Preparation method of graphene supported palladium iridium nanoparticle catalyst and its electrocatalytic application in formic acid oxidation

A nanoparticle and graphene technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as insufficient catalytic performance, difficult removal, environmental pollution and safety hazards, etc. Application scope and prospect, easy operation, high practical value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

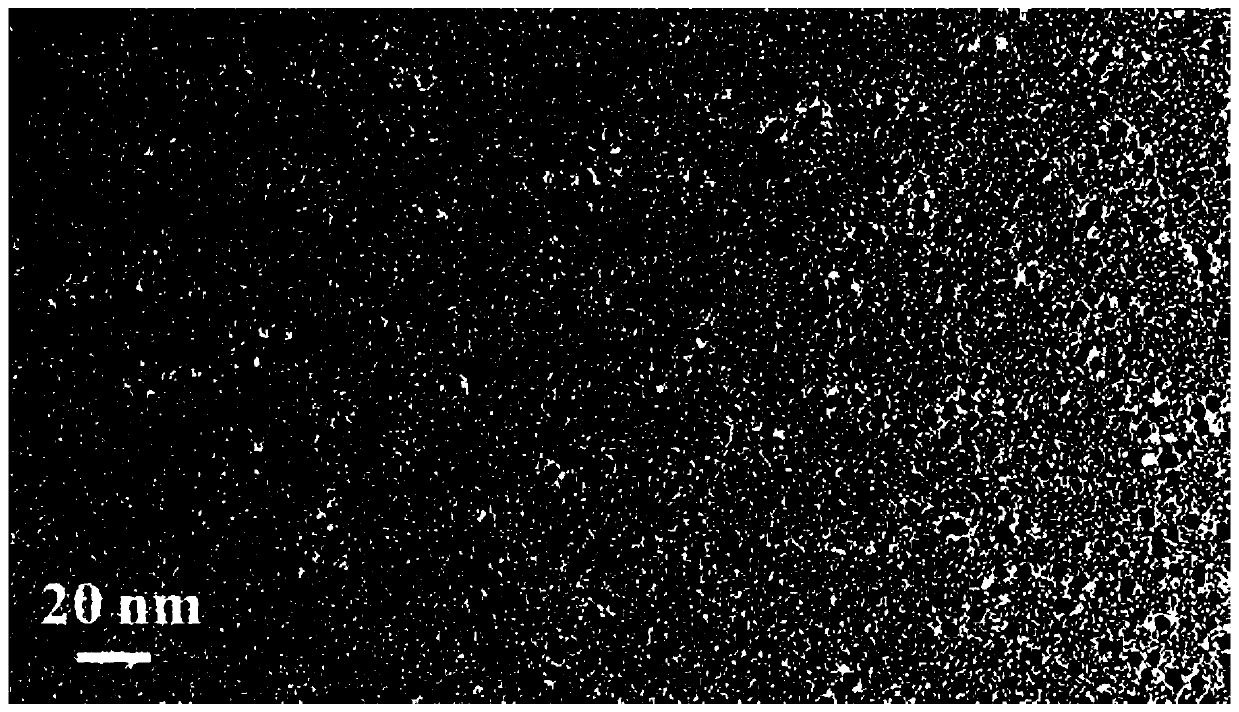

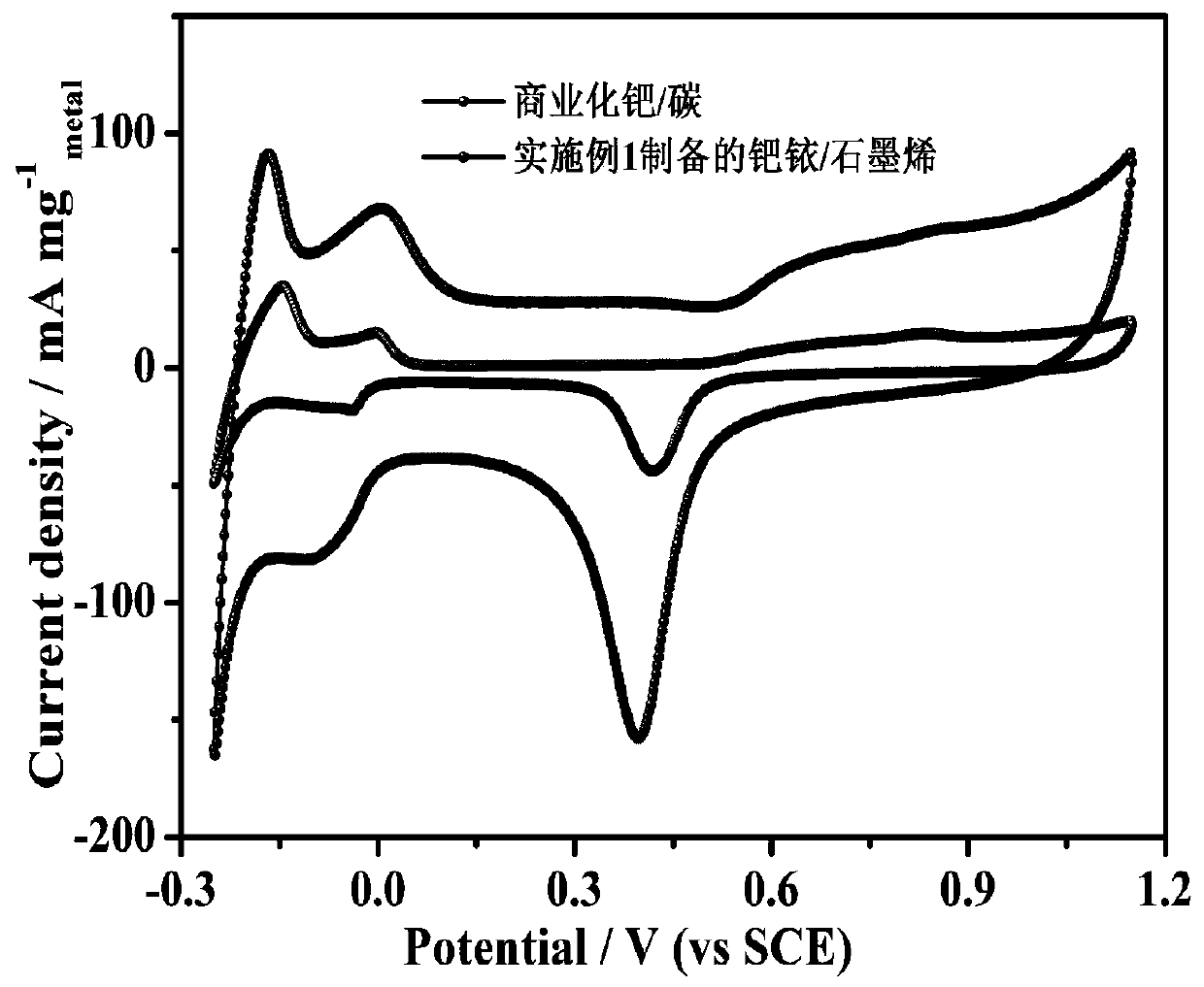

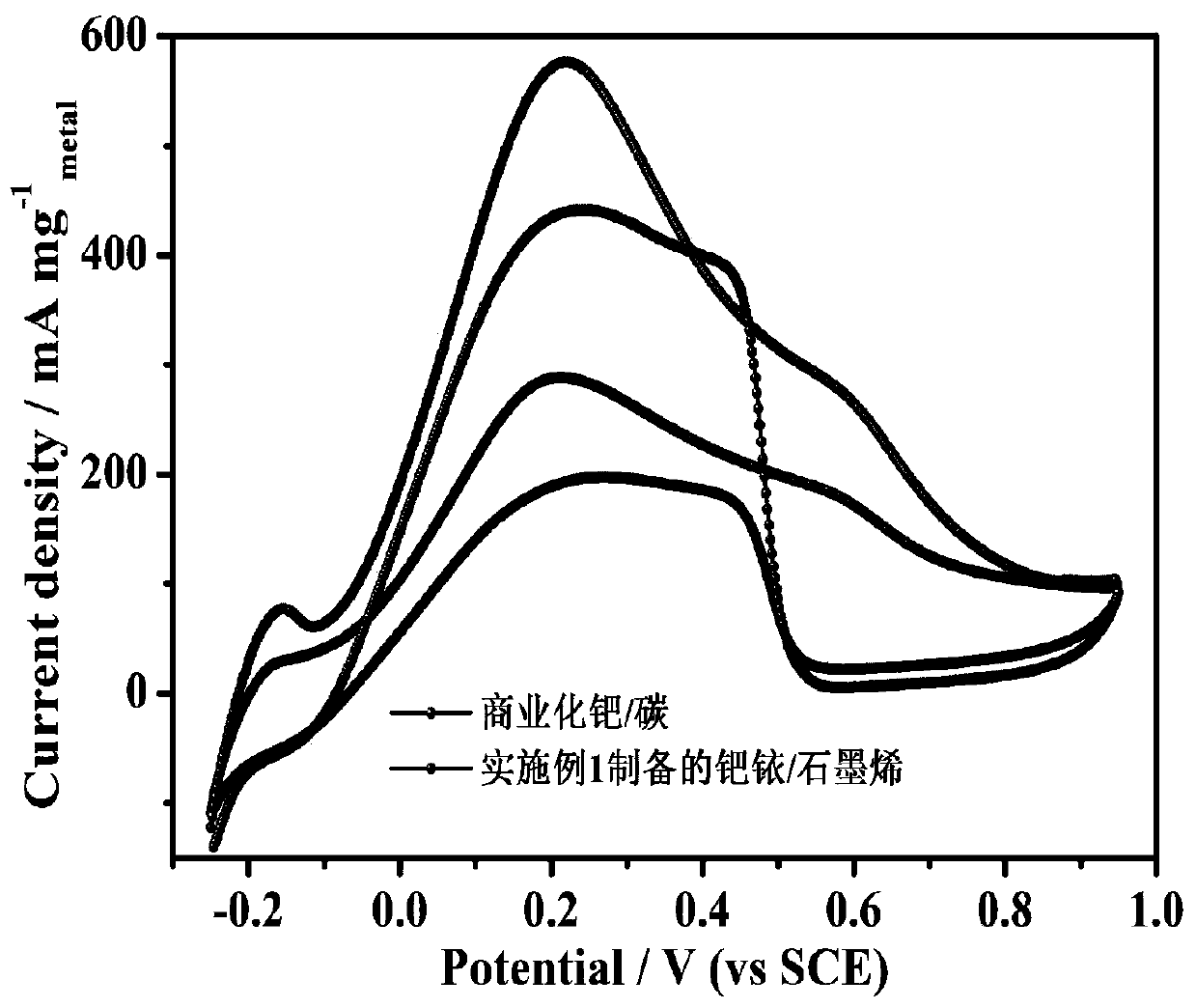

[0038] The preparation method of the palladium iridium / graphene high-performance formic acid oxidation catalyst of the present embodiment may further comprise the steps:

[0039] 1) Add 15mg of graphene to 8mL of formic acid solution and mix uniformly by ultrasonic at 90°C, the ultrasonic power is 300W.

[0040] 2) 0.286mL chloroiridic acid (7mg·mL -1 Ir ) and 0.221mL sodium chloropalladate (20mg·mL -1 Pd ) the mixed solution prepared by ultrasonication for 1h, the ultrasonic power is 300W.

[0041] 3) Heat the solution homogeneously mixed in step 2) to 90°C.

[0042] 4) Rapidly inject the mixed solution in step 3) into the mixed solution of graphene and formic acid in step 1), and perform ultrasonic treatment for 5 hours under sealed conditions at 90° C., with an ultrasonic power of 300W.

[0043] 5) The product obtained by the reaction is washed and dried at 60° C. for 10 h, which is a palladium-iridium / graphene high-performance formic acid oxidation catalyst.

[0044]...

Embodiment 2

[0049] The preparation method of the palladium iridium / graphene high-performance formic acid oxidation catalyst of the present embodiment may further comprise the steps:

[0050] 1) Add 15 mg of graphene to 5 mL of formic acid solution and mix uniformly by ultrasonic at 80° C., and the ultrasonic power is 300 W.

[0051] 2) 0.286mL chloroiridic acid (7mg·mL -1 Ir ) and 0.221mL sodium chloropalladate (20mg·mL -1 Pd ) the mixed solution prepared by ultrasonication for 2h, the ultrasonic power is 500W.

[0052] 3) Heat the solution homogeneously mixed in step 2) to 80°C.

[0053] 4) Rapidly inject the mixed solution in step 3) into the mixed solution of graphene and formic acid in step 1), and perform ultrasonic treatment for 8 hours under sealed conditions at 80° C., with an ultrasonic power of 500 W.

[0054] 5) The product obtained by the reaction is washed and dried at 80° C. for 16 hours, which is a palladium-iridium / graphene high-performance formic acid oxidation catal...

Embodiment 3

[0060] The preparation method of the palladium iridium / graphene formic acid oxidation catalyst of the present embodiment may further comprise the steps:

[0061] 1) Add 15 mg of graphene to 8 mL of sodium borohydride aqueous solution (2 mg / mL) and mix uniformly by ultrasonic at 90° C. with an ultrasonic power of 300 W.

[0062] 2) 0.286mL chloroiridic acid (7mg·mL -1 Ir ) and 0.221mL sodium chloropalladate (20mg·mL -1 Pd ) the mixed solution prepared by ultrasonication for 1h, the ultrasonic power is 300W.

[0063] 3) Heat the solution homogeneously mixed in step 2) to 90°C.

[0064] 4) Rapidly inject the mixed solution in step 3) into the mixed solution of graphene and sodium borohydride in step 1), and perform ultrasonic treatment for 5 hours under sealed conditions at 90° C., and the ultrasonic power is 300W.

[0065] 5) The product obtained by the reaction is washed and dried at 60° C. for 10 h, which is the palladium iridium / graphene-1 formic acid oxidation catalyst....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com