A chemical inspection and repair equipment trolley

A trolley and equipment technology, applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of difficult and fast completion of equipment, heavy equipment, etc., to reduce personnel input and cost, small structure, small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

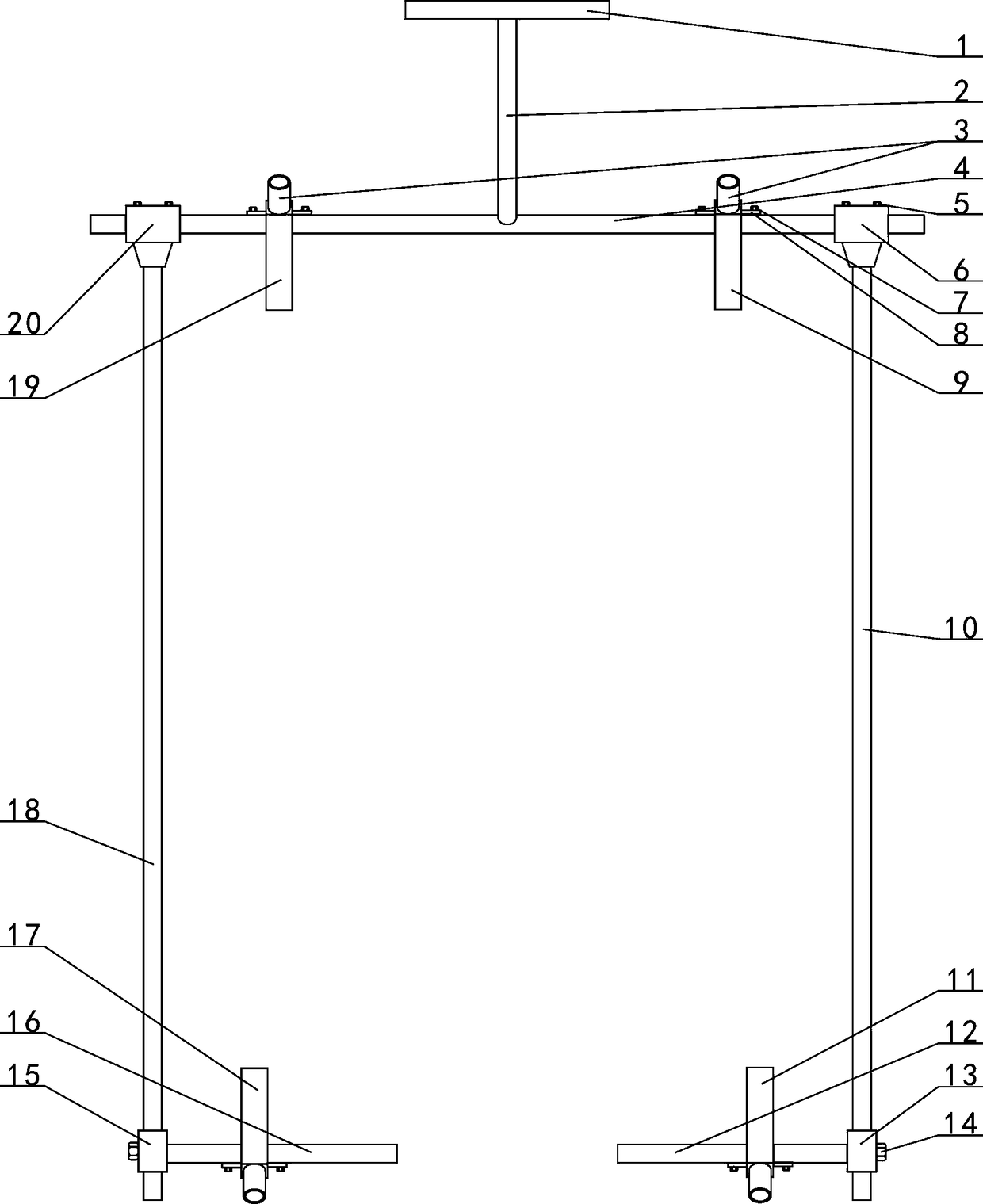

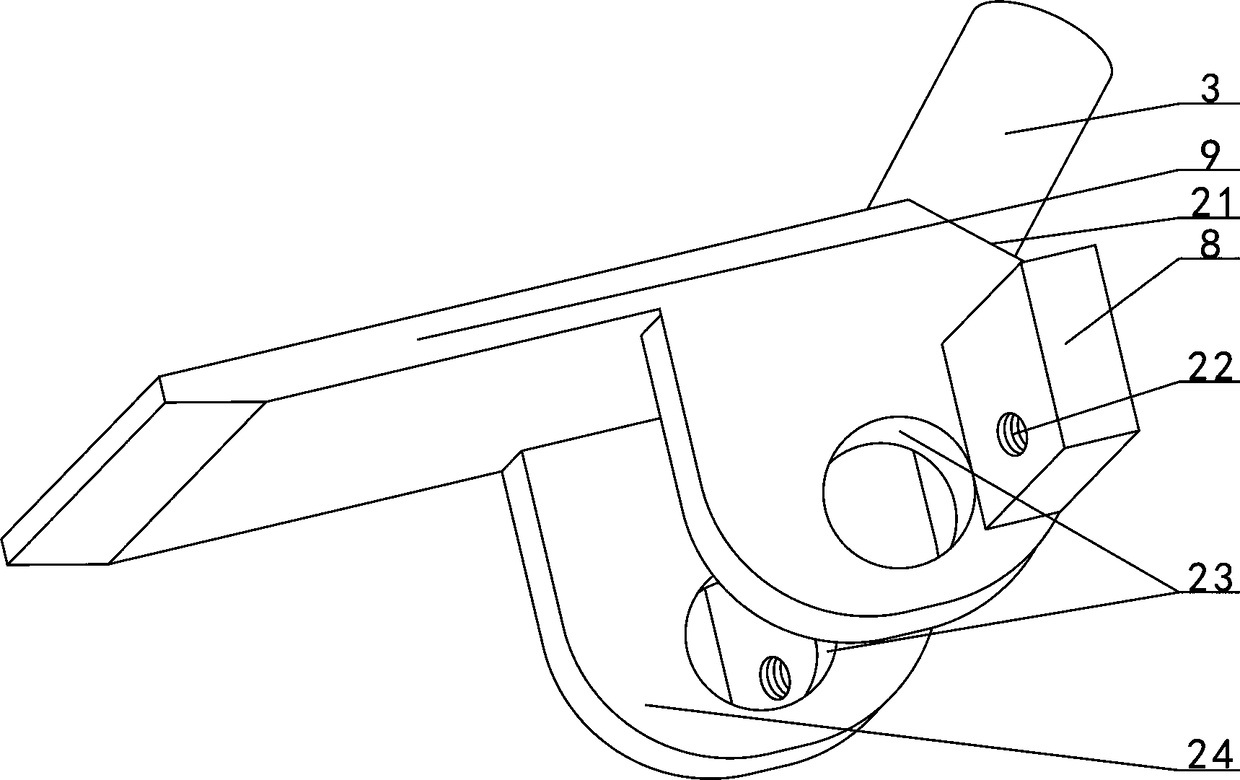

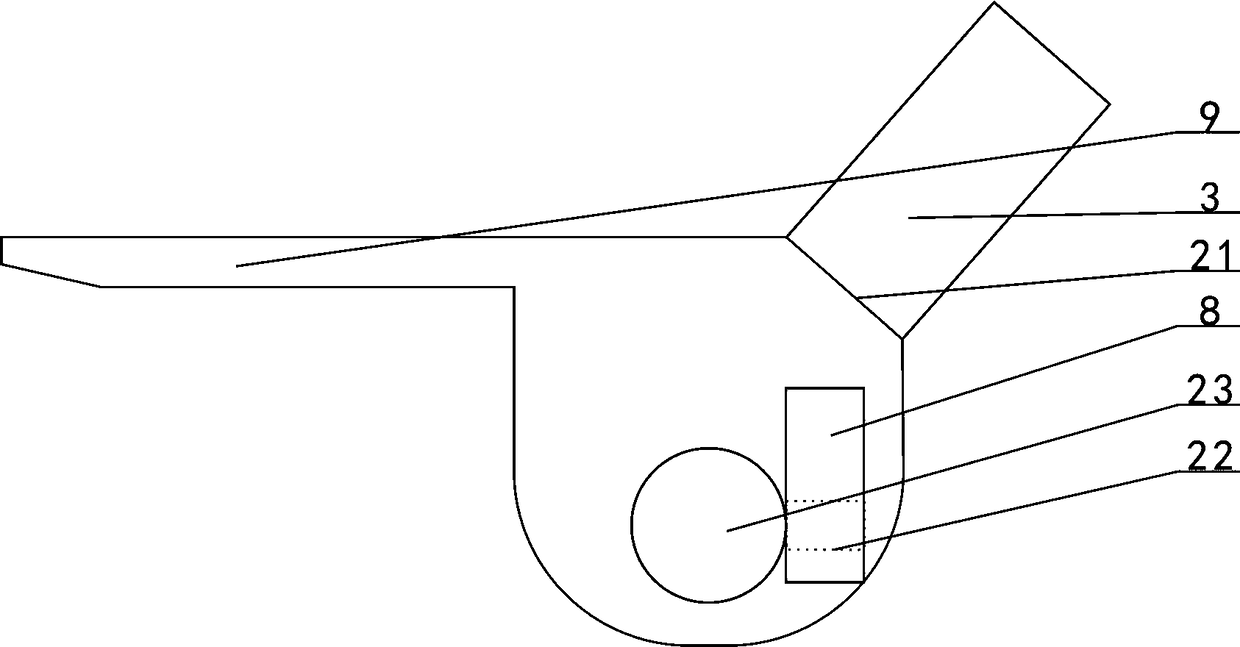

[0028] combined with Figure 1-9 The trolley for chemical maintenance equipment described in includes pull rod 2, front rod 4, connecting rod A10, connecting rod B18, rear rod A12, rear rod B16, wheels, shovel plate and crowbar intubation tube 3. The front end of the pull rod 2 is provided with a handle 1, and the handle 1 arranged at the front end of the pull rod 2 is a ring structure or a straight structure. Shovel plates with wheels are respectively arranged on the top, and a plurality of equidistant blind holes 25 are arranged on the front surface of the front ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com