Method for improving reliability of main engine of oil-free screw compressor, and axial bearing locking structure

An axial bearing and compressor technology, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc. The assembly process is simple, the mechanical reliability is improved, and the process is controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method to improve the reliability of an oil-free screw compressor. It changes the installation position of the locking round nut and the synchronous gear on the rotor shaft, so that the locking round nut is installed next to the axial bearing, and the locking round nut is directly pressed on the On the inner shaft ring of the axial bearing, it is transmitted to the outer shaft ring through balls, and finally to the body through the outer shaft ring, so that the synchronous gear is not affected by the axial thrust during the working process, and the work of the synchronous gear is improved. The purpose of the condition is to prolong its service life and improve the reliability of the compressor. The synchronous gear includes a synchronous driving gear installed on the male rotor shaft and a synchronous driven gear installed on the female rotor shaft, and the locking round nut also includes The locking round nut, the axial bearing also includes the axial bearing install...

Embodiment 2

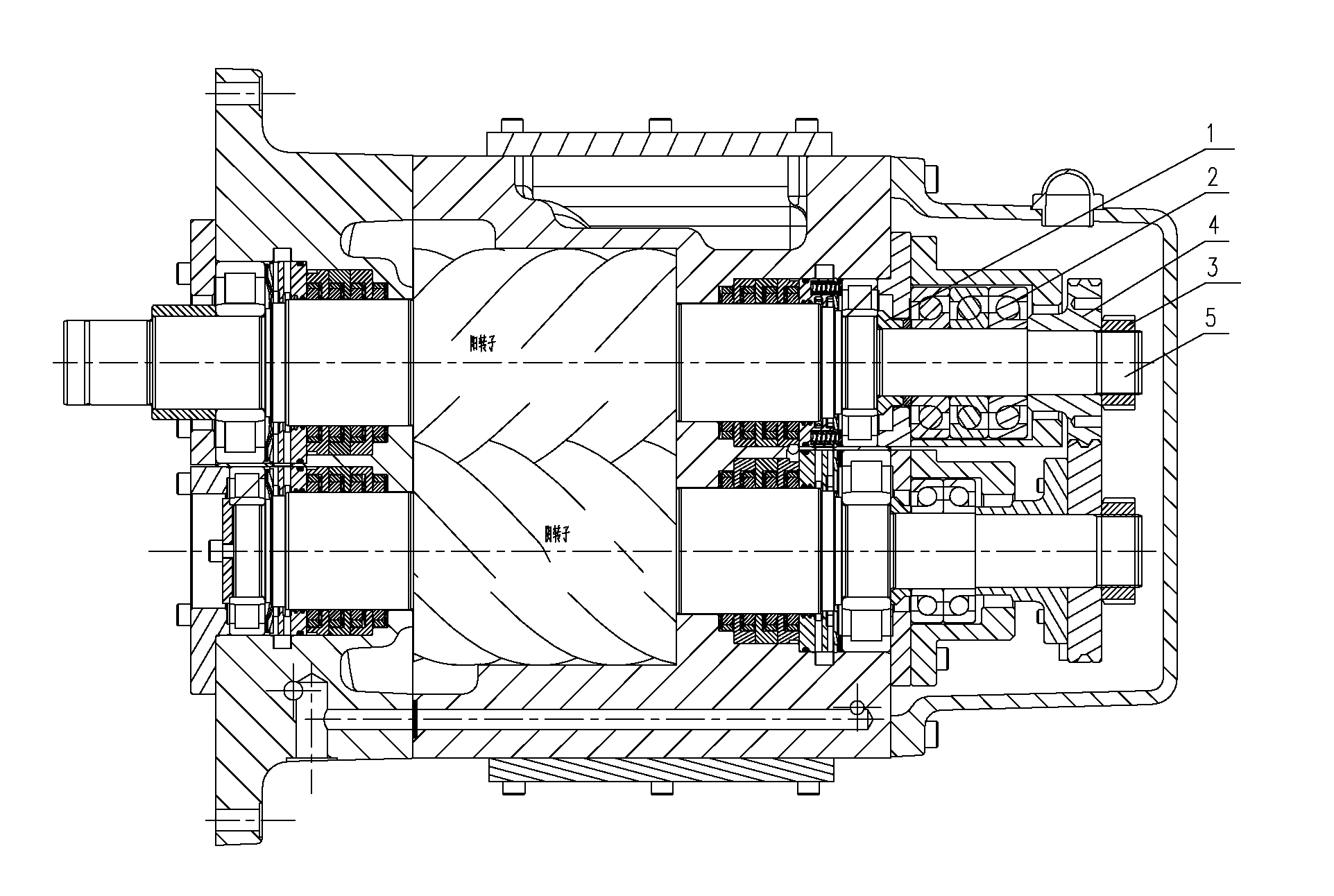

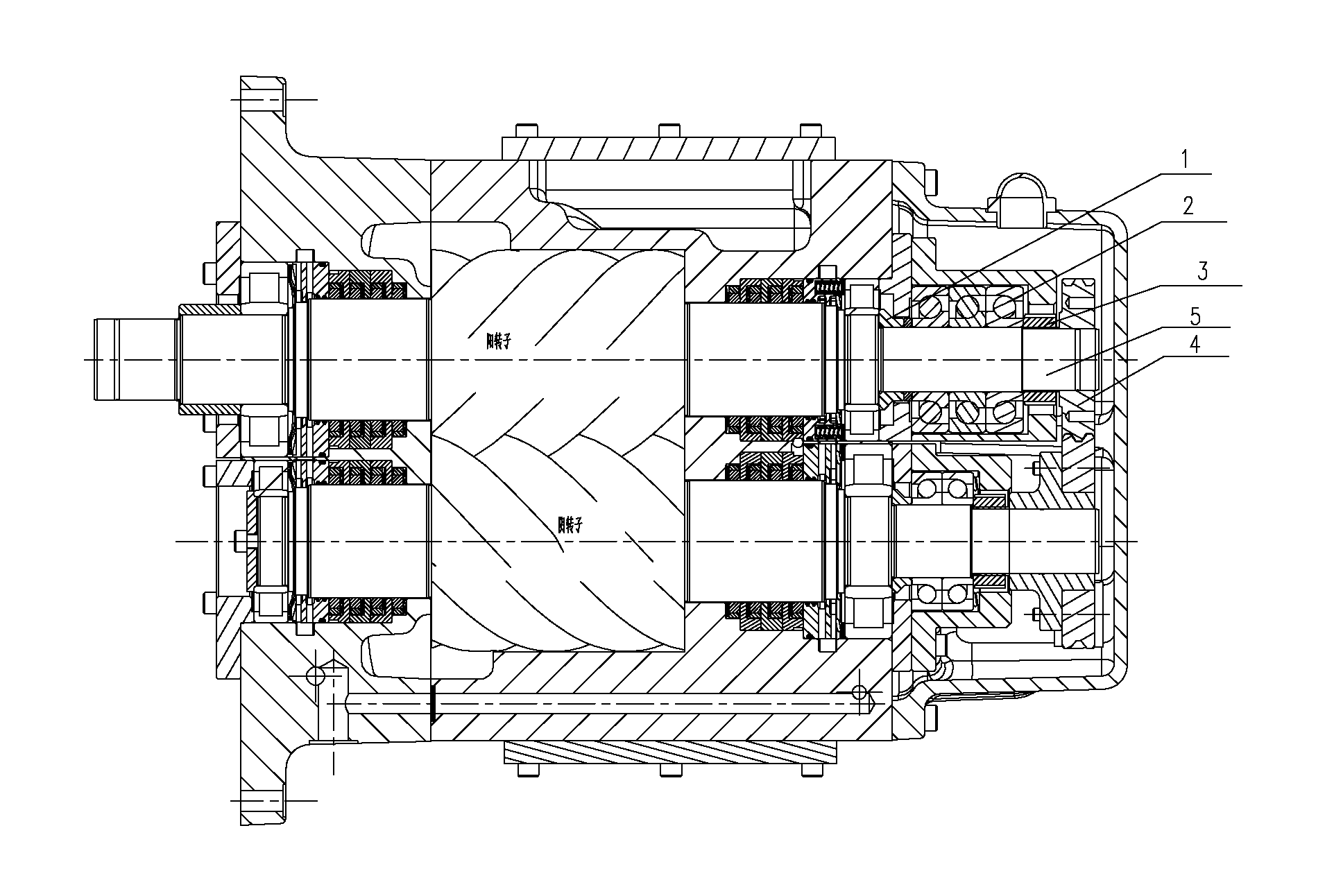

[0020] Such as figure 2 shown.

[0021] A locking structure for the axial bearing of the main engine of an oil-free screw compressor, which is mainly composed of an adjusting pad 1, an axial bearing 2, a locking round nut 3 and a synchronous gear 4, and the adjusting pad 1 is connected with the rotor shaft (including the male rotor and the female rotor) Rotor (with the same structure) offsets the left end of the axial bearing 2 to locate the left end. The axial bearing 2 is installed and positioned on the rotor shaft 5 between the adjusting pad 1 and the locking round nut 3. The locking round nut 3 realizes the axial The right end of the bearing is fixed, and the synchronous gear 4 is installed on the rotor shaft 5, the outside of the locking round nut 3. Such as figure 2 shown. In the present invention, the locking round nut 3 is moved between the axial bearing 2 and the synchronous gear 4, and the assembly is to adjust the rotor exhaust end surface clearance (the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com