Two-functional valve element

A technology of functional valves and spools, applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of high-pressure pull, easy wear of products, and difficult drilling, etc., to achieve small rotation angle, high production and manufacturing speed The effect of increasing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

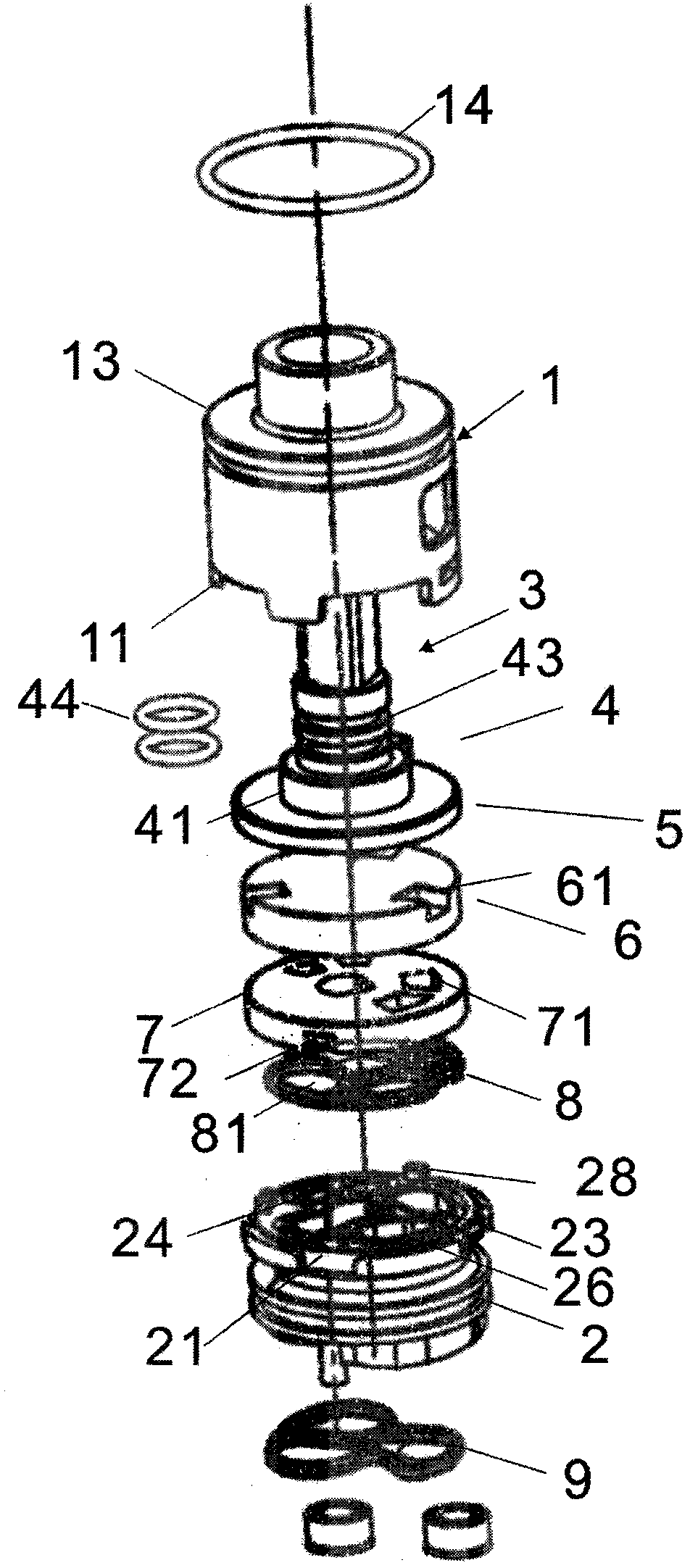

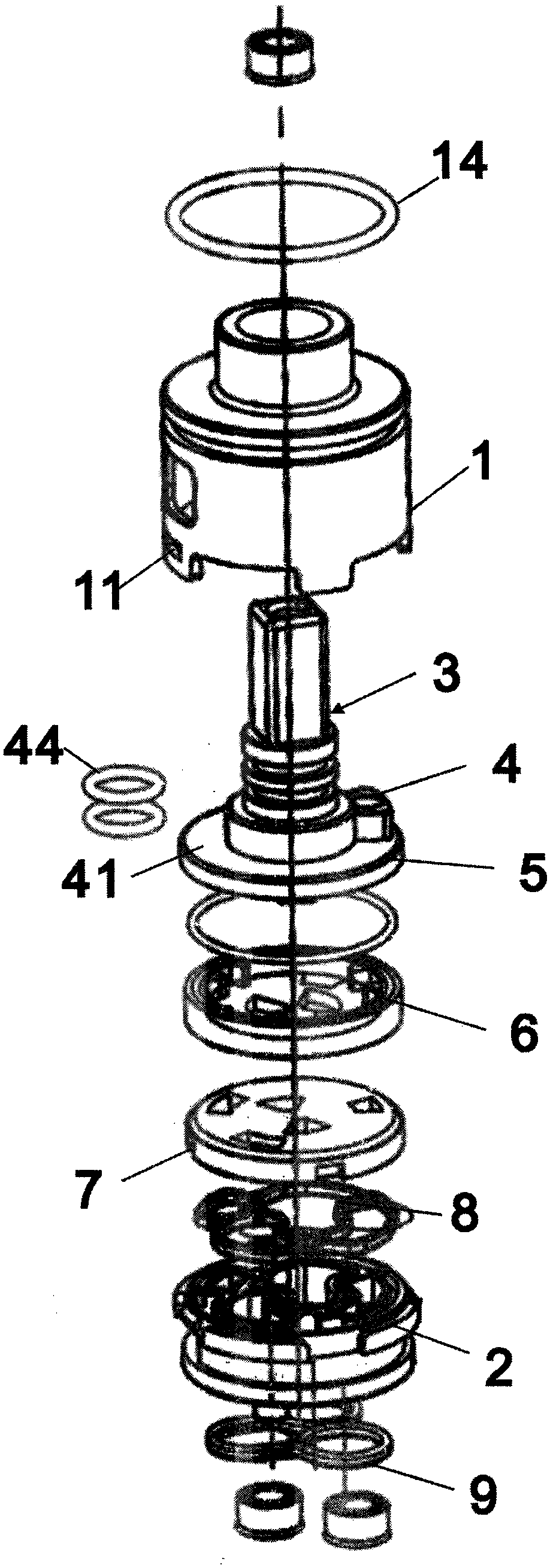

[0022] Such as figure 1 and 7 As shown, a dual-function spool of this embodiment includes a spool housing 1, a base 2, a handle 3, a rotor 4, a dial 5, a moving porcelain piece 6, a static porcelain piece 7, an upper silica gel sealing ring 8 and a lower Silicone sealing ring 9 also includes rotor sealing ring 44 and spool sealing ring 14;

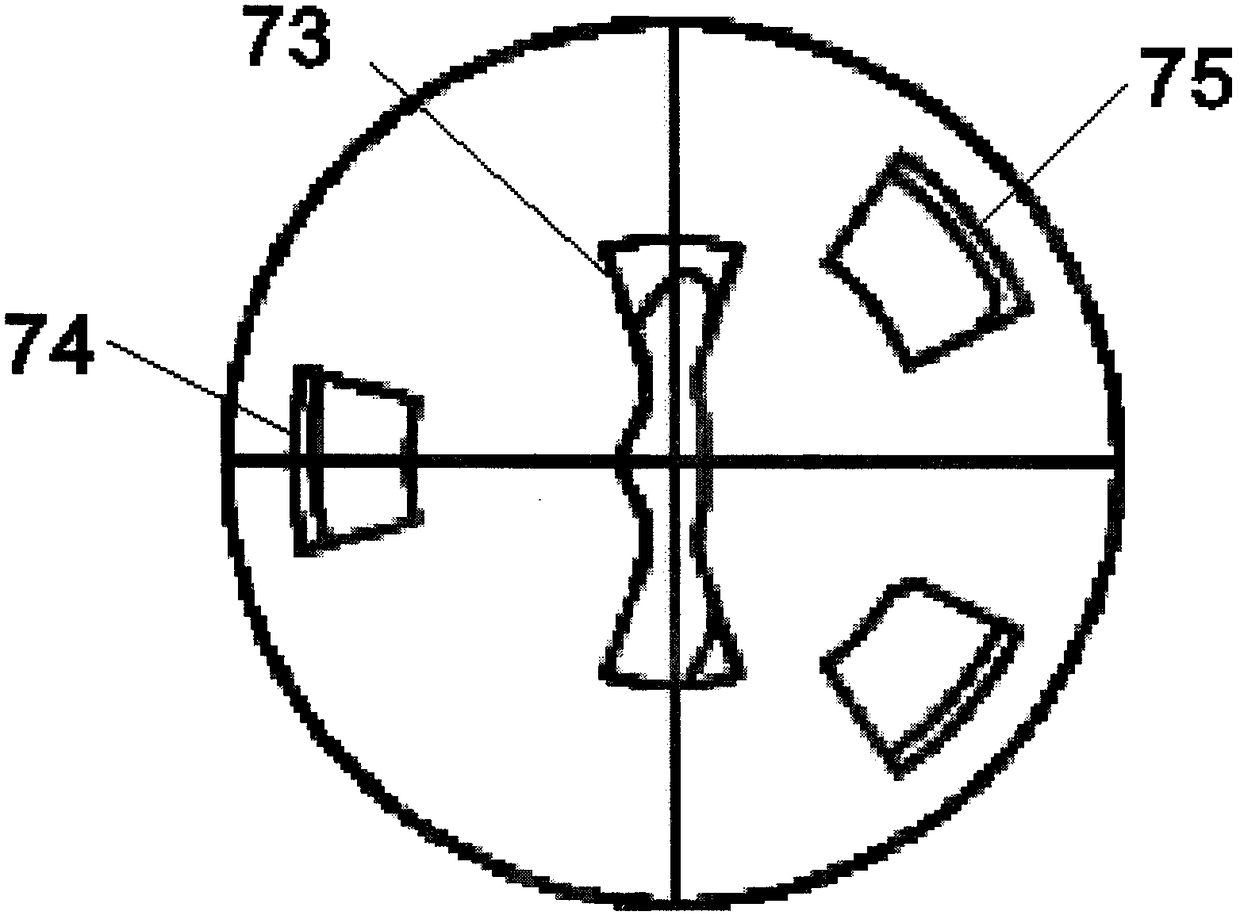

[0023] The bottom of the base 1 is provided with a convex portion 27, and the lower silica gel sealing ring 9 is sleeved on the convex portion 27 to play a role of sealing installation. The upper silica gel sealing ring 8 is installed on the base 1 for sealing the static porcelain The static ceramic sheet 7 is installed in the base 1 and the static ceramic sheet 7 is provided with two notches 721, and the base 1 is provided with an insertion piece 28 corresponding to the two notches 72, which are inserted into each other, The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com