Automatic detecting and centering device for spline phase of power cabin

An automatic detection and centering device technology, which is applied in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of low connection accuracy, high labor intensity of workers, and difficulties in docking spline shafts and spline holes etc. to achieve the effect of convenient operation and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

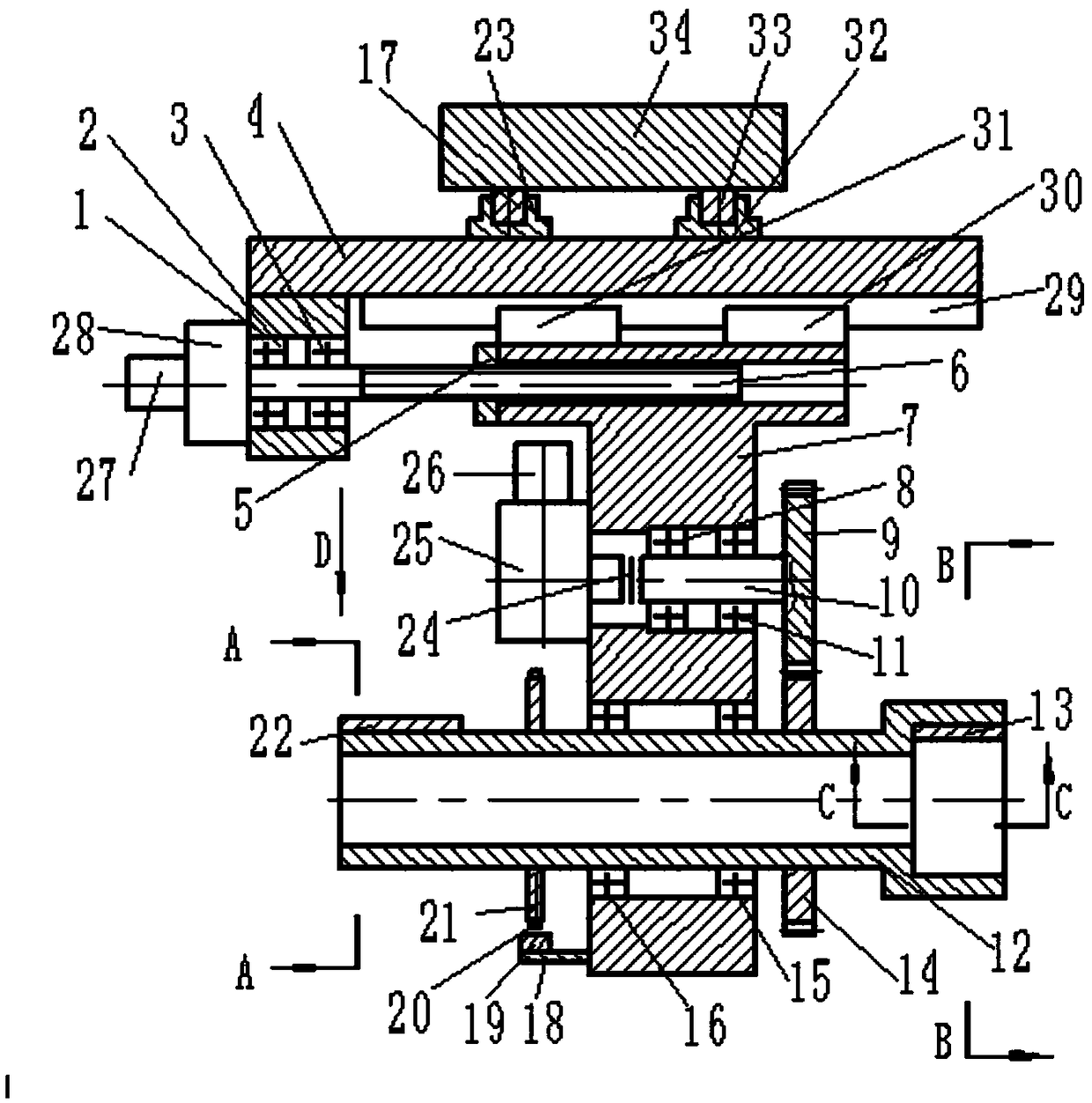

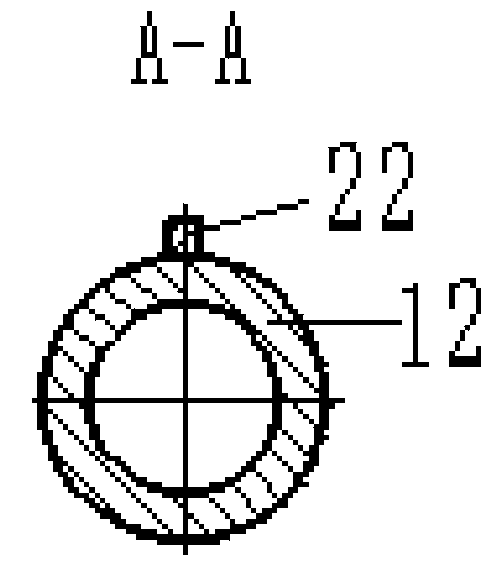

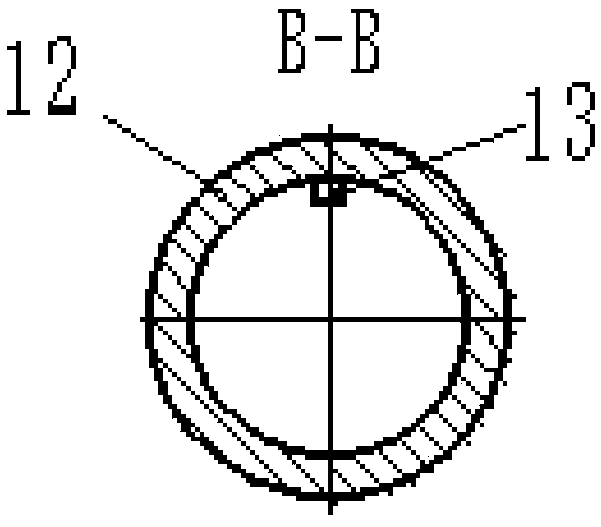

[0021] exist Figure 1 to Figure 5 In the shown schematic diagram of the present invention, the support beam 34 is fixed, and the longitudinal rolling guide rail A17 and the longitudinal rolling guide rail B33 are parallelly fixed on the lower surface of the supporting beam, and the longitudinal rolling guide rail A and the longitudinal rolling guide rail B are respectively slidably connected to each other. The rolling guide rail slide A23 and the longitudinal rolling guide slide B32, the longitudinal rolling guide slide A23 and the longitudinal rolling guide slide B32 are fixed on the upper surface of the longitudinal slide 4, and the lower surface of the longitudinal slide 4 is provided with a horizontal rolling guide 29. The lower part of the lateral rolling guide rail is provided with a lateral rolling guide rail slider A30 and a lateral rolling guide rail slider B31, and the lateral rolling guide rail slider A30 and the lateral rolling guide rail slider B31 are fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com