Marking rod assembling device, full-automatic production line and marking rod assembling method

An assembly device and assembly method technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of inaccurate control of the angle of the marker rod, and achieve the effect of improving installation efficiency, achieving accurate installation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

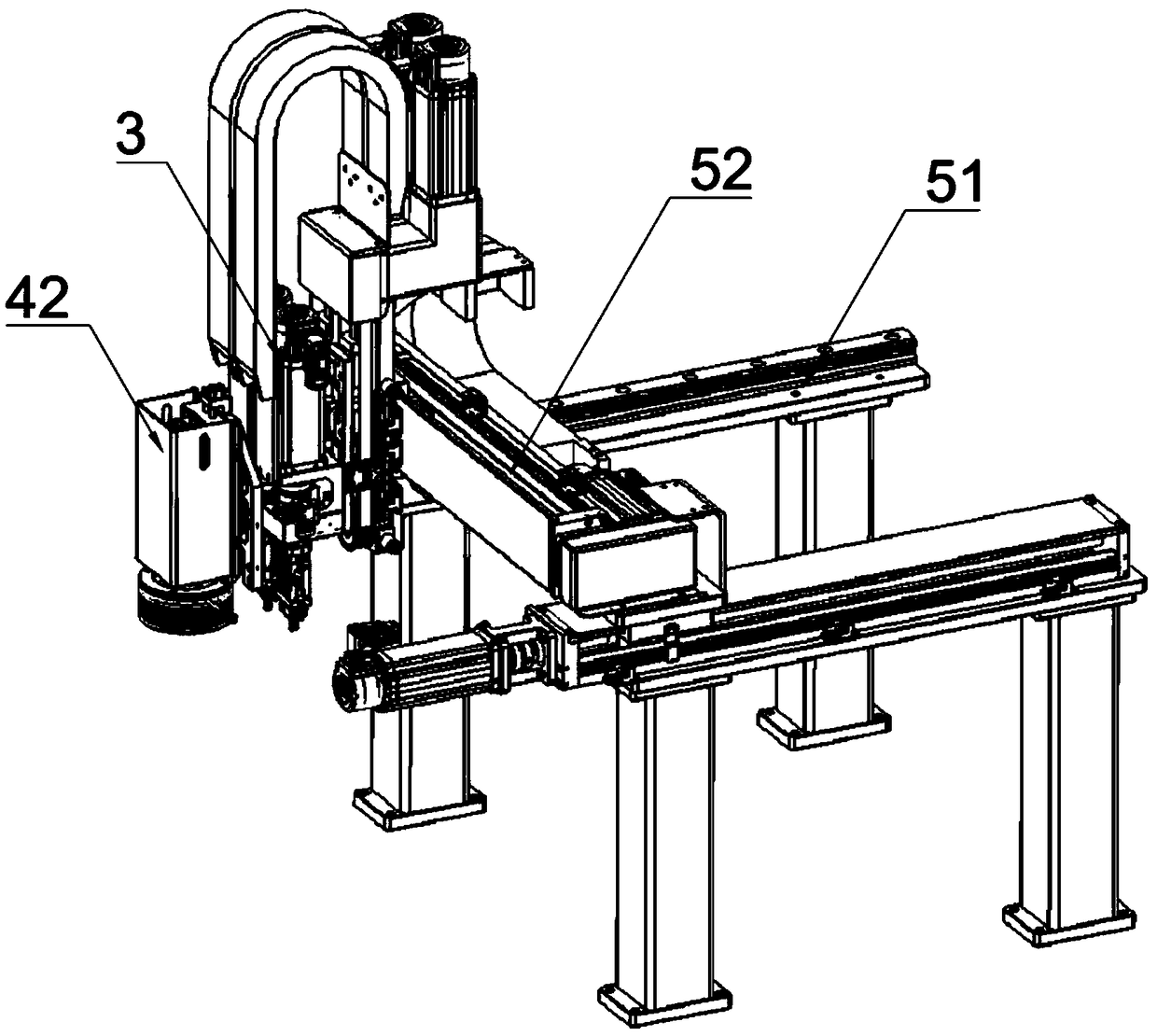

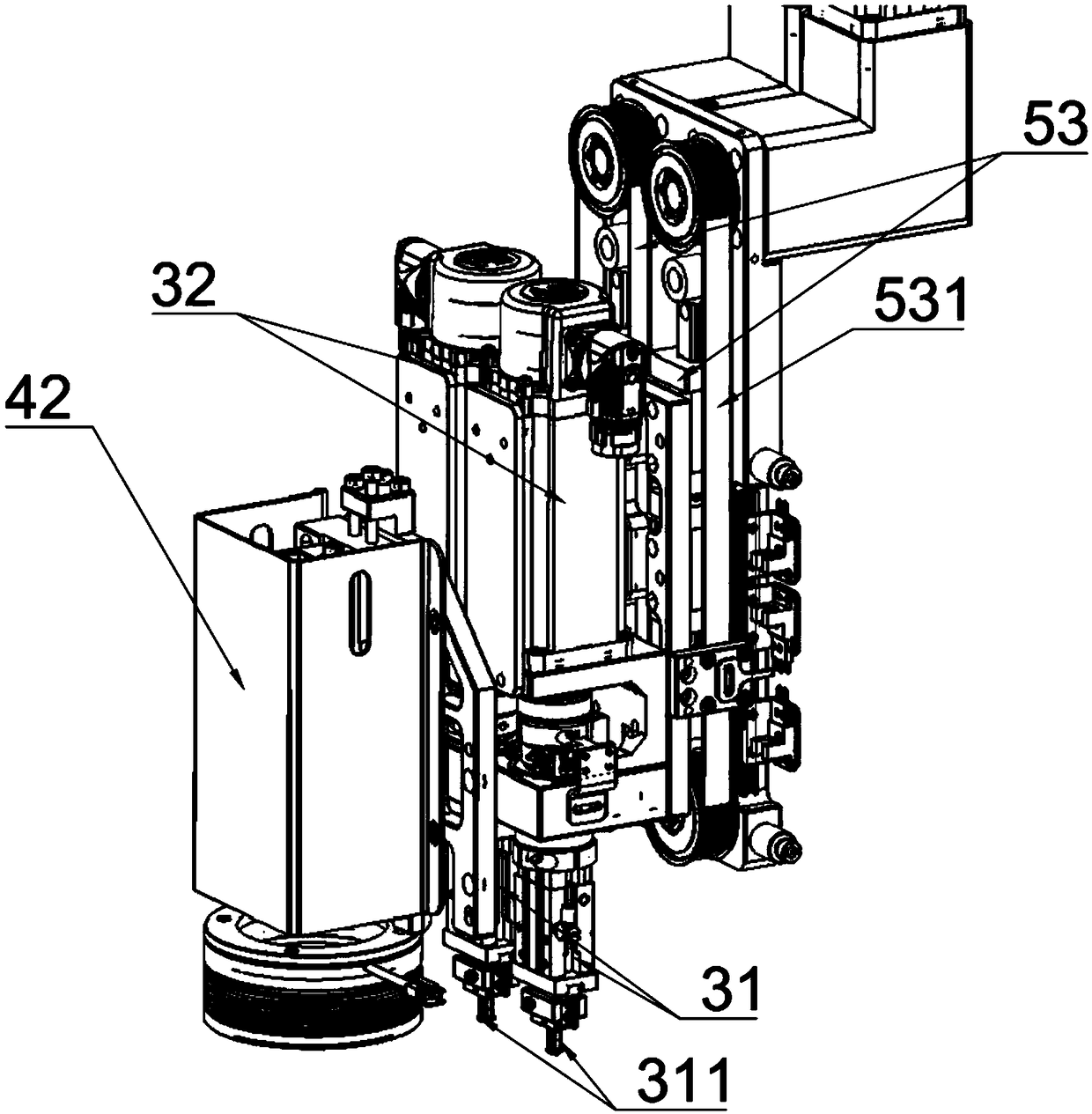

[0048] This embodiment provides a fully automatic production line, including the marking rod assembly device in Embodiment 1, workpieces and identification codes, the workpiece has several mounting holes for the marking rods to be inserted to distinguish products, and the installation positions of the identification codes and marking rods One-to-one correspondence, read the identification code before the production line operation to set the installation angle of the marking rod, adjust the marking rod to the installation angle by the rotating structure 32, and transport it to the pre-assembly position by the installation mechanism 5 Assembling, the accurate installation of the marking rod is realized, and the production efficiency is improved.

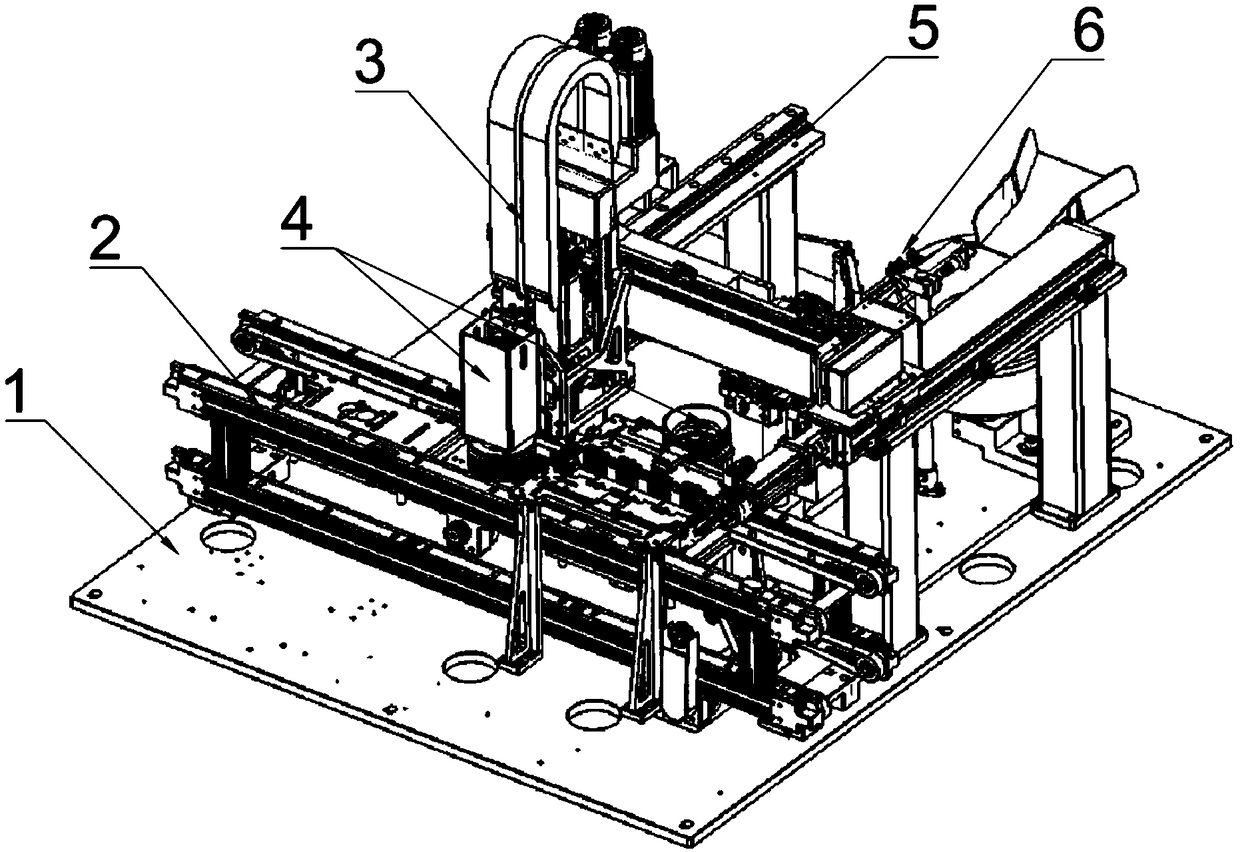

[0049] The marking rod assembly device provided by this embodiment has a structure such as figure 1 shown in . It is used to install the marking rod on the workpiece in batches, and make the marking rod installed on the workpiece at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com