A method for preparing a multi-kink atom Pd-Cu alloy nano-chain catalyst and product and application thereof

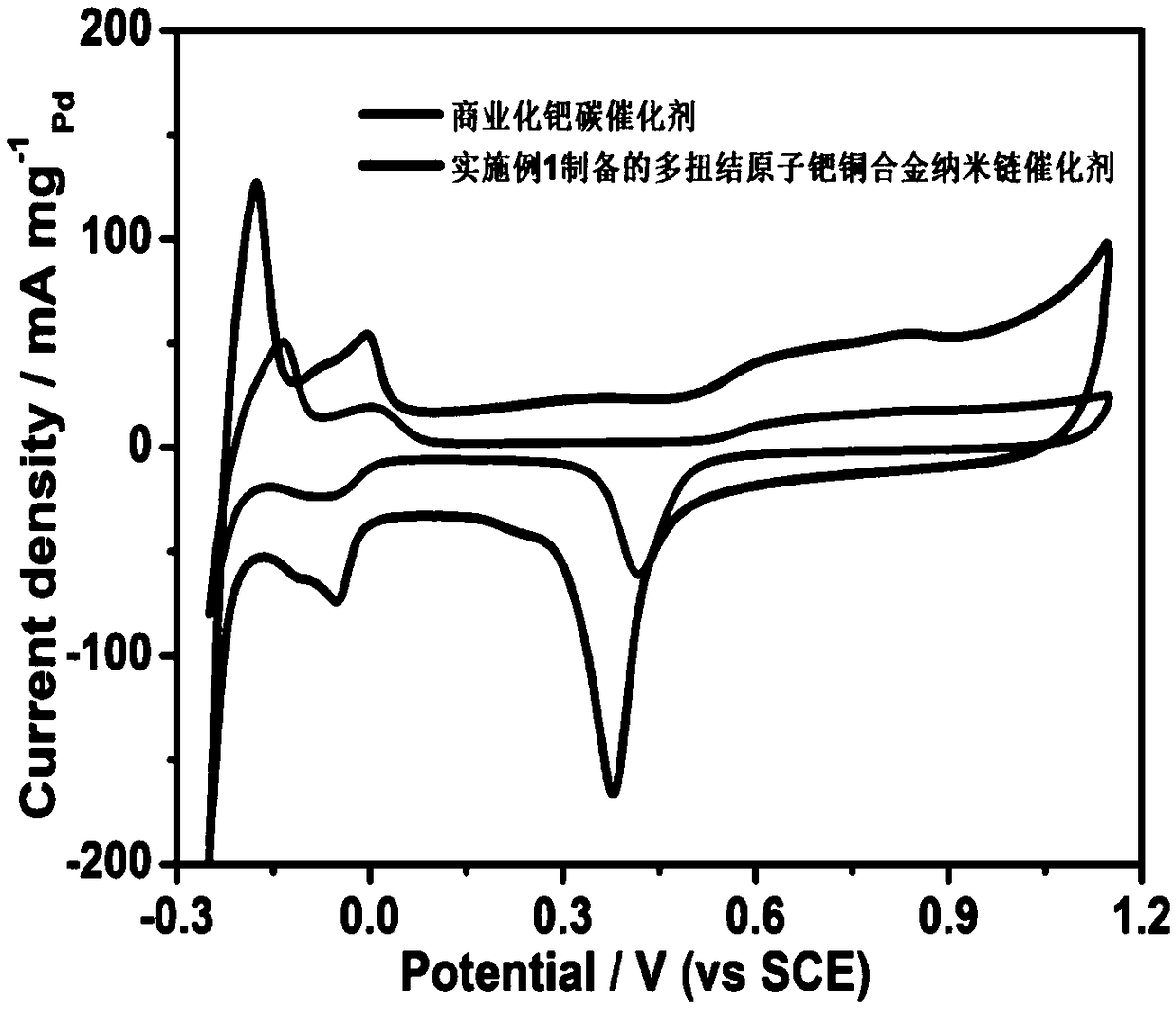

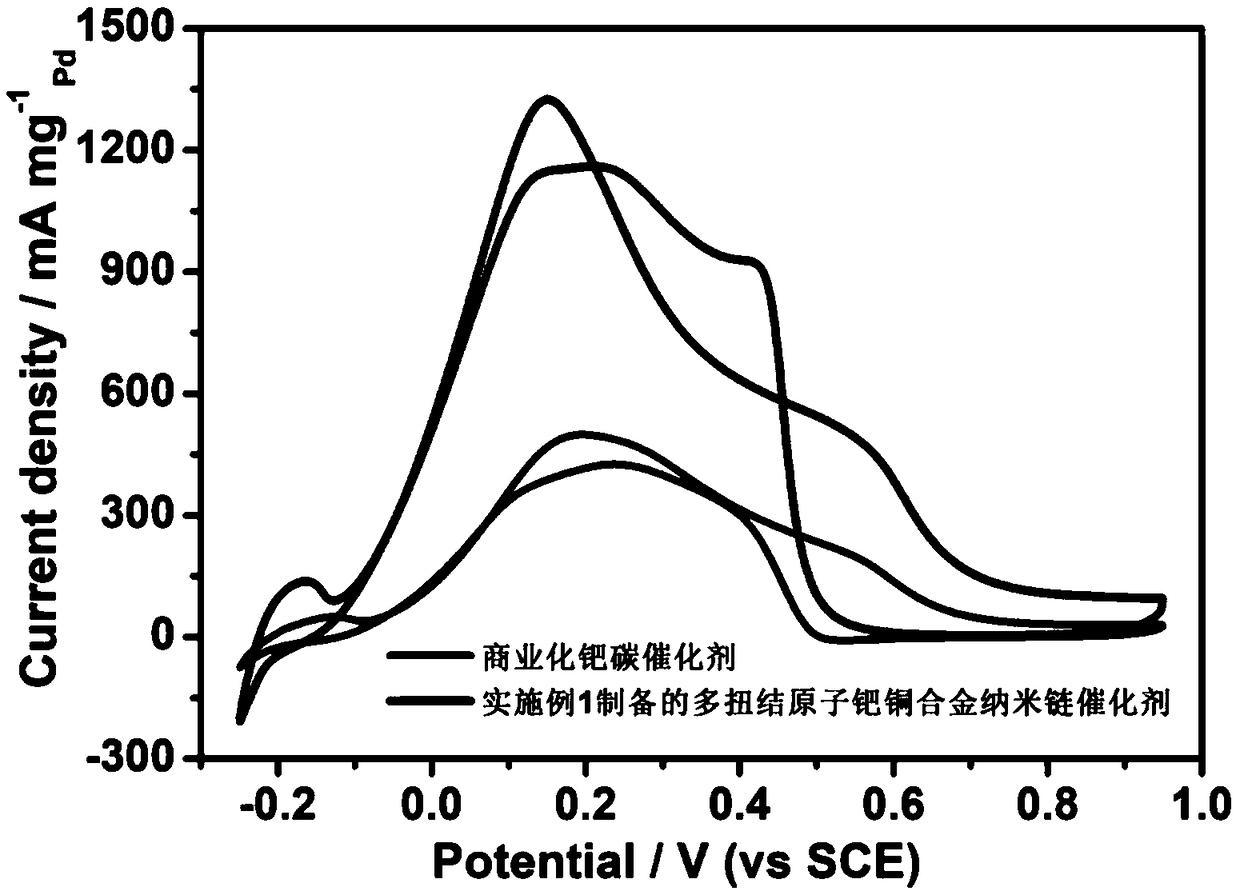

A palladium copper alloy, catalyst technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of formic acid catalytic oxidation activity and cycle stability are not good enough, and achieve excellent cycle stability , Wide range of applications and prospects, the effect of high formic acid catalytic oxidation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of multi-kink atom palladium-copper alloy nano chain catalyst comprises the following steps:

[0034] 1) Add 30.46mg of palladium acetylacetonate (n(Pd)=0.1mol), 19.97mg of copper acetate (n(Cu)=0.1mol), 20mg of PVP, 5mg of citric acid and 10mg of Pluronic F-127 gel into 40ml of ethyl alcohol Ultrasonic mixing in diol solution;

[0035] 2) Transfer the mixture to a 50mL reactor, and feed high-purity nitrogen to saturation, then raise the temperature to 110°C for 3h, then raise the temperature to 170°C for 1.5h, then raise the temperature to 230°C for 1.5h;

[0036] 3) The resulting product is cleaned by centrifugation;

[0037] 4) Add the prepared sample and 30mg XC-72 carbon into ethanol and mix evenly with 100W ultrasound for 30min, then centrifuge and dry at 80°C for 10h.

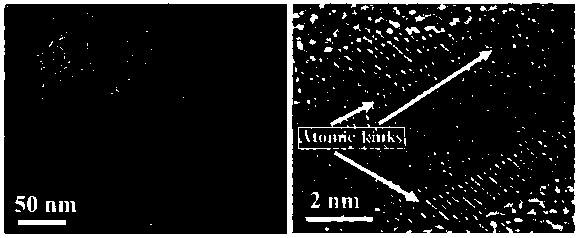

[0038] figure 1 The transmission electron microscope image of the multi-kink atom palladium-copper alloy nanochain catalyst prepared for this embodiment; it can be clearl...

Embodiment 2

[0044] The preparation method of multi-kink atom palladium-copper alloy nano chain catalyst comprises the following steps:

[0045] 1) Add 30.46mg palladium acetylacetonate (n(Pd)=0.1mol), 3.33mg(n(Cu)=0.016mol) copper acetate, 20mg PVP, 5mg citric acid and 10mg Pluronic F-127 gel to 40ml B Ultrasonic mixing in diol solution;

[0046] 2) Transfer the mixture to a 50mL reaction kettle, and feed high-purity nitrogen to saturation, then raise the temperature to 130°C for 1.5h, then raise the temperature to 150°C for 3h, and then raise the temperature to 210°C for 3h;

[0047] 3) The resulting product is cleaned by centrifugation;

[0048] 4) Add the prepared sample and 30mg of XC-72 carbon into ethanol and mix evenly with 600W ultrasound for 0min, then centrifuge and dry at 60°C for 20h.

[0049] Figure 5 The transmission electron microscope image of the multi-kink atom palladium-copper alloy nanochain catalyst prepared for this embodiment; it can be clearly seen from the fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com