Assembly and detection all-in-one machine and assembly and detection method thereof

A detection method and an all-in-one machine technology, applied in metal processing equipment, sorting, metal processing, etc., can solve the problems of investing a large amount of process station auxiliary equipment, high overall cost, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

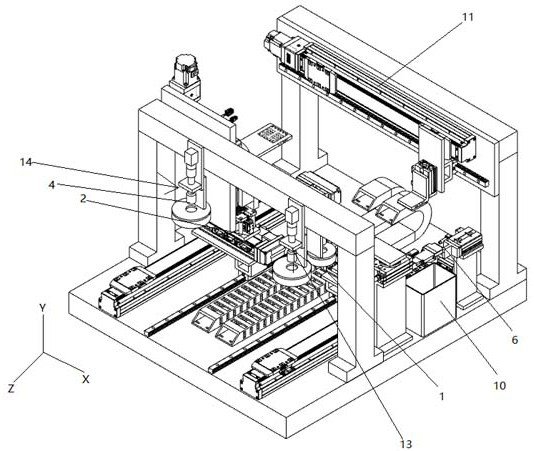

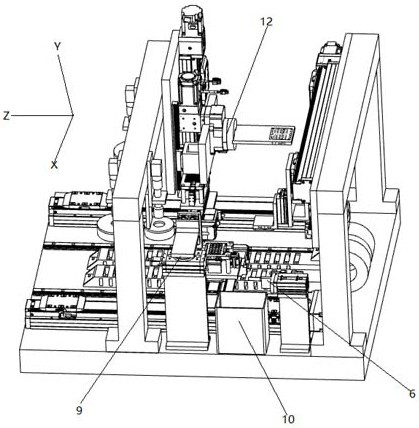

[0052] Please refer to Figures 1 to 4 , this embodiment mainly introduces the structure of the assembly and detection all-in-one machine, including the workbench, which is equipped with:

[0053] The first feeding mechanism includes a first feeding device 1, a first detector 13 and a waste kicking mechanism; the first feeding mechanism is used for feeding, detecting and screening a group of first workpieces;

[0054] An assembly mechanism, including a transfer module and an overturning assembly device 12; the assembly mechanism is used for assembling and laminating a group of first workpieces and a group of second workpieces;

[0055] The second feeding mechanism includes a second feeding device 2 and a second detector 14; the second feeding mechanism is used for loading a group of second workpieces, detecting and unloading a group of processed parts.

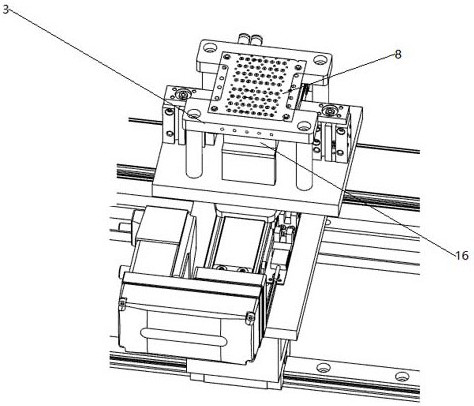

[0056] Wherein, the first feeding device 1 and the second feeding device 2 have the same structure, and both are composed o...

Embodiment 2

[0063] The improvement and replacement scheme of this embodiment on embodiment 1, the same parts will not be described in detail;

[0064] The first moving module includes X-axis, Y-axis and Z-axis perpendicular to each other, so as to realize the position adjustment of the three-dimensional carrier 3;

[0065] The first detection machine 13 and the second detection machine 14 also include a mechanical arm, the industrial camera 4 is arranged at the moving end of the mechanical arm, and the mechanical arm can detect the position of the carrier 3 through a displacement sensor to adjust the position of the industrial camera 4 Location;

[0066] The turntable 9 on the second mobile module can be replaced by X-axis and Z-axis to realize plane displacement;

[0067] The width of the auxiliary clamping block 15 is adapted to the distance between adjacent workpieces.

Embodiment 3

[0069] This embodiment mainly introduces the assembly and detection method of the assembly and detection all-in-one machine, including the following steps:

[0070] S100 The first loading device transports the first workpiece to the first inspection station, and the second loading device transports the second workpiece to the assembly station;

[0071] S200 The first inspection machine performs defect judgment on the first workpiece at the first inspection station; the first inspection machine generates the overall defect map of the workpiece and transmits it to the computing device; the computing device uses the overall defect map of the workpiece according to the The arrangement of the holes is divided into several workpiece data, and the computing equipment judges the workpiece data, analyzes the judgment results, and divides them into qualified parts and waste parts;

[0072] The S300 waste kicking mechanism performs waste kicking treatment on the first workpiece according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com