Waste glass crushing device

一种废弃玻璃、置物台的技术,应用在建筑废料回收、固体废物的清除、回收利用技术等方向,能够解决安全性能差等问题,达到防止飞溅、加快击碎速度、安全性能好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

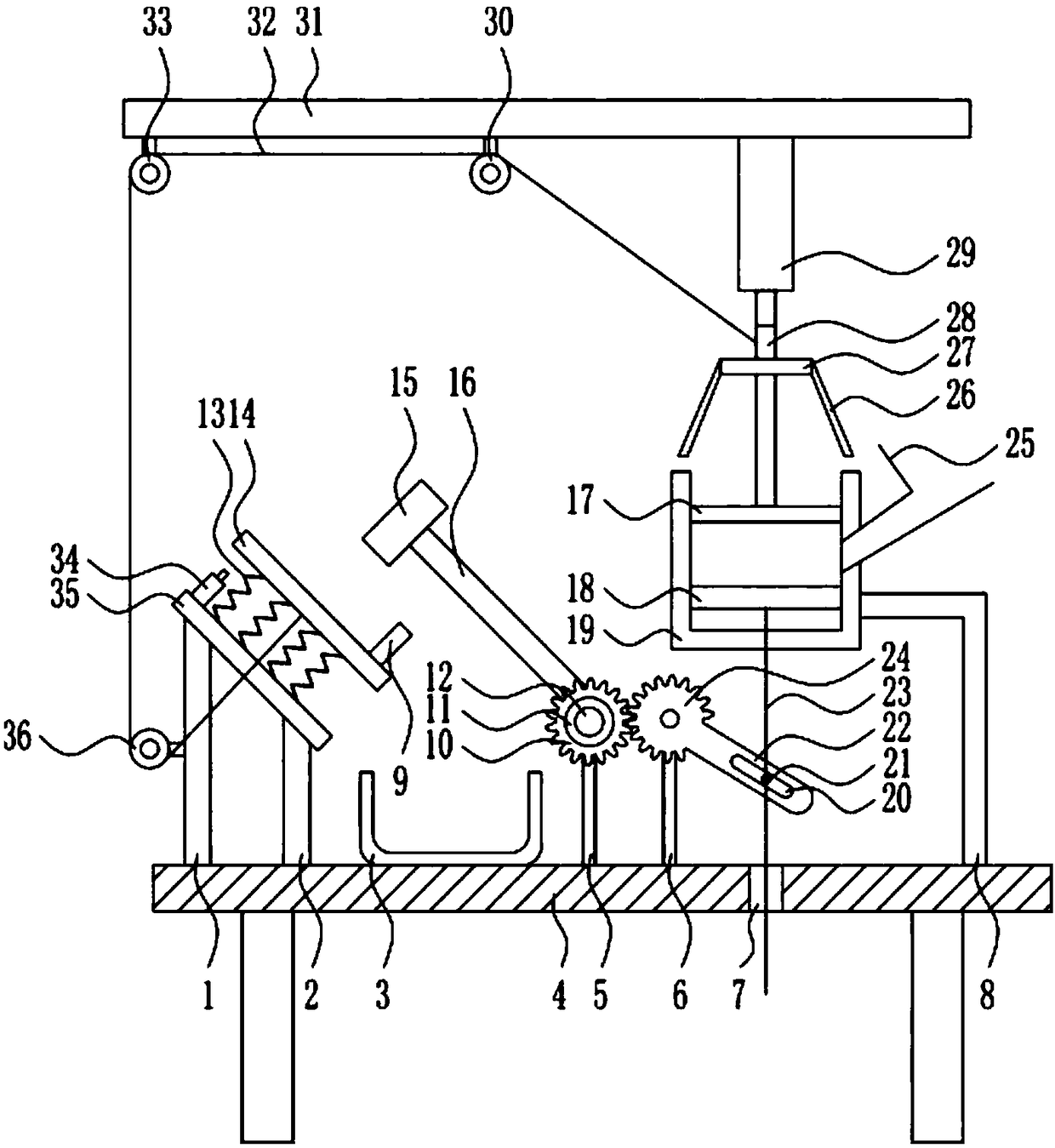

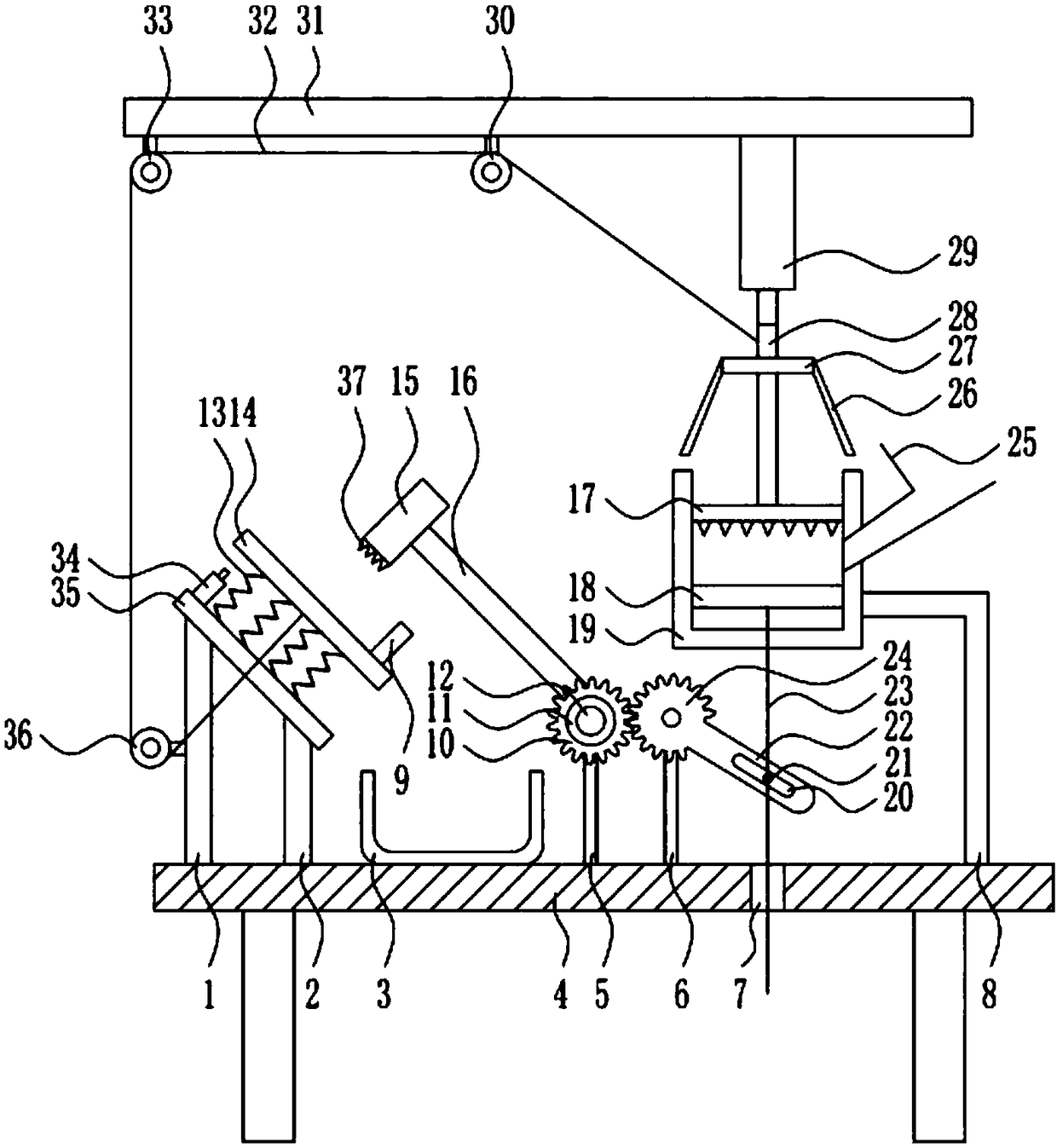

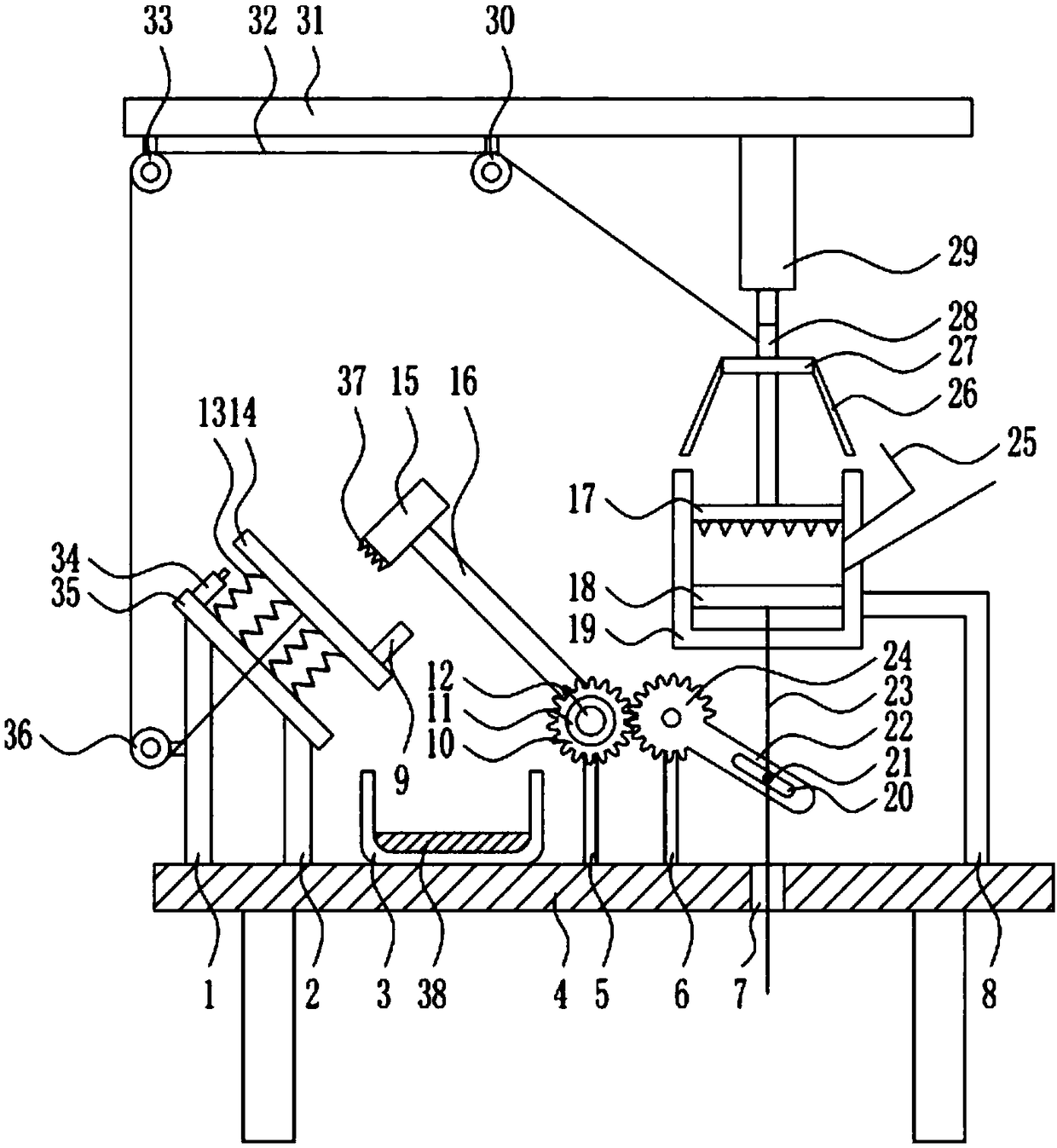

[0031] A high-safety crushing device for waste glass used in construction, such as Figure 1-5As shown, it includes a first pole 1, a second pole 2, a collection tank 3, a storage table 4, a third pole 5, a fourth pole 6, a bracket 8, a bump 9, a second gear 10, and a rotating shaft 11. Rotating motor 12, elastic member 13, pressing plate 14, crushing head 15, straight rod 16, pressing block 17, pushing block 18, crushing box 19, sliding shaft 21, swinging rod 22, lifting rod 23, first gear 24. Feed hopper 25, baffle plate 26, fixed block 27, fifth pole 28, second electric push rod 29, third guide wheel 30, mounting plate 31, pull cord 32, second guide wheel 33, first An electric push rod 34, a fixed plate 35 and a first guide wheel 36; a through hole 7 is opened on the storage table 4, and the top of the storage table 4 is sequentially provided with a first pole 1, a second pole 2, and a third pole from left to right. Pole 5, the 4th pole 6 and support 8, the 4th pole 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com