Preparation method of graphene-loaded ultra-small palladium-copper nano-dot high-performance formic acid catalytic oxidant and its products and applications

A graphene, ultra-small palladium technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of formic acid catalytic oxidation activity and cycle stability are not good enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a graphene-loaded ultra-small palladium-copper nano-dot high-performance formic acid catalytic oxidant, comprising the following steps:

[0039] 1) Add 30.46mg of palladium acetylacetonate (n(Pd)=0.1mol) and 3.99mg of copper acetate (n(Cu)=0.02mol) into 5mL of benzyl alcohol solution and mix well by ultrasonication for 5min with a power of 600W;

[0040] 2) Add 50mg of ascorbic acid (Vc), 86mg of polyvinylpyrrolidone (PVP) and 19.8mg of graphene into 10mL of ethanol and mix well by ultrasonication for 80min with a power of 600W;

[0041] 3) Ultrasonicate the solution obtained in step 1) and step 2) for 20min with a power of 600W, mix evenly, transfer to a 50ml glass bottle, heat to 95°C for 13h in a blast drying oven;

[0042] 4) The obtained product is centrifuged and washed with a mixed solution of ethanol and water with a volume ratio of 1:1 to 2:1, and then vacuum-dried at 60°C for 10 hours.

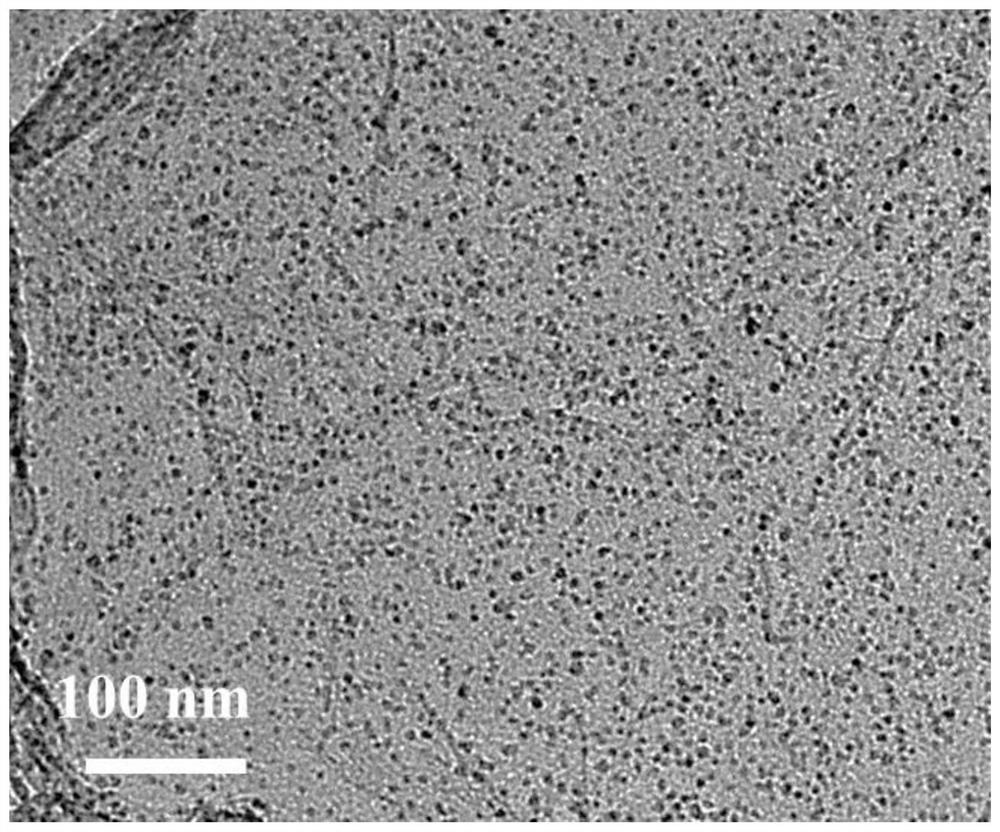

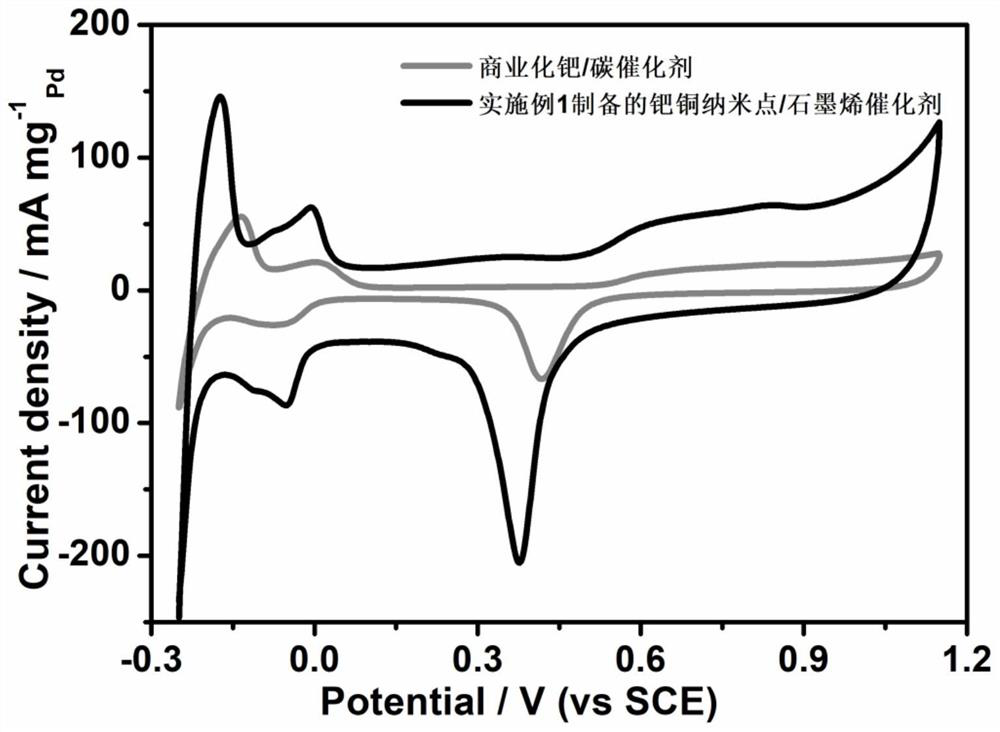

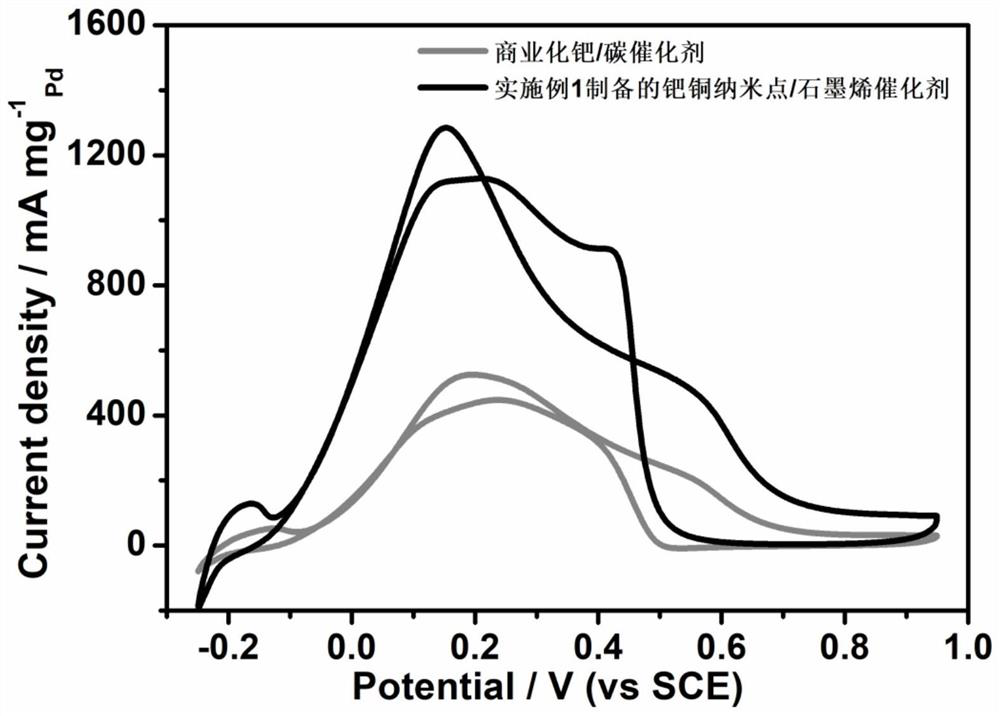

[0043] figure 1 For the transmission electron mi...

Embodiment 2

[0049] A method for preparing a graphene-loaded ultra-small palladium-copper nano-dot high-performance formic acid catalytic oxidant, comprising the following steps:

[0050] 1) Add 30.46mg of palladium acetylacetonate (n(Pd)=0.1mol) and 19.97mg of copper acetate (n(Cu)=0.1mol) into 5mL of benzyl alcohol solution and mix well by ultrasonication for 10min with a power of 100W;

[0051] 2) Add 50mg of ascorbic acid (Vc), 86mg of polyvinylpyrrolidone (PVP) and 19.8mg of graphene into 10mL of ethanol and ultrasonically mix for 60min, with a power of 600W;

[0052] 3) Ultrasonicate the solution obtained in step 1) and step 2) for 30min with a power of 100W, mix evenly, transfer to a 50ml glass bottle, heat to 80°C in a blast drying oven and keep it warm for 15h;

[0053] 4) The obtained product is centrifuged and washed with a mixed solution of ethanol and water with a volume ratio of 1:1 to 2:1, and then vacuum-dried at 60°C for 10 hours.

[0054] Figure 5 The transmission elec...

Embodiment 3

[0060] A method for preparing a graphene-loaded ultra-small palladium-copper nano-dot high-performance formic acid catalytic oxidant, comprising the following steps:

[0061] 1) Add 20mg of palladium acetylacetonate (n(Pd)=0.1mol) and 6.66mg of copper acetate (n(Cu)=0.03mol) into 5m L of benzyl alcohol solution and mix well by ultrasonication for 5min with a power of 600W;

[0062] 2) Add 50mg of ascorbic acid (Vc), 86mg of polyvinylpyrrolidone (PVP) and 19.8mg of graphene into 10mL of ethanol and mix well by ultrasonication for 80min with a power of 600W;

[0063] 3) Ultrasonicate the solution obtained in step 1) and step 2) for 30min with a power of 100W, mix evenly, transfer to a 50ml glass bottle, heat to 120°C for 10h in a blast drying oven;

[0064] 4) The obtained product is centrifuged and washed with a mixed solution of ethanol and water with a volume ratio of 1:1 to 2:1, and then vacuum-dried at 60°C for 10 hours.

[0065] Figure 9 The transmission electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com