A kind of palladium-palladium tungsten chromium nano catalyst and its preparation method and application

A technology of nano-catalyst and palladium salt, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve good stability, high practical value, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the present embodiment, the preparation method of palladium-palladium tungsten chromium nanocatalyst comprises the following steps:

[0039] (1) Add sodium chloropalladate (0.75 mg·mL) to a solution of DMF (12 mL) and acetic acid (8 mL) under ultrasonic conditions -1 ), chromium acetate (0.2mg·mL -1 ) and tungsten carbonyl (2.5mg·mL -1 ), making a mixed solution;

[0040] (2) Pass high-purity nitrogen into the mixed solution to remove dissolved oxygen, then heat up to 230° C., and react for 2 hours;

[0041] (3) Centrifuge the product obtained in step (2), wash it with ethanol aqueous solution, and obtain it.

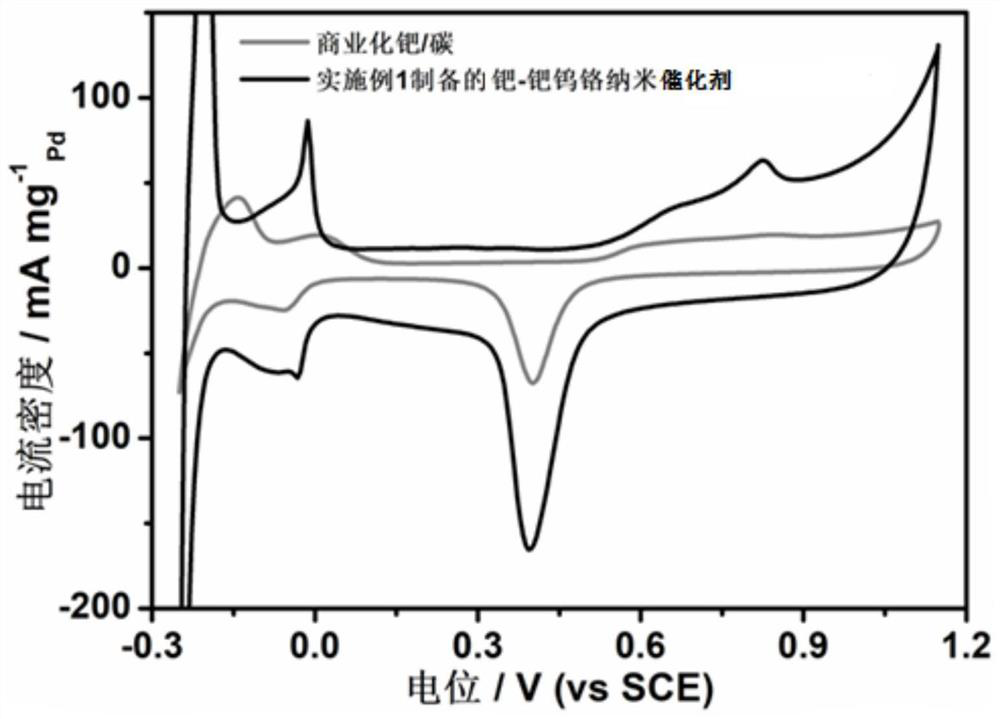

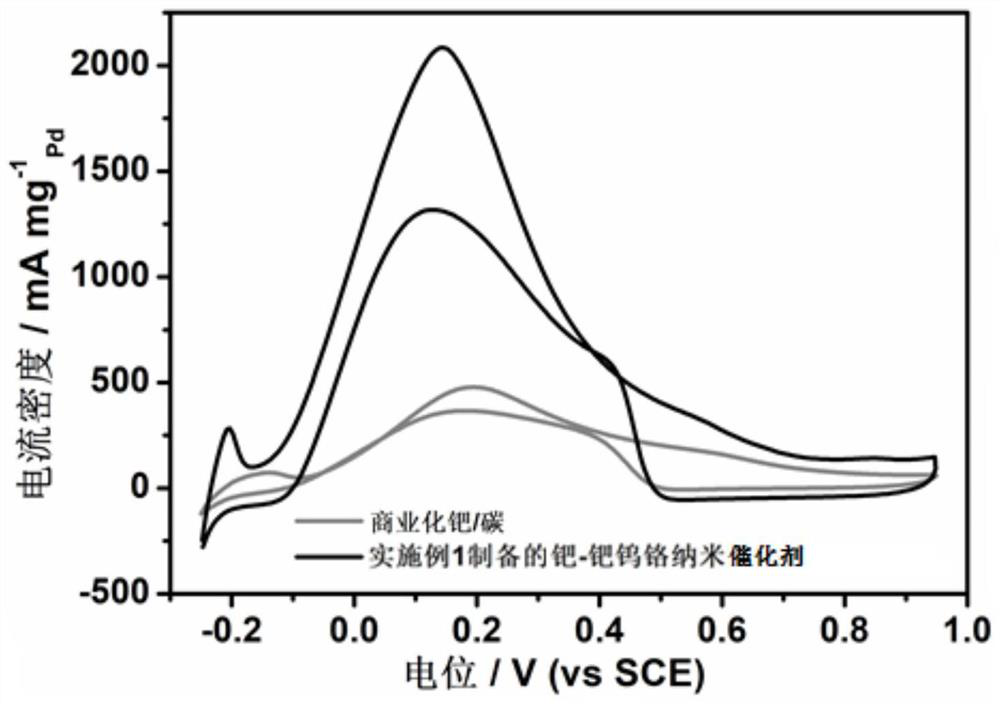

[0042] Detection and Analysis

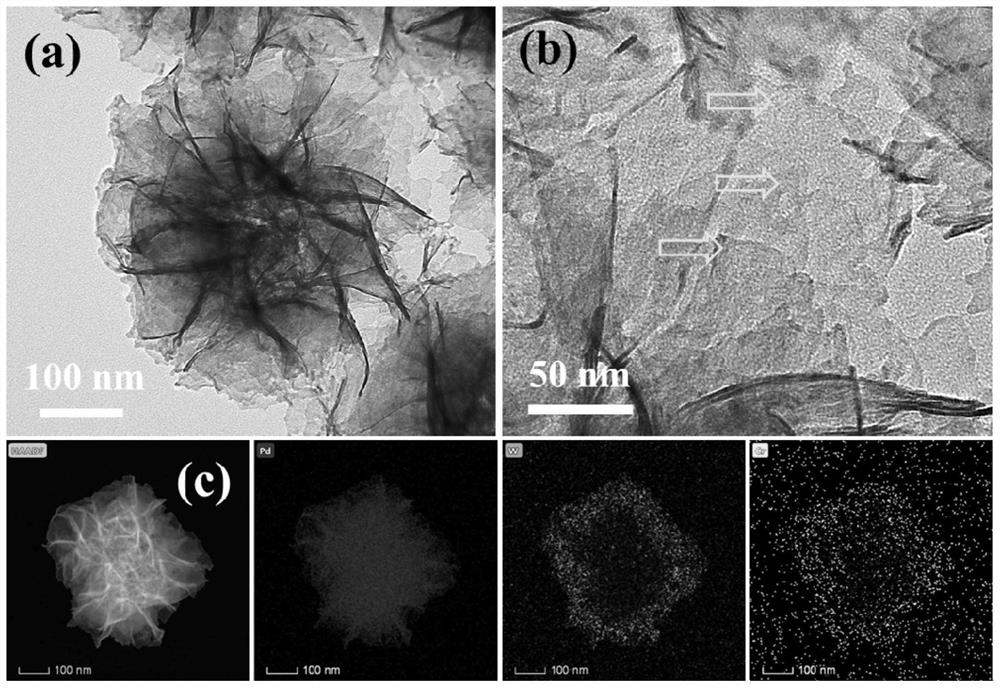

[0043] 1) the palladium-palladium tungsten chromium nanocatalyst that present embodiment 1 makes is carried out transmission electron microscope detection analysis, and the result is as follows figure 1 shown.

[0044] from figure 1 It can be seen from the analysis that the prepared palladium-palladium tungsten-chromium n...

Embodiment 2

[0055] In the present embodiment, the preparation method of palladium-palladium tungsten chromium nanocatalyst comprises the following steps:

[0056] (1) Add sodium chloropalladate (1mg·mL) to a solution of DMF (15mL) and acetic acid (5mL) under ultrasonic conditions -1 ), chromium acetate (0.25mg·mL -1 ) and tungsten carbonyl (4mg·mL -1 ), making a mixed solution;

[0057] (2) Pass high-purity nitrogen into the mixed solution to remove dissolved oxygen, then heat up to 300°C and react for 70 minutes;

[0058] (3) Centrifuge the product obtained in step (2), wash it with ethanol aqueous solution, and obtain it.

[0059] Detection and Analysis

[0060] 1) the palladium-palladium tungsten chromium nano-catalyst that present embodiment 2 makes is carried out transmission electron microscope detection analysis, and the result is as follows Figure 5 shown.

[0061] from Figure 5 It can be seen from the analysis that the prepared palladium-palladium tungsten-chromium nanoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com