Oil smoke condition automatic reorganization range hood

A range hood and automatic identification technology, which is applied in the field of kitchen fume treatment, can solve the problems of inability to realize remote detection and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

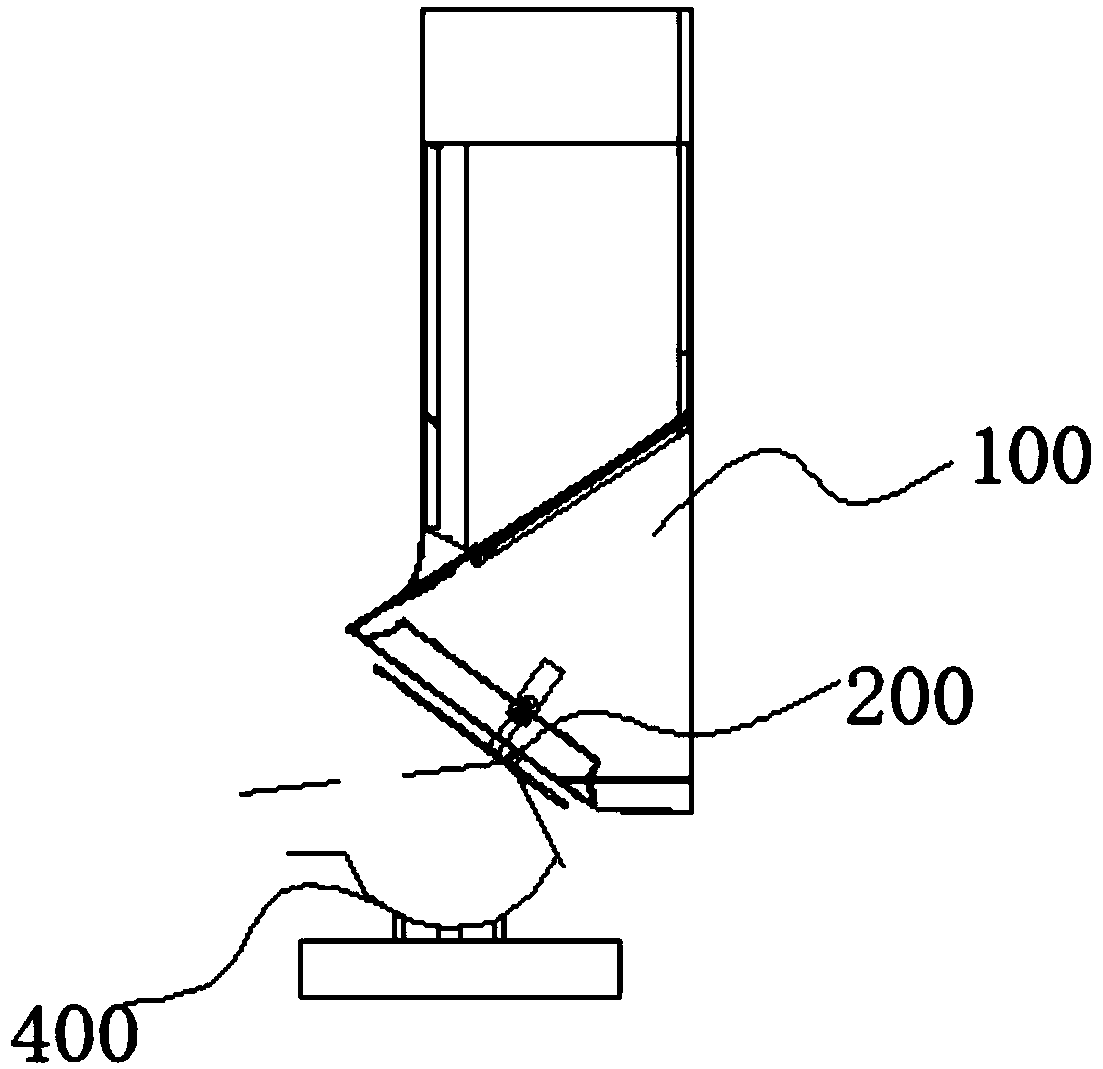

[0057] A range hood that automatically recognizes the state of cooking fume. The visual imaging module continuously images the target area of the stove and sends the imaging pictures to the processing module; the processing module receives the imaging pictures sent by the visual imaging module and processes them to obtain the smoke concentration and area. information.

[0058] The visual imaging module is at least provided with a camera, such as figure 1 As shown, the camera 200 is built into the casing of the hood main body 100, and the lens of the camera faces the target area of the stove 400, and the output end of the camera is electrically connected to the processing module. The camera is used to take images of the cooktop area, and send the taken pictures to the processing module for processing.

[0059] The camera is equipped with waterproof, anti-fog, anti-smoke lenses and anti-blurring glass to avoid the impact of water vapor and oily smoke above the smoke hood on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com