A motor bearing precision mounting machine

A technology for installing machines and motors, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low work efficiency, labor, and high labor intensity, and achieve good installation quality, improved quality, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

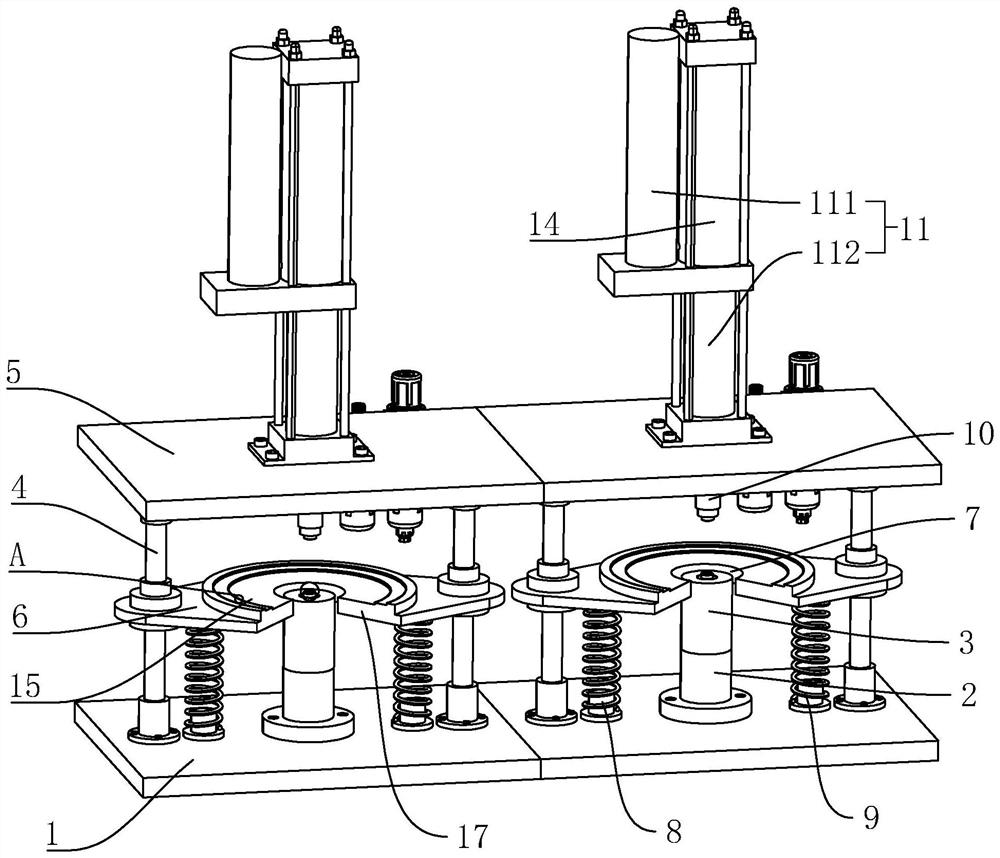

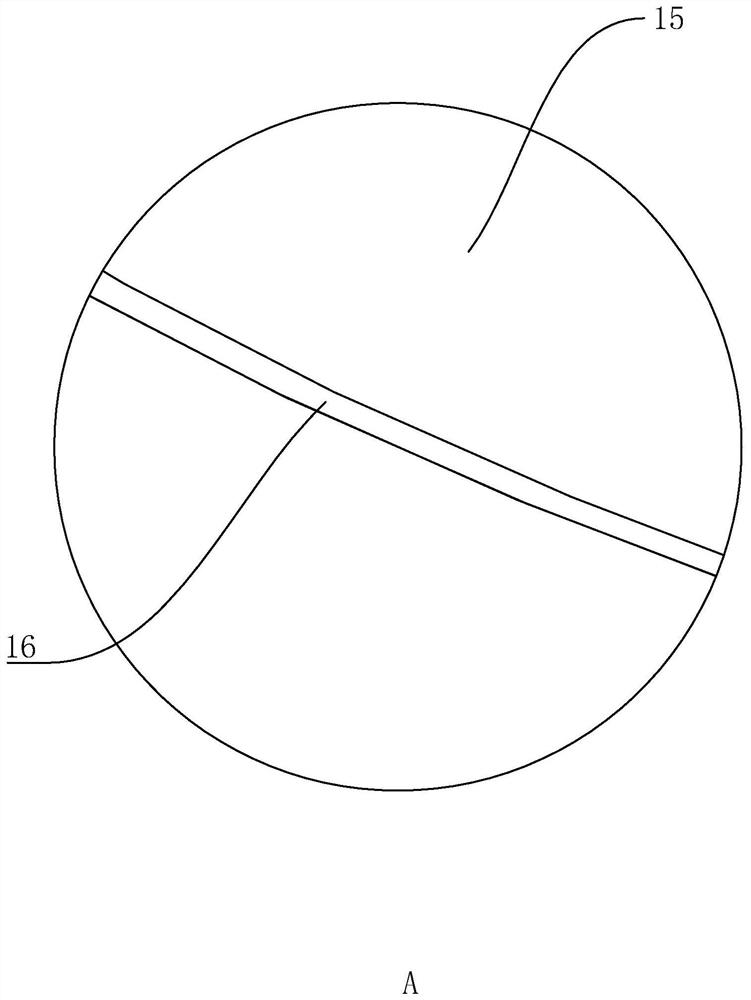

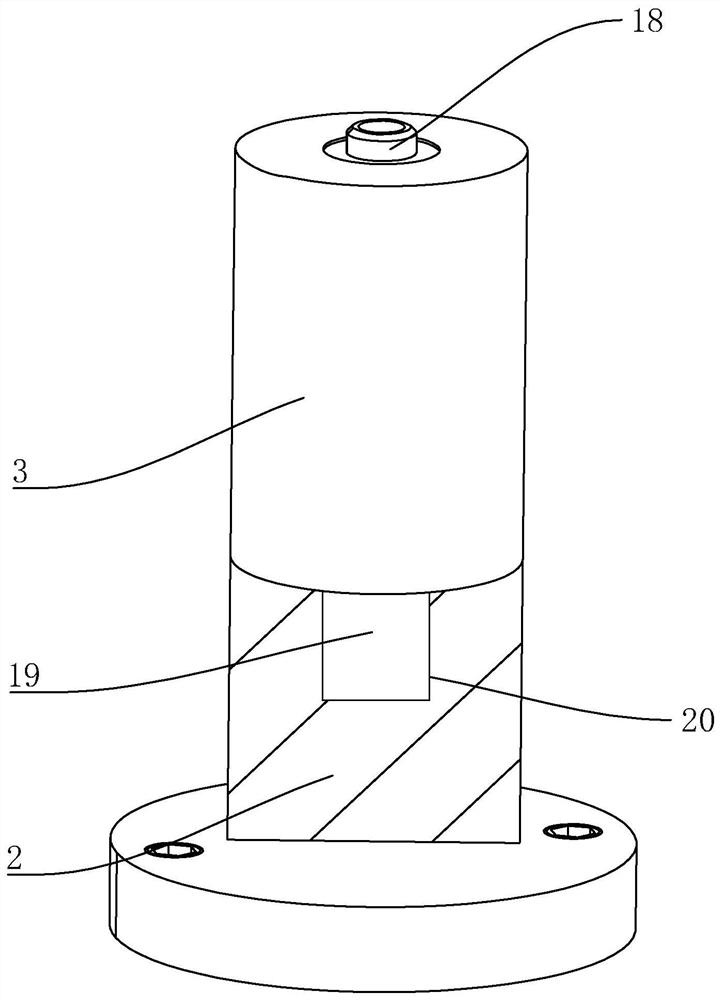

[0034] Example: a precision mounting machine for motor bearings, such as figure 1 As shown, including a support frame 1, the upper end of the support frame 1 is fixedly connected with four guide support rods 4, wherein every two guide support rods 4 are a group, and the upper end of each group of guide support rods 4 is fixedly connected with a support plate 5 , an end cover placing plate 6 is arranged between the support plate 5 and the upper end face of the support frame 1, the end cover placing plate 6 is slidably connected between the two guiding support rods 4, and the center position of the end cover placing plate 6 is provided with an installation slot 7. The upper end of the support plate 5 is provided with a drive mechanism 11, and the drive mechanism 11 is linked with a pressing punch 10. The pressing punch 10 is slidably inserted on the support plate 5 and is arranged opposite to the end cover placement plate 6. The support frame 1 The upper end is provided with a b...

specific Embodiment approach

[0042] Specific implementation: firstly, the sealing ring is sleeved on the outer side of the fixed rod 13, then the bearing is placed on the upper end of the bearing placing table 3, and finally the motor end cover is placed on the upper end of the end cover placing plate 6, and then the cylinder 14 is activated, and the piston of the cylinder 14 The rod is linked with the piston rod of the second oil cylinder 112, and the piston rod of the second oil cylinder 112 is linked with the pressing punch 10, so that the pressing punch 10 drives the sealing ring to move down quickly, the sealing ring can be quickly installed in the end cover, and then the first An oil cylinder 111 makes the first oil cylinder 111 link with the second oil cylinder 112, so that the pressing punch 10 can continue to abut the end cover, so that the bearing can be accurately installed in the end cover, and the sealing ring and the bearing can be installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com