Patents

Literature

30results about How to "Simultaneous installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Software installation method and device

ActiveCN103605537AThere will be no frequent synchronization problemsPerformance is not affectedProgram loading/initiatingSoftware engineeringData file

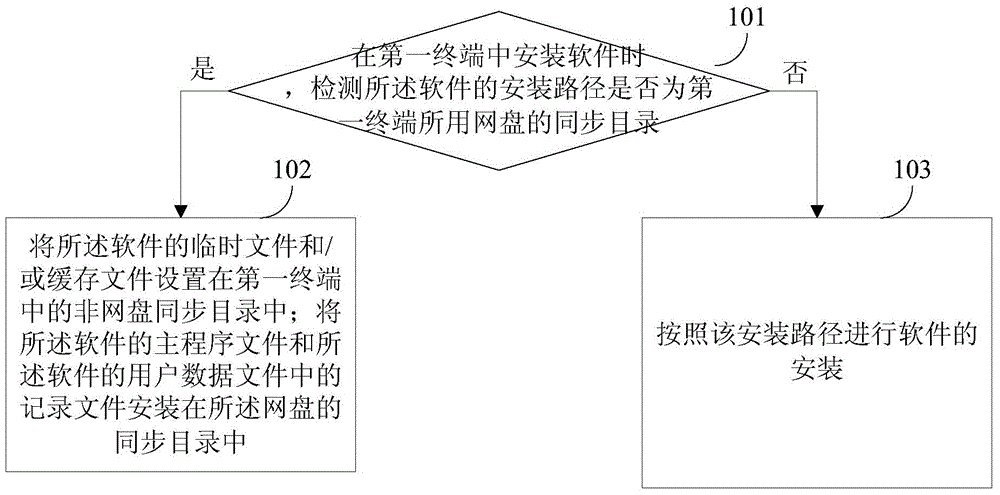

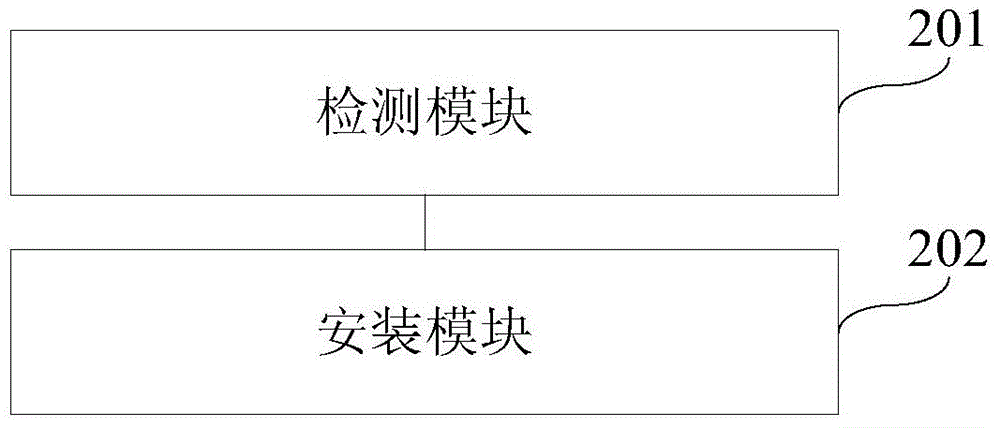

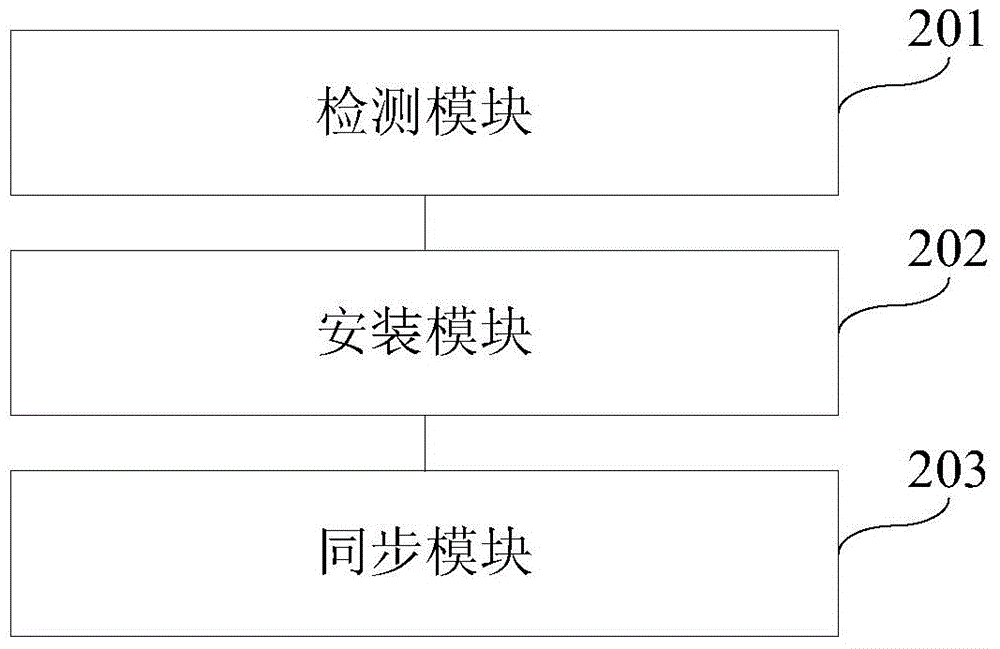

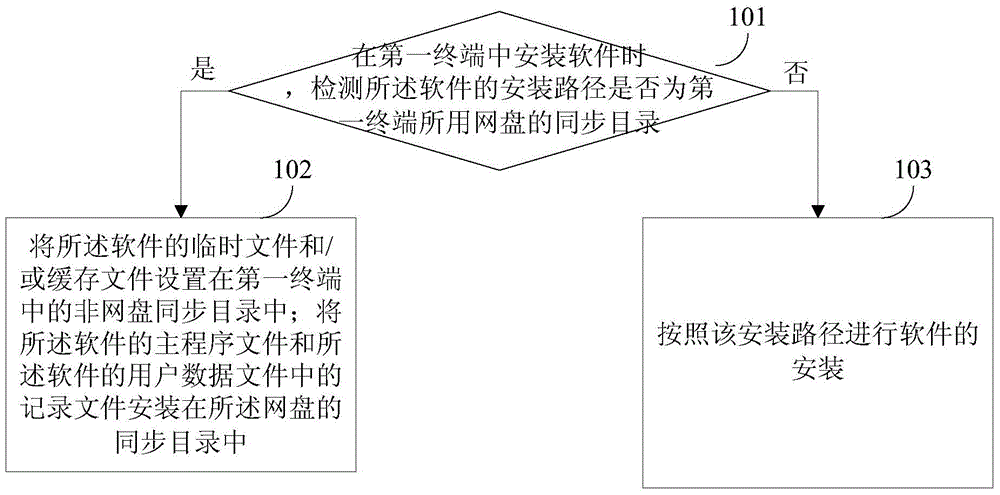

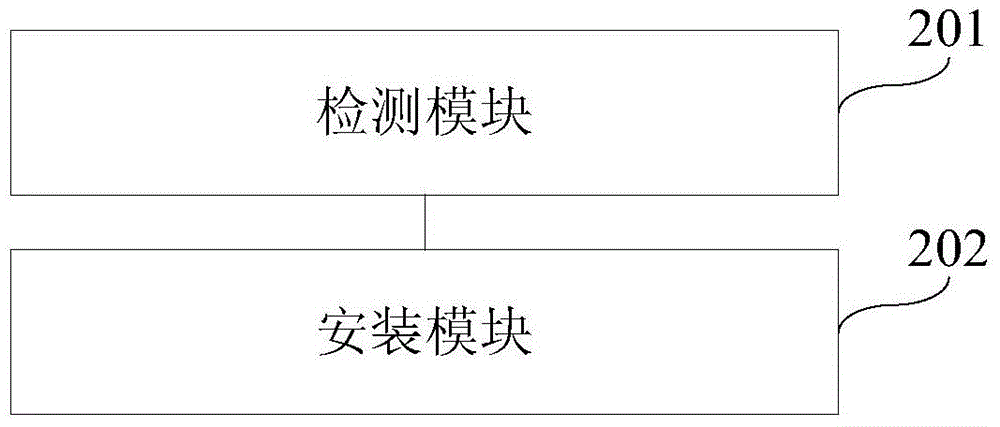

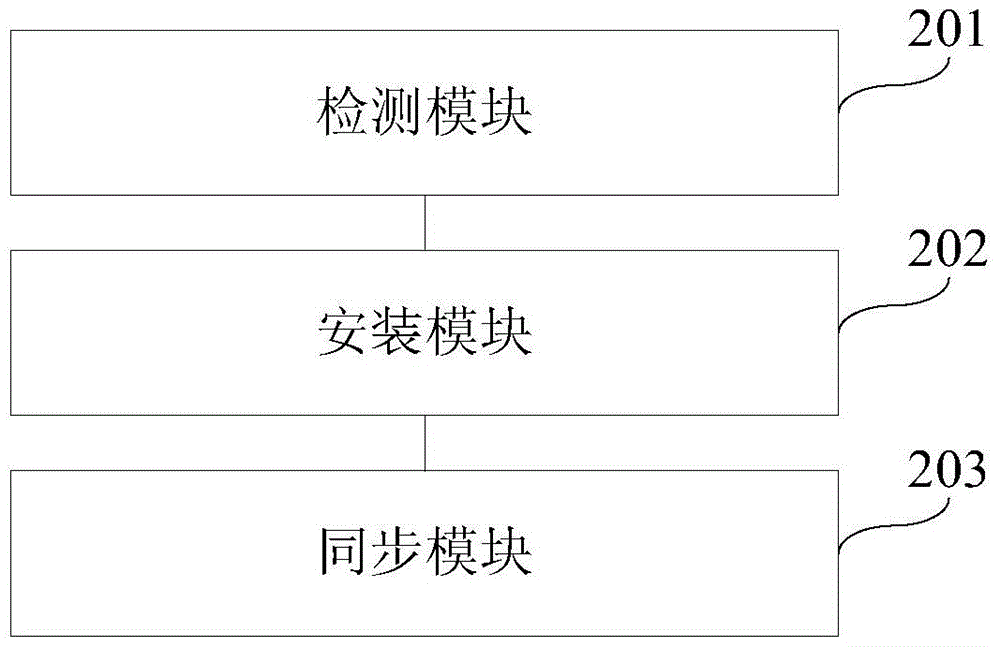

The invention discloses a software installation method and device. The method includes: when software is installed in a first terminal, detecting whether an installation path of the software is a synchronous directory of a network disk used by the first terminal or not; if yes, setting a temporary file and / or a cache file of the software in a non-network-disk synchronous directory in the first terminal; installing a master program file of the software and a log file in a user data file of the software in the synchronous directory of the network disk. Therefore, the software can be prevented from frequent synchronization even if being installed in the network disk, and performance of a computer and the software cannot be affected.

Owner:BEIJING QIHOO TECH CO LTD

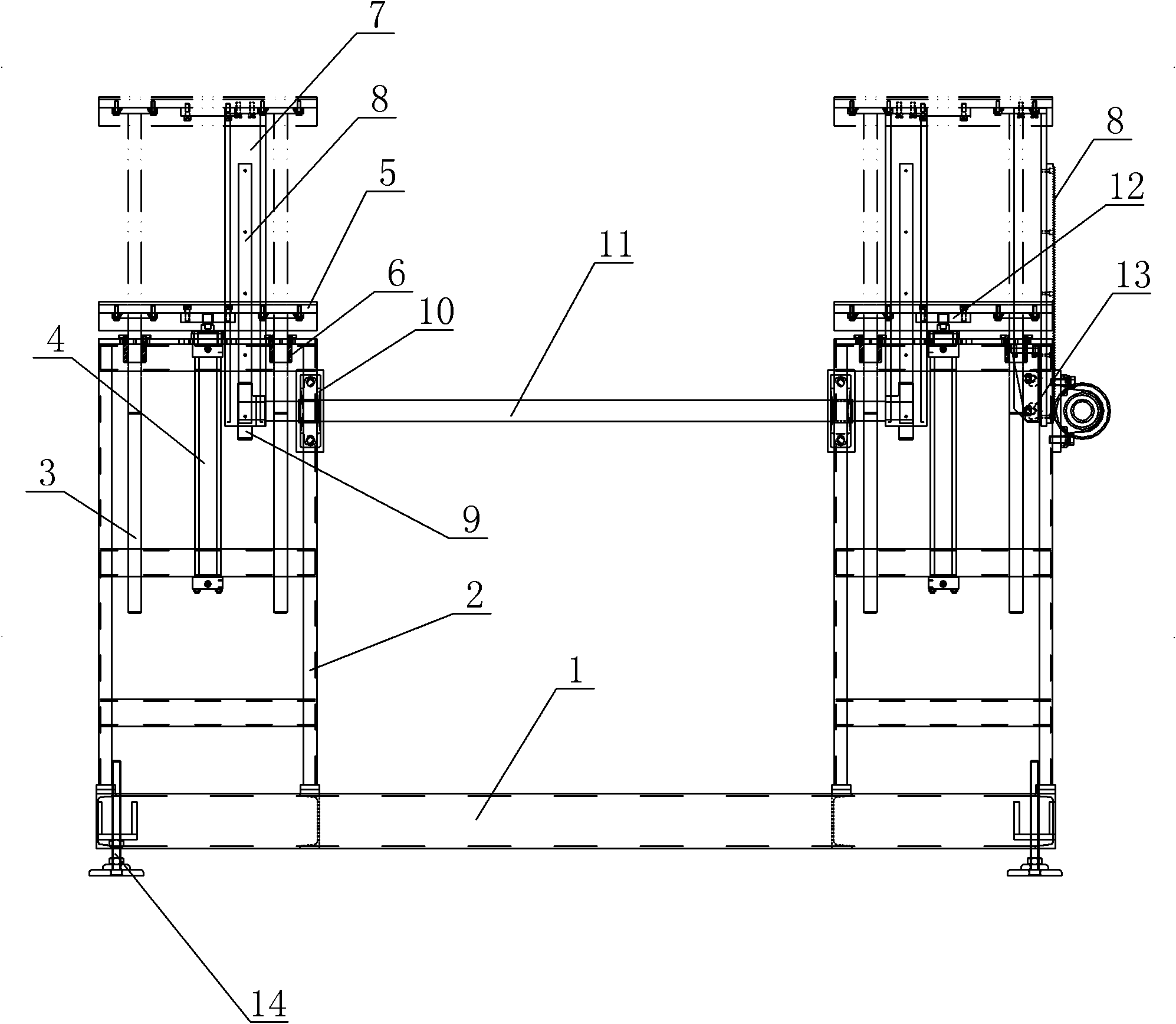

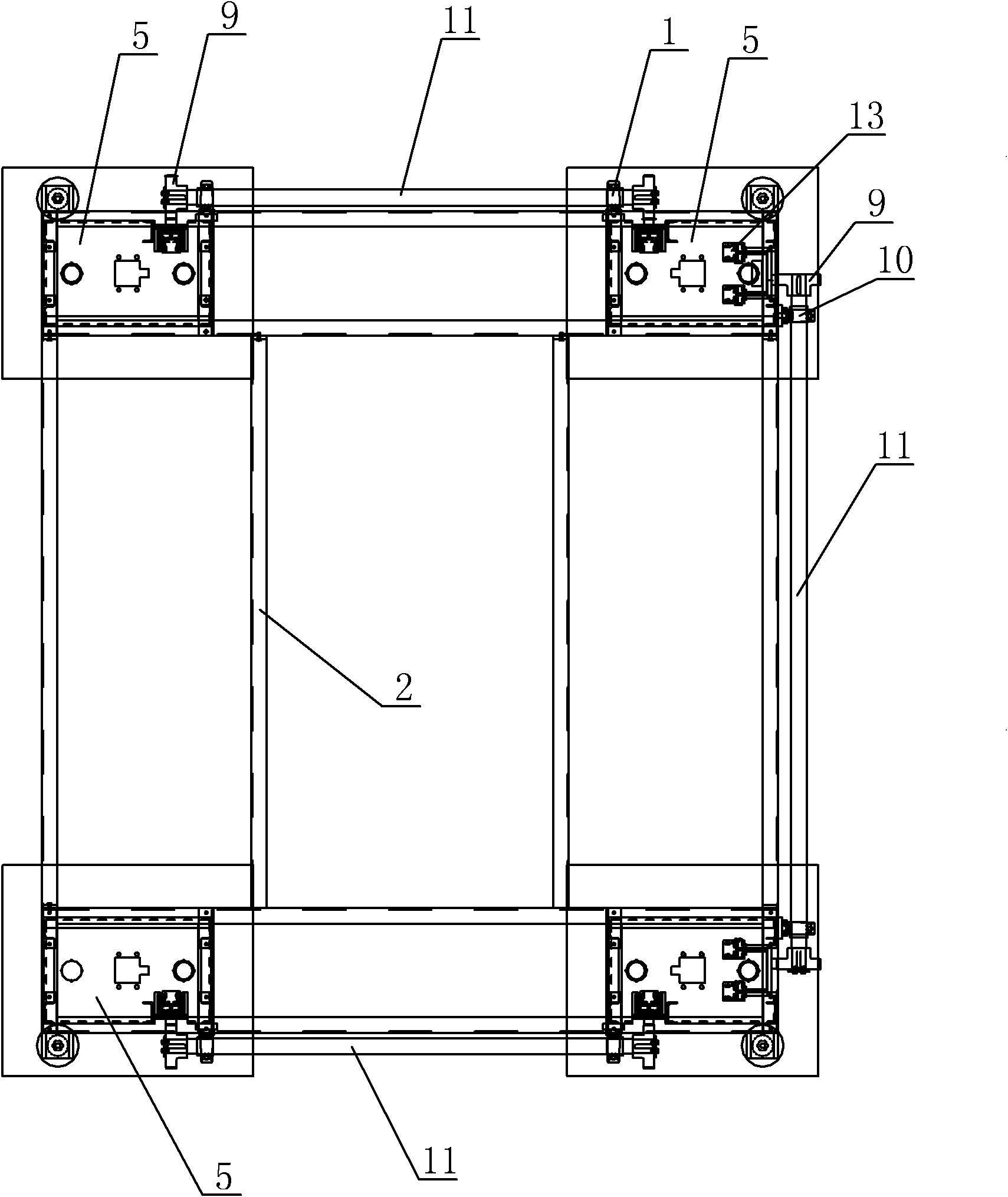

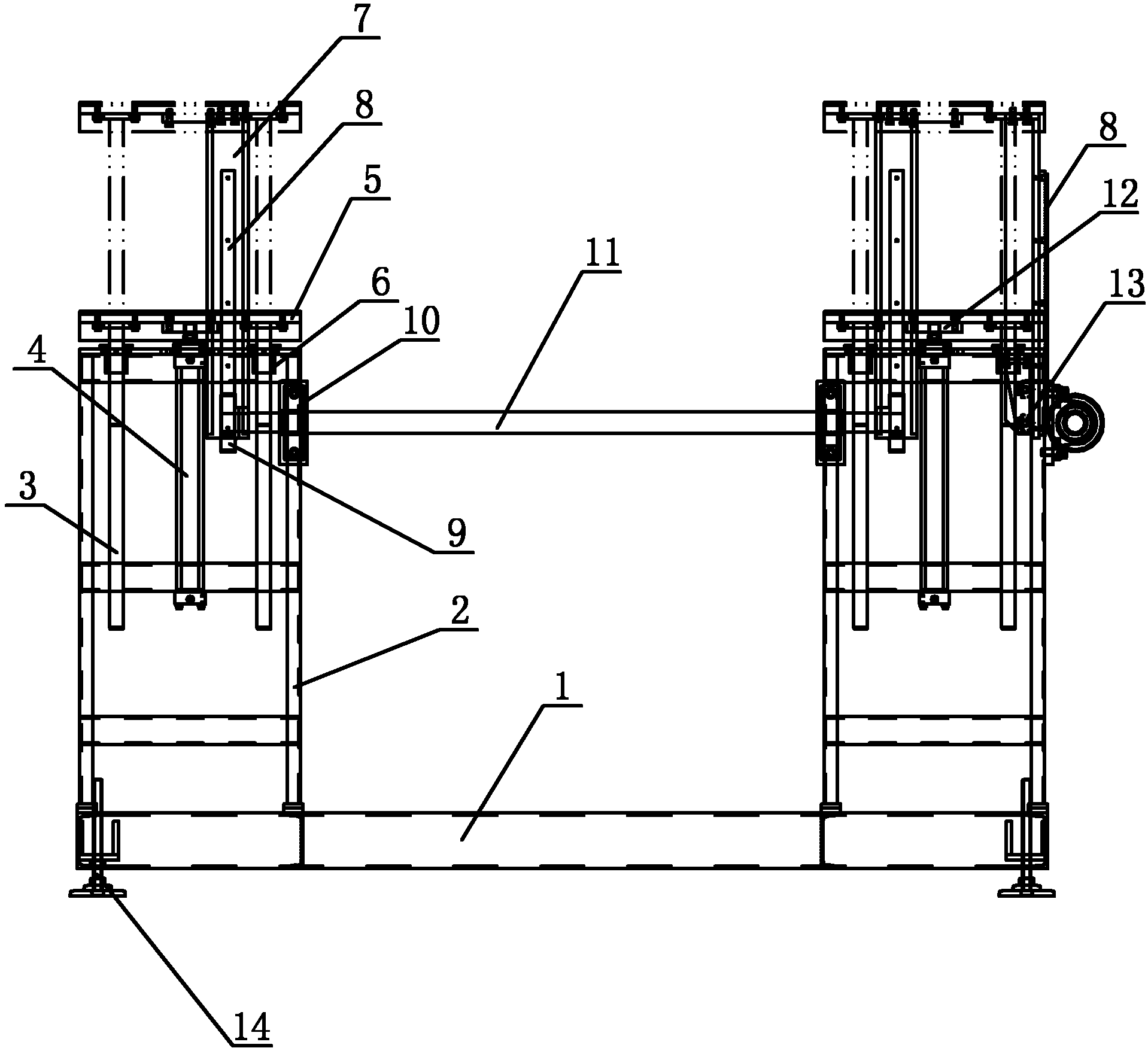

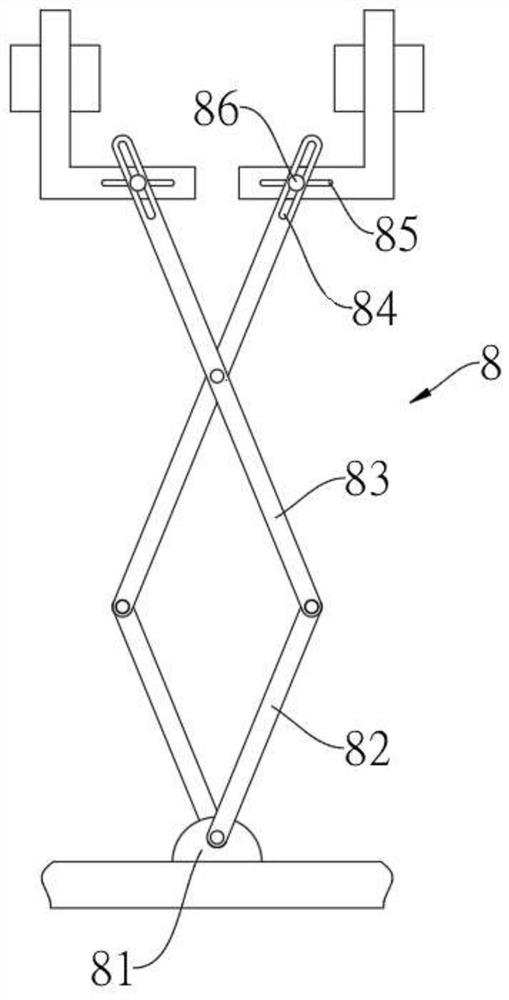

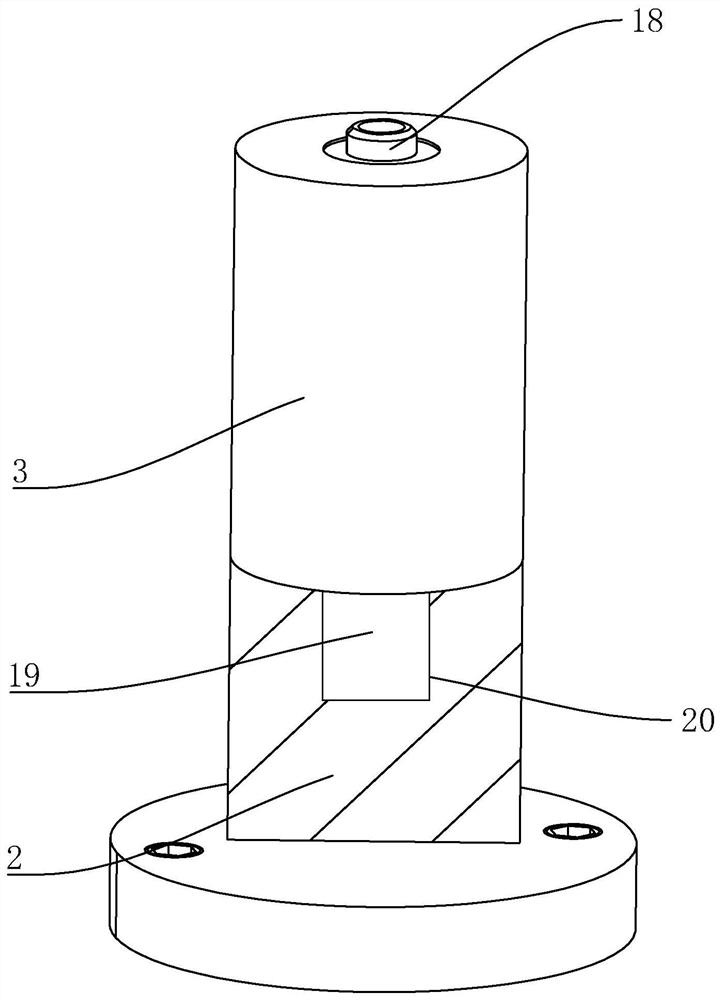

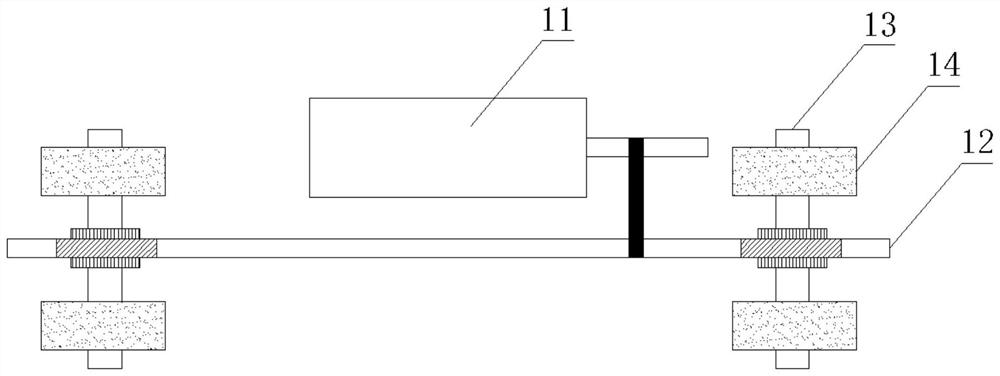

Synchronous lifting platform with four columns

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

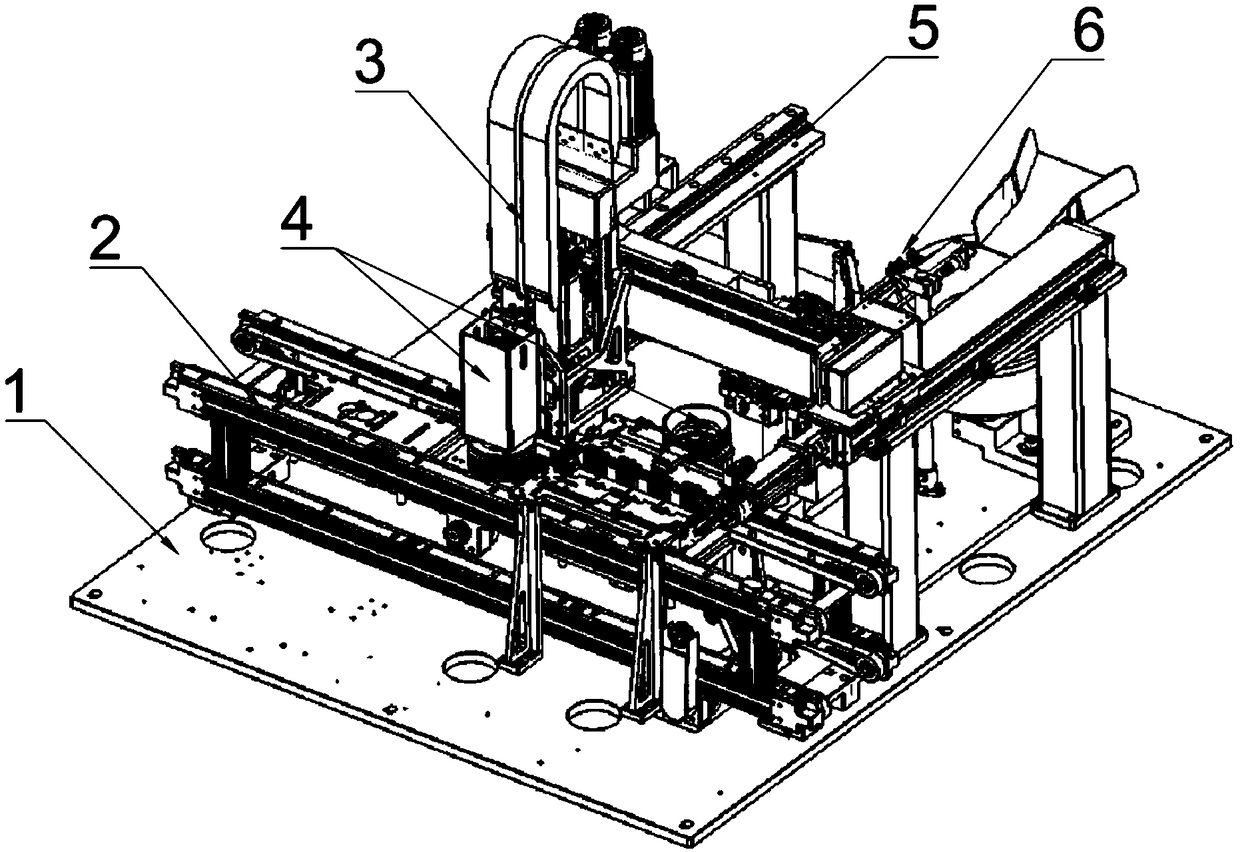

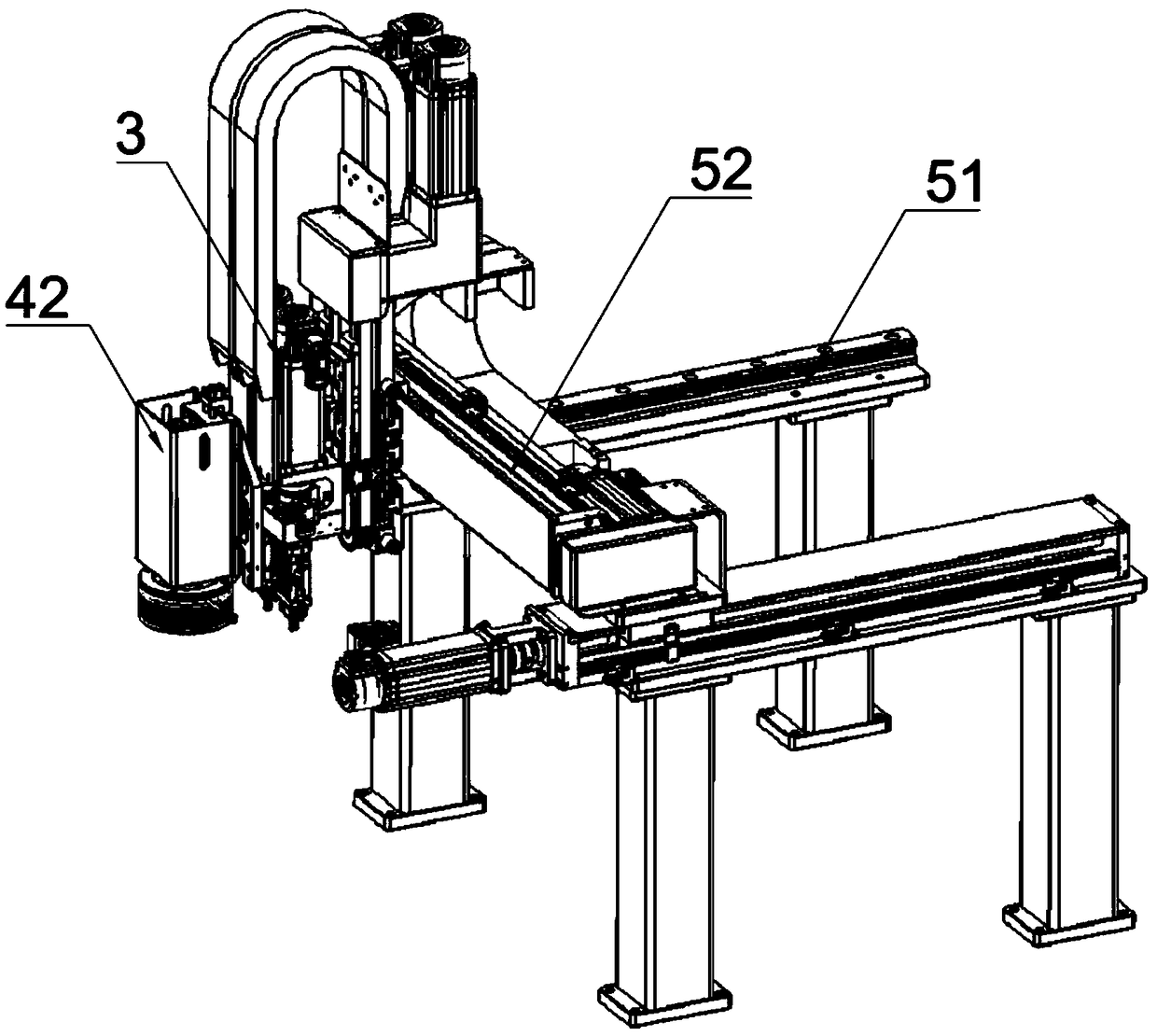

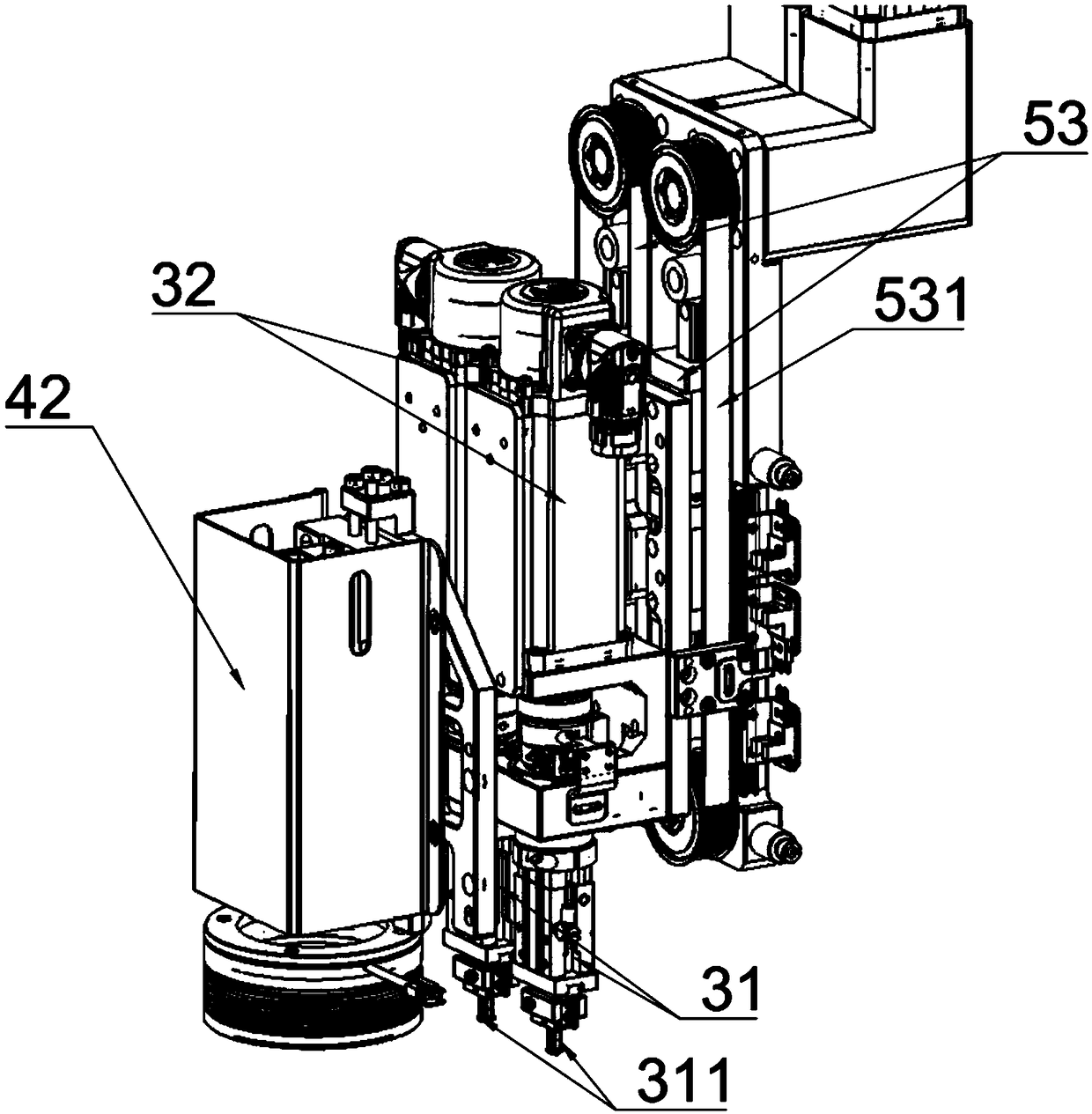

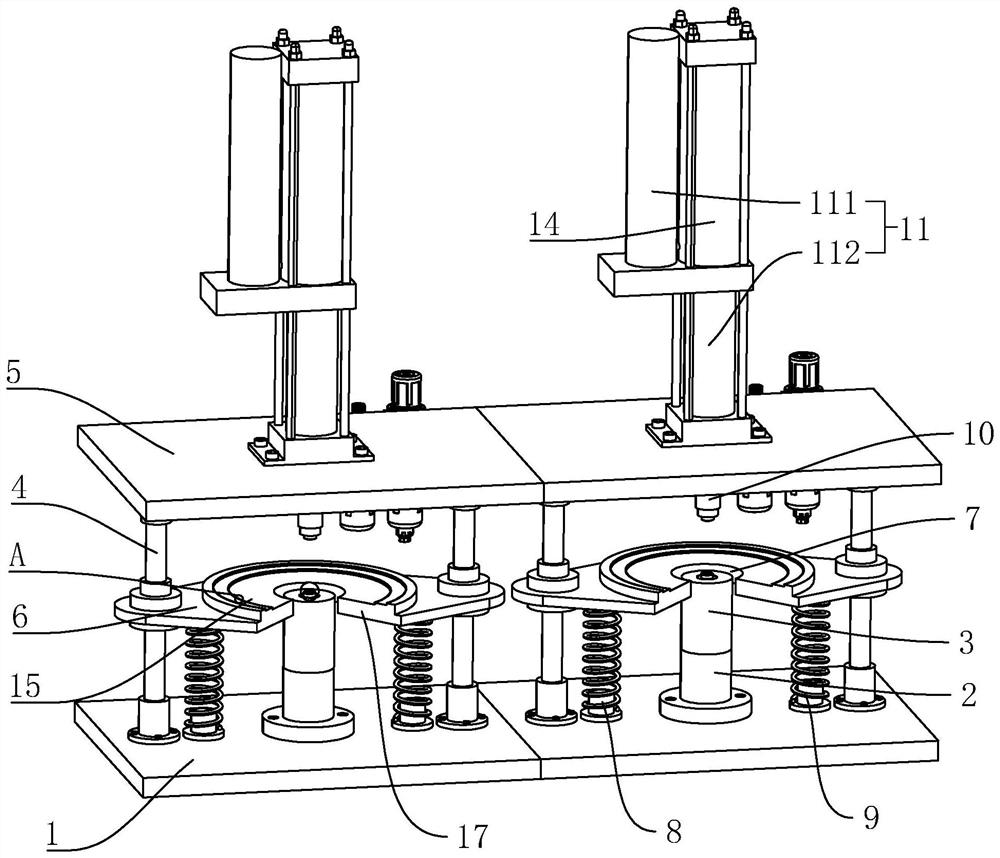

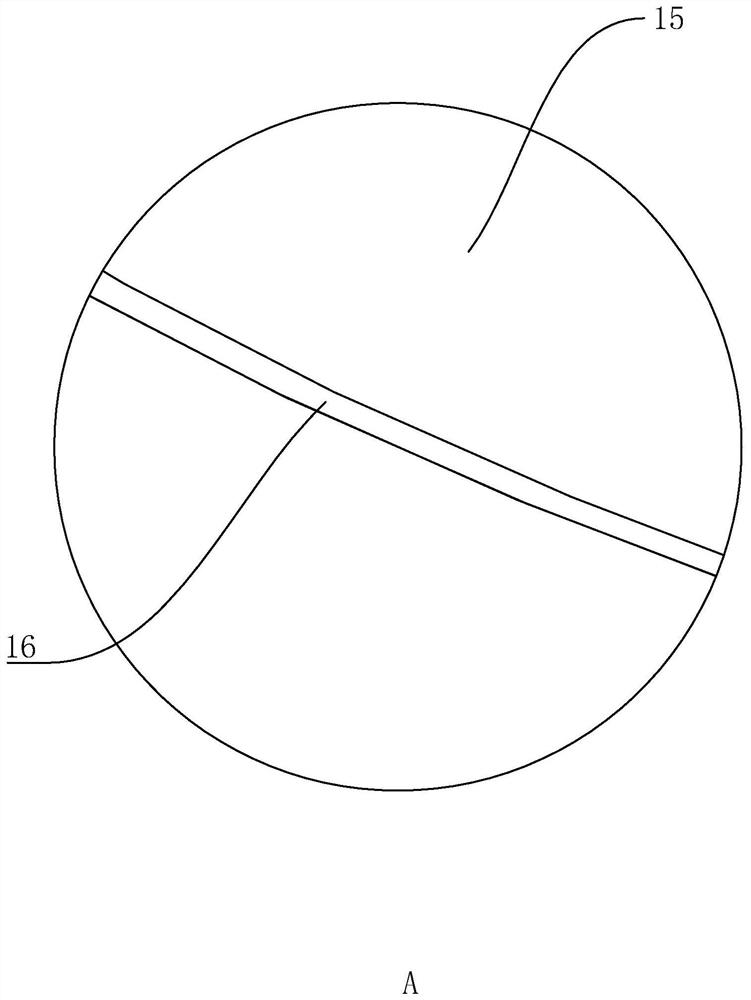

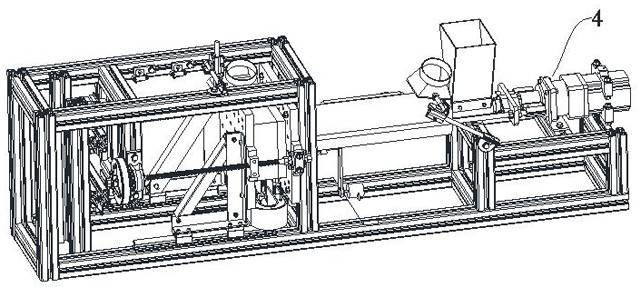

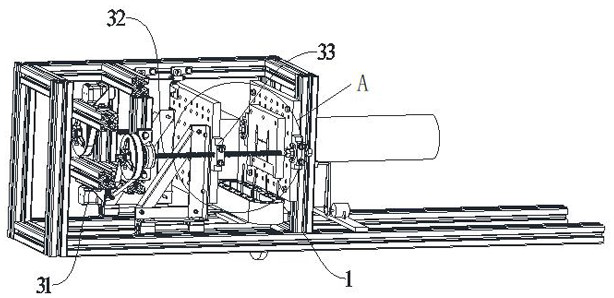

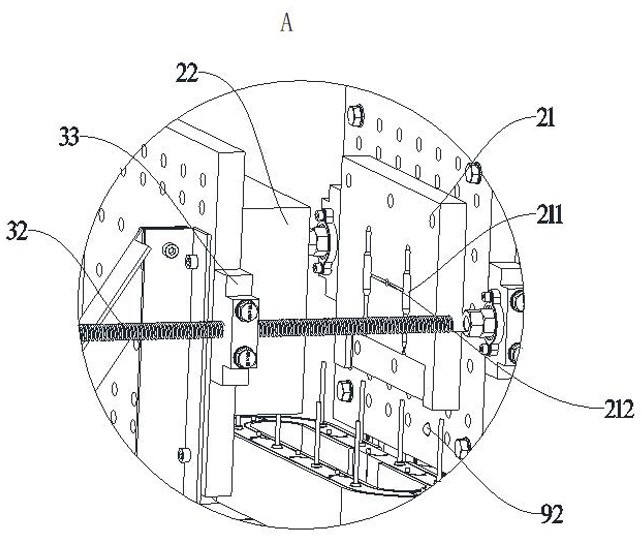

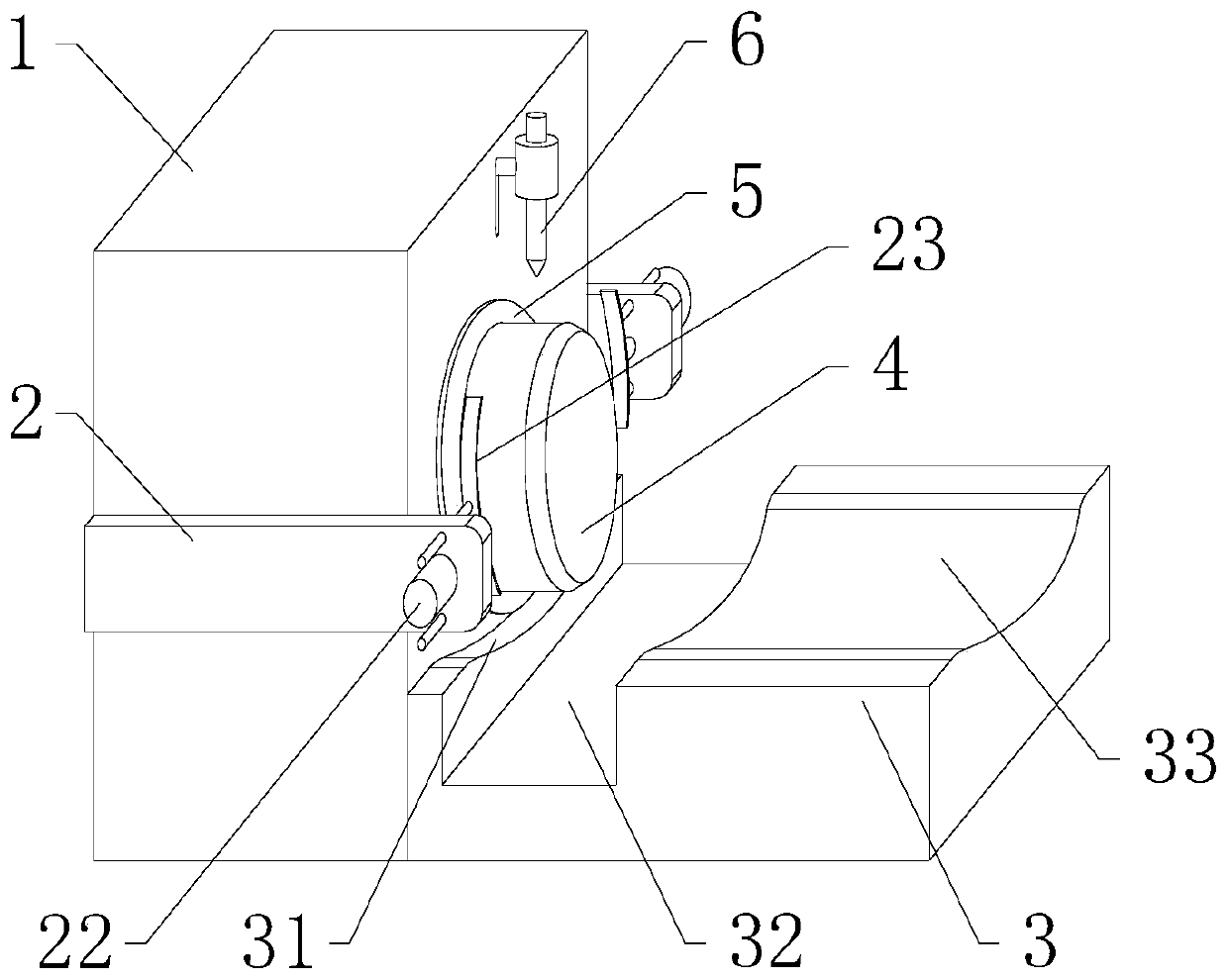

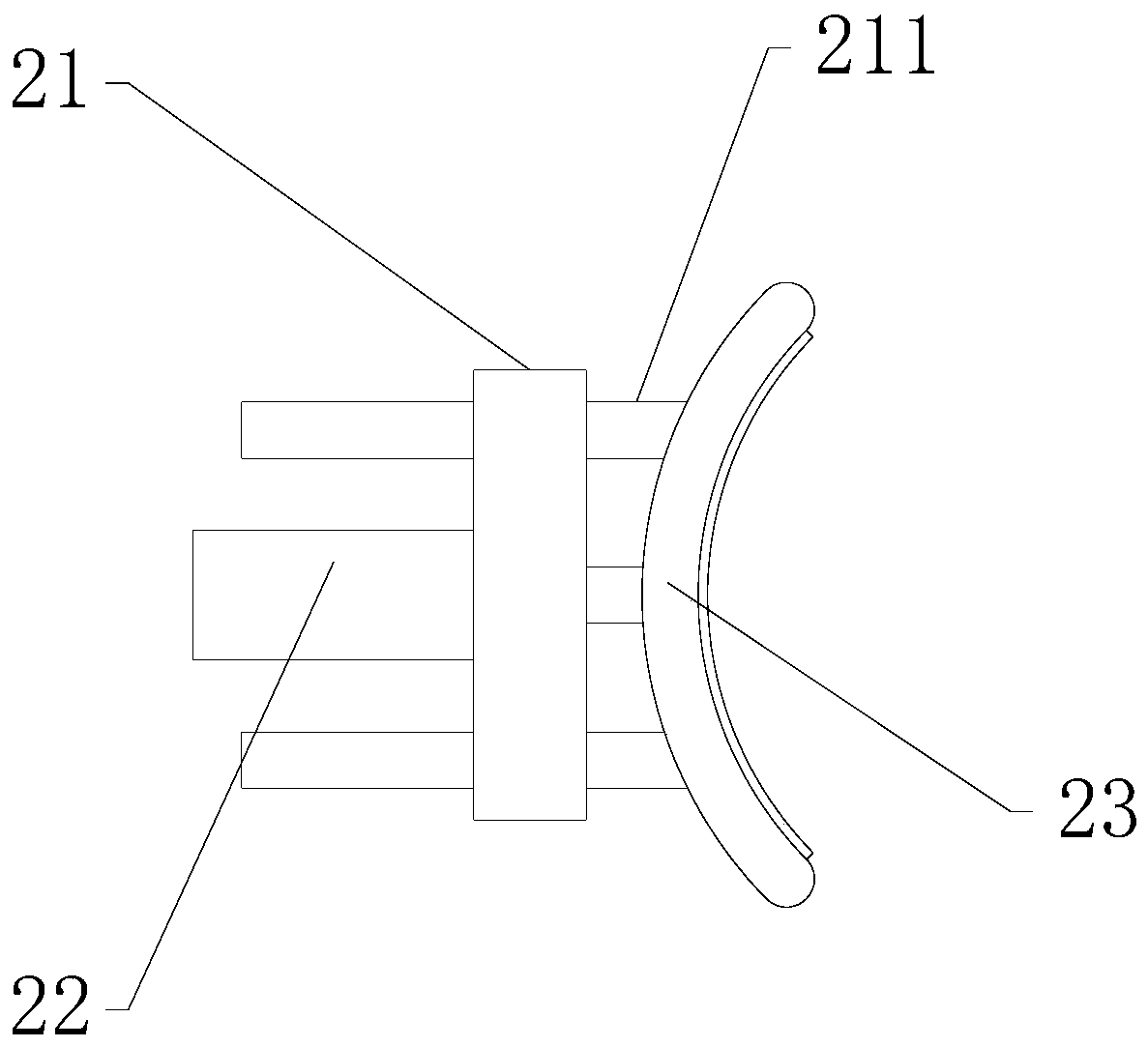

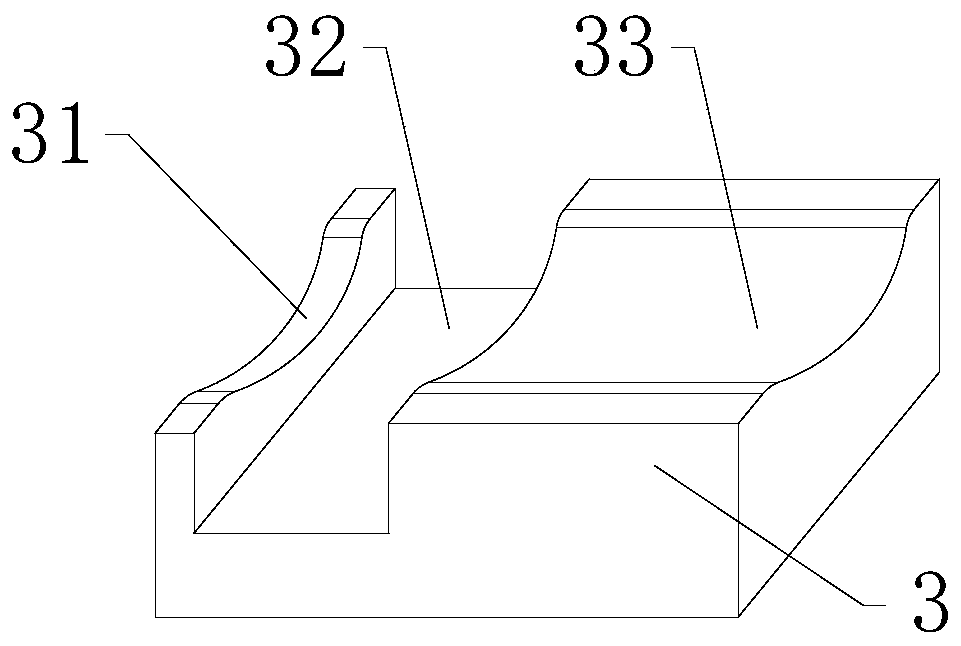

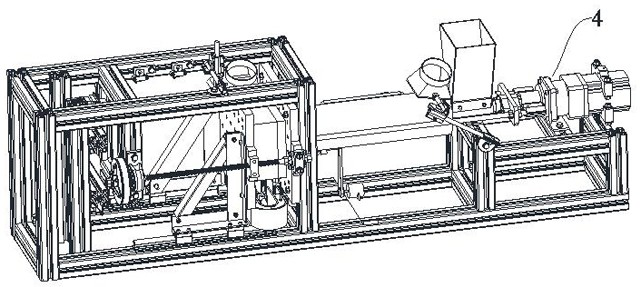

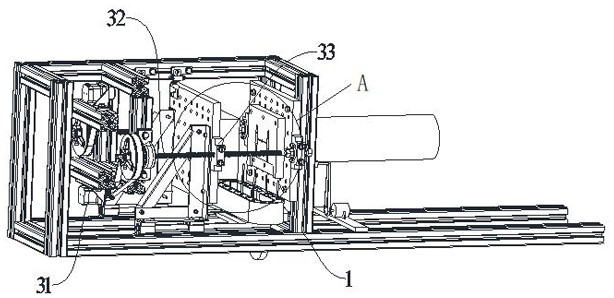

Marking rod assembling device, full-automatic production line and marking rod assembling method

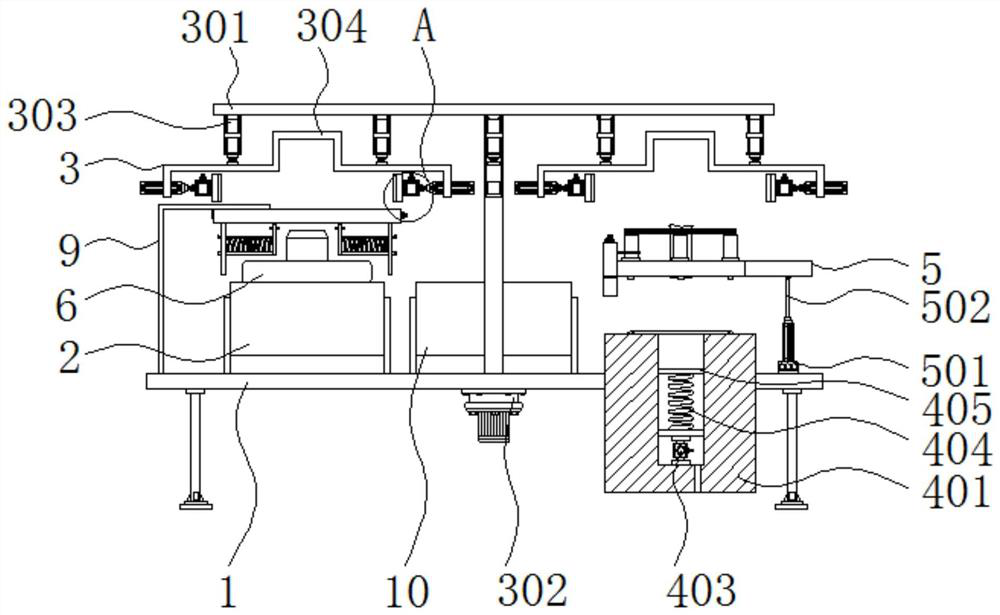

InactiveCN109048271AImprove installation efficiencyGuaranteed installation angle accuracyMetal working apparatusProduction lineIndustrial engineering

The invention provides a marking rod assembling device. The marking rod assembling device comprises a carrier conveying line, a marking rod feeding mechanism, a detecting mechanism, a rotation clamping mechanism and a mounting mechanism; the detecting mechanism detects and acquires the initial angle of a marking rod clamped by the rotation clamping mechanism, then the rotation clamping mechanism rotates the marking rod to a preset assembling angle according to the detection results of the detecting mechanism, and the rotation clamping mechanism is driven by the mounting mechanism move to a pre-assembling position for inserting the marking rod onto a workpiece. After detection of the detecting mechanism, the clamping rotation mechanism automatically adjusts the angle of the marking rod, themounting efficiency of the marking rod is improved, the mounting angle accuracy of the marking rod is ensured, the effects that error are liable to occur in the manual assembling process is avoided,and automatic assembling production of the marking rod is achieved. The invention further provides a full-automatic production line comprising the marking rod assembling device, and a marking rod assembling method. Full-automatic assembling of the marking rod is achieved.

Owner:SUZHOU RS TECH

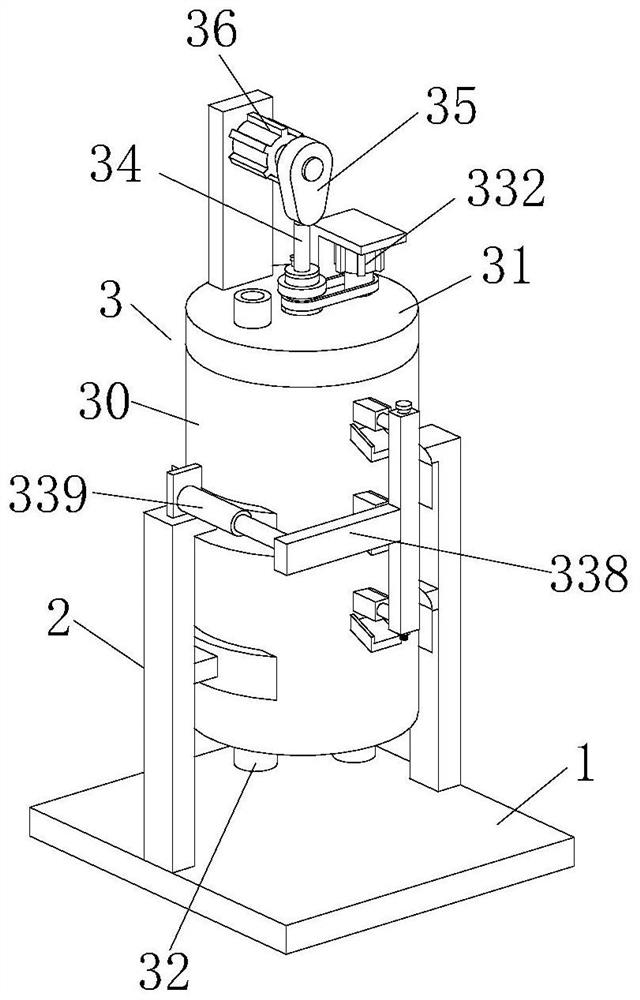

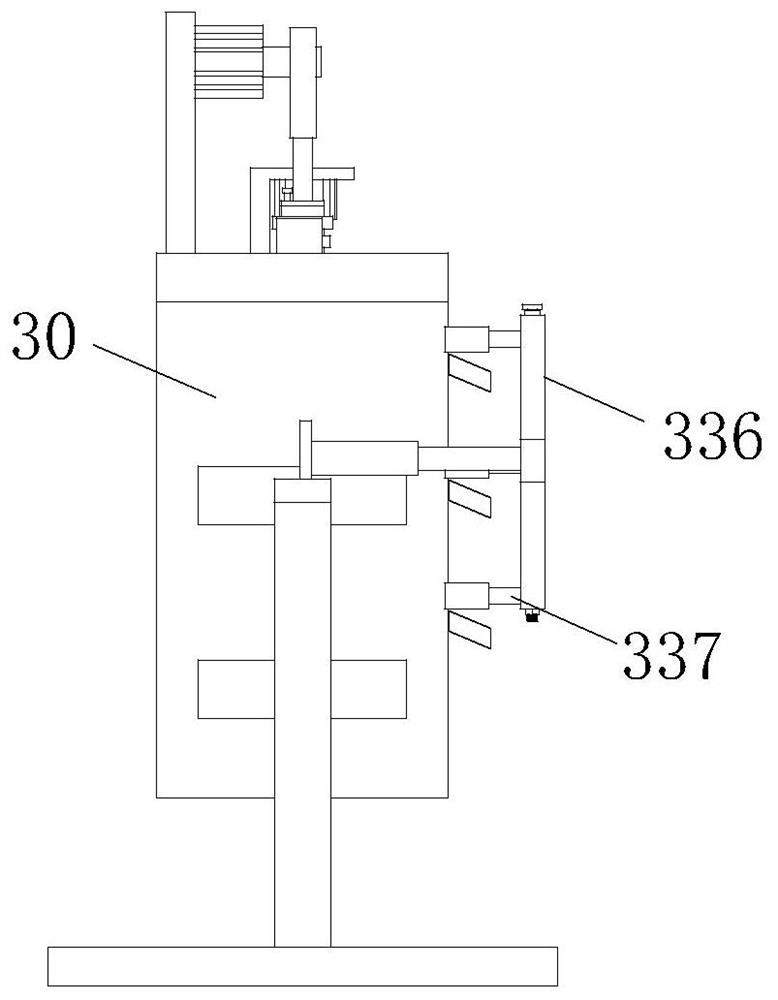

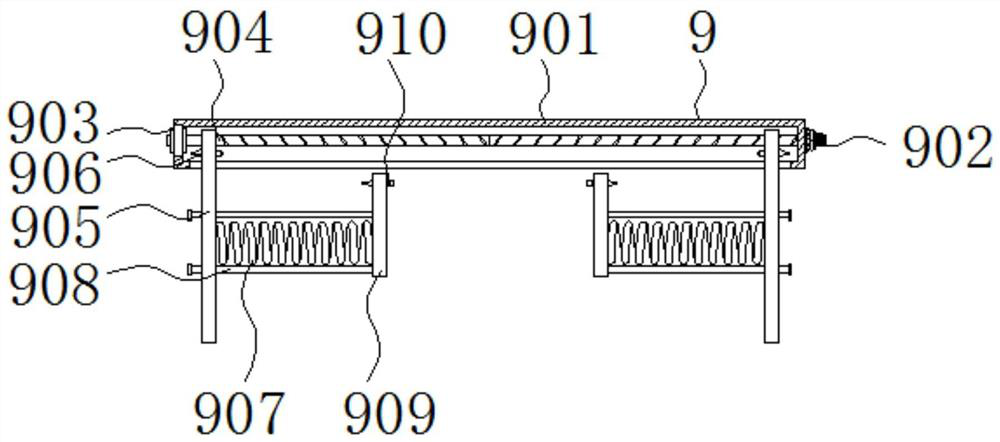

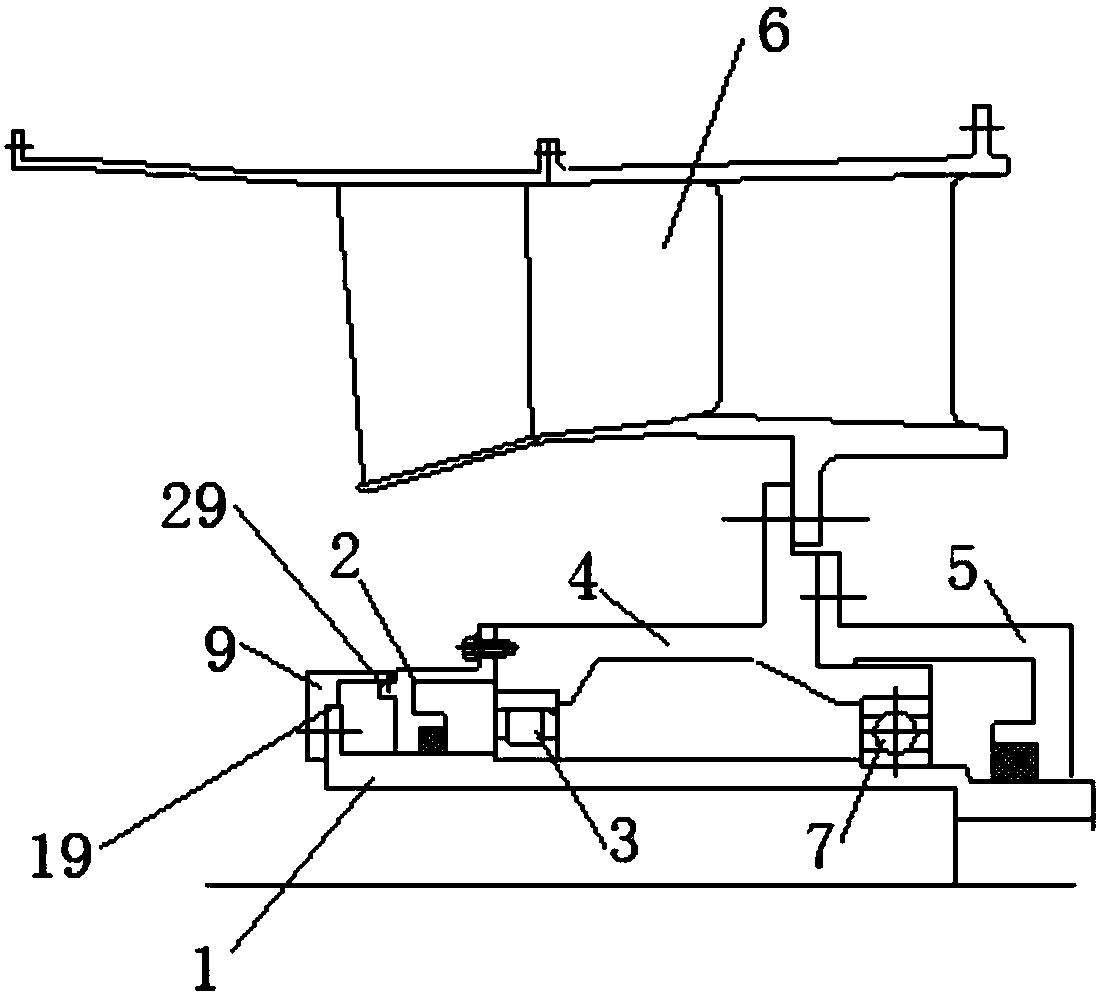

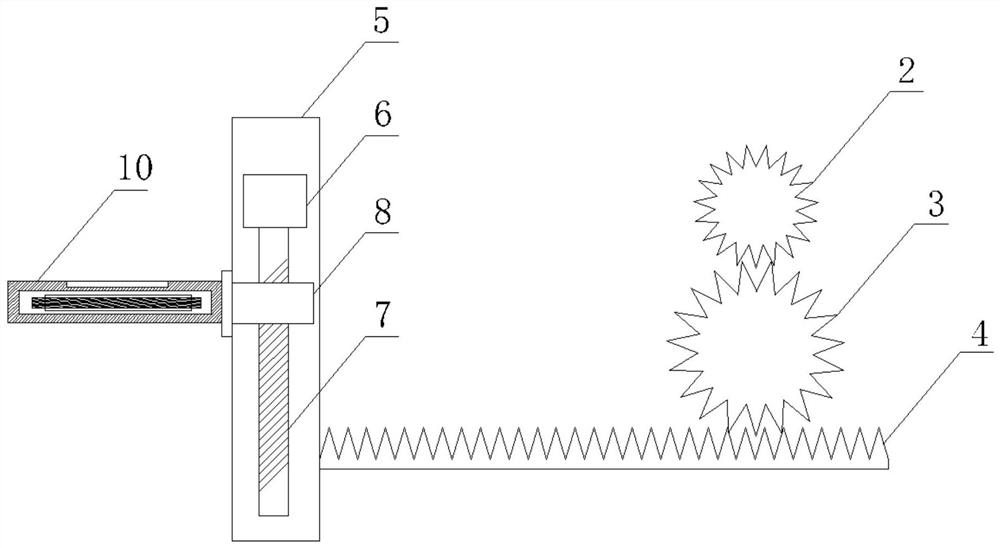

Domestic sewage environment-friendly pretreatment equipment and pretreatment method

ActiveCN113368566AImprove filtering effectImprove preprocessing effectStationary filtering element filtersElectric machineryPre treatment

The invention relates to domestic sewage environment-friendly pretreatment equipment and a pretreatment method. The domestic sewage environment-friendly pretreatment equipment comprises a base, fixing frames and a filtering device, the lower end of the base is connected with the existing ground, the fixing frames are installed at the upper end of the base in a bilateral symmetry mode, and the filtering device is installed between the two fixing frames; the filter screens in the filtering device can realize the function of sludge filtration of domestic sewage, and multiple filter screens can realize multi-stage filtration at the same time so that the filtration effect of the equipment on the domestic sewage is enhanced, and the pretreatment effect of the equipment on the domestic sewage is further enhanced; a first motor, a cam and a cylindrical rod in the filtering device are matched to enable the filter screens to move up and down in the filtering process, a flexible brush in the filtering device can clean filtering holes in the filter screens in the up-down moving state in time, and the situation that the filtering holes are blocked due to the fact that sludge is accumulated in the filtering holes is avoided.

Owner:深圳粤港工程技术服务有限公司

A software installation method and device

ActiveCN103605537BSimultaneous installationThere will be no frequent synchronization problemsProgram loading/initiatingData fileSoftware engineering

Owner:BEIJING QIHOO TECH CO LTD

Turn-over and detection integrated device for flange processing

PendingCN113418555AQuick flipImprove accuracyEdge grinding machinesPolishing machinesTransmission beltMachining

The present invention relates to a turn-over and detection integrated device for flange processing. The device comprises a device base and an upper airtightness detection assembly, and the front side of the upper end of the device base is sequentially provided with a width measurement mechanism, a first belt conveyor, a transfer and turn-over structure, a lower airtightness detection assembly and an upper airtightness detection assembly from left to right, wherein the left side of the upper end of the upper airtightness detection assembly is connected with the rotating assembly through a second transmission belt. The turn-over and detection integrated device for flange processing has the beneficial effects that the turnover and detection integrated equipment for flange machining has double rotating speed during reverse rotation, so that the equipment can be quickly turned over, the equipment performs deburring and cleaning treatment on a flange before detection, the detection accuracy of the equipment is improved, meanwhile, the equipment can simulate installation of the flange to perform airtight detection, the detection structure is more accurate, automatic hole alignment can be carried out on the flange when the flange is installed, and two plates can be driven by one power to be in close contact with two positions of the flange for measurement when the equipment measures and detects the flange.

Owner:江苏润泰电力设备有限公司

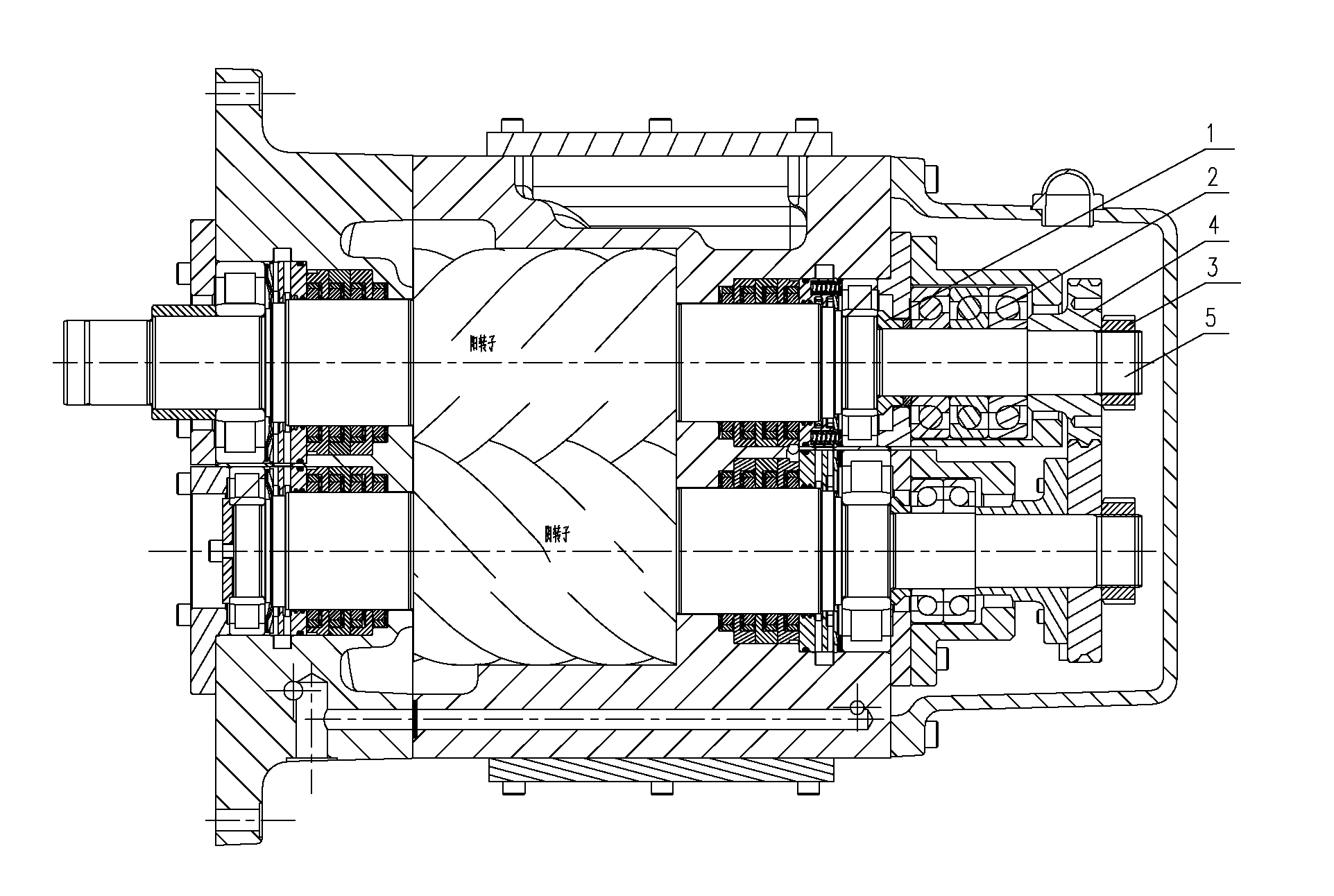

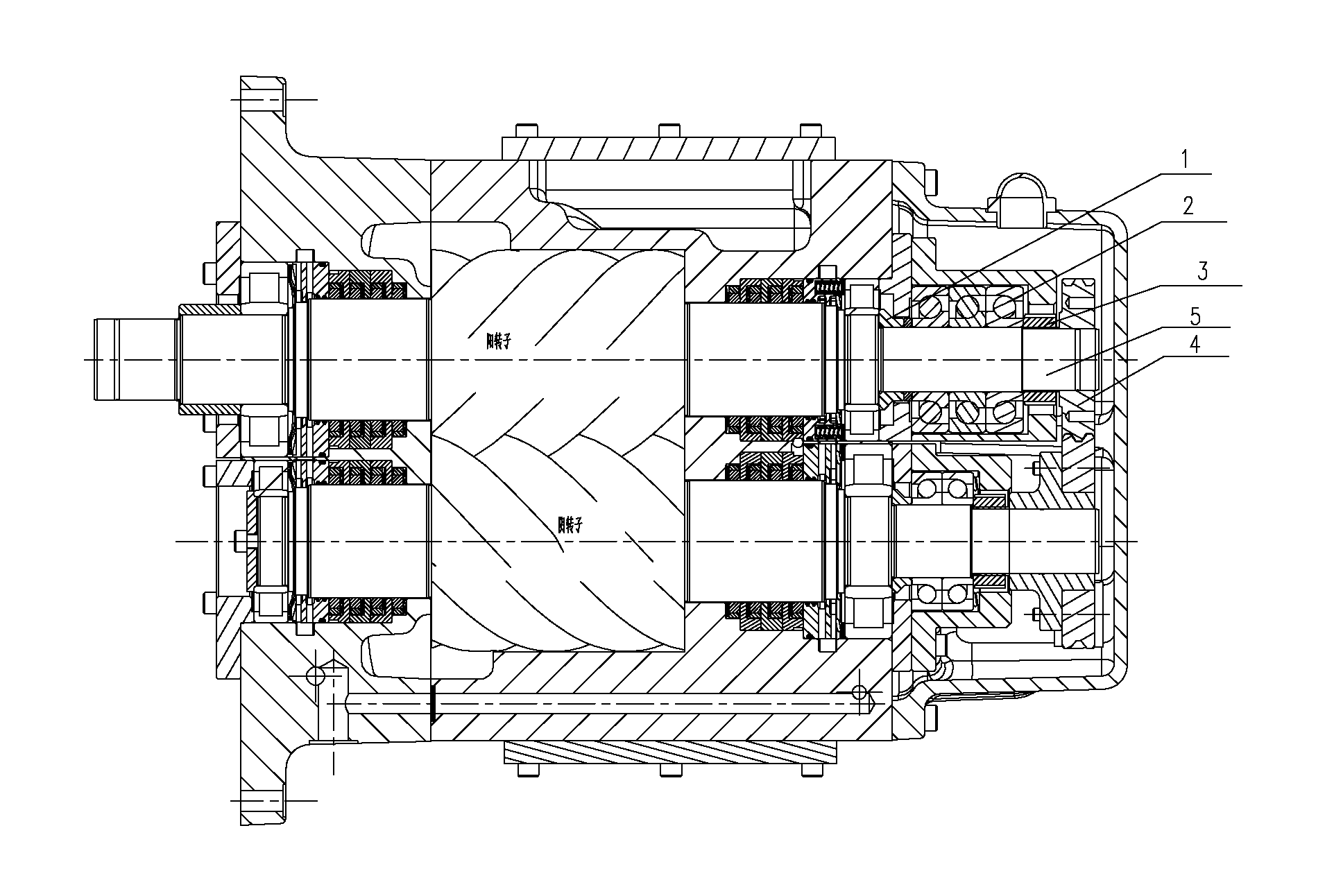

Method for improving reliability of main engine of oil-free screw compressor, and axial bearing locking structure

InactiveCN103062061AReduce stressHigh mechanical reliabilityRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

Owner:NANJING COMPRESSOR

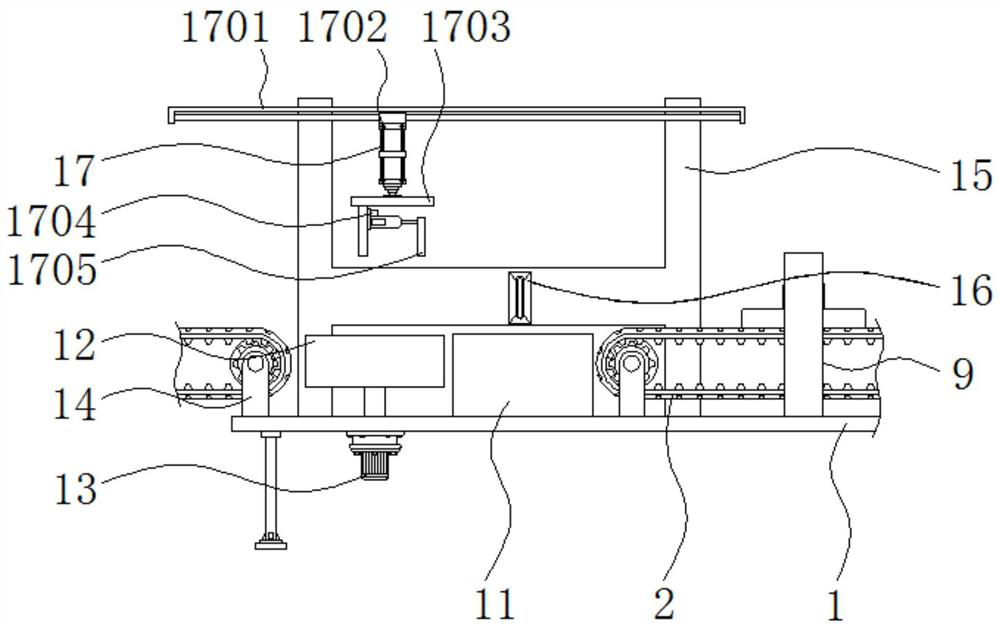

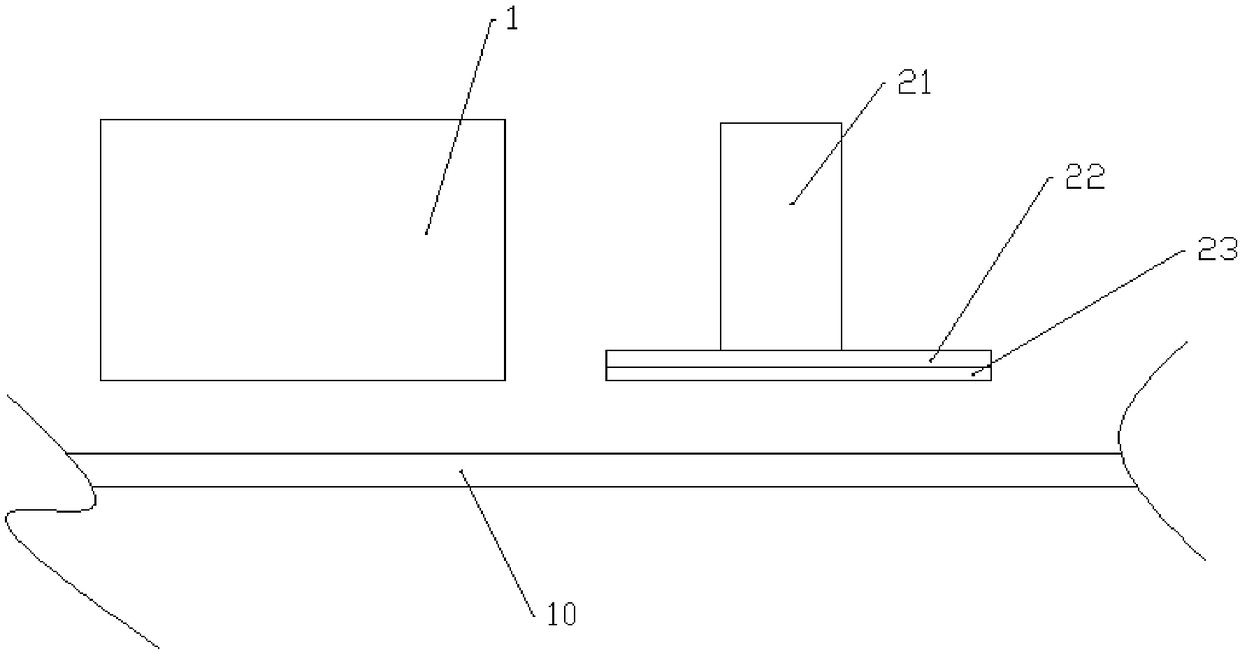

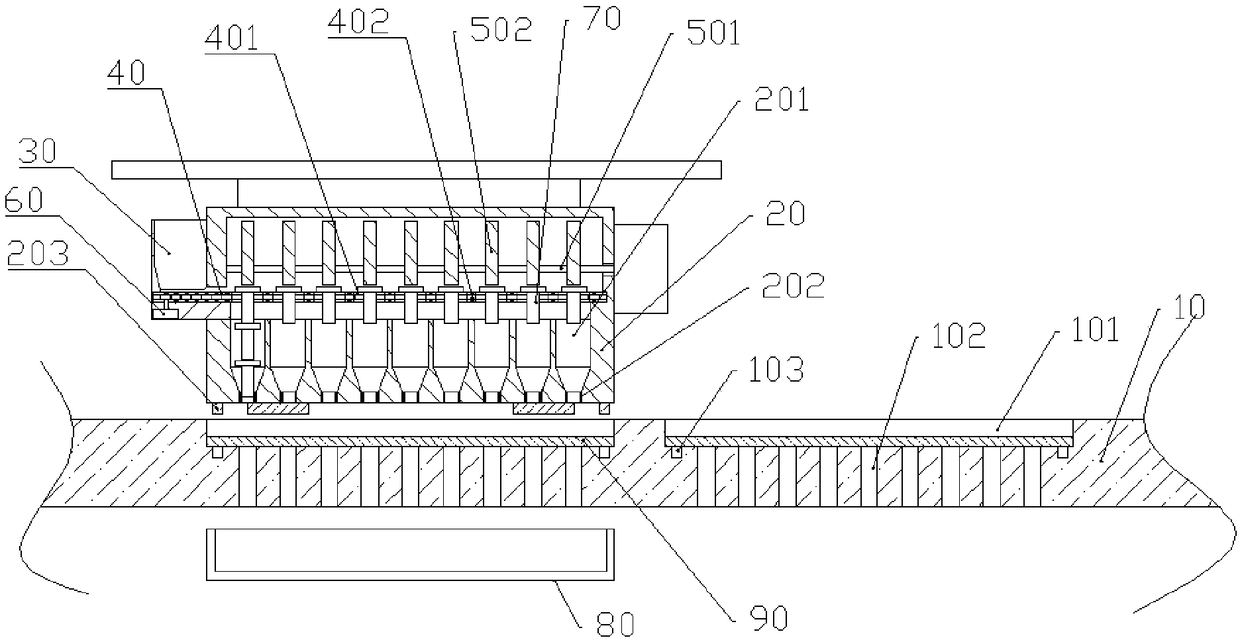

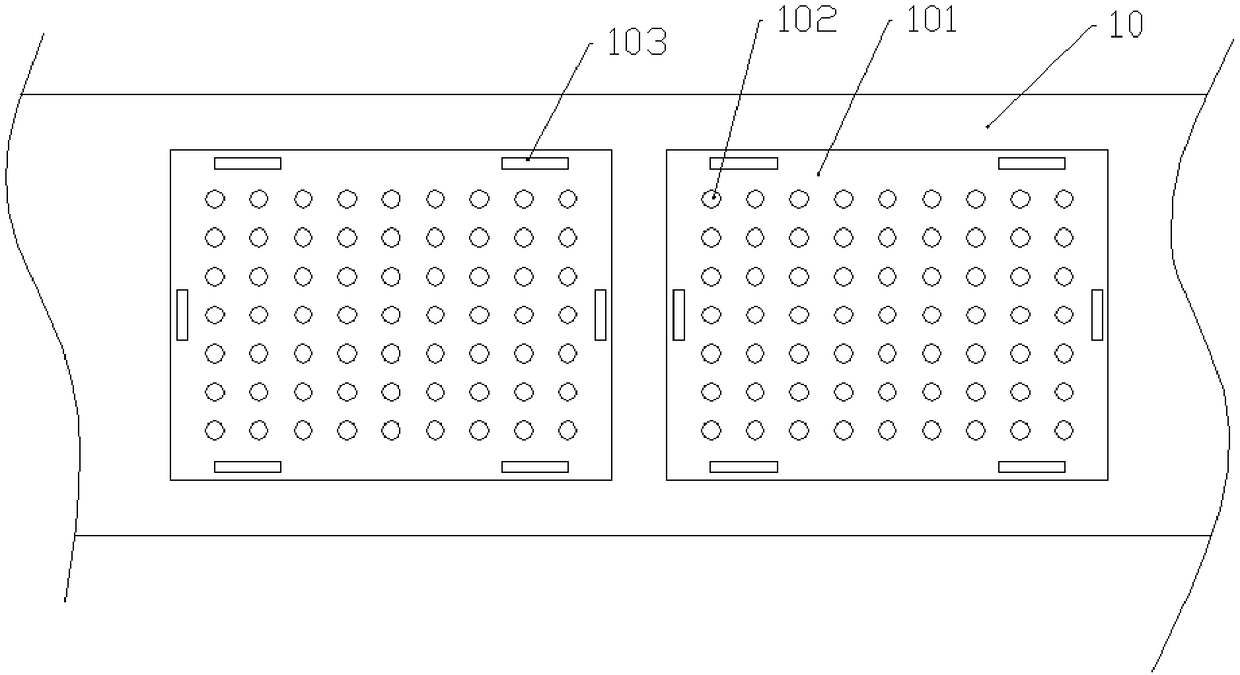

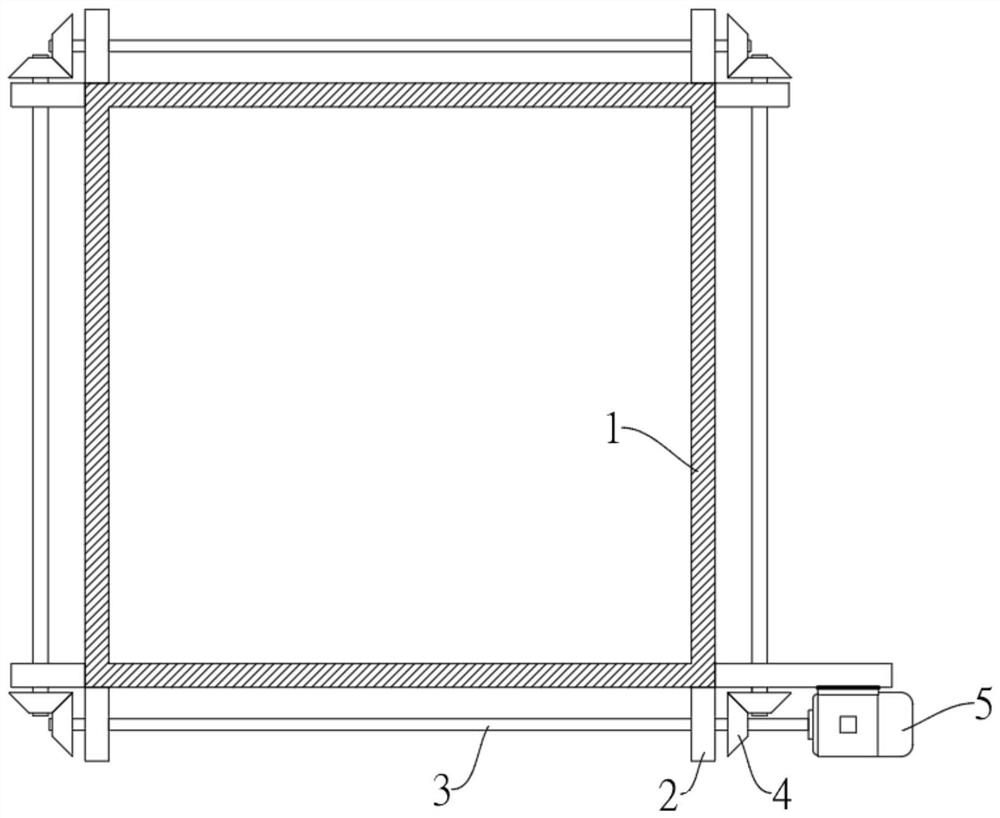

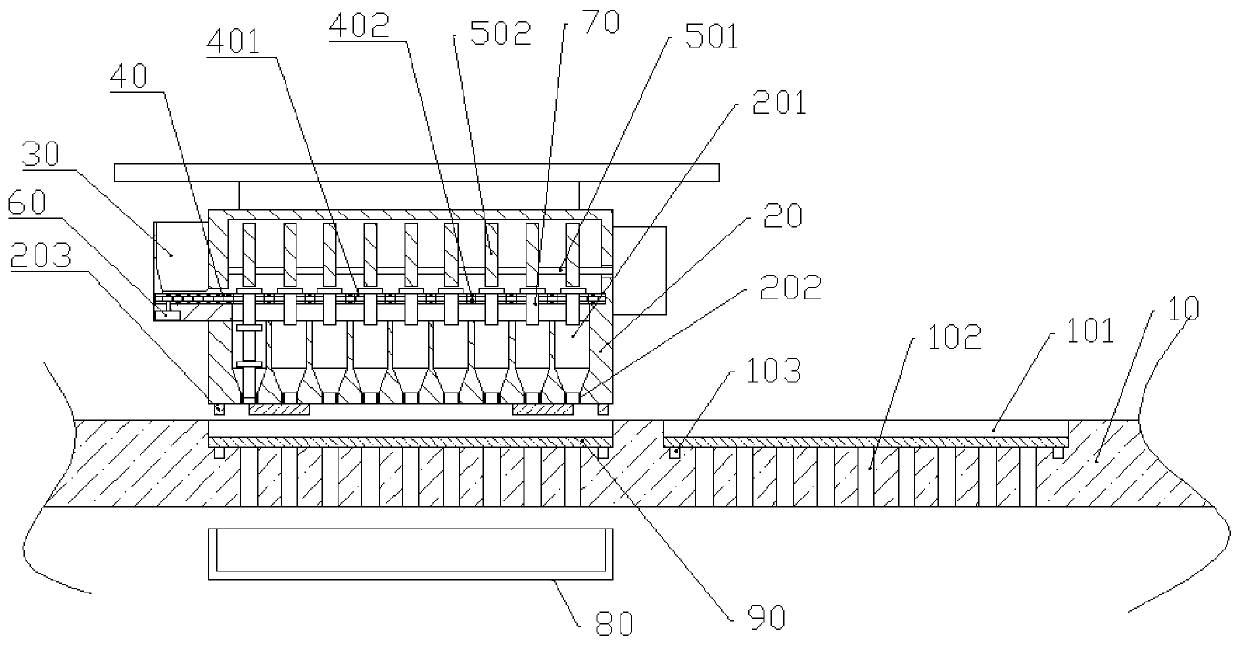

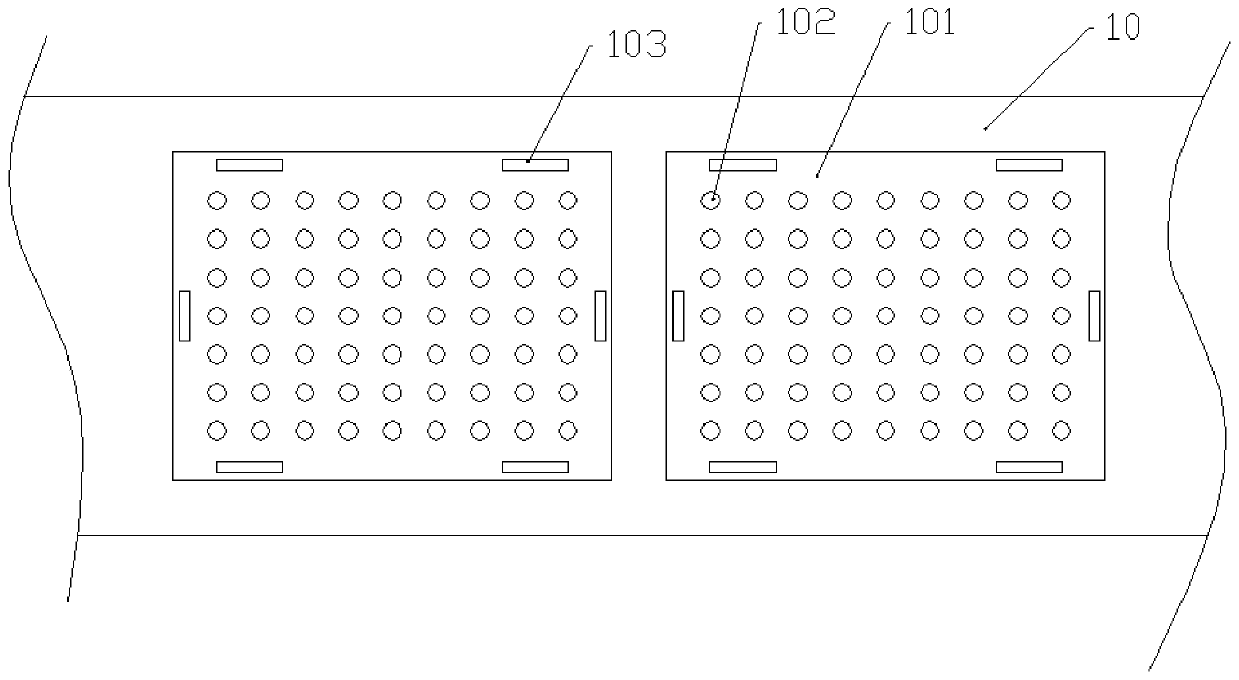

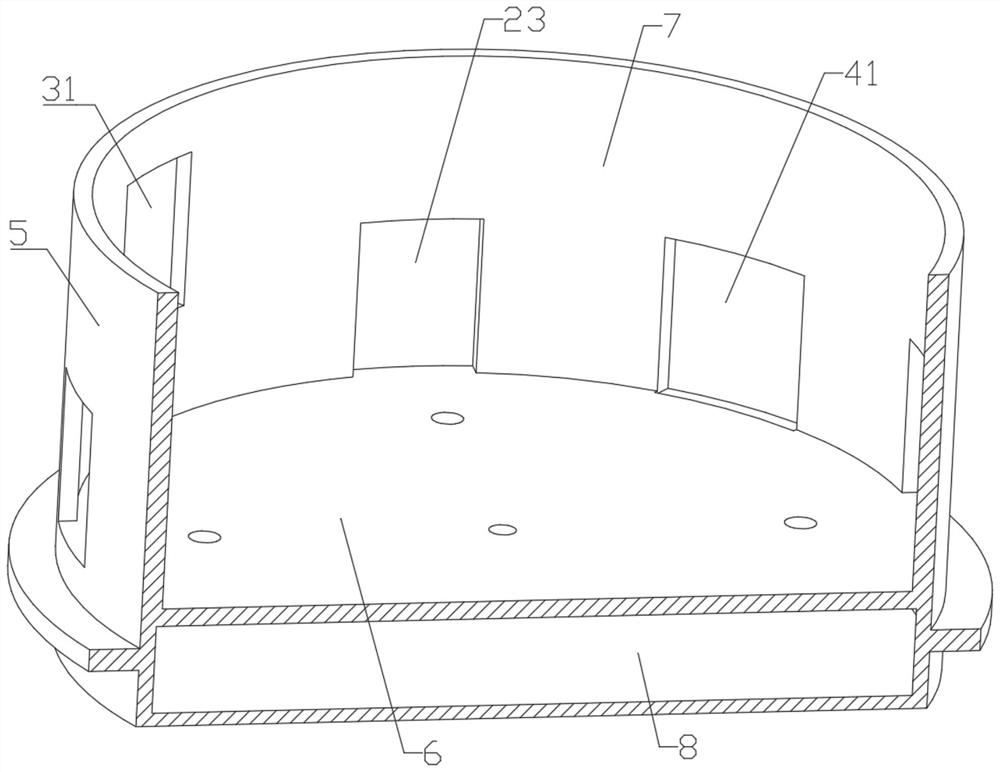

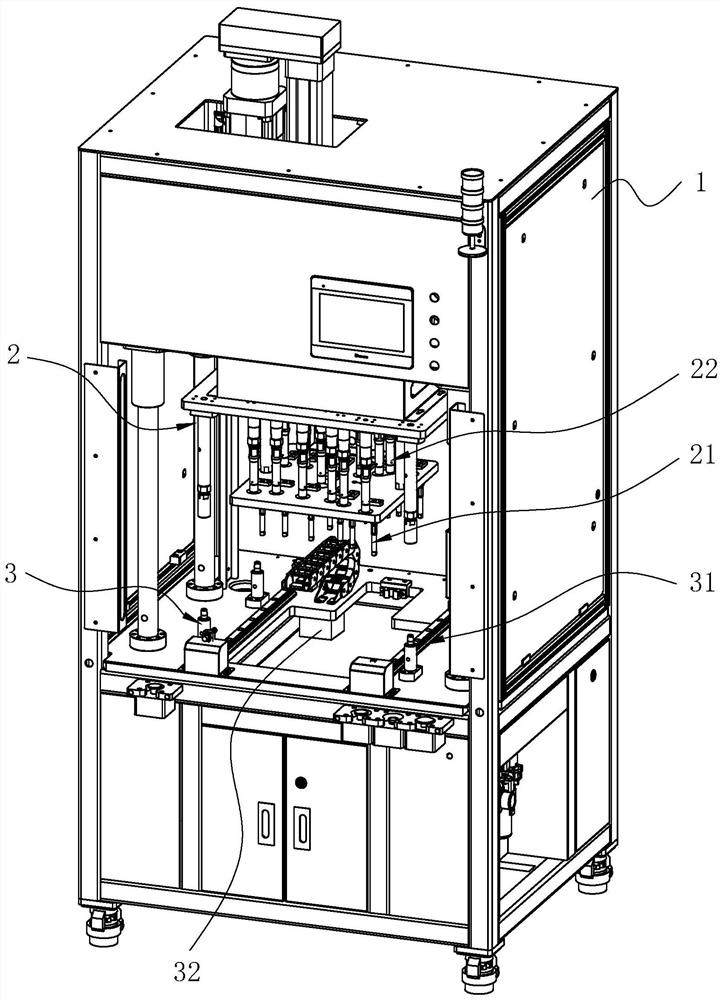

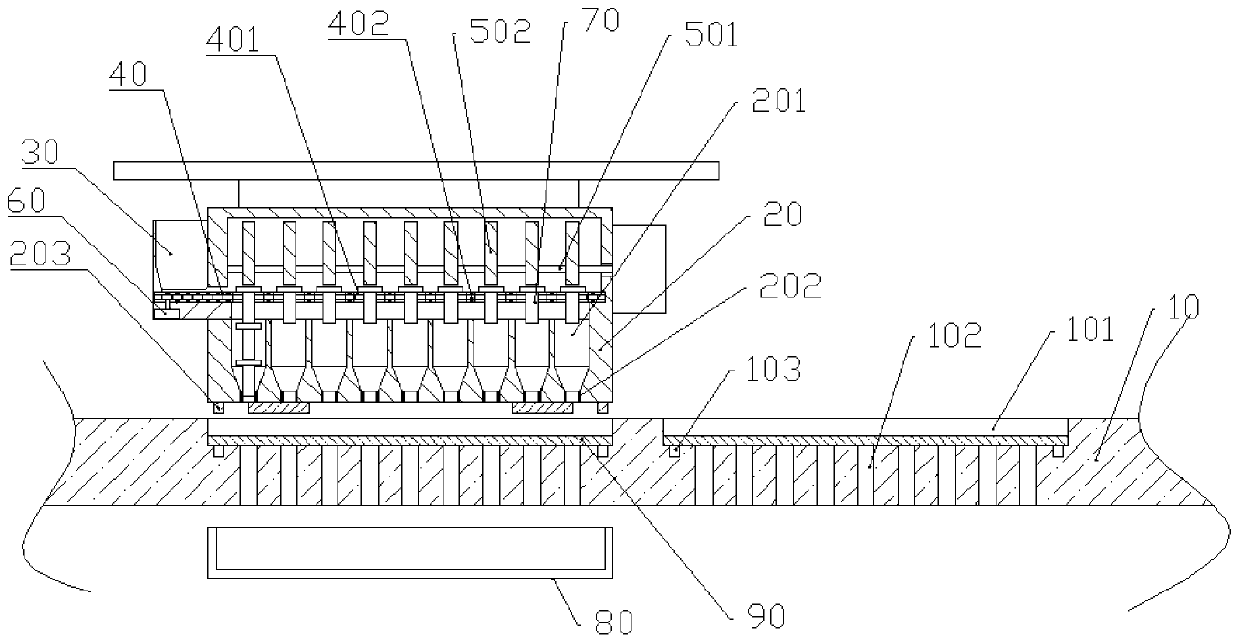

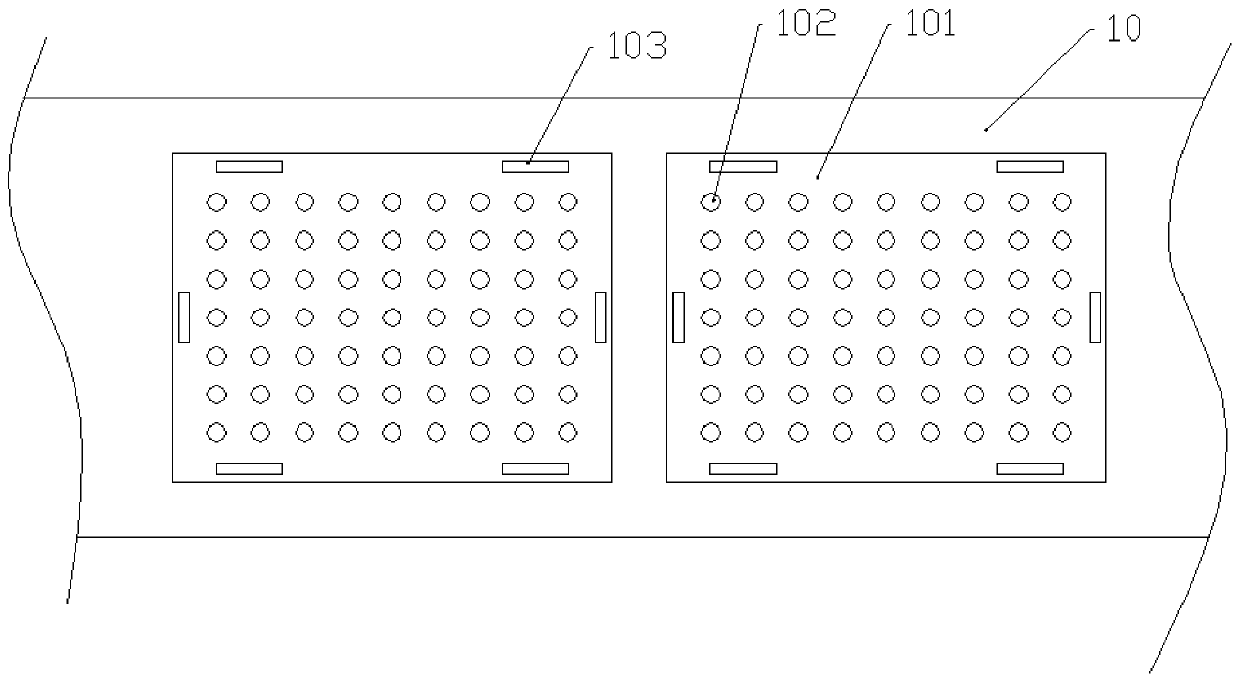

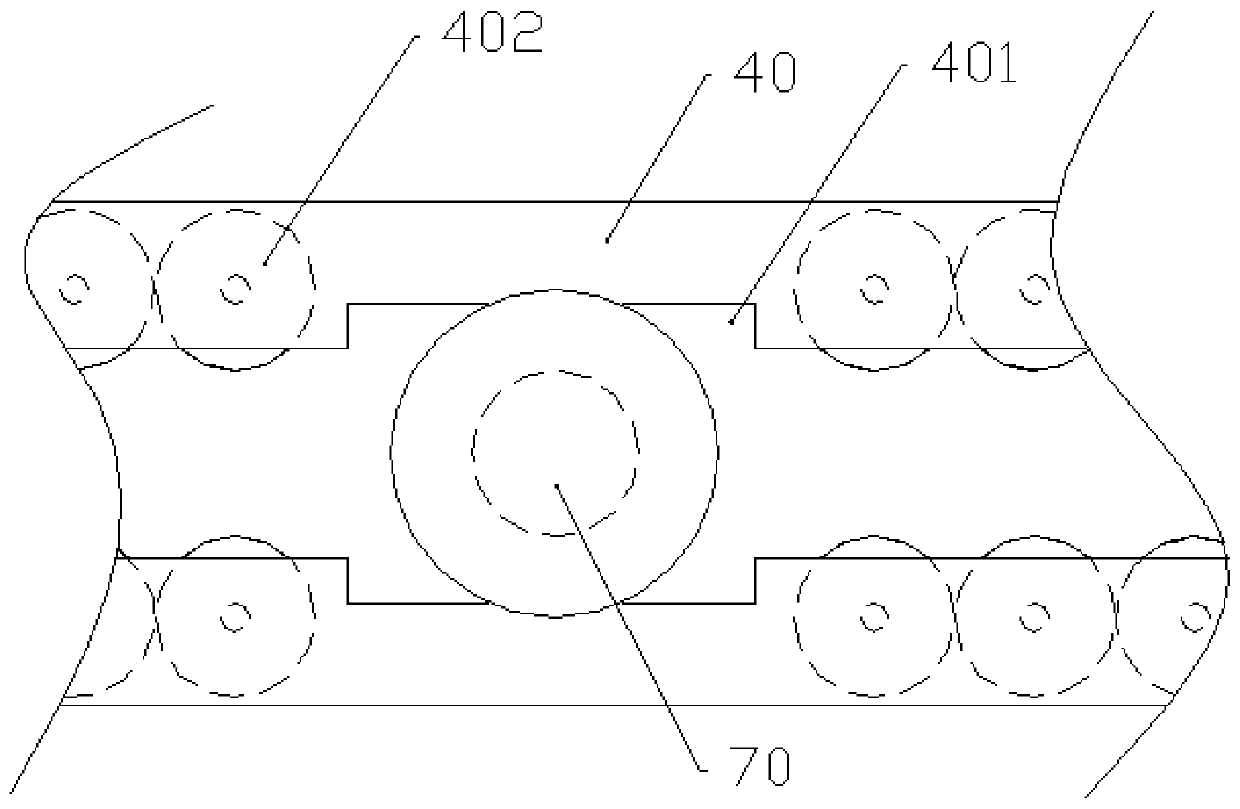

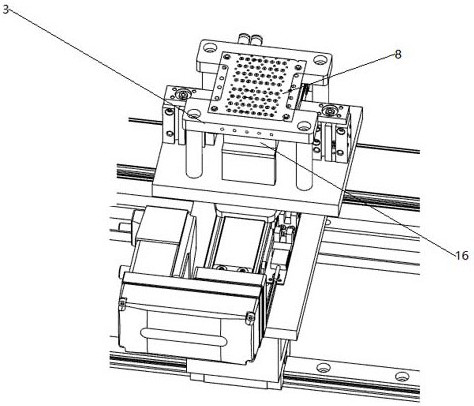

Screw metering and packaging system

ActiveCN108454964AEasy to installEasy to limitPackaging automatic controlMetal working apparatusTelescopic cylinderElectric heating

The invention relates to the field of part packaging, and particularly discloses a screw metering and packaging system. The screw metering and packaging system comprises a conveying belt, a counting device and a packaging device. The conveying belt is arranged horizontally. Conveying grooves for containing plastic plates are arranged on the conveying belt. Multiple vertical first through holes areformed in each conveying groove. The counting device comprises a mounting box, a feeding groove and multiple arrangement units. The packaging device comprises a pressing block and a telescopic air cylinder. The air cylinder is fixedly mounted above the conveying belt, and the pressing block is fixedly mounted at the lower end of the air cylinder. Multiple second electric heating wires are arranged on the lower end face of the pressing block. The pressing block can be opposite to the conveying grooves, and the shape of the cross section of the pressing block is consistent with that of the cross sections of the conveying grooves. According to the scheme, screws can be arranged and packaged.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

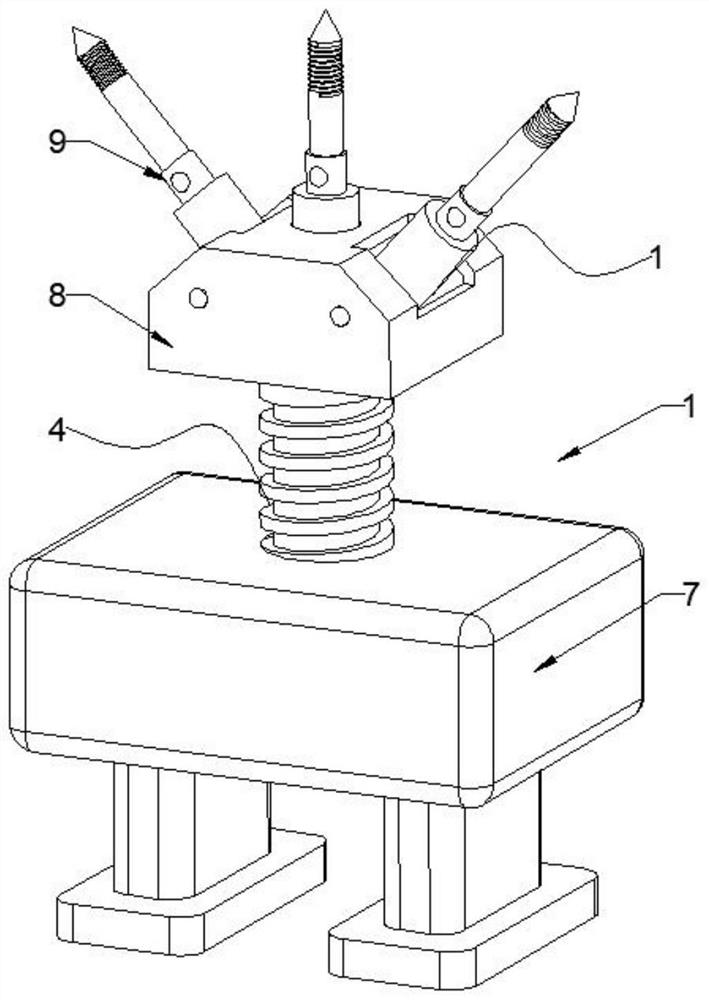

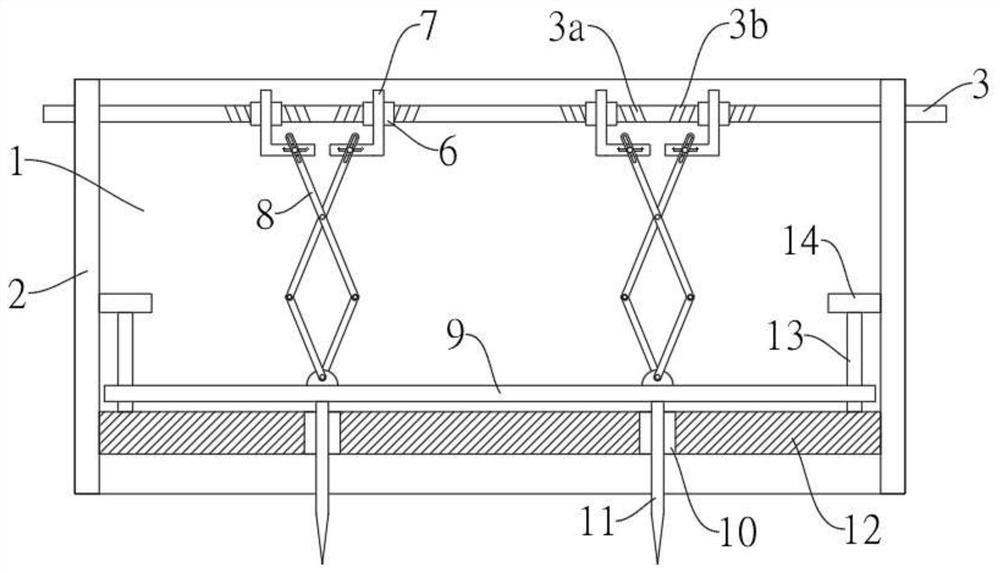

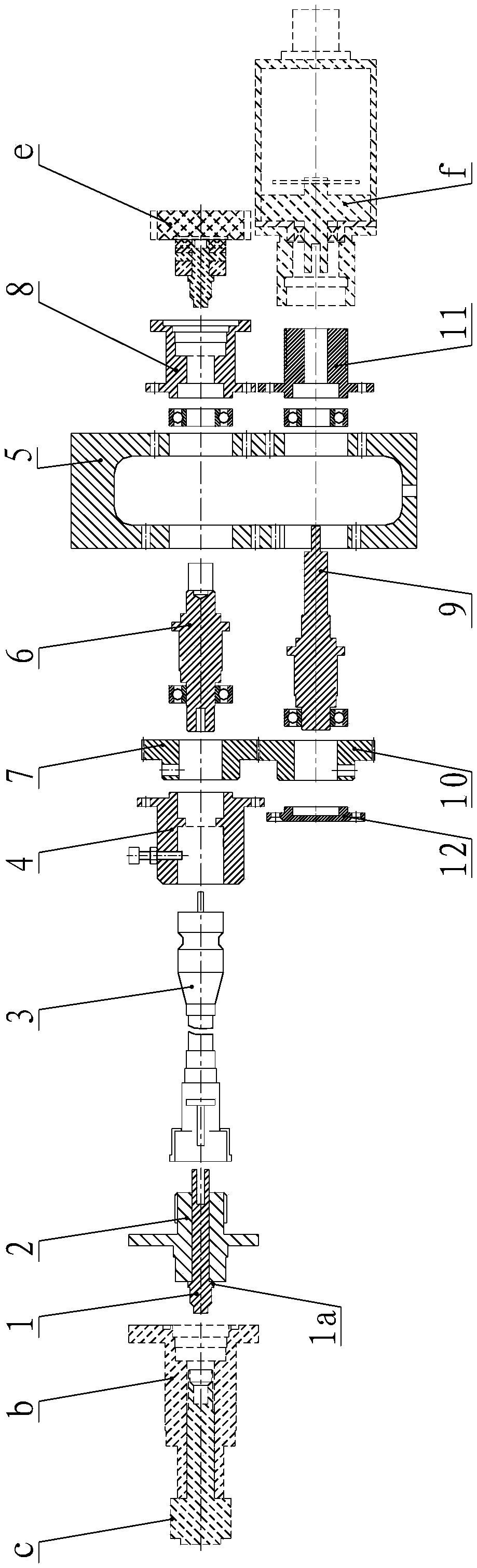

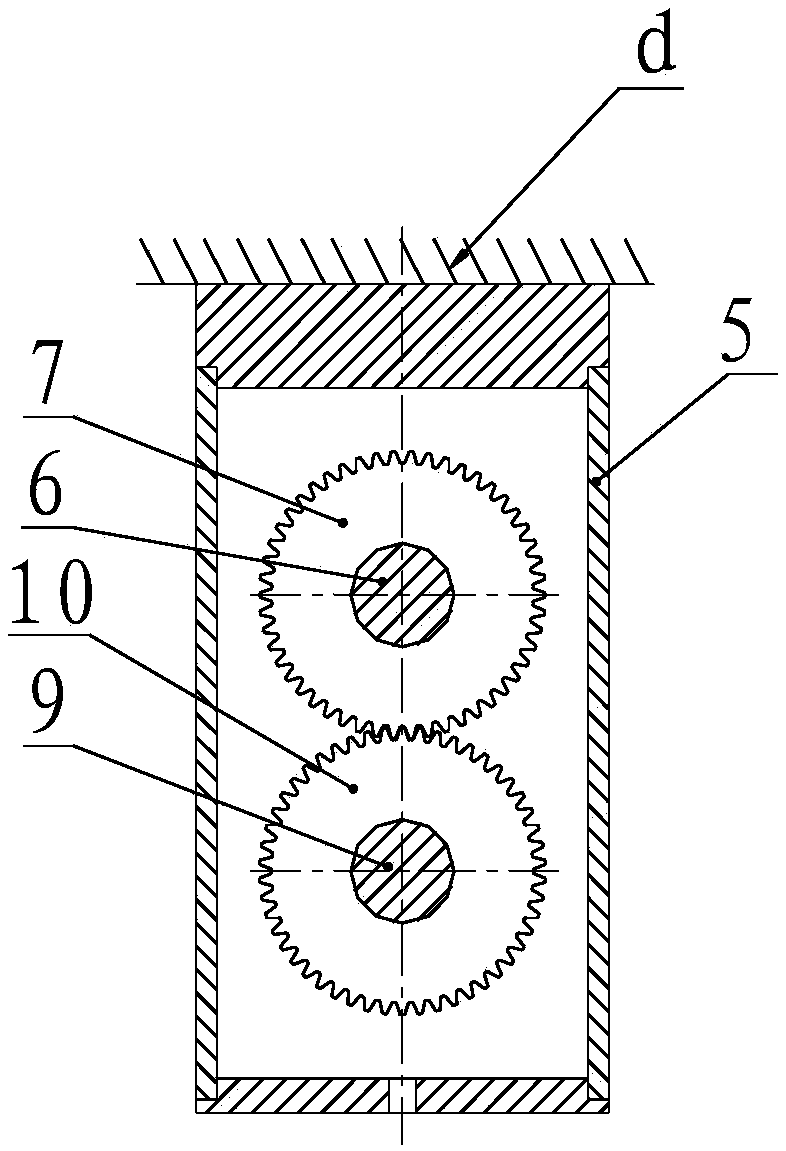

Convenient anchor rod construction equipment for building construction

The invention relates to the technical field of building construction, and provides convenient anchor rod construction equipment for building construction. The convenient anchor rod construction equipment for the building construction comprises a base, a placing piece and an anchor rod, and further comprises a mounting mechanism connected with the base and used for mounting the anchor rod; and a driving mechanism connected with the placing piece and the mounting mechanism and used for driving the mounting mechanism to rotate and lift, wherein the mounting mechanism comprises a rotating shaft A, mounting pieces, a transmission assembly and an adjusting assembly, the rotating shaft A is connected with the driving mechanism, the transmission assembly is connected with the rotating shaft A, the mounting pieces and the adjusting assembly, the transmission assembly comprises a gear A, a gear B and a rotating piece, the gear A is meshed with the gear B, the gear A and the gear B are both connected with the mounting pieces, the mounting pieces are rotationally connected with the rotating piece, and the rotating piece is connected with the adjusting assembly. According to the convenient anchor rod construction equipment for the building construction, the plurality of anchor rods for supporting a tunnel can be installed at the same time.

Owner:青岛康太源建设集团有限公司

Lintel-free non-grooving distribution box concrete encapsulating construction process

InactiveCN111852007ASimultaneous installationAchieve stretchingForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringPrefabrication

The invention discloses a lintel-free non-grooving distribution box concrete encapsulating construction process. The process comprises the following steps that 1, concrete encapsulating dimensions aredetermined based on dimensions of a wall and modulus; 2, formwork erecting is conducted and reinforcement is realized; 3, after erecting is completed, fine stone concrete at the same level as a construction column is cast, and concrete vibration is conducted in the process of casting; and 4, form stripping is conducted after casting and maintenance. By using concrete to encapsulate a distributionbox, the distribution box becomes a stress component which can bear vertical stresses, and lintel prefabrication and installation can be canceled; by determining the encapsulating thickness based onthe dimensions of the wall and the modulus, the wall becomes building blocks that can be built by bricklaying; and a traditional plastering bricklaying method can be adopted for construction and secondary grooving is omitted.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

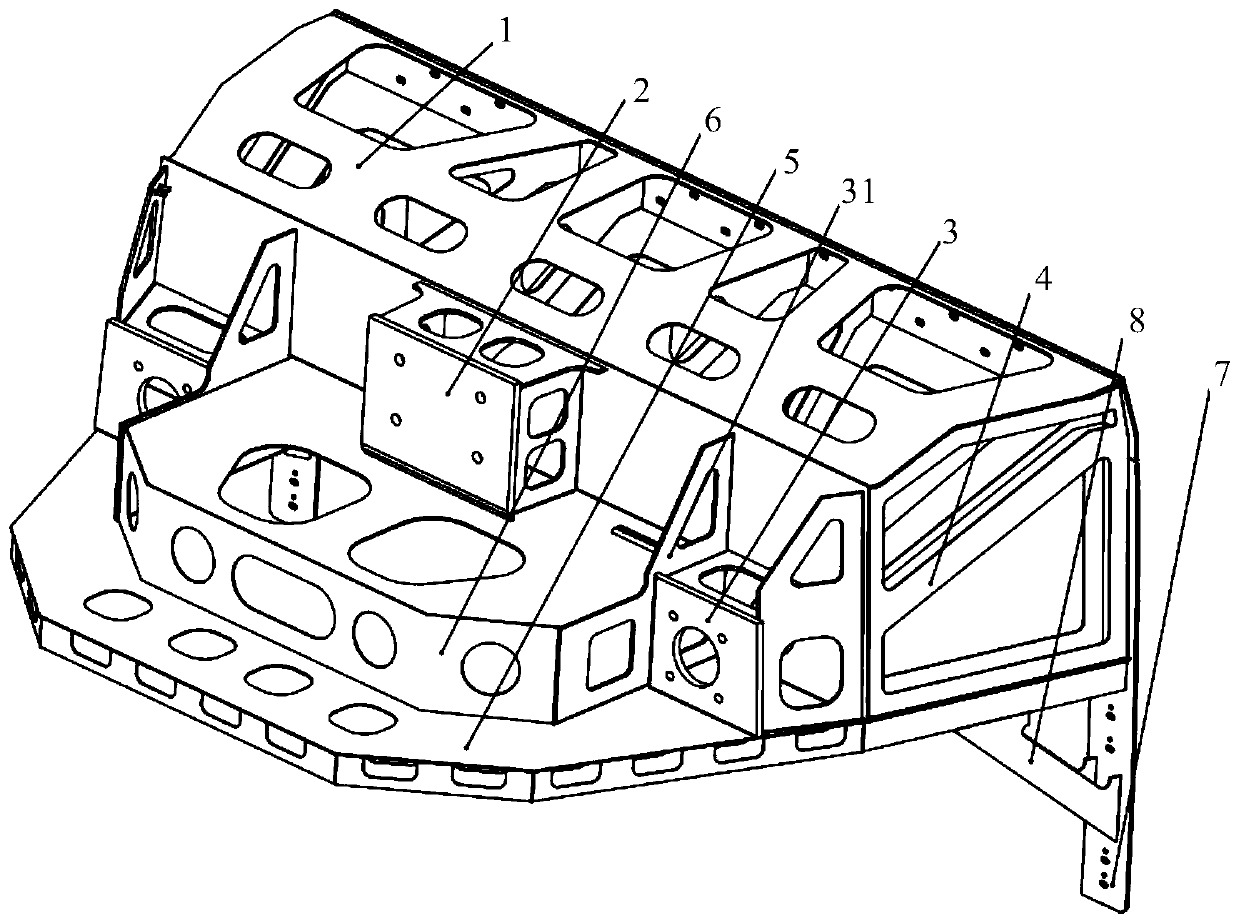

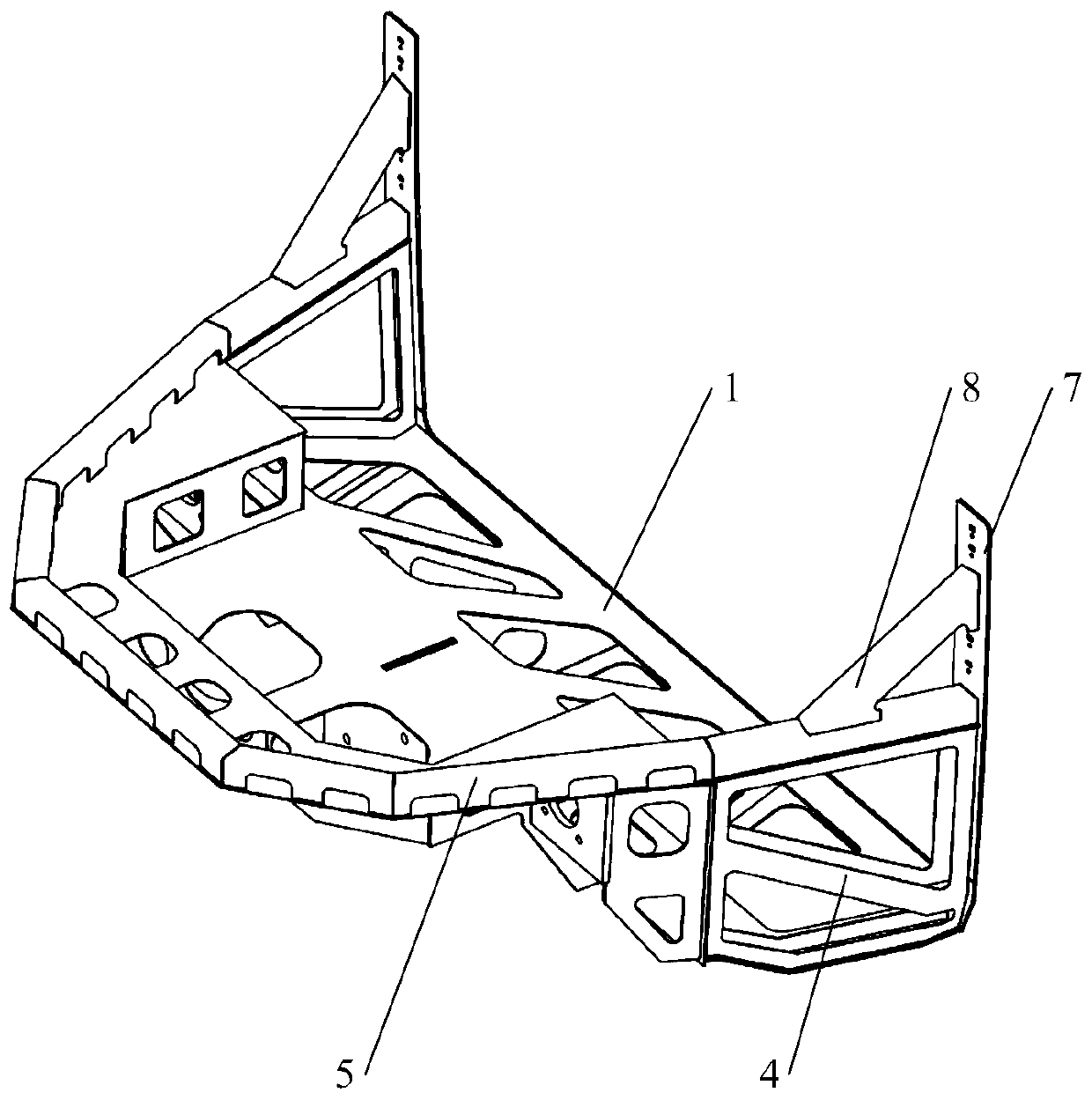

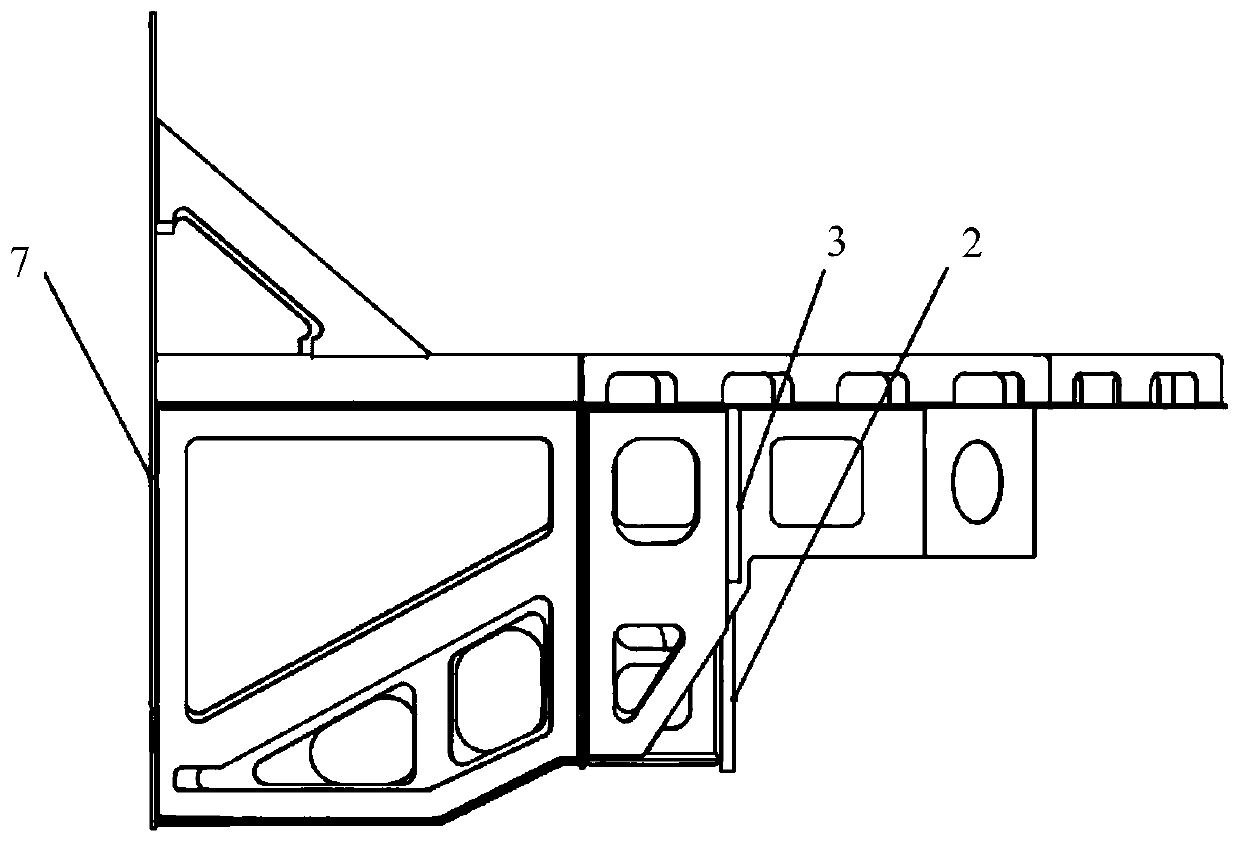

Driver's cab structure of a low-floor vehicle and the low-floor vehicle

ActiveCN108860180BMeet the installationSimultaneous installationRailway wheel guards/bumpersRailway couplingsMechanical engineeringAutomotive engineering

The invention discloses a driver cab structure of a low-floor vehicle. The driver cab structure comprises a driver cab base assembly welding element, a vehicle hook installing seat assembly welding element and an anticreeper installing seat assembly welding element, wherein the vehicle hook installing seat assembly welding element and the anticreeper installing seat assembly welding element are arranged at the front end of the driver cab base assembly welding element, and are in staggered arrangement in the height direction. The driver cab structure has the advantages that the layout of a hookinstalling structure and an anticreeper installing structure is optimized by the space under a driver cab table; the installation of an anticreeper and a hook is met in a mode of staggered arrangement of the vehicle hook installing seat assembly welding element and the anticreeper installing seat assembly welding element in the height direction; the goal of simultaneously installing the hook andthe anticreeper at the front end of the vehicle body is realized; the problem that the driver cab structure of the low-floor vehicle is simultaneously provided with the hook and the anticreeper, so that the space is insufficient is solved. The invention also discloses the low-floor vehicle comprising the driver cab structure.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

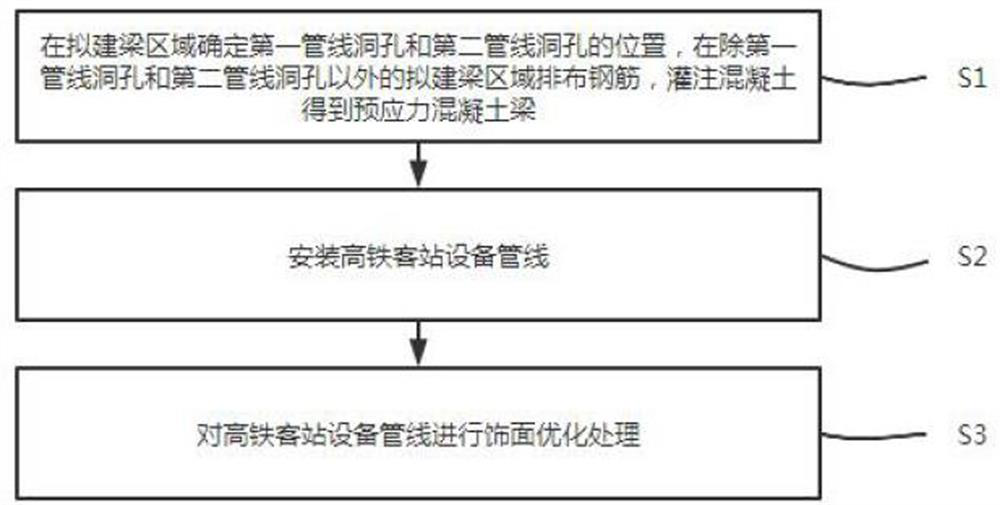

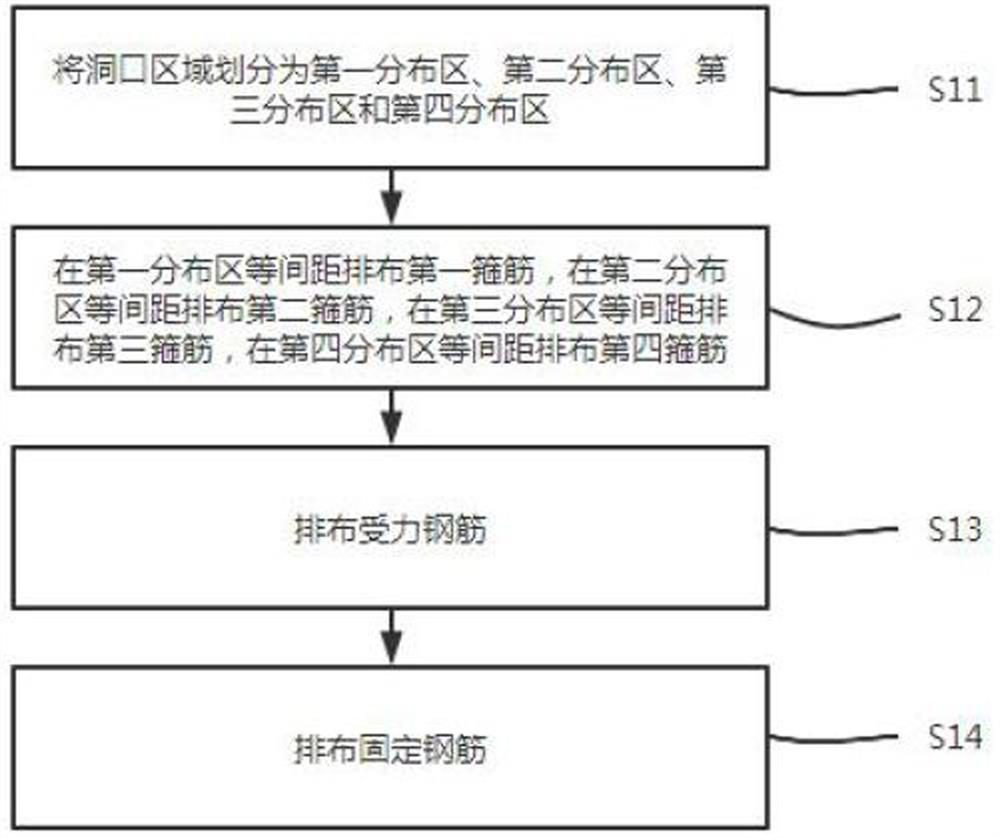

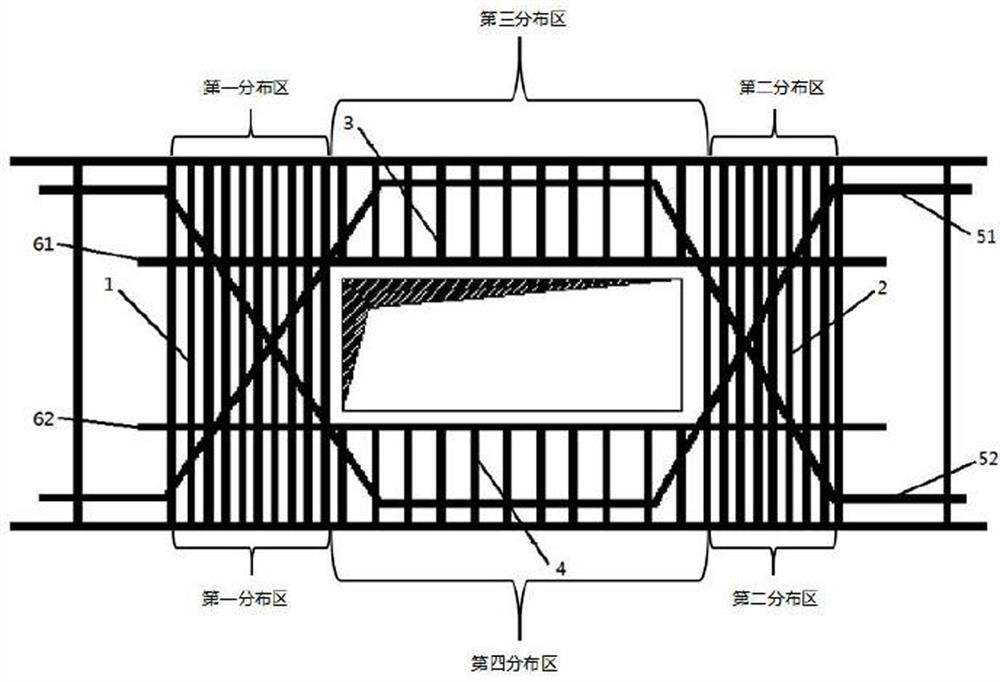

A construction method for expanding the ceiling space of small and medium-sized high-speed railway passenger stations

ActiveCN114319692BSimultaneous installationImprove aestheticsCeilingsGirdersPrestressed concrete beamPre stress

This application provides a construction method for expanding the ceiling space of small and medium-sized high-speed rail passenger stations, arranging the steel bars of the prestressed concrete beams with the first pipeline hole and the second pipeline hole reserved, pouring concrete to obtain the prestressed concrete beam, and placing the air conditioning pipeline It is divided into the first air-conditioning pipeline and the second air-conditioning pipeline, which are installed perpendicular to the prestressed concrete beam through the first pipeline hole and the second pipeline hole respectively, and the comprehensive pipeline is installed perpendicular to the prestressed concrete beam on the prestressed concrete below the beam. Finishing optimization of air-conditioning pipelines and integrated pipelines. In this application, the original high-speed rail passenger station equipment pipeline installed in the ceiling space is installed through the beam and outside the beam, releasing the ceiling space between the first air-conditioning pipeline and the second air-conditioning pipeline, raising the elevation of the high-speed railway station, and further optimizing small and medium-sized high-speed railways The space utilization rate of the passenger station creates a comfortable and spacious sense of space for passengers.

Owner:中铁北京工程局集团北京有限公司

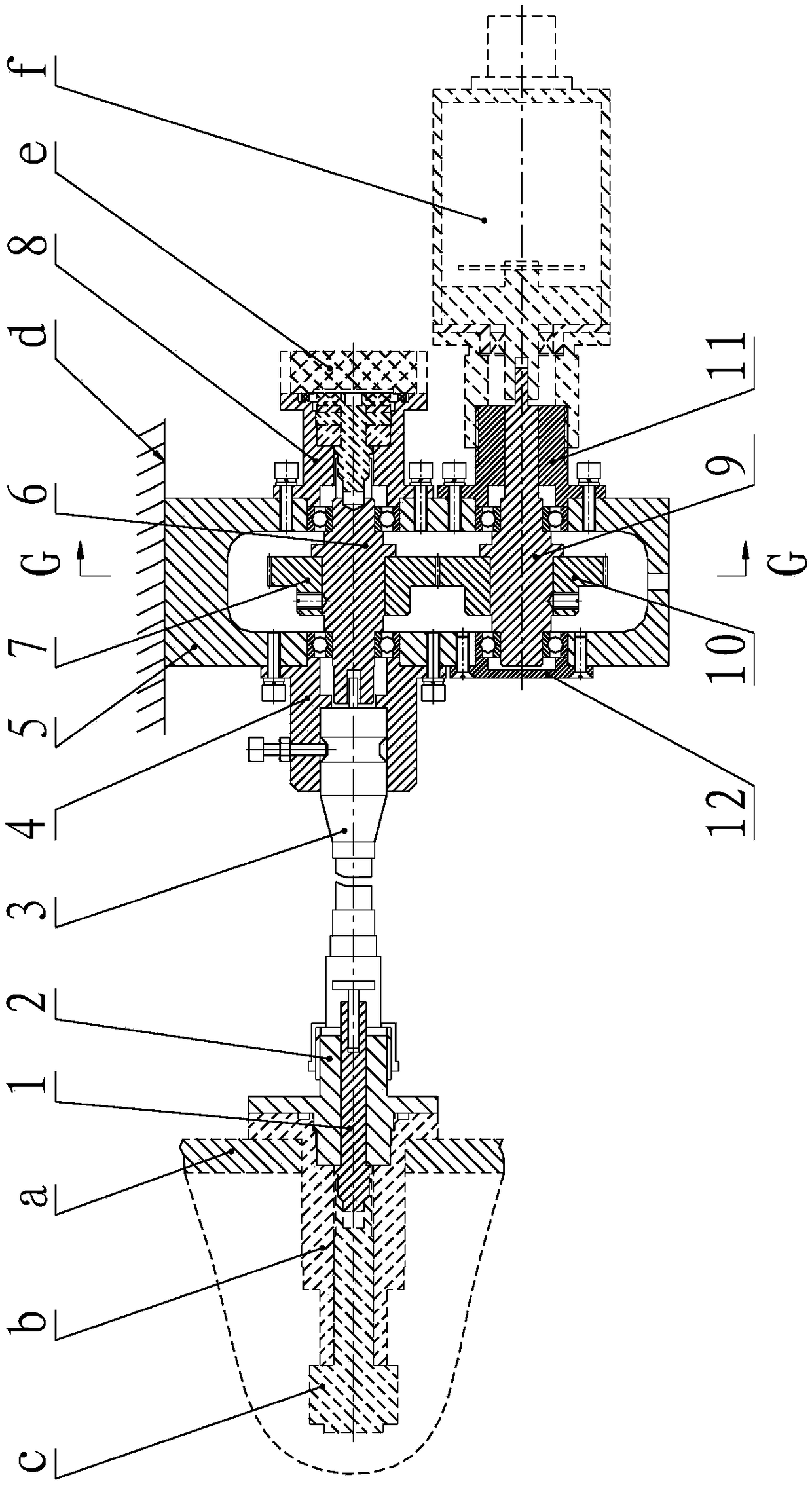

A car odometer distributor

ActiveCN106891726BSimultaneous installationLow costNavigation instrumentsVehicle componentsTransfer caseOdometer

The invention relates to a car odometer distributor. The car odometer distributor comprises a connecting shaft and is characterized in that the first end of the connecting shaft is inserted into an output connector and connected with a transfer case output shaft, a connecting mounting seat sleeves the second end of the connecting shaft and fixedly mounted on an output connector, the second end of the connecting shaft is connected with the inner core of the first end of a soft shaft, the pipe wall of the first end of the soft shaft sleeves the outer end of the connecting mounting seat, the pipe wall of the second end of the soft shaft is inserted into a soft shaft mounting seat, the soft shaft mounting seat is mounted on a car chassis through a distributor mounting seat, a Hall output shaft is mounted in the distributor mounting seat, one end of the Hall output shaft is connected with the inner core of the second end of the soft shaft, the other end of the Hall output shaft is a bayonet connector, a Hall mounting seat is mounted on the distributor mounting seat, a Hall gear is arranged on a Hall output shaft, an odometer output shaft is mounted in the distributor mounting seat, an odometer gear is arranged on an odometer output shaft, the odometer gear meshes with the Hall gear, one end of the odometer output shaft is an I-shaped connector, and an odometer mounting seat is mounted on the distributor mounting seat. The car odometer distributor is applicable to cars.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Screw Metering Packaging System

ActiveCN108454964BEasy to installEasy to limitPackaging automatic controlMetal working apparatusStructural engineeringElectric heating

The invention relates to the field of part packaging, and particularly discloses a screw metering and packaging system. The screw metering and packaging system comprises a conveying belt, a counting device and a packaging device. The conveying belt is arranged horizontally. Conveying grooves for containing plastic plates are arranged on the conveying belt. Multiple vertical first through holes areformed in each conveying groove. The counting device comprises a mounting box, a feeding groove and multiple arrangement units. The packaging device comprises a pressing block and a telescopic air cylinder. The air cylinder is fixedly mounted above the conveying belt, and the pressing block is fixedly mounted at the lower end of the air cylinder. Multiple second electric heating wires are arranged on the lower end face of the pressing block. The pressing block can be opposite to the conveying grooves, and the shape of the cross section of the pressing block is consistent with that of the cross sections of the conveying grooves. According to the scheme, screws can be arranged and packaged.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

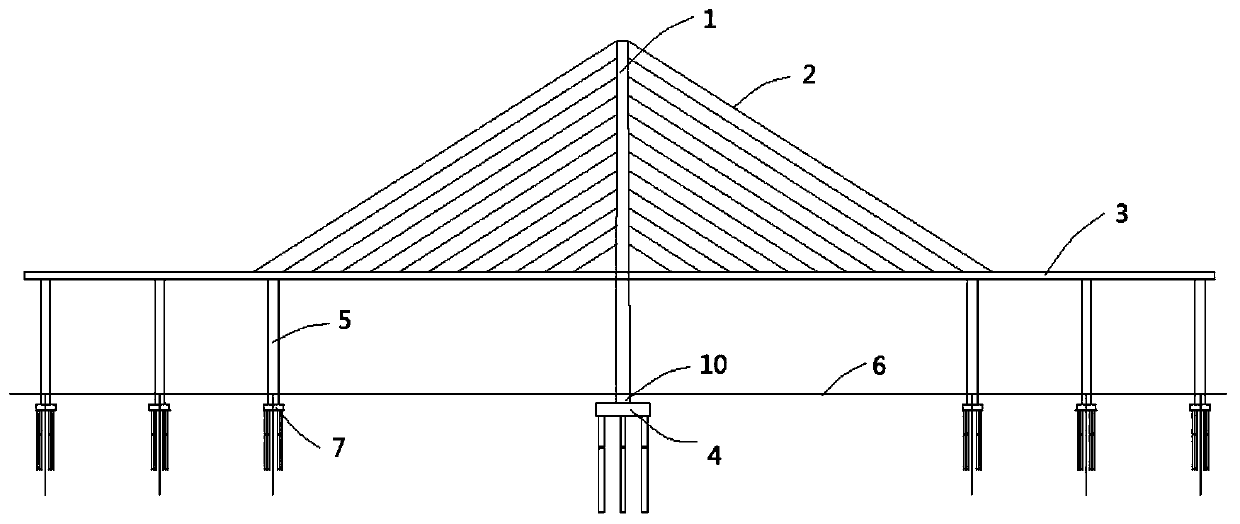

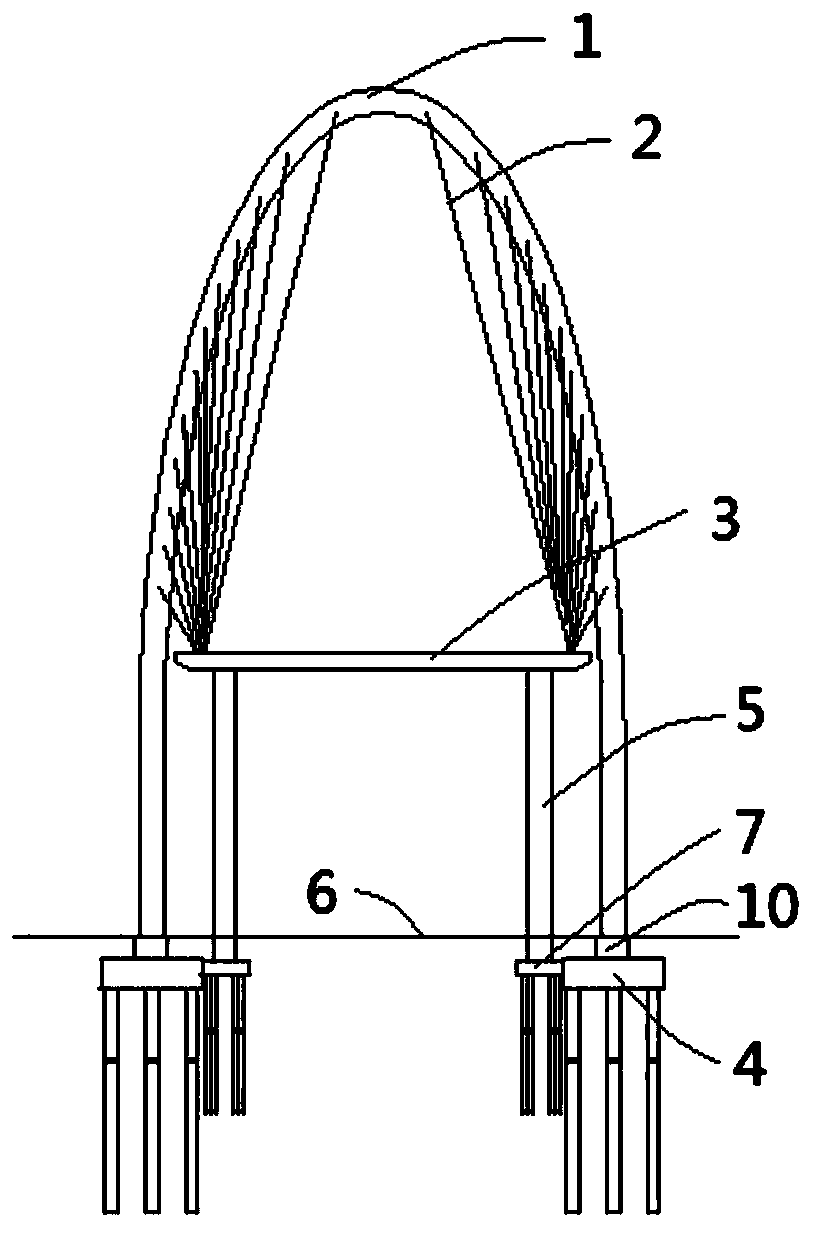

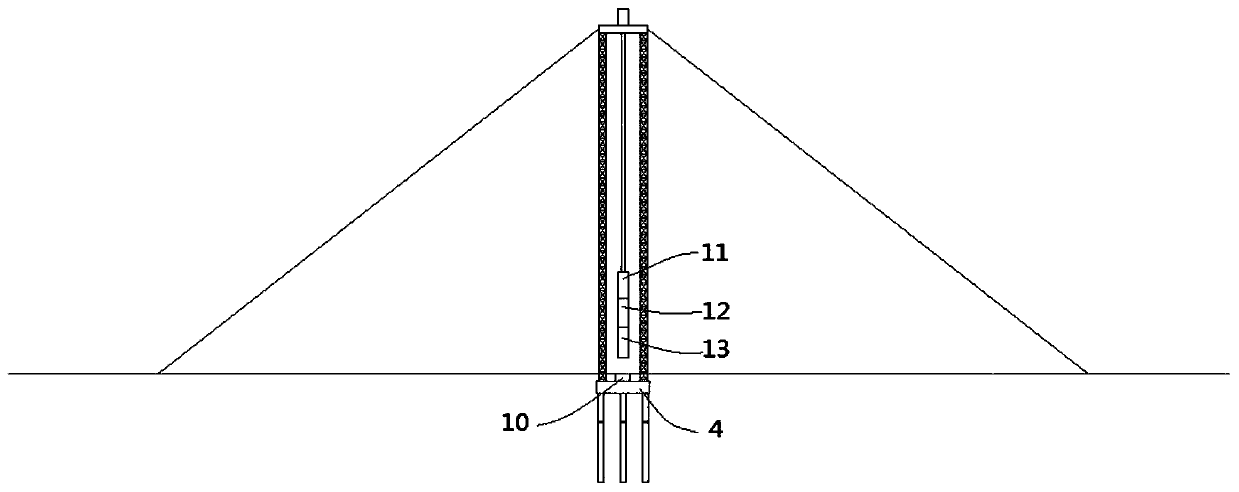

Upright steel arch cable-stayed bridge and manufacturing method thereof

PendingCN110093846AImprove aestheticsImprove bearing capacityCable-stayed bridgeBridge structural detailsCable stayedEngineering

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

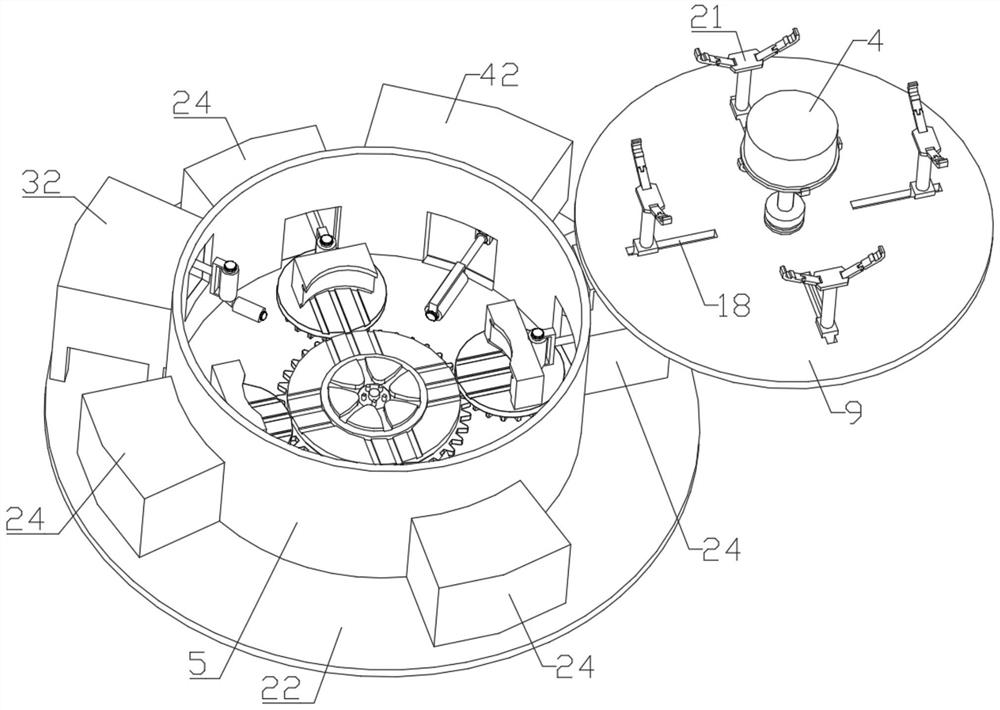

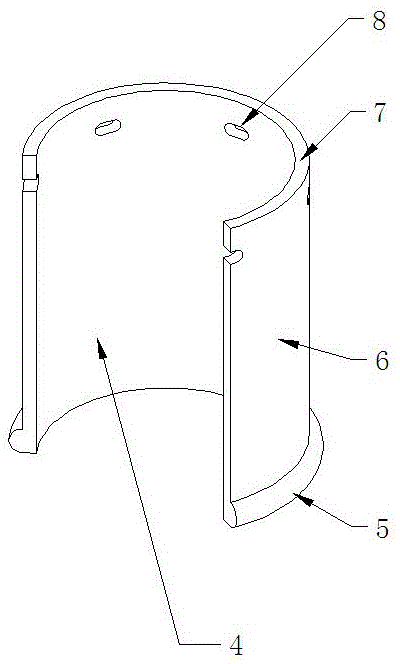

A maintenance device for a hub mold

ActiveCN113441445BEasy to cleanReduce labor intensityLiquid surface applicatorsFoundry mouldsEngineeringMechanical engineering

Owner:重庆众异特巧匠模具科技有限公司

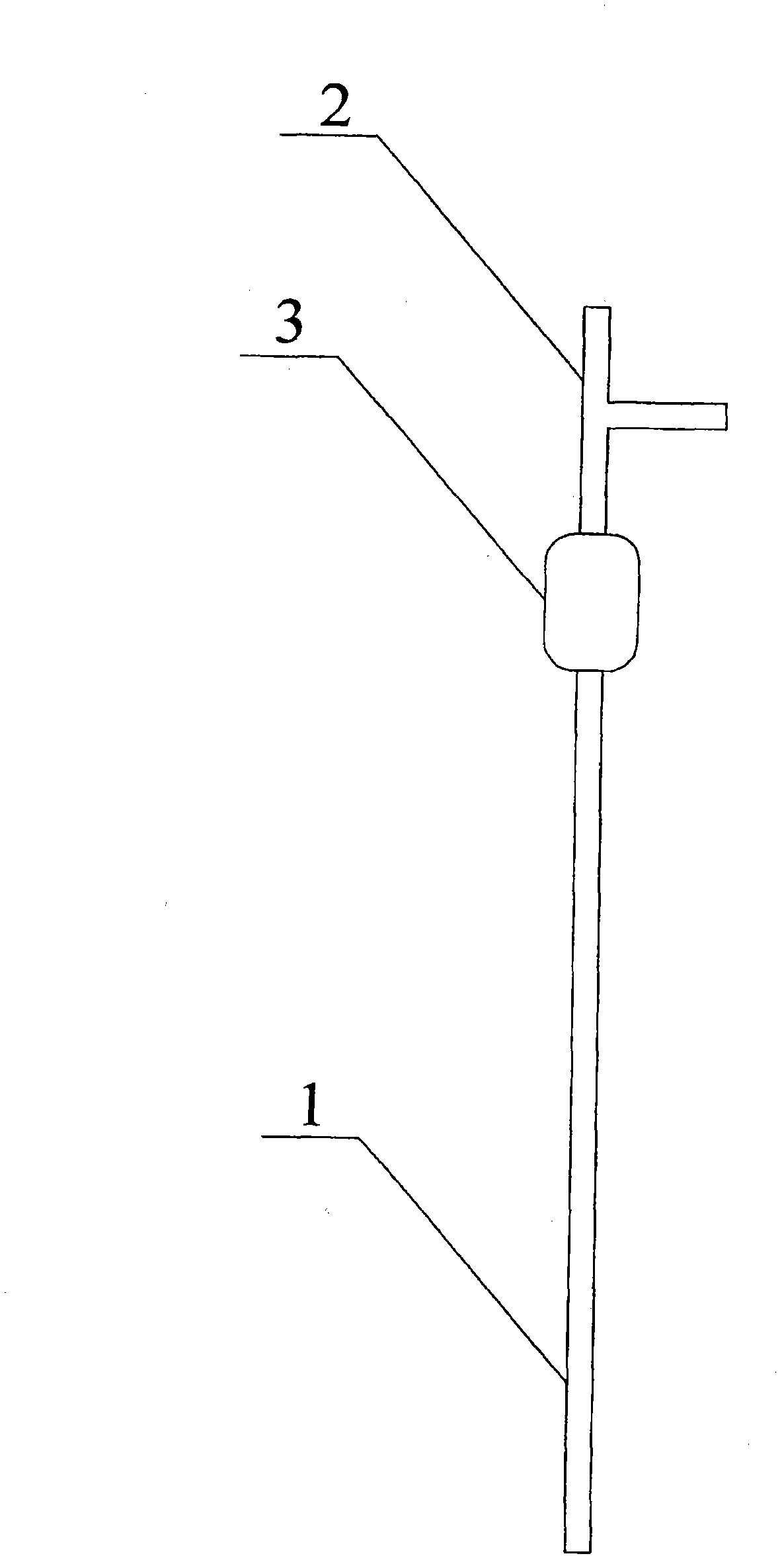

Alarming type insulating bar

InactiveCN103138188ASimple structureSimultaneous installationCurrent/voltage measurementSwitchgearEngineeringElectrical and Electronics engineering

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER

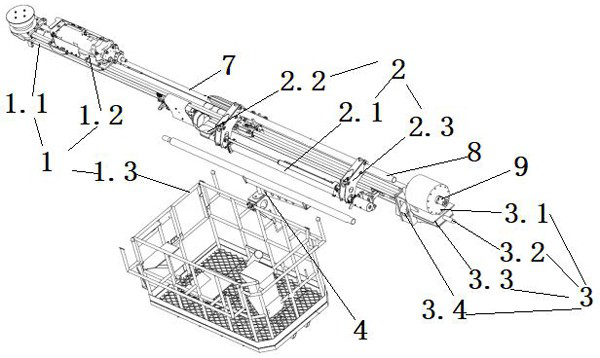

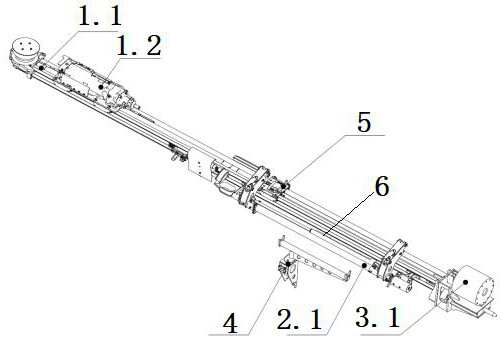

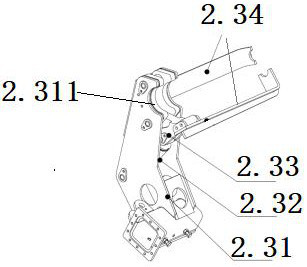

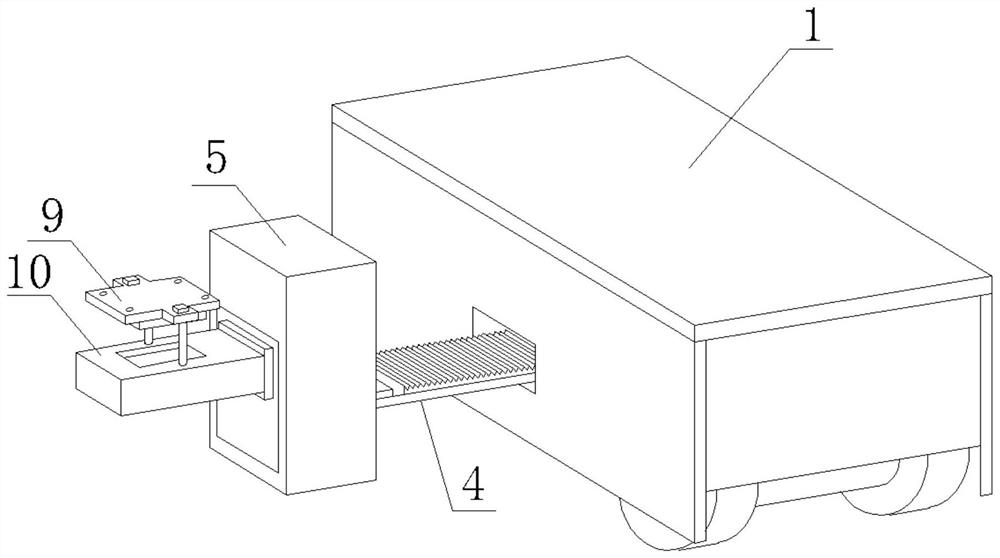

A construction device and construction method for follow-up pipe shed while drilling

ActiveCN113775294BSimultaneous installationSolve the problem that the pipe shed cannot be installedDrilling rodsTunnelsRock cuttingStructural engineering

The invention discloses a pipe shed construction device while drilling, which comprises a pipe shed grasping assembly, a crimping assembly and a root canal drill; the pipe shed grasping assembly includes a rotating shaft, a power part and a first manipulator; The drill rod is driven by the rock drill of the rock drilling rig to pass through the crimping machine and connected to the root canal drill bit. The tube shed tube is sleeved on the drill rod. While drilling, it can drive the pipe shed pipes forward, realize synchronous installation, solve the problem that the pipe shed cannot be installed when the hole is difficult, and improve the installation efficiency; and the two pipe shed pipes can be crimped together by the crimping machine, so that Instead of the threaded connection between the pipe-shelf pipes, the connection time of the pipe-shelf pipes is shortened, and the installation efficiency is improved. The invention also discloses a construction method for following-up pipe shed while drilling, which adopts a construction device for following-up pipe shed while drilling, which can realize automatic installation of pipe shed pipe while drilling, and has high installation efficiency.

Owner:CHINA RAILWAY CONSTR HEAVY IND

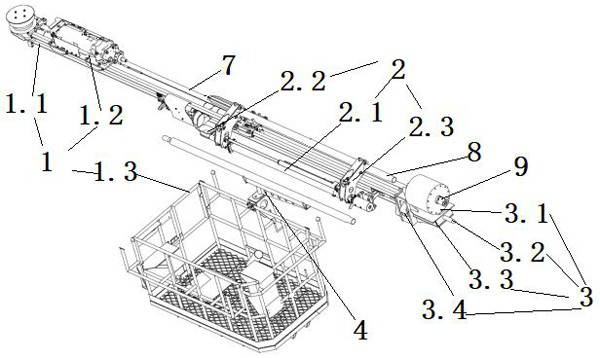

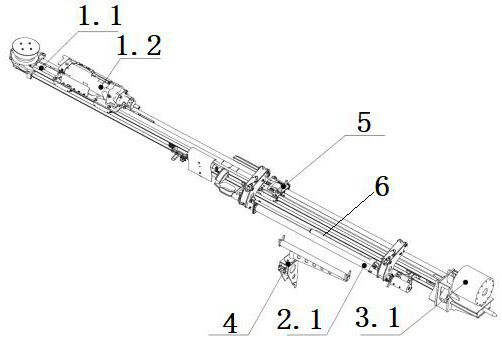

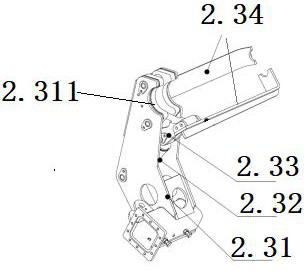

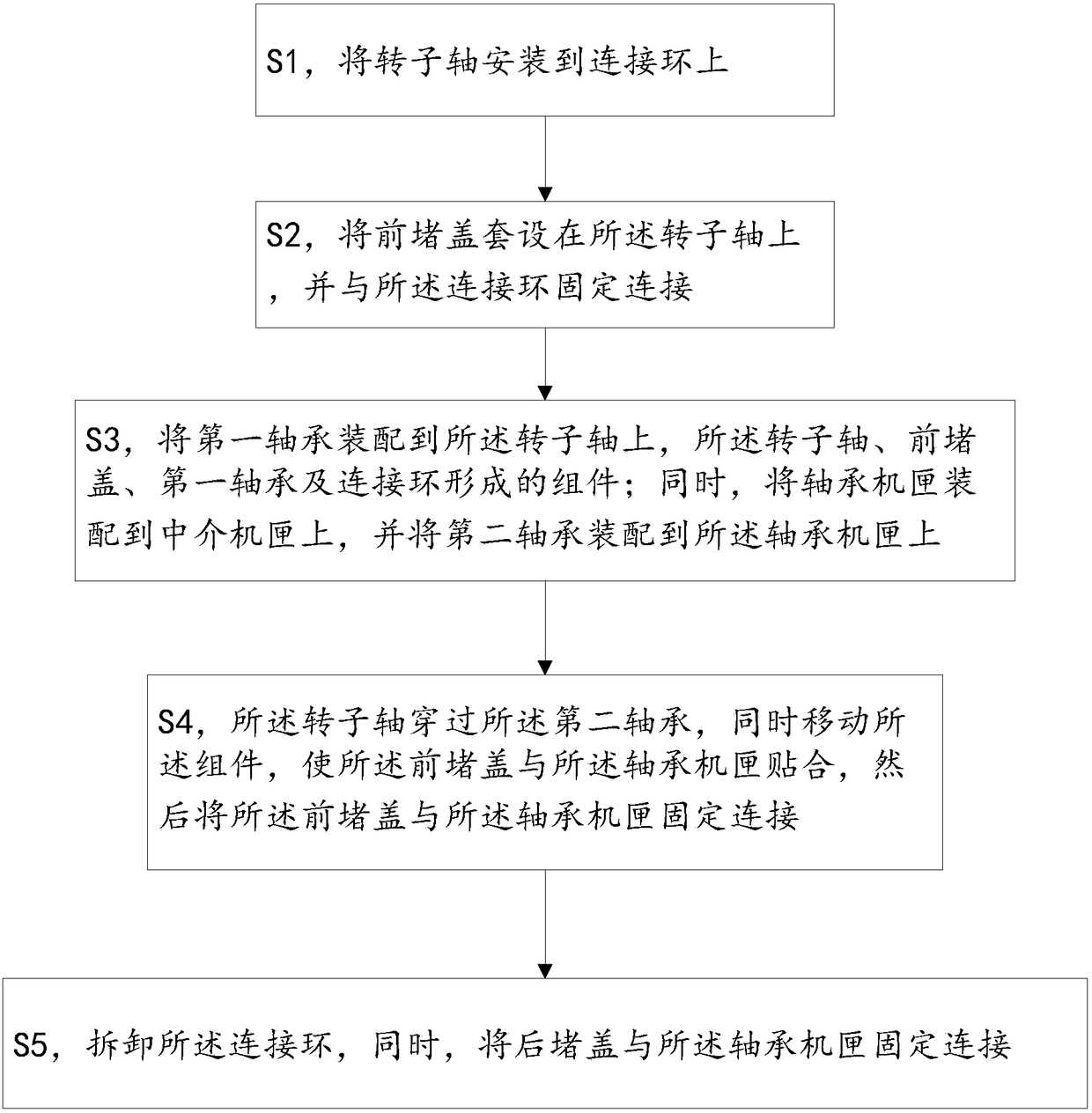

A method for installing an engine rotor shaft, a connecting ring and a blocking cover

ActiveCN106078193BMeet needsAchieve installationBlade accessoriesAssembly machinesEngineeringMechanical engineering

The invention discloses a method for installing an engine rotor shaft, a connecting ring and blanking covers, and relates to the technical field of engines. The method for installing the engine rotor shaft includes the following steps that S1, the rotor shaft is installed on the connecting ring; S2, the front blanking cover is arranged on the rotor shaft in a sleeving mode and is fixedly connected with the connecting ring; S3, a first bearing is assembled on the rotor shaft, so that the rotor shaft, the front blanking cover, the first bearing and the connecting ring form an assembly; a bearing case is installed on an intermediate case, and a second bearing is assembled on the bearing case; S4, the assembly is moved to make the front blanking cover attached to the bearing case; and S5, the connecting ring is removed; and meanwhile, the rear blanking cover and the bearing case are fixedly connected. The connecting ring is used for the installing method of the engine rotor shaft. The blanking covers are also used for the installing method of the engine rotor shaft. The method has the beneficial effects that the demand of a high speed engine can be met, and rotors and stators can be installed quickly.

Owner:AECC SHENYANG ENGINE RES INST

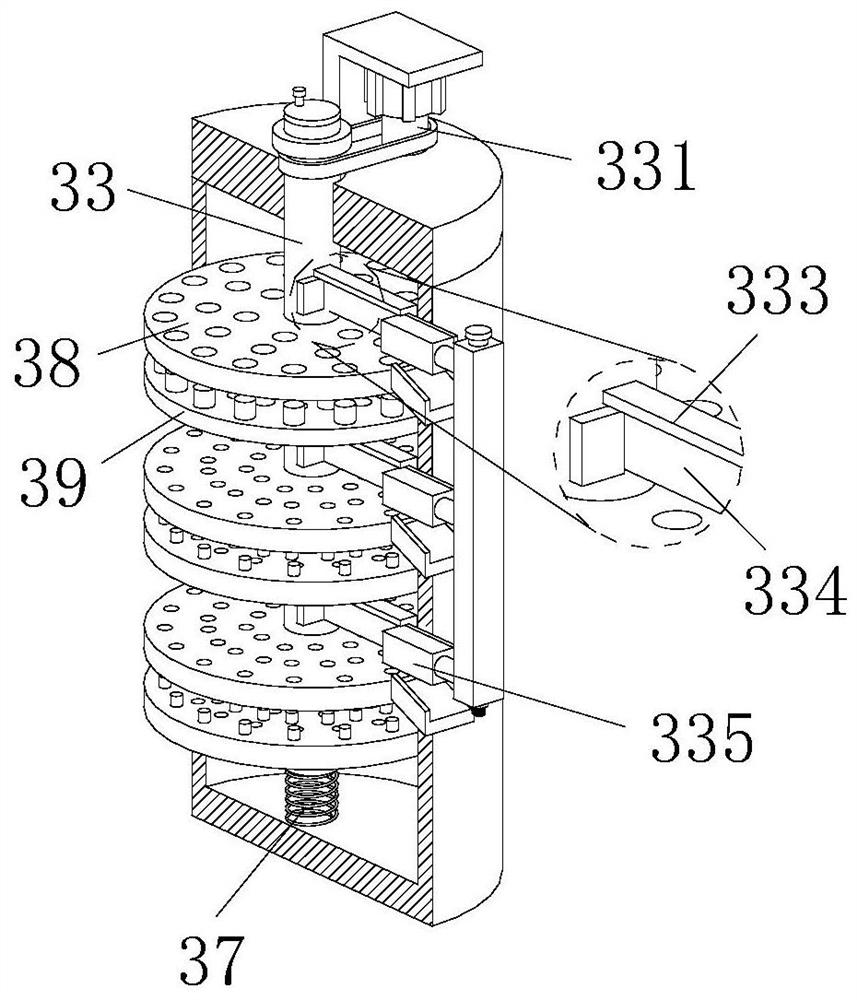

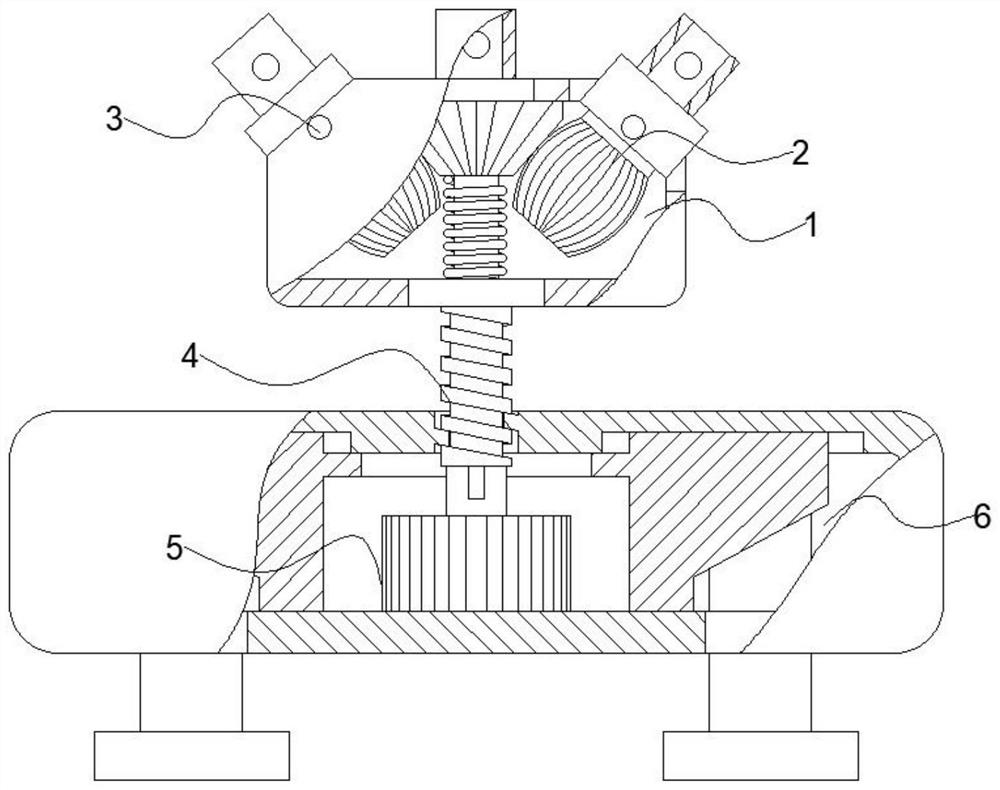

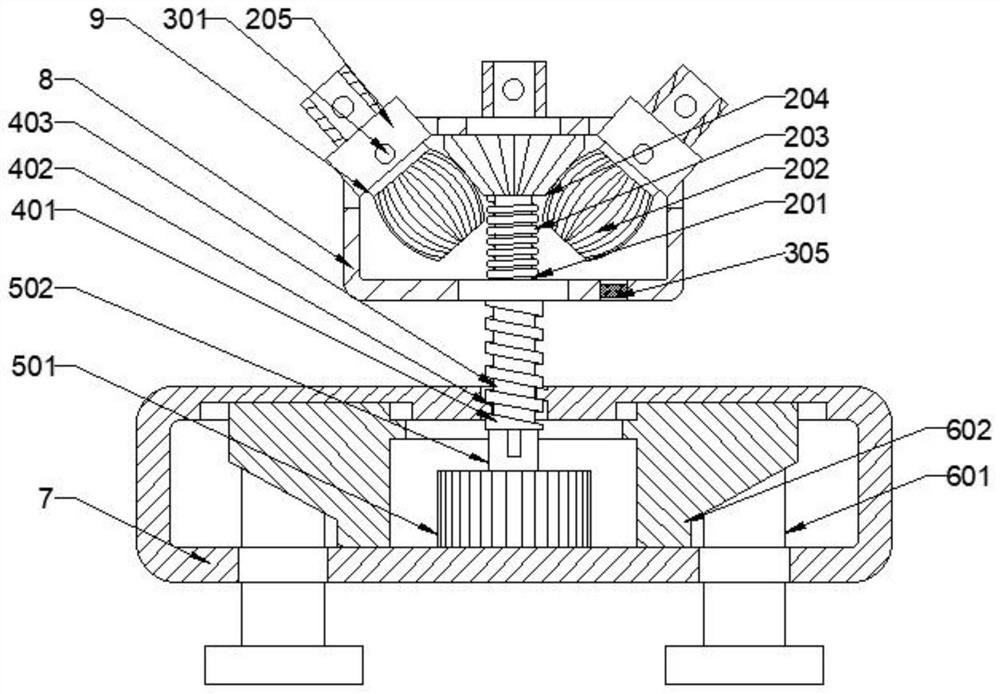

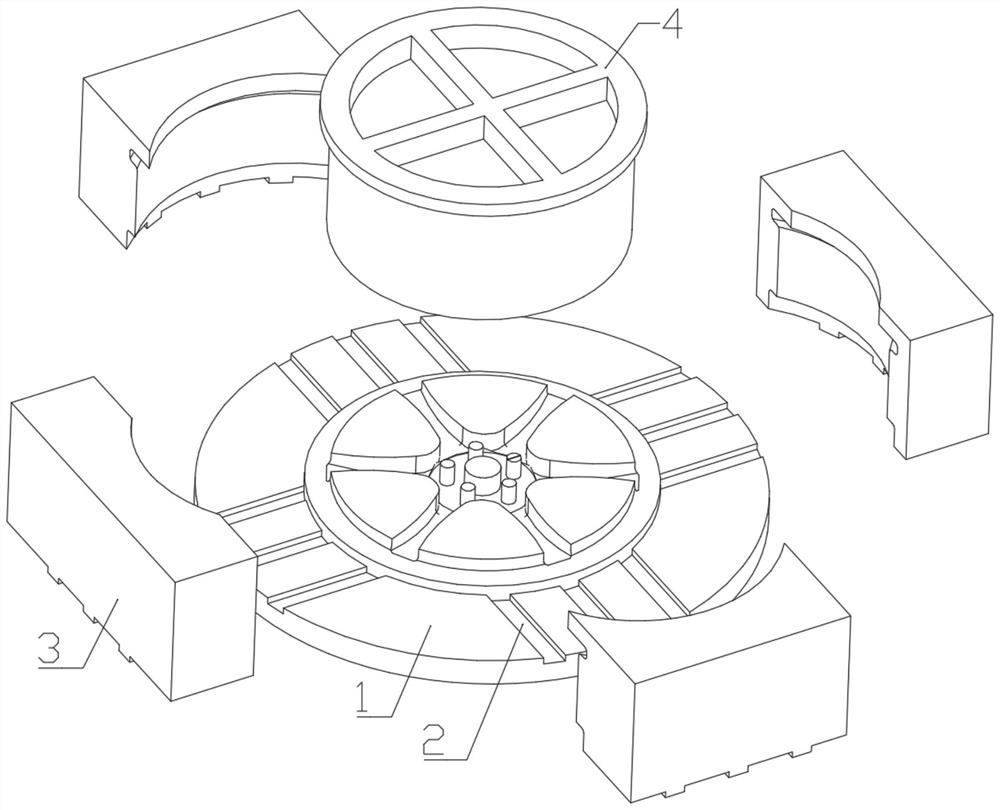

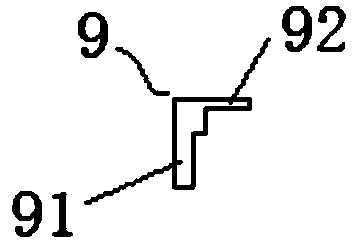

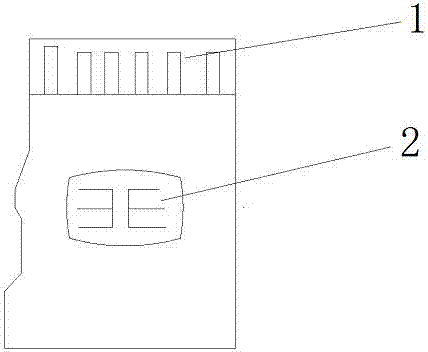

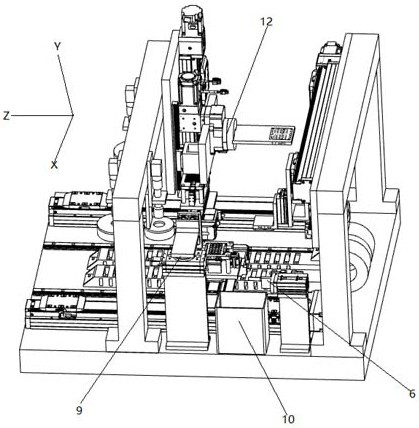

A motor bearing precision mounting machine

ActiveCN110524223BQuick installationReduce in quantityMetal working apparatusClassical mechanicsMachine

The invention relates to a precise mounting machine for a motor bearing. The machine comprises a supporting frame, the upper end of the support frame is fixedly connected with four guide supporting rods; every two guide supporting rods are arranged in a group; the upper ends of each group of guide supporting rods are fixedly connected with a supporting plate; an end cover placing plate is arrangedbetween the supporting plate and the upper end surface of the supporting frame; the end cover placing plate is connected between the two guide supporting rods in a sliding mode, a mounting groove isformed in the center of the end cover placing plate, a driving mechanism is arranged at the upper ends of the supporting plates, the driving mechanism is in linkage with an abutting punch, the abutting punch is inserted into the supporting plates in a sliding mode and is opposite to the end cover placing plate, and a bearing containing table is arranged at the upper end of the supporting frame. When the bearing is installed, the bearing is placed on the bearing containing table, the end cover is placed on the end cover placing plate, and then the driving mechanism is started and is enabled tobe in linkage with the abutting punch, so that the abutting punch downwards abuts against the end cover, the end cover abuts against the bearing, and the bearing and the end cover are installed.

Owner:无锡市极光电动科技有限公司

A kind of ceramic spark plug molding equipment and its control method

ActiveCN112582888BSimultaneous installationContinuous processingSparking plugs manufactureEngineeringMaterials science

The invention relates to a ceramic spark plug molding device, which comprises: a frame, a fixed mold, a movable mold, a driving mechanism, a feeding mechanism, and an electrode installation mechanism. The fixed mold is fixed on the frame, and the fixed mold is provided with a first mold cavity; the movable mold is provided with a second mold cavity, and the second mold cavity can cooperate with the first mold cavity to form The mold cavity is complete; the driving mechanism is installed on the frame, and can control the movable mold to approach or move away from the fixed mold; the feeding mechanism can inject raw materials into the mold cavity. The present invention has the advantages that: the formation of the spark plug and the installation of the electrodes can be completed synchronously by setting the electrode installation mechanism; the electrode installation mechanism can automatically switch the electrodes, so that the processing of the spark plug can be continued.

Owner:ZHEJIANG WANLI UNIV

Clamp welding device for iron hoop barrel

PendingCN110900030ASimultaneous installationRealize positioning installationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention provides a clamp welding device for an iron hoop barrel. A body is included. A base is arranged at the edge position of the lower side of the right end of the body. The middle position of the right end of the body is fixedly connected with a positioning column, and the positioning column is located on the upper side of the base. The front end and the rear end of the body are fixedlyconnected with clamping assemblies, and the two clamping assemblies are located on the front side and the rear side of the positioning column. The edge position of the upper side of the right end of the body is connected with a welding head, the welding head is located on the upper side of the positioning column, the annular outer side of the positioning column is in sliding connection with a positioning ring, and the positioning ring is arranged at the right end of the body. Through the design, clamp welding and installing are synchronously conducted, usage is convenient, and the work efficiency is improved.

Owner:肥城瑞鑫包装材料有限公司

Ceramic spark plug forming equipment and control method thereof

ActiveCN112582888ASimultaneous installationContinuous processingSparking plugs manufactureMaterials scienceSpark plug

The invention relates to ceramic spark plug forming equipment. The ceramic spark plug forming equipment comprises a frame, a fixed mold, a movable mold, a driving mechanism, a feeding mechanism and anelectrode mounting mechanism. The fixed mold is fixed on the frame, and a first mold cavity is formed in the fixed mold; the movable mold is provided with a second mold cavity, and the second mold cavity can be matched with the first mold cavity to form a complete mold cavity; the driving mechanism is mounted on the frame and can control the movable mold to be close to or far away from the fixedmold; and the charging mechanism can be used for charging raw materials into the die cavity. The spark plug forming equipment has the advantages that by arranging the electrode mounting mechanism, forming of the spark plug and mounting of the electrode can be synchronously completed; and the electrode mounting mechanism can automatically switch the electrodes, so that the spark plug can be continuously processed.

Owner:ZHEJIANG WANLI UNIV

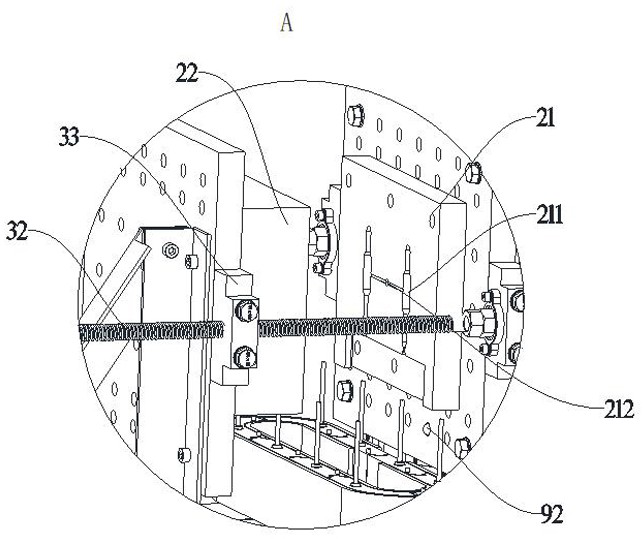

Card tray with storage function

InactiveCN107995338ACard space savingSimultaneous installationTransmissionTelephone set constructionsEngineeringMobile phone

The invention discloses a card tray with a storage function. The card tray comprises a (1) used as the part of the storage function and a (2) used as the card tray of the Nano sim in a figure; the card tray is assembled at a mobile phone card slot part, and a card slot location is saved; the card tray can be arranged at the card slot location as the communication as well as the storage. The card tray is characterized in that a storage chip thereof can be used as the mobile phone memory card, and can provide the arrangement of the Nano sim card at the same time. Through the above settings, thesimultaneous installation of the memory card and the Nano sim card can be realized by using one card position, and the limited card position of the mobile phone is saved; the card tray disclosed by the invention facilitates the use of extensive mobile phone users, and has good social benefit and economic benefit.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

A rubber sleeve screw assembly mechanism

ActiveCN111872659BSimultaneous installationImprove efficiencyMetal working apparatusClassical mechanicsStructural engineering

The invention relates to the technical field of auto parts assembly, and discloses a rubber sleeve screw assembly mechanism, which includes a frame, and the frame is provided with a feeding mechanism and a positioning mechanism used in conjunction with the feeding mechanism; the pre-installed screw of the product The rubber sleeve is preset at the installation hole, and the feeding mechanism includes a compacting assembly for pressing the rubber sleeve into the installation hole and a screw feeding assembly for installing the screw into the rubber sleeve; the screw feeding assembly includes a feeding The driver and multiple clamps for screws driven by the feeding drive; the compaction assembly includes a compaction drive and multiple compaction rods driven by the compaction drive, and the screw clamps and compaction rods are arranged correspondingly ; The positioning mechanism includes a sliding device for translation of the product and a sliding driving member for controlling the translation of the product on the sliding device. The present invention has the effect of improving screw installation efficiency.

Owner:上海施赛自动化科技有限公司

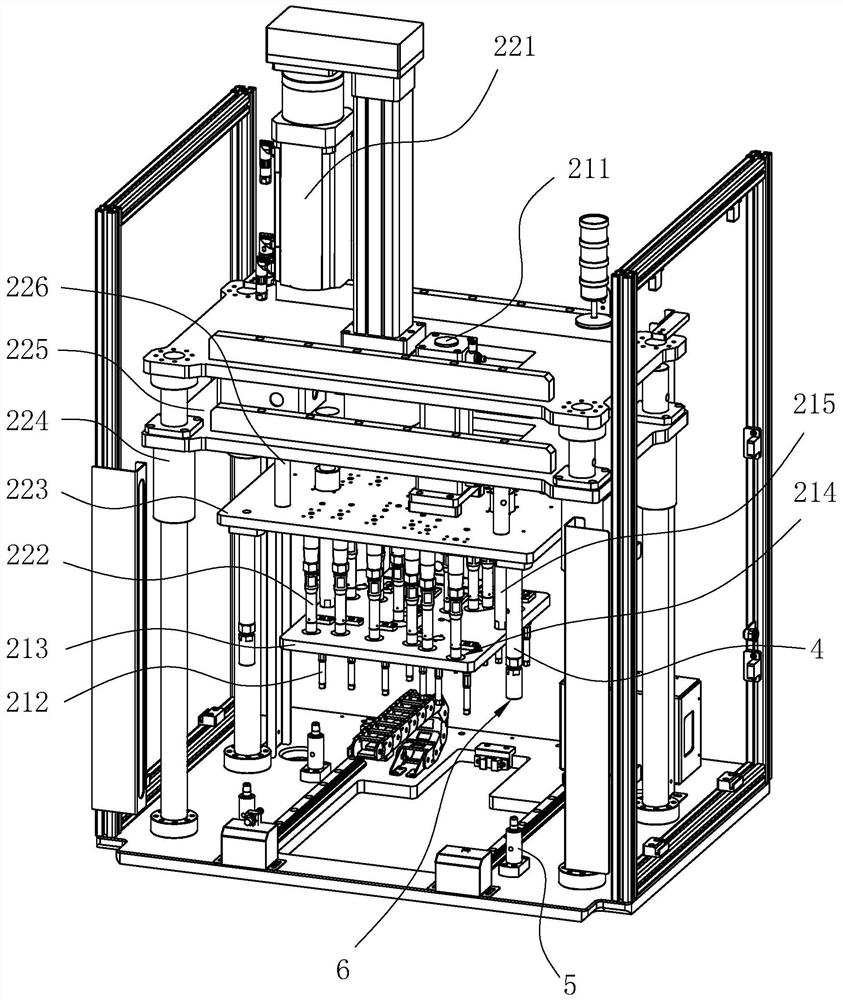

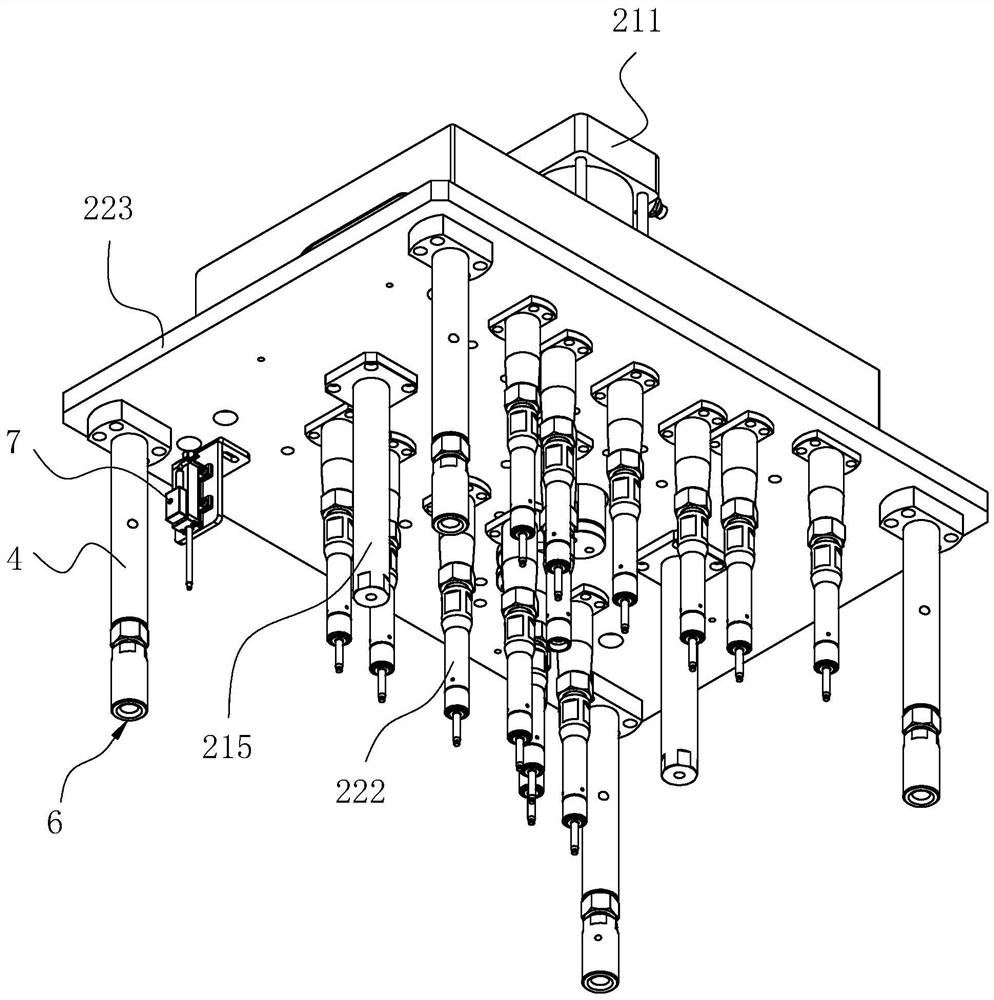

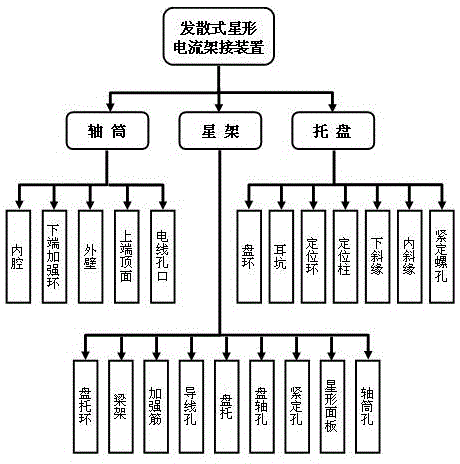

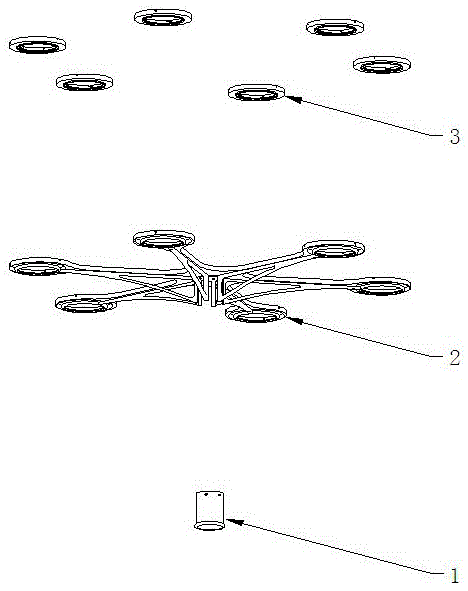

Divergent star current connection device

ActiveCN103956610BAchieve distributionLean structureCoupling device detailsWorking environmentStructural engineering

The invention relates to a current bridge joint device, in particular to a star-shaped device which is divergent from inside to outside and can be simultaneously used for bridge joint of multiple current generators. The divergent star current bridge joint device consists of a shaft barrel, a star frame and a tray and comprises 21 constituent parts including a lower-end reinforcing ring, an outer wall, an upper-end top face, an electric wire orifice, a tray support ring, a beam frame, a reinforcing rib, a lead wire hole, a tray support, a tray shaft hole, a tightening hole, a star-shaped panel, a shaft barrel hole, a tray ring, a lug pit, a positioning ring, a positioning column, a lower oblique edge, an inner oblique edge and the like, is a multidirectional current bridge joint device which is capable, vigorous, simple, convenient, stable, efficient and wide in application range, can be widely applied to plains, mountainous areas, hills, islands, upper air and other working environments, meets the using demands of electrical, mechanical and other industries, has the excellent advantages of simple in implementation and simple and easy to manufacture, is attractive, elegant, convenient to use, wide in market space and has high application vale and added economic value.

Owner:南通市展成商品混凝土有限公司

While-drilling follow-up pipe shed construction device and construction method

ActiveCN113775294AImprove installation efficiencyShorten connection timeDrilling rodsTunnelsDrill holeDrill bit

The invention discloses a while-drilling follow-up pipe shed construction device which comprises a pipe shed pipe grabbing assembly, a buckling and pressing assembly and a root pipe drill bit. The pipe shed pipe grabbing assembly comprises a rotating shaft, a power piece and a first mechanical arm. The buckling and pressing assembly comprises a buckling and pressing machine; a rock drill of a drill jumbo drives a drill rod to penetrate through the buckling and pressing machine and is connected with the root pipe drill bit, a pipe shed pipe sleeves the drill rod, the root pipe drill bit and the pipe shed pipe are fastened together by the buckling and pressing machine, the drill rod can drive the pipe shed pipe to advance while drilling, synchronous mounting is realized, the problem that a pipe shed cannot be mounted when it is hard to form the hole is solved, and the mounting efficiency is improved; and the two pipe shed pipes can be buckled and pressed together through the buckling and pressing machine, so that threaded connection between the pipe shed pipes is replaced, the connecting time of the pipe shed pipes is shortened, and the mounting efficiency is improved. The invention further discloses a while-drilling follow-up pipe shed construction method, the follow-up-while-drilling pipe shed construction device is adopted, the pipe shed pipe can be automatically installed while drilling is achieved, and the mounting efficiency is high.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Parts Packaging Transfer Equipment

The invention relates to the field of part machining and particularly discloses part packaging and conveying equipment. The part packaging and conveying equipment comprises a conveyor belt, a mountingbox, a feed chute, a plurality of conveying wheels, supporting belts, a rotary rod and cams. The conveyor belt is provided with conveying grooves. Each conveying groove is internally provided with first through holes. The supporting belts are arranged oppositely and horizontally fixed to the interior of the mounting box. One end of each supporting belt is located in the feed chute. The distance between the adjacent supporting belts is consistent with the diameter of a thread of each screw. The supporting belts are provided with opposite falling slots. The conveying wheels are uprightly and rotatably mounted in the supporting belts. The two adjacent conveying wheels make contact with each other. Moreover, the conveying wheels make contact with the threads of the corresponding screws. The lower surface of the mounting box is provided with a plurality of second through holes. The first through holes, the corresponding falling slots and the corresponding second through holes are located on the same vertical axes. The rotary rod is mounted in the mounting box. The cams are coaxially mounted on the rotary rod. The side faces f the cams make contact with the tops of the corresponding screws. The part packaging and conveying equipment can be used for arranging and packaging the screws.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

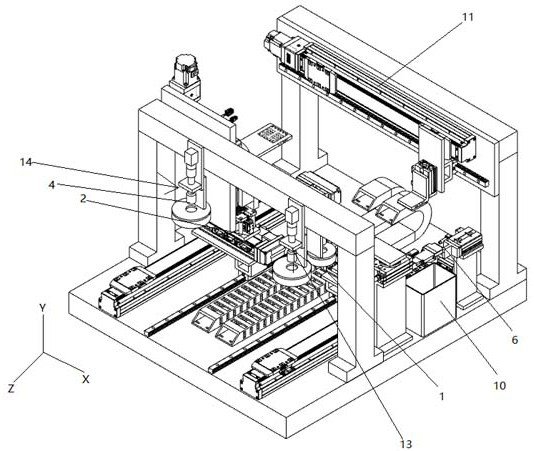

Assembly and detection all-in-one machine and assembly and detection method thereof

ActiveCN113245214BSimultaneous installationPrecise ClippingSortingMetal working apparatusEngineeringMachine

The invention discloses an assembly and detection integrated machine and an assembly and detection method thereof. The feeding mechanism is used for feeding, testing and screening a group of first workpieces; the assembly mechanism includes a transfer module and a flipping assembly device; the assembly mechanism is used for combining a group of first workpieces with a group of second workpieces Assembling and bonding; the second feeding mechanism includes a second feeding device and a second detector; the second feeding mechanism is used for loading a group of second workpieces, detecting and unloading a group of processed parts; Through defect input and defect judgment, the present invention can realize defect updating during use, and perform intensive comparison; it can also perform double defect detection on the whole and individual, and can continuously perform self-inspection of the detection machine, and can also analyze and judge through defect coding The overall quality of the same batch of workpieces.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

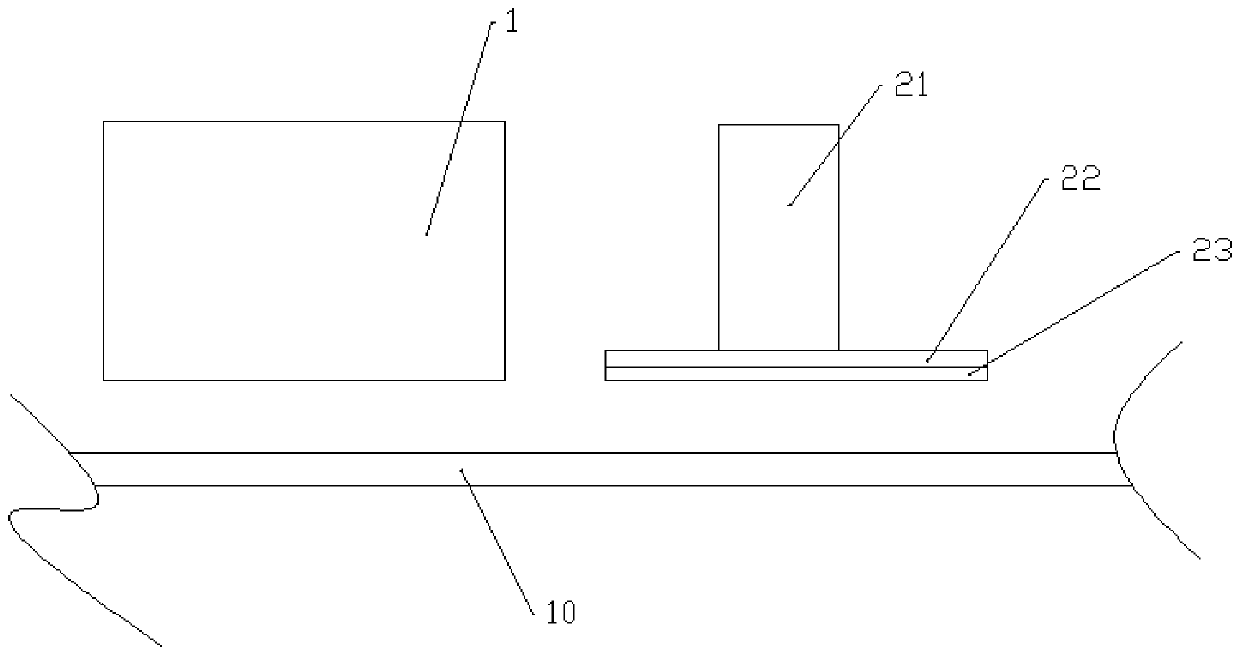

Storage yard single-machine large-arm laser scanner assembly structure

PendingCN113390364AAccurate adjustment positionReal-time guidance of production operationsUsing optical meansLoading/unloadingElectric machineryLaser scanning

The invention discloses a storage yard single-machine large arm laser scanner assembly structure, which comprises a base, a horizontal displacement assembly, a vertical displacement assembly and a fixing assembly; the base moves on a large arm of a stacker of a storage yard; in the horizontal displacement assembly, a first driving motor drives a driving gear to be meshed with a driven gear to be meshed with a rack, so that the rack extends out of or retracts into a notch in the transverse direction; in the vertical displacement assembly, a rack is fixed to one side of a traction box, a vertical opening is formed in the other side of the traction box, and a second driving motor is fixedly installed on the traction box and drives a lead screw to rotate to drive a lead screw nut to ascend and descend; and in the fixing assembly, the mounting box is fixedly connected to a lead screw nut through a mounting block, and a mounting hole of the laser scanner is formed in the mounting table. The position of the laser scanner can be accurately adjusted, the shape of a coal stack can be continuously and accurately scanned in real time under the severe condition, use and operation are easy, debugging is convenient, maintenance is not needed, the reliability is high, and production operation is guided in real time.

Owner:CCCC MECHANICAL & ELECTRICAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com