Turn-over and detection integrated device for flange processing

A kind of equipment, turning technology, applied in the direction of metal processing equipment, grinding/polishing equipment, cleaning methods and utensils, etc., can solve the problems of misjudgment, flange classification waste, detected data errors, etc., to achieve accurate structure, The effect of facilitating hole alignment and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

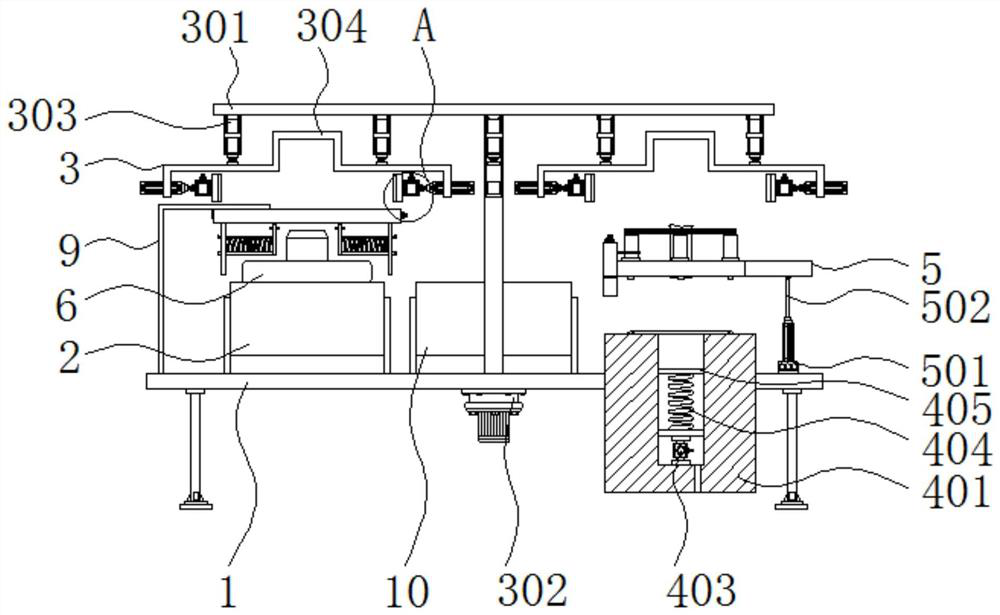

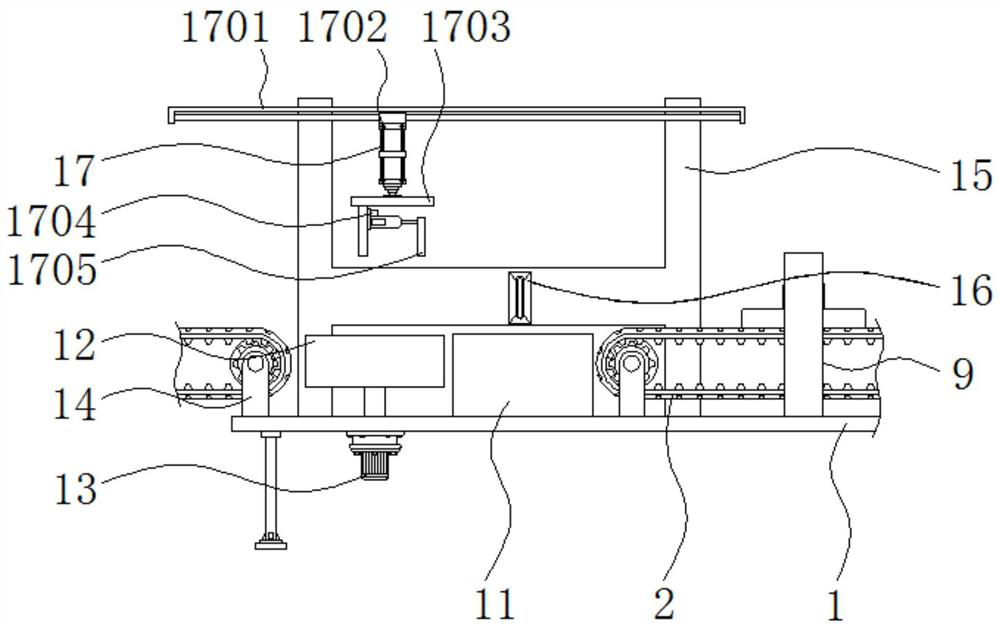

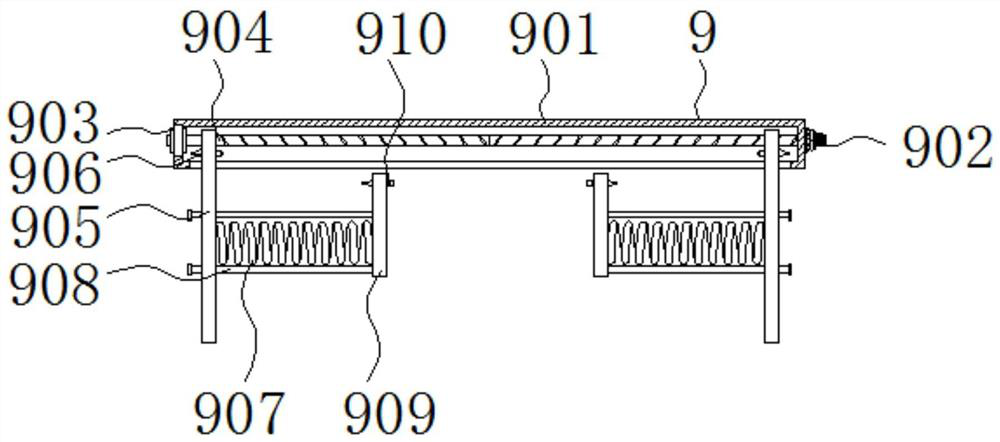

[0029] Such as Figure 1 to Figure 6As shown, the present invention provides a technical solution: an integrated equipment for turning over and detecting flanges, including an equipment base 1 and an upper airtight detection assembly 5, and the front side of the upper end of the equipment base 1 is sequentially provided with widths from left to right. The measuring mechanism 9, the first belt conveyor 2, the transfer and turning structure 3, the lower airtight detection assembly 4 and the upper airtight detection assembly 5, and the upper end of the first belt conveyor 2 is placed with a flange body 6, and the upper airtight detection assembly The left side of the upper end of the component 5 is connected with the rotating component 8 through the second transmission belt 7, and the rear side of the upper end of the equipment base 1 is provided with a cleaning box 11, a fixed frame 15 and a second belt conveyor 10 in sequence from left to right, and the cleaning The rear end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com