A construction device and construction method for follow-up pipe shed while drilling

A technology for construction devices and pipe sheds, applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as low installation efficiency and difficulty in installing pipe shed pipes, and achieve improved installation efficiency, shortened connection time, and safety good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

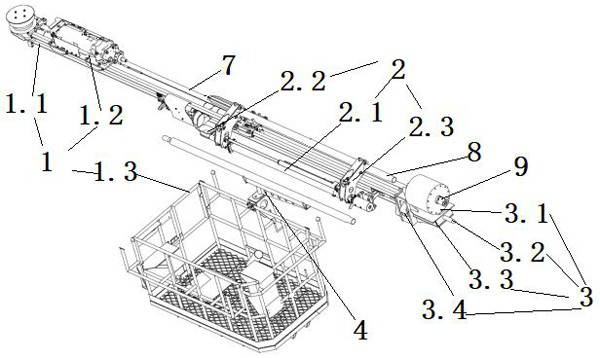

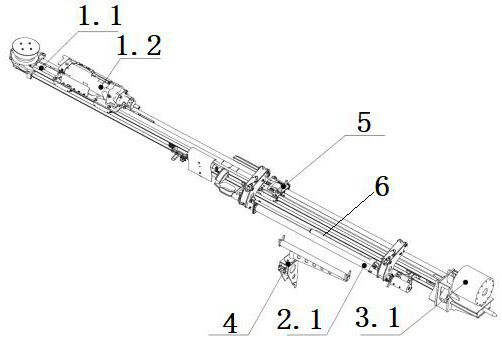

[0047] A pipe shed construction device for follow-up while drilling, comprising a pipe shed grabbing assembly 2, a crimping assembly 3 and a root canal drill bit 9, such as Figure 1-5 As shown, the details are as follows;

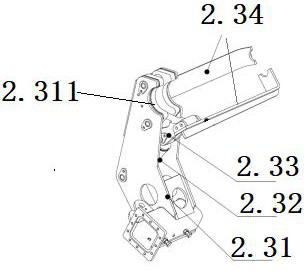

[0048] Such as Figure 1-2 As shown, the pipe shed pipe grabbing assembly 2 includes a rotating shaft 2.1, a power part 2.2, a first manipulator 2.3, a mounting seat 1 and a mounting seat 2; the rotating shaft 2.1 is arranged on the rock drilling jumbo 1 through the mounting seat 1 The propulsion mechanism 1.1 (such as a propulsion beam), and the axial direction of the rotating shaft 2.1 is parallel to the length direction of the propulsion mechanism 1.1; the power part 2.2 is installed on the propulsion mechanism 1.1 through the mounting seat 2, and the output end of the power part 2.2 Connected with the rotating shaft 2.1, the rotating shaft 2.1 can be driven to rotate through the power part 2.2, and the power part 2.2 is preferably a motor;

[0049] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com