°C water bath to 50-60°C, add 12g of C16 / C18 fatty aminohydroxypropyl sulfonate and 4g of coconut amine polyoxyethylene ether under stirring Phosphate ester, after fully dissolved, add 19g of 10% hydrochloric acid, then add 20g of -10 diesel oil, stir for 0.5h, and obtain light yellow and transparent oil-displacing microlactic acid.

Embodiment 3

[0034] Add 65g of polyhydric acid into a 400ml plastic beaker, heat to 50-60°C in a 60°C water bath, add 10g of C16 / C18 fatty aminohydroxypropyl sulfonate and 5g of tallow amine polyoxyethylene ether under stirring After fully dissolving the phosphoric acid ester, add 5g of 10% hydrochloric acid, then add 15g of -20 diesel oil, stir for 0.5h, and obtain light yellow and transparent oil-displacing microlactic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com