Slurry surface detection and slurry supplementing method for grouting sleeve

A grouting sleeve, surface detection technology, applied in the direction of measuring device, liquid level indicator, engine lubrication, etc., can solve the problems of poor grouting effect, decreased slurry fluidity, unreliable grouting effect, etc. High quality, easy operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

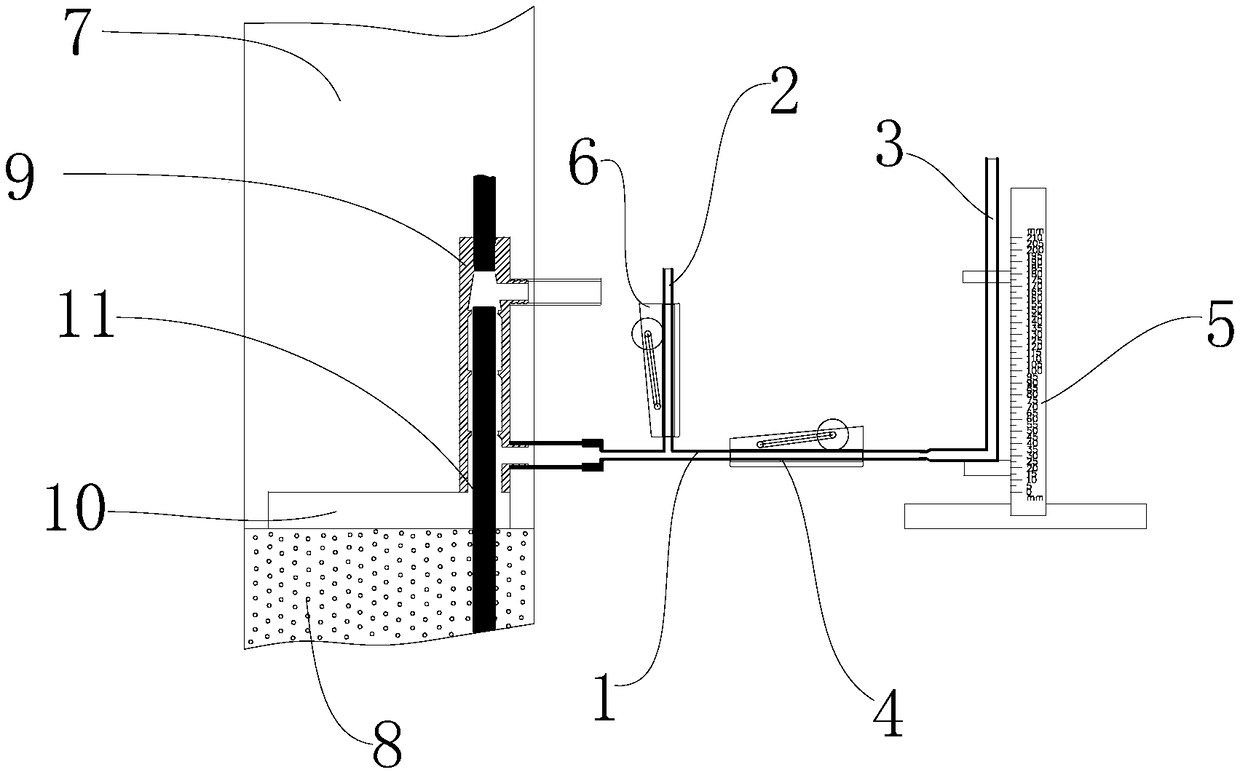

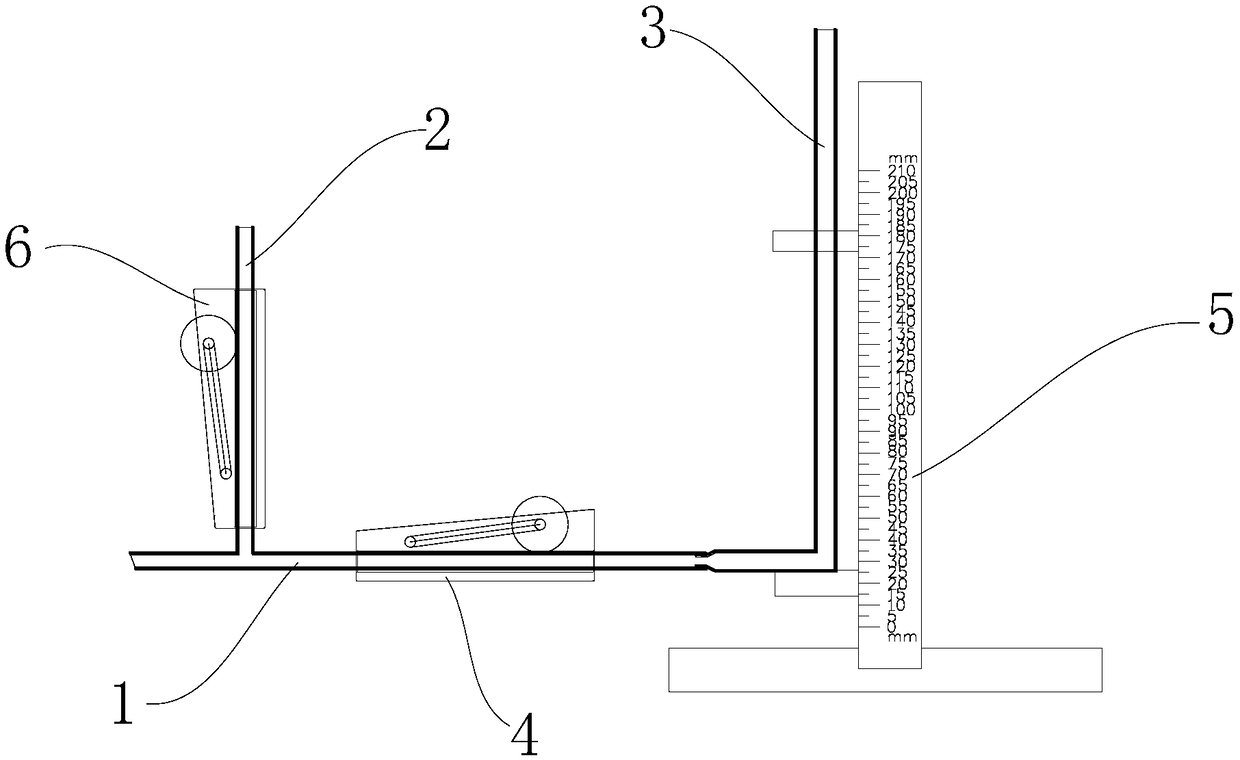

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

[0032] Embodiments of the present invention are as follows, as figure 1 , a grout surface detection and grout filling method for a grouting sleeve, comprising the following steps:

[0033] (1) Assembling the prefabricated parts: hoisting the prefabricated parts, the protruding steel bars 11 of the lower prefabricated parts 8 are docked with the pre-buried grouting sleeves 9 in the upper prefabricated part 7, and the upper and lower prefabricated parts are sealed to build the warehouse;

[0034](2) Installation of slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com