Method for carrying out double-side deburring on injection-molded part

A technology for deburring and injection molding parts, applied in the field of deburring equipment, can solve the problems of increased noise on the sliding surface of the machine, laminar flow, affecting the normal operation of the system, etc., and achieve the effect of accurate deburring operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

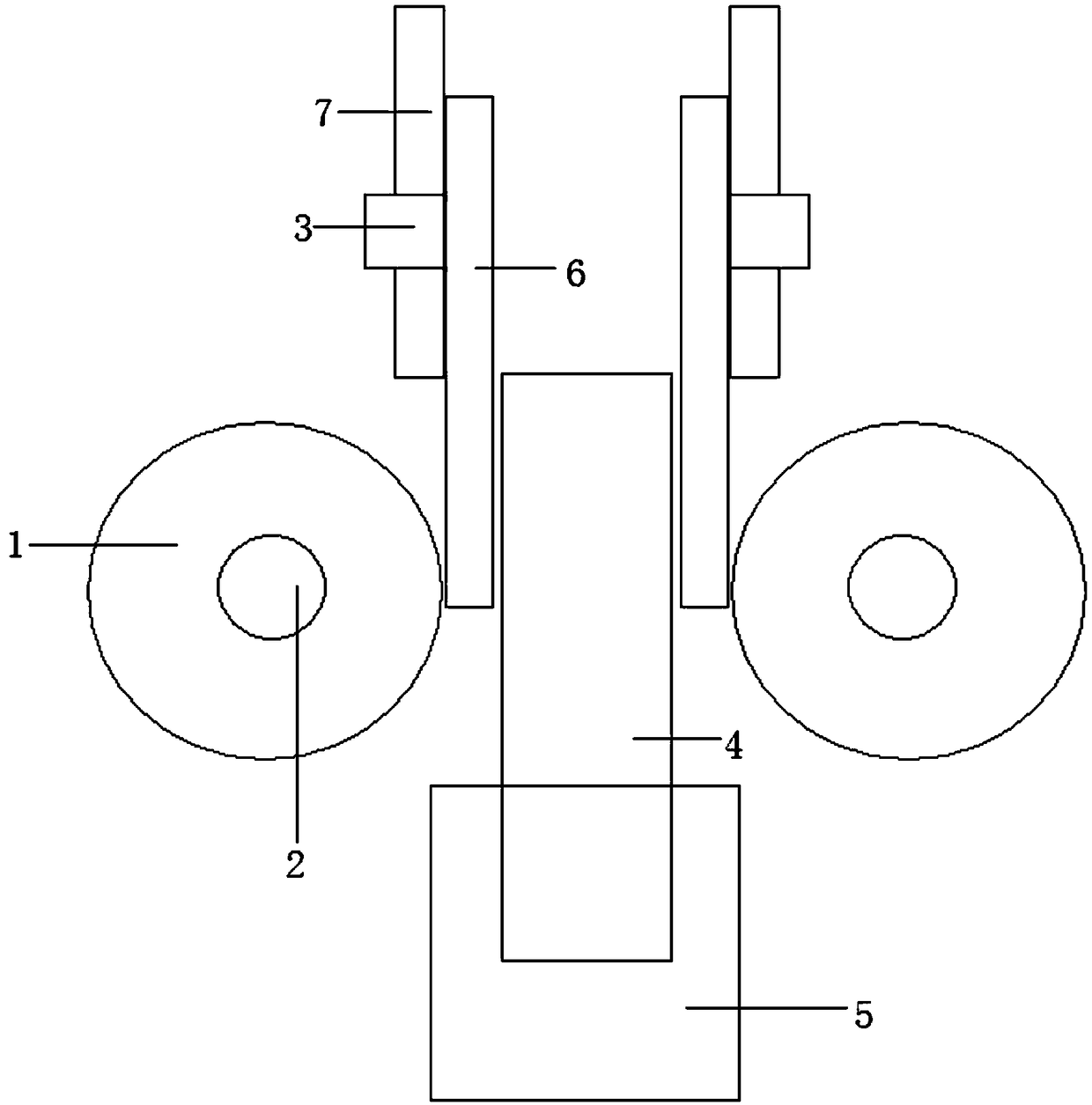

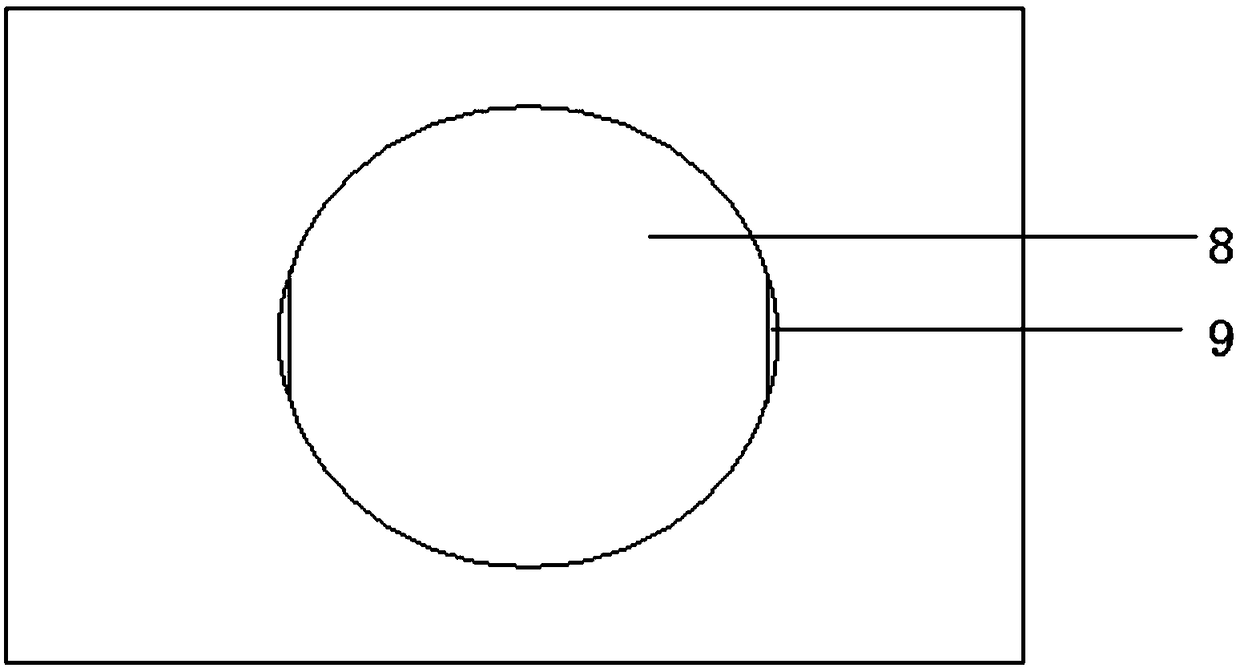

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0027] Such as Figure 1-Figure 2 As shown, the present invention includes the following technical features: pressing plate 1, rotating shaft 2, slider 3, injection molded part to be deburred 4, clamping device 5, push plate 6, fixing plate 7, cylindrical groove 8, elongated Groove 9.

[0028] A method for double-sided deburring of injection molded parts of the present invention comprises the following steps:

[0029] The first step: make the clamping device, choose a square clamping block, dig a groove in the center of the clamping block, and this groove is used to fix the injection molded part to be deburred;

[0030] The second step: install the push dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap