Patents

Literature

42results about How to "Won't twist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

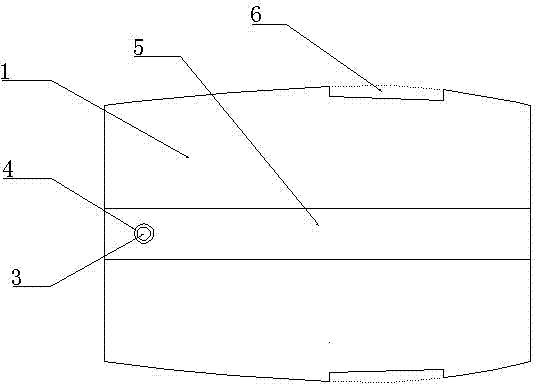

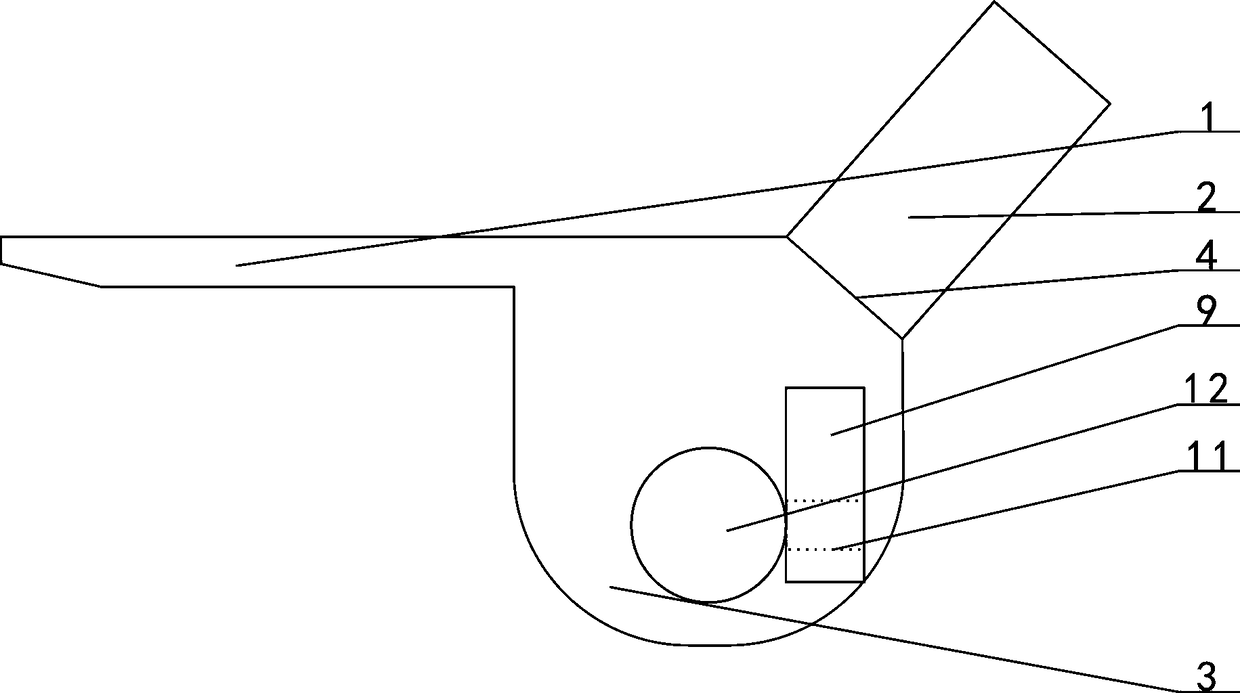

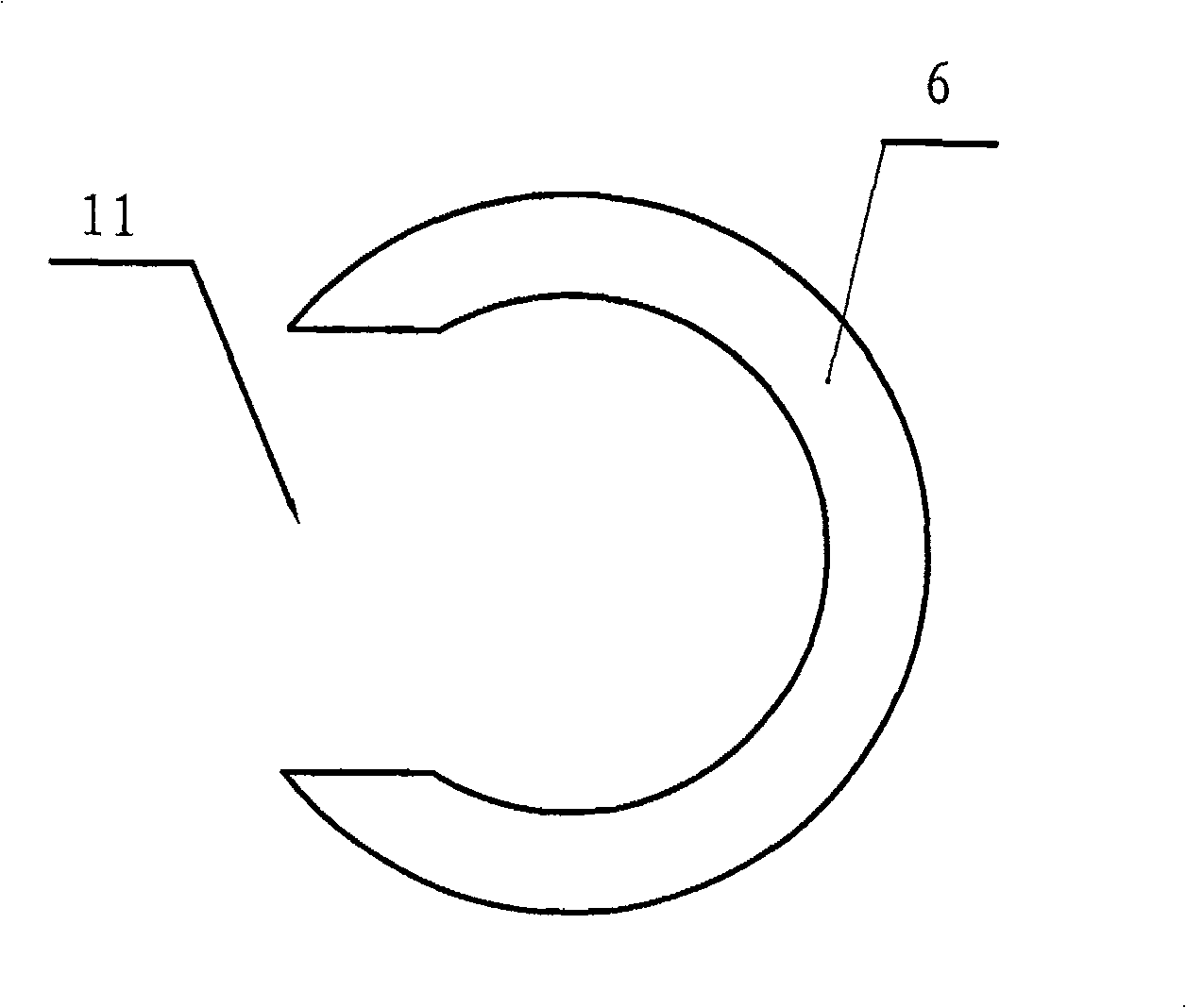

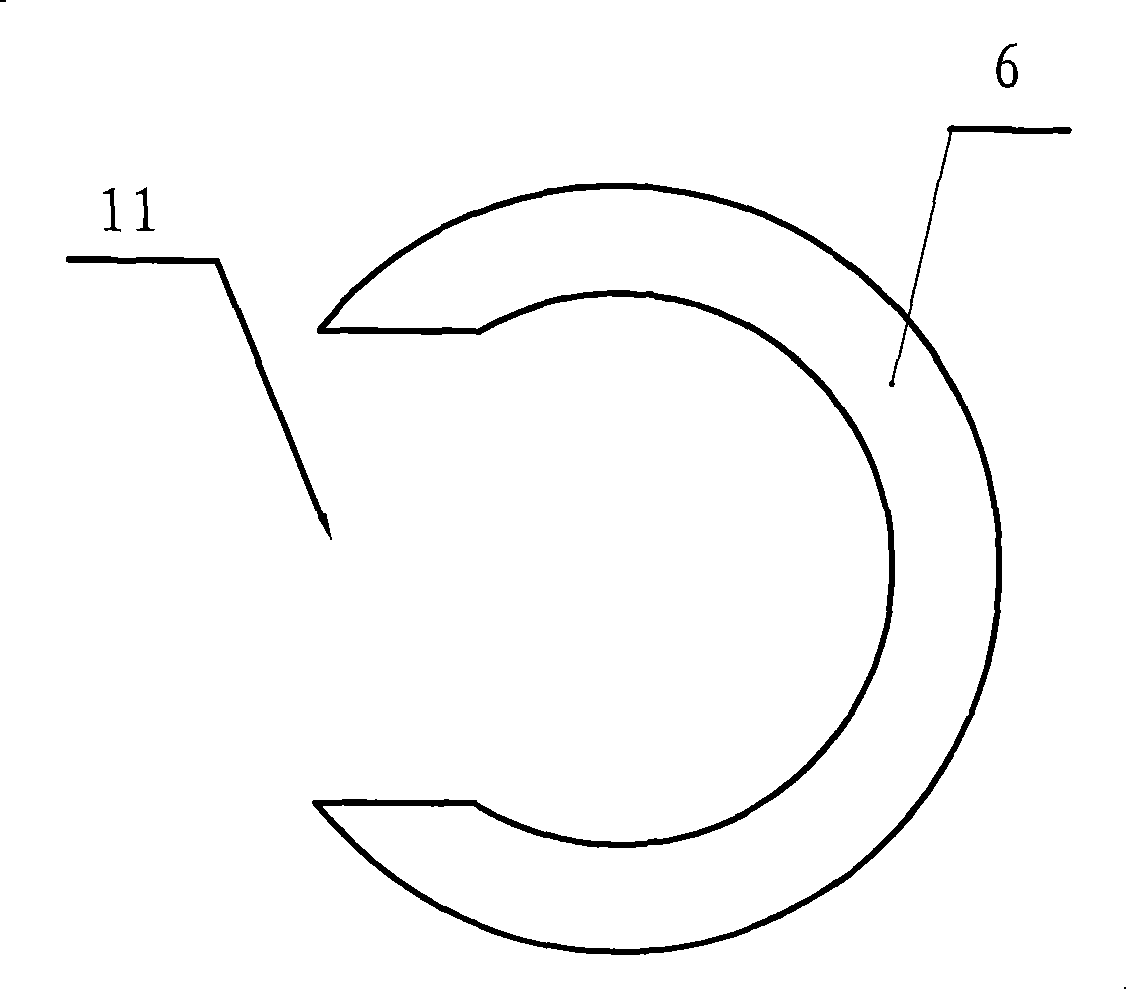

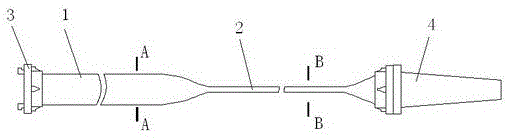

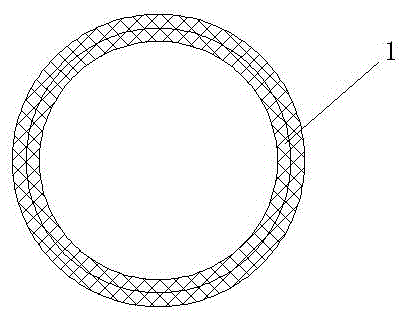

Friction roller suitable for conical bobbin

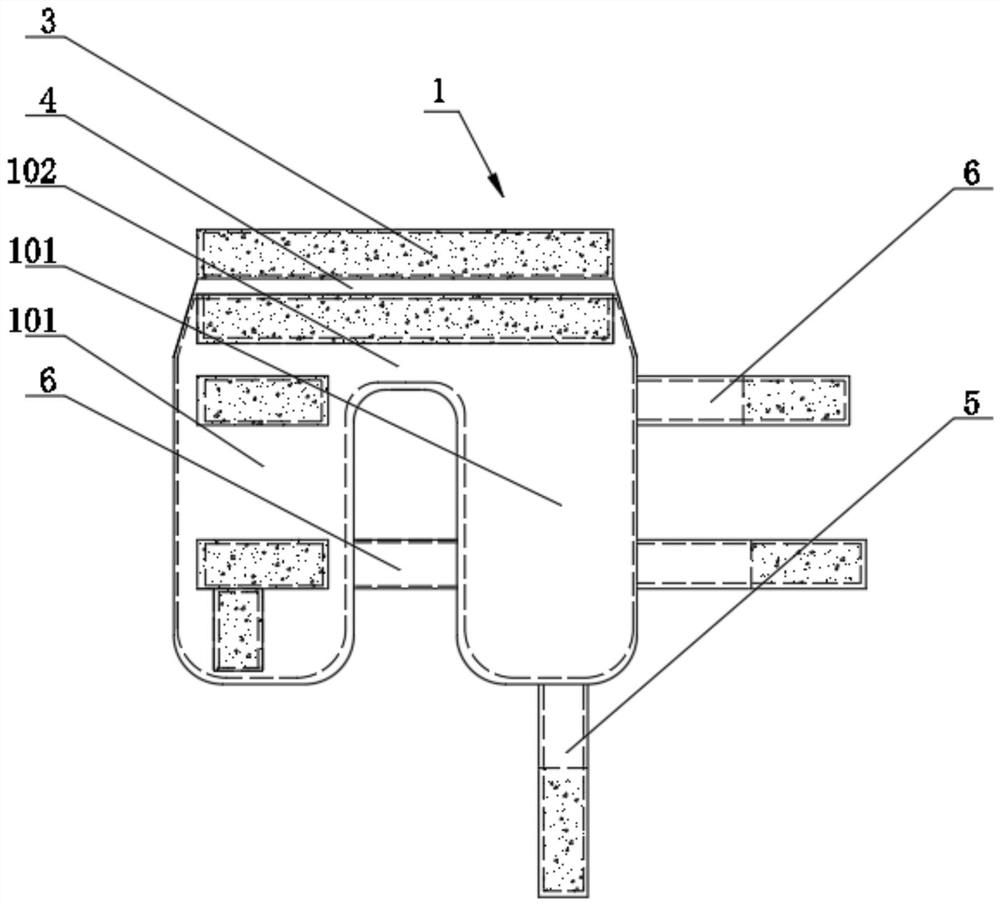

The invention discloses a friction roller suitable for a conical bobbin. The friction roller suitable for the conical bobbin comprises a friction roller body (1), a rubber sheet (2) and a jackscrew (3). The friction roller suitable for the conical bobbin is characterized in that the friction roller body is a cylinder with the side face protruded and is provided with a rubber sheet shallow groove (6) which surrounds the friction roller body (1) for a circle and is arranged in the side deviating the centerline of the side face of the friction roller, the rubber sheet (2) is in a ring shape with a certain width, and the rubber (2) is arranged on the side face of the friction roller body (1) along the periphery in a sleeved mode. According to the friction roller suitable for the conical bobbin, an irregular cylindrical friction roller is changed to the friction roller with the protruded side face, the conical bobbin can not be distorted or twisted in the process of winding, a maximum outside diameter part is moved to the rubber sheet (2), and crimp is guaranteed and slipping can not happen when the rubber sheet and the conical bobbin (7) is in complete contact. The friction roller suitable for the conical bobbin has the advantages of being simple in structure, stable in working and the like.

Owner:WUJIANG YILAI TEXTILE SCI & TECH

Scrubbing-type cleaning device for communication cables

ActiveCN108526115AEasy to cleanWon't twistCleaning using toolsCleaning using liquidsWater useEngineering

Owner:陈建明

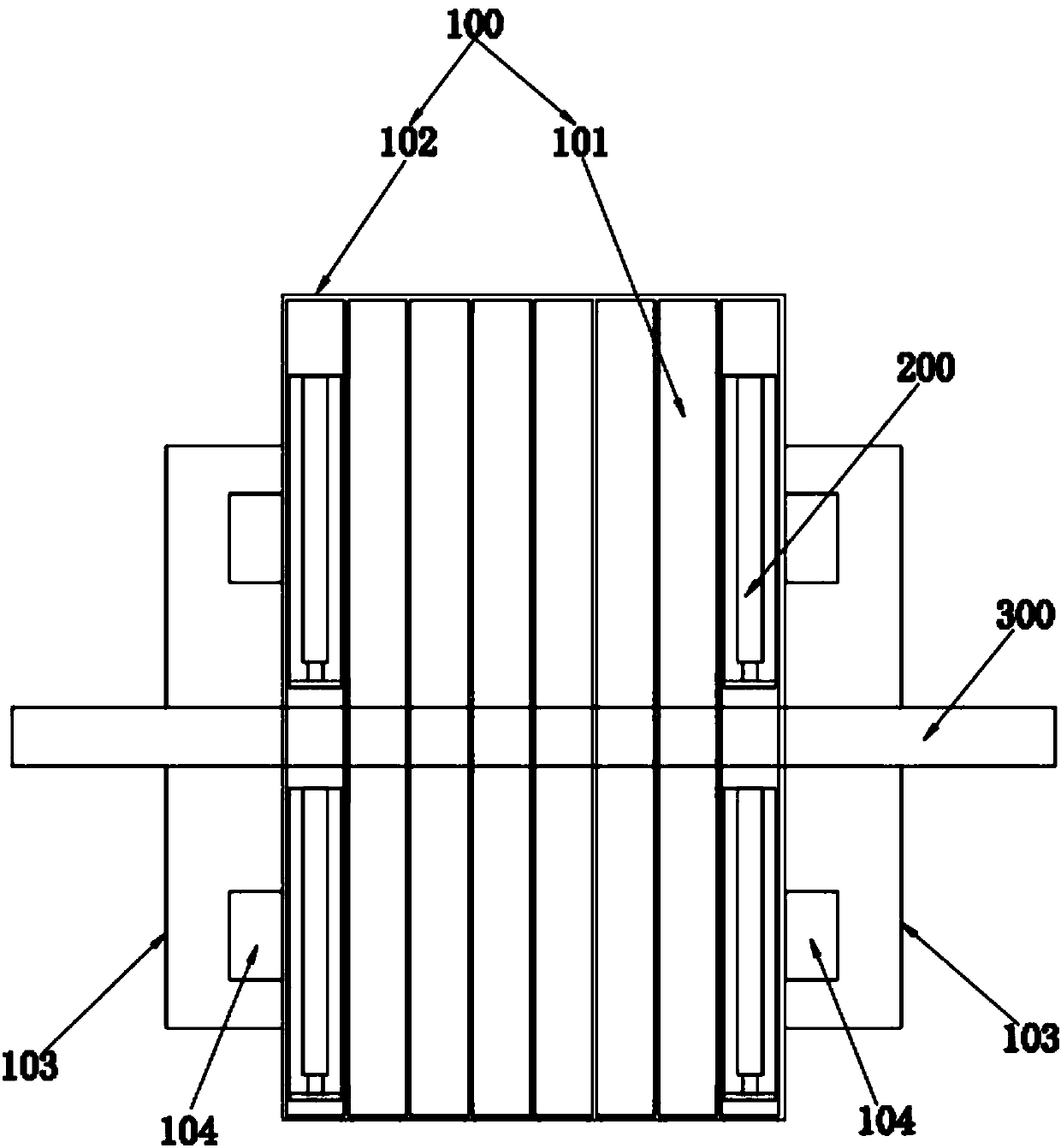

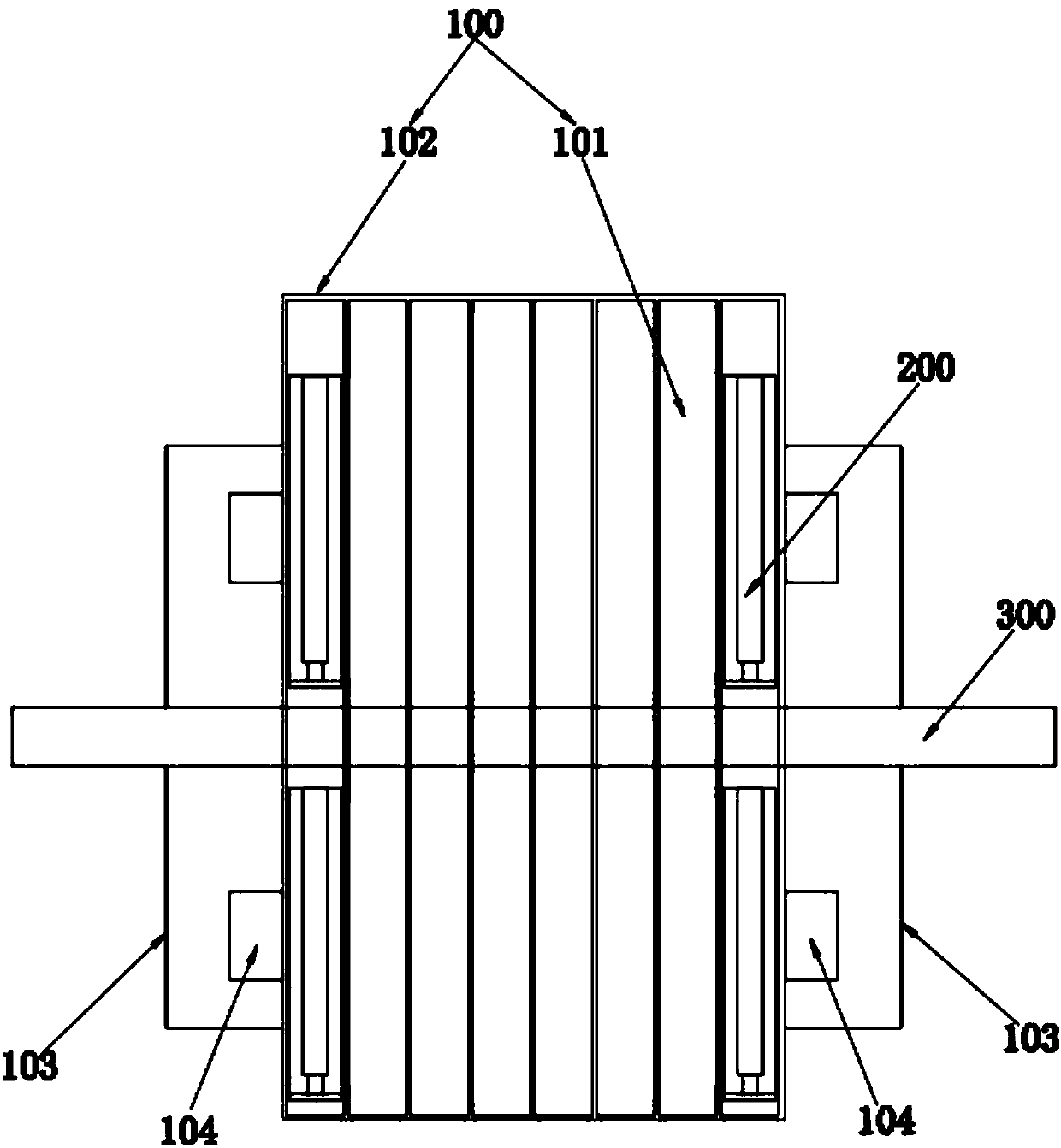

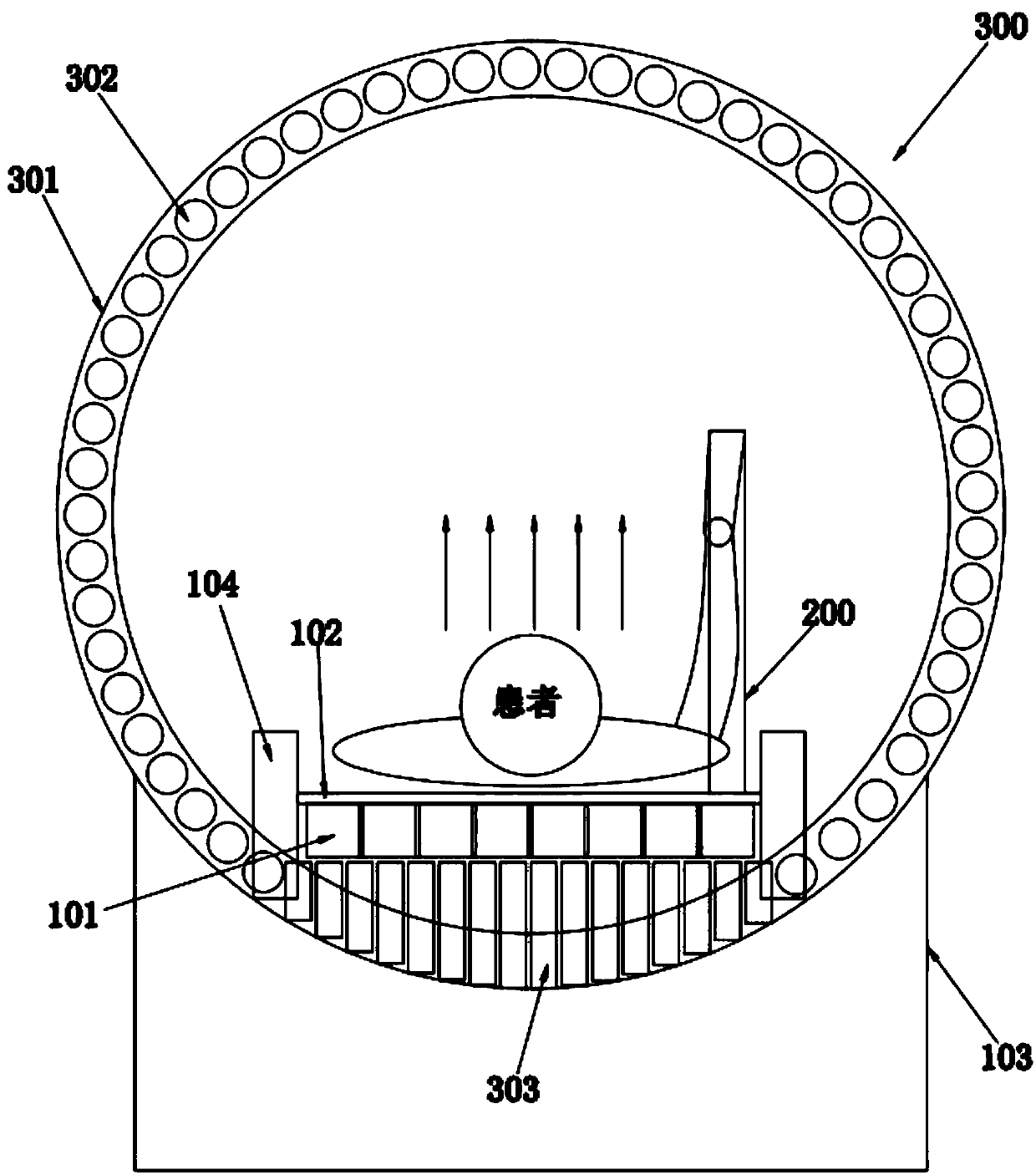

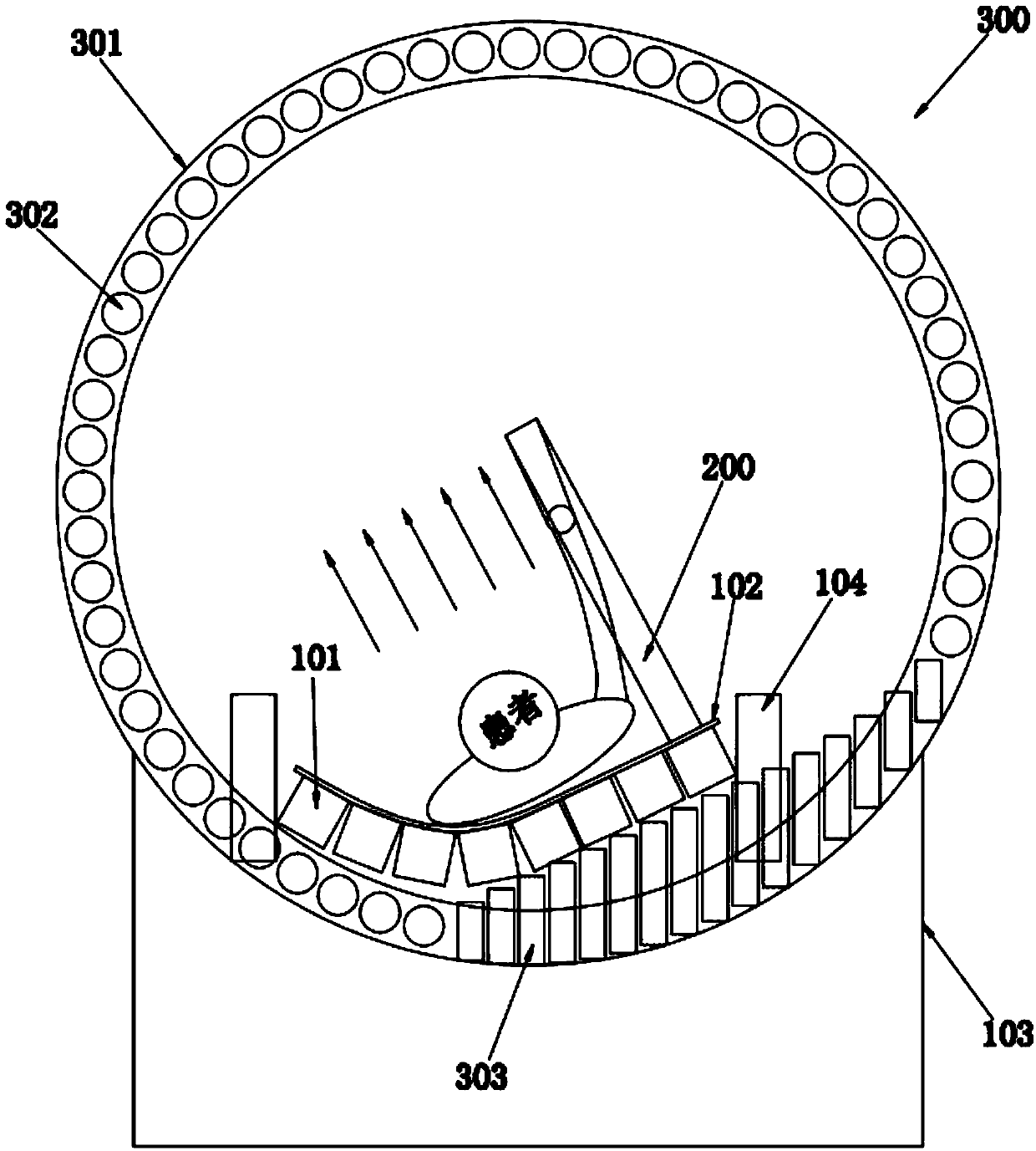

Hospital bed

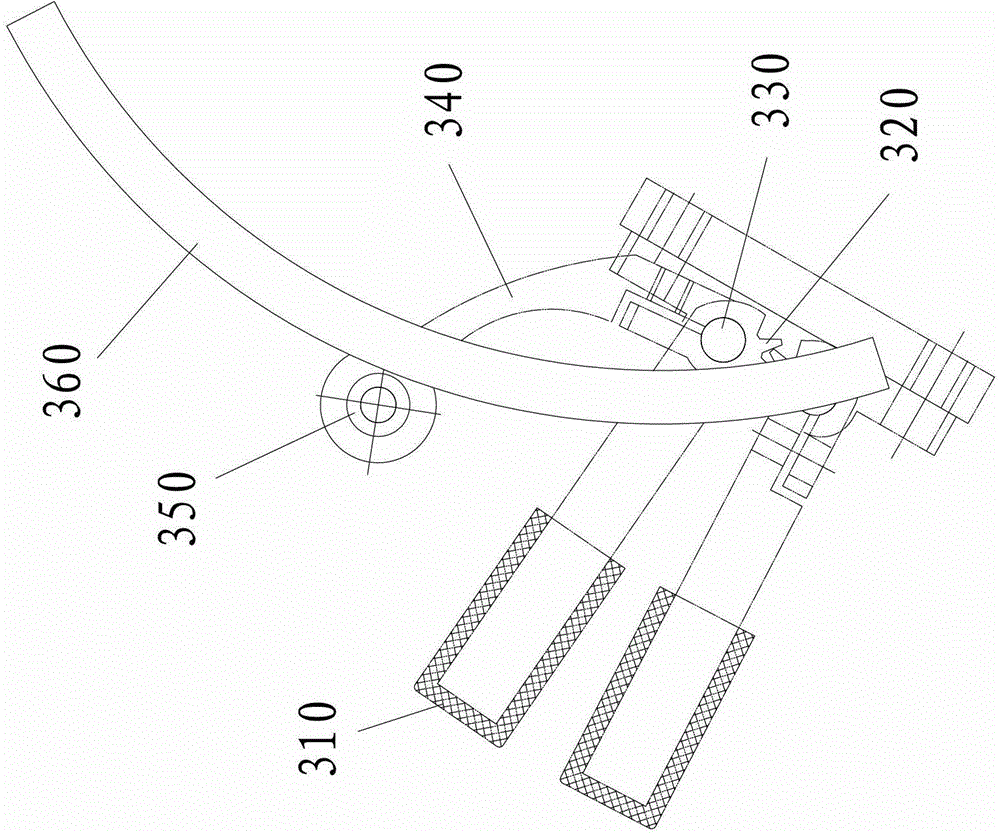

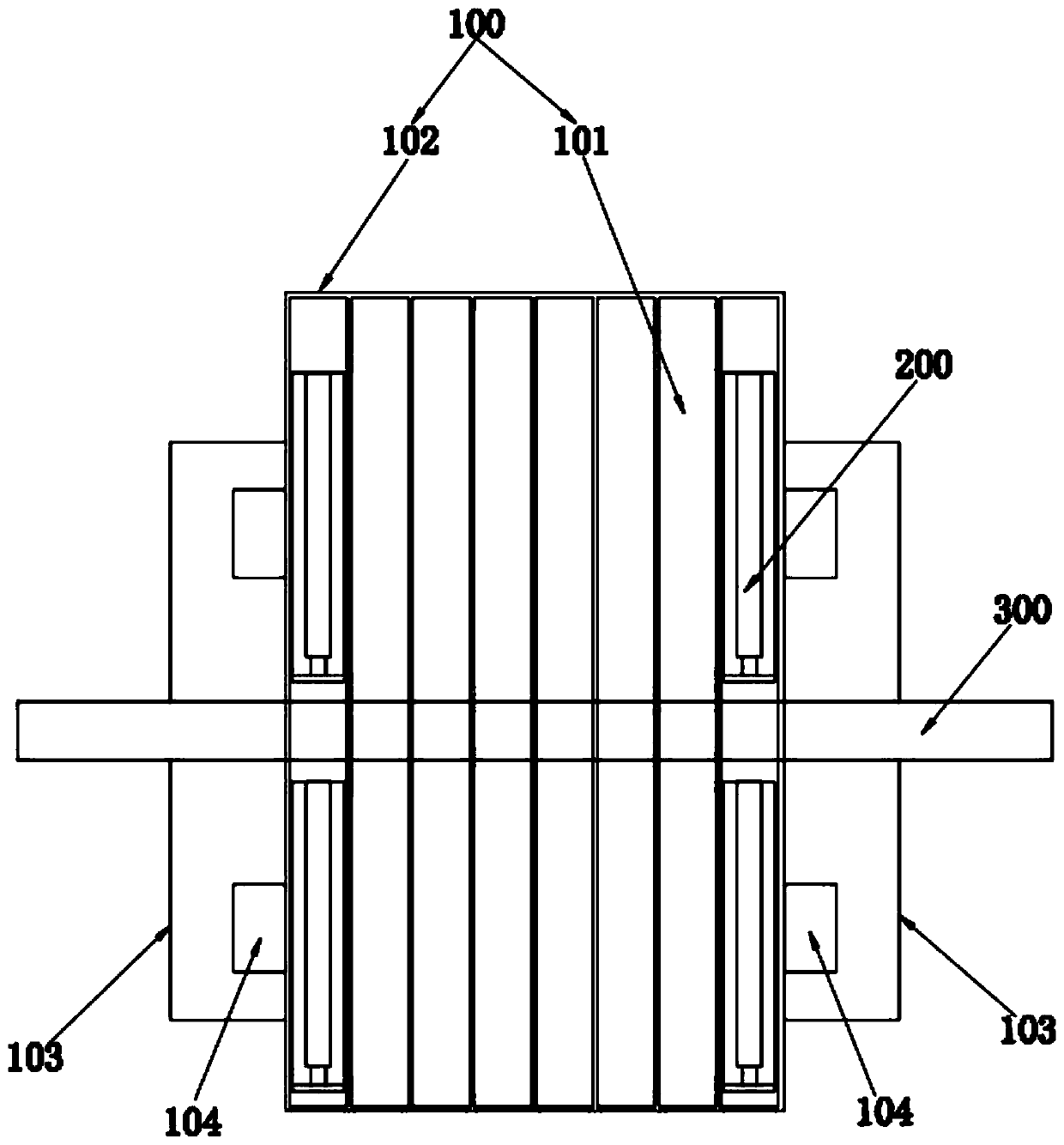

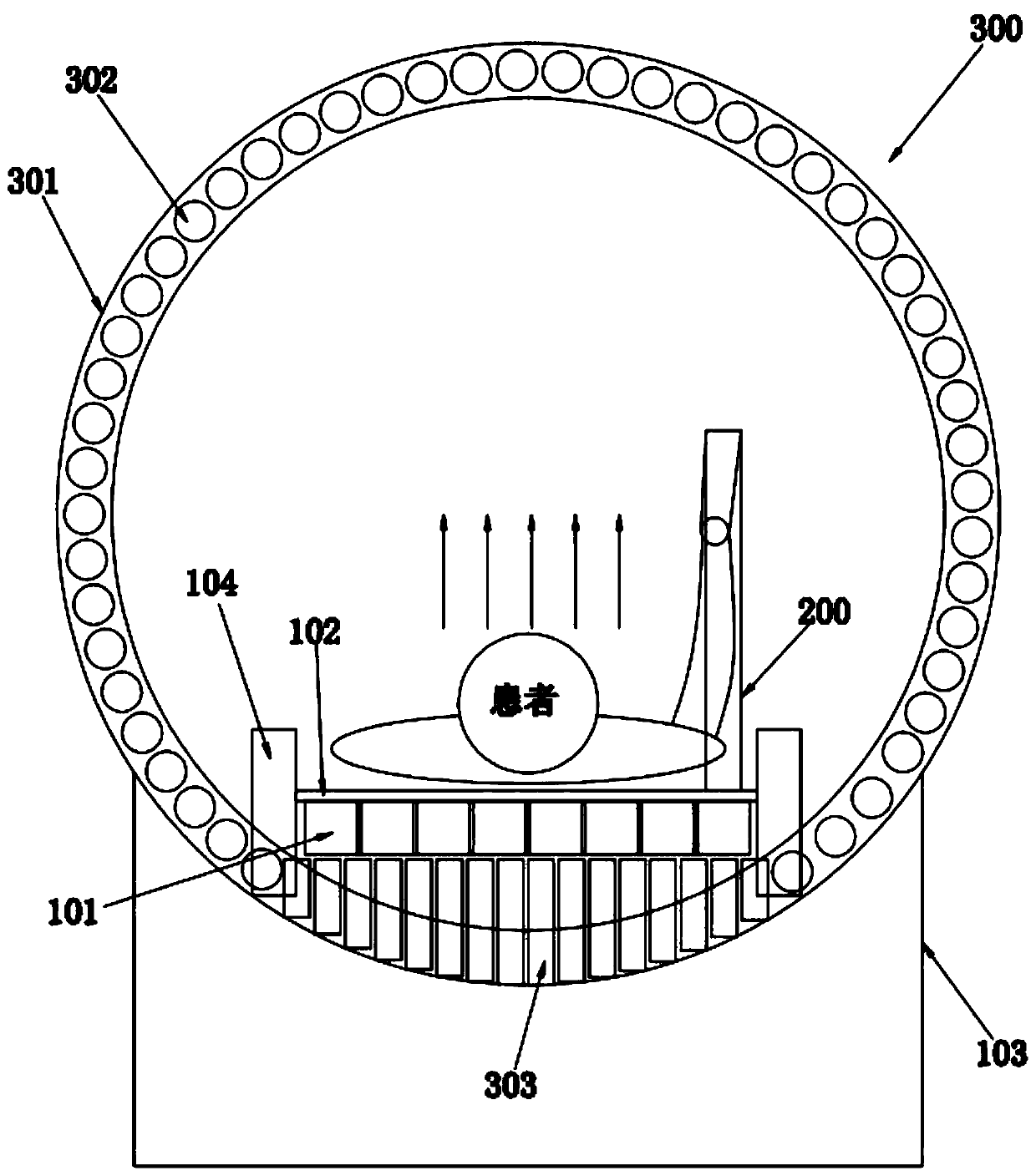

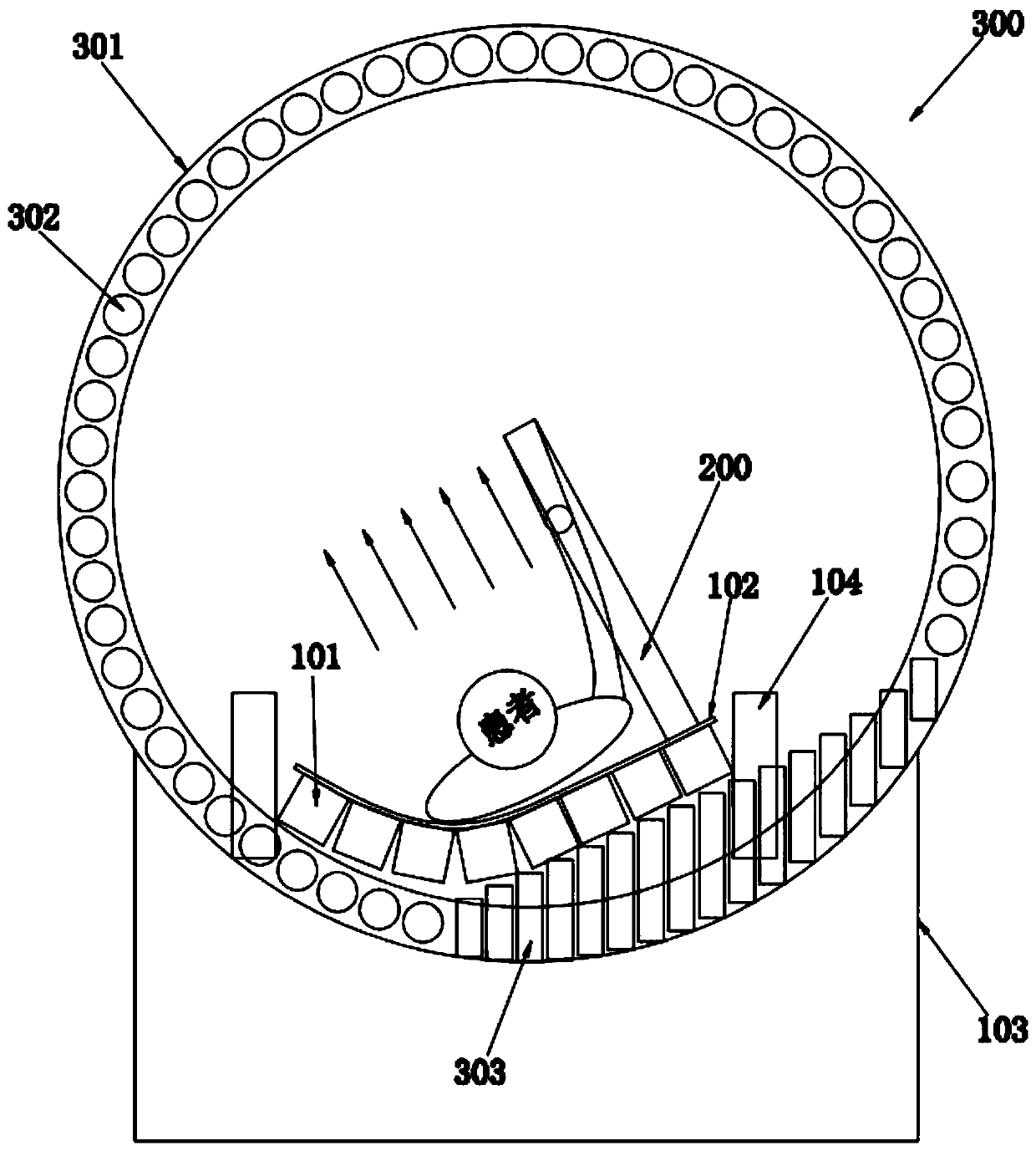

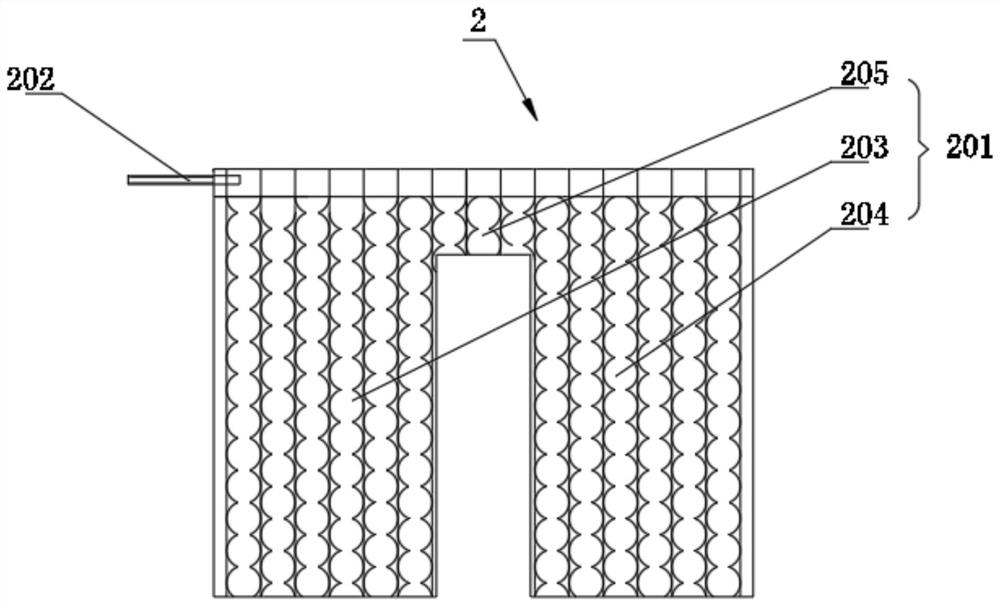

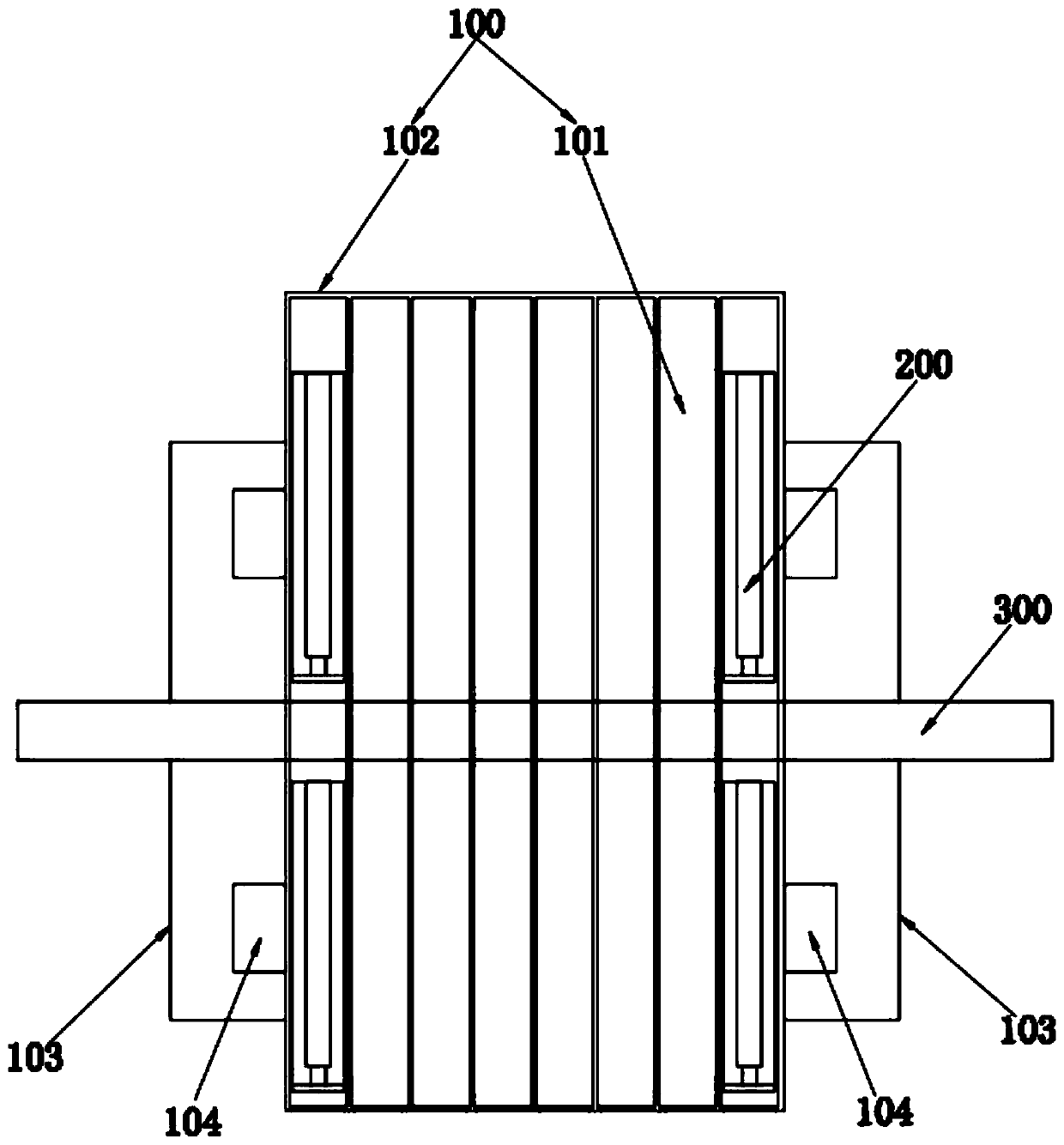

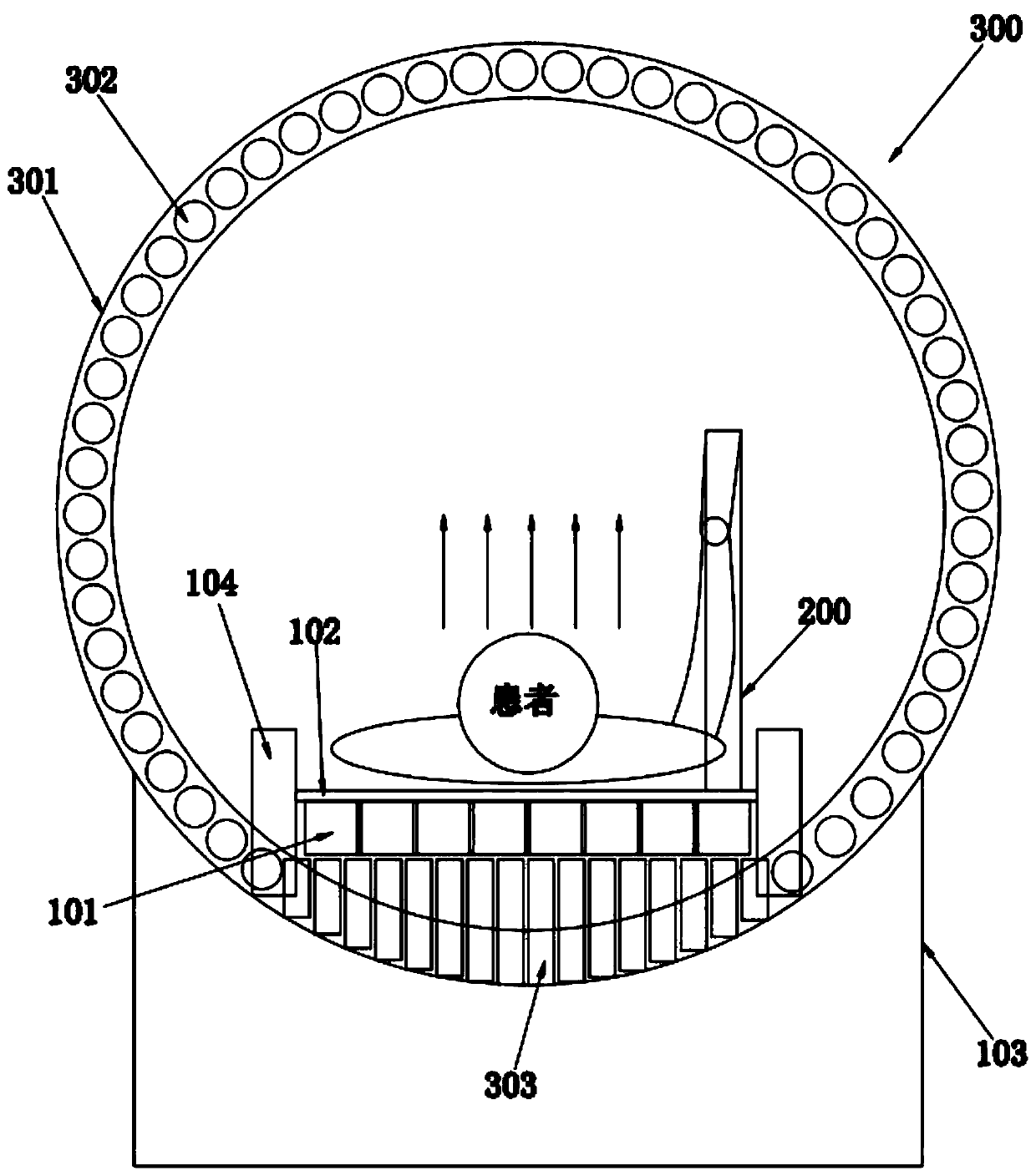

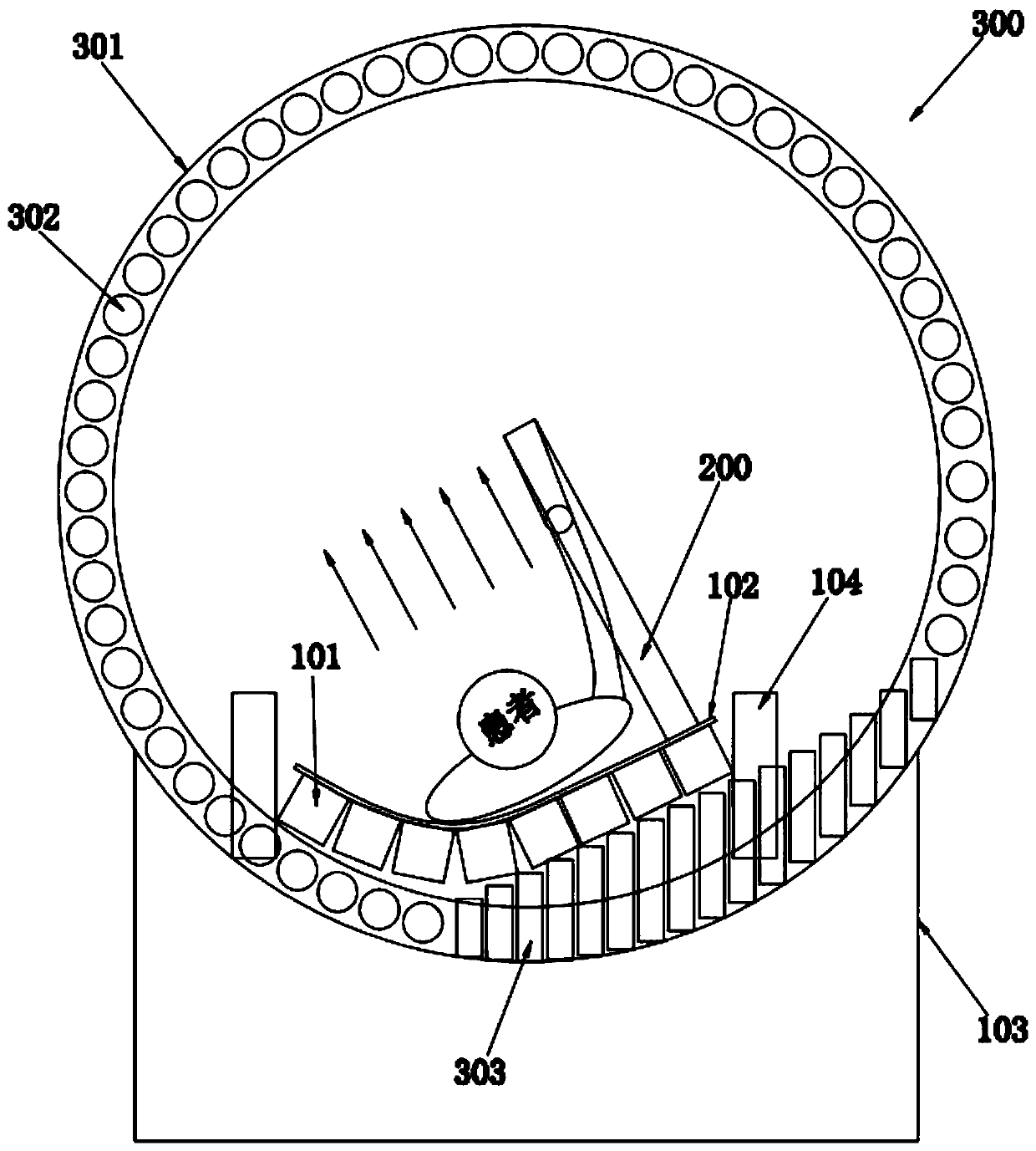

The invention provides a hospital bed. The hospital bed comprises a bed body (100), a supporting frame (200), a guide platform (300) and a locking part (500), and the bed body comprises at least threebed plates (101), a bed sheet (102), a bed frame (103) and a limiting plate (104); the supporting frame is arranged on the bed plates (101); the guide platform comprises an annular guide rail (301),a ball (302) and a supporting block (303). Compared with the prior art, the hospital bed has the advantages that through the structure, when a patient lays on the bed and his / her four limbs are hung,he can turn over arbitrarily, and the hung joint cannot be twisted.

Owner:路万虹

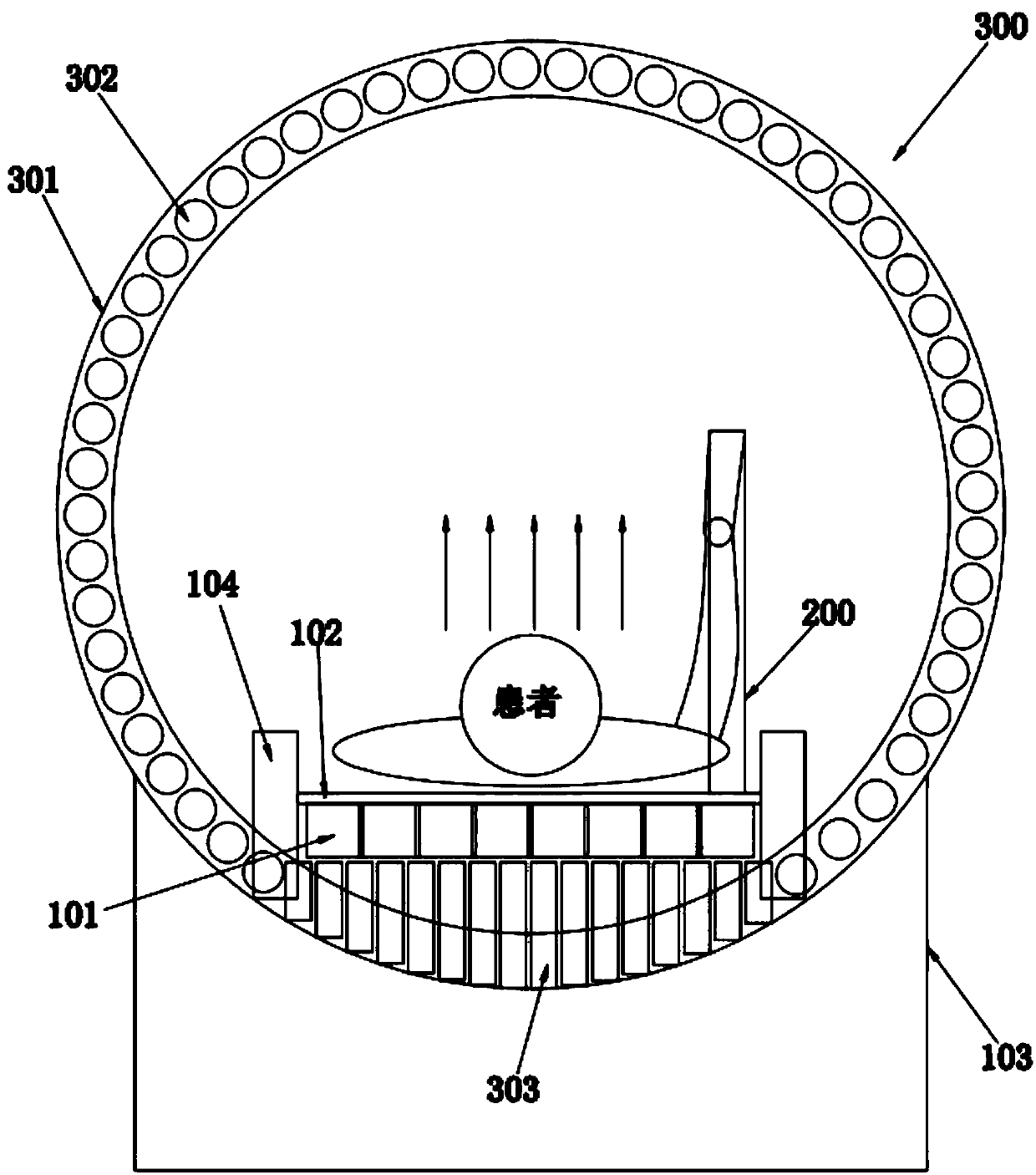

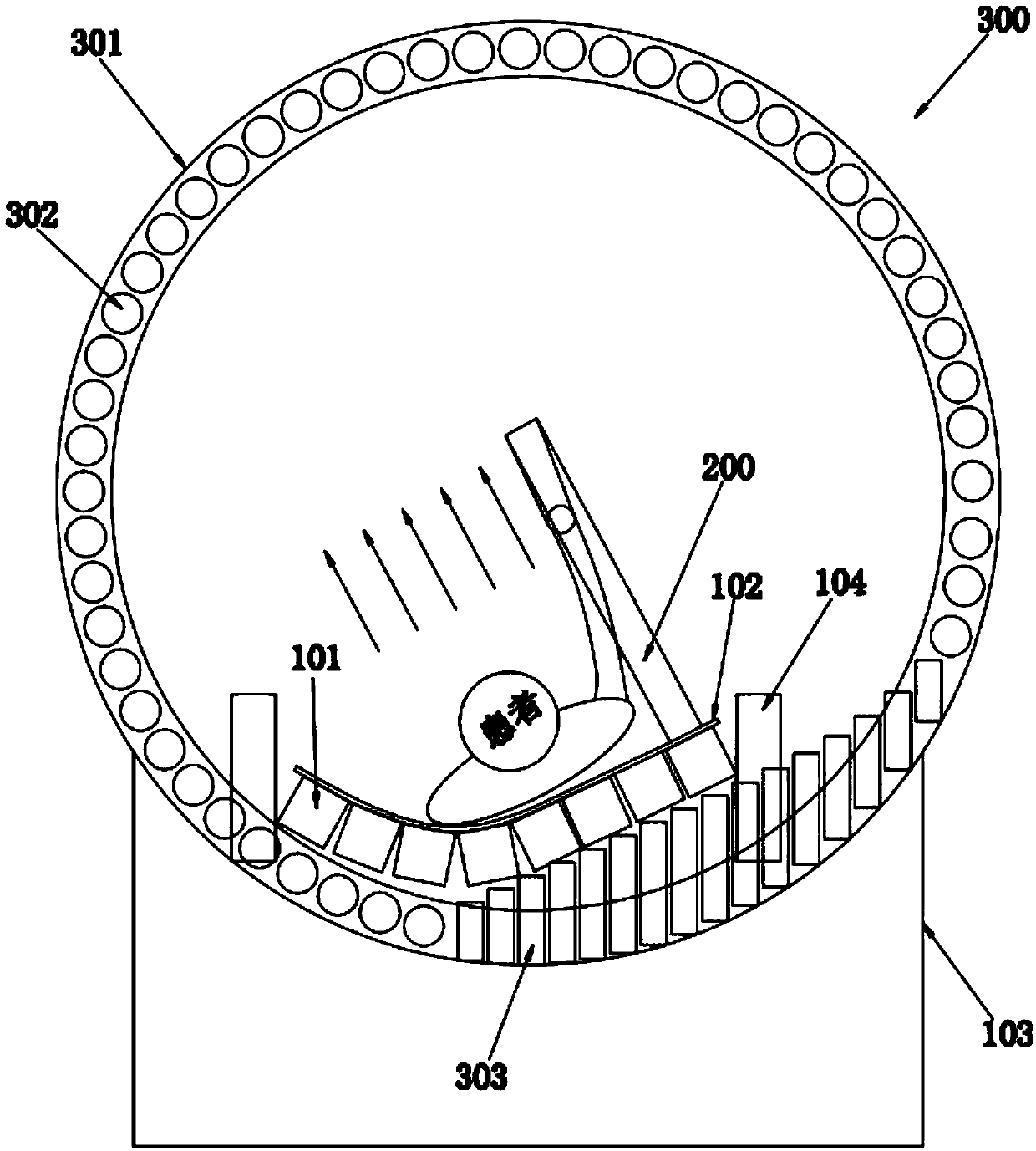

Medical sickbed used in orthopedics department

InactiveCN107789135AChange ups and downsWon't twistDiagnosticsNursing bedsOrthopedic departmentEngineering

The invention provides a medical sickbed used in the orthopedics department. The medical sickbed comprises a bed body (100), a supporting frame (200) and a guide table (300), wherein the bed body (100) comprises at least three bed boards (101), a bed sheet (102), a bed frame (103) and limiting plates (104); the supporting frame (200) is arranged on the bed board (101); the guide table (300) comprises an annular guide rail (301), rolling balls (302) and supporting blocks (303). Compared with the prior art, the medical sickbed used in the orthopedics department has the advantages that by means of the structure, it can be achieved that a patient can turn over at random when the patient lies in bed or the limbs of the patient is suspended, and the suspended joints cannot be wriggled.

Owner:THE SIXTH AFFILIATED HOSPITAL OF XINJIANG MEDICAL UNIV

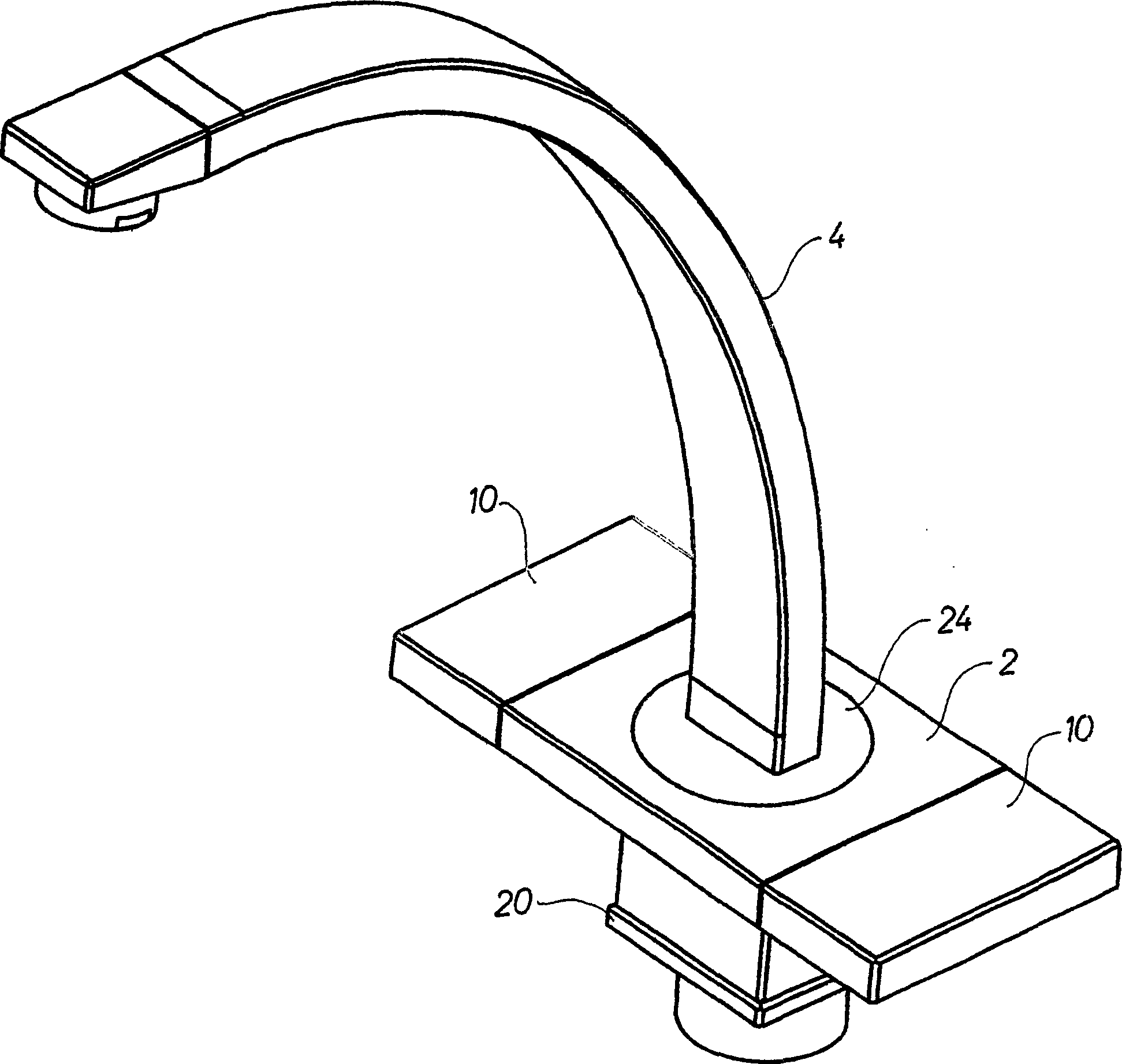

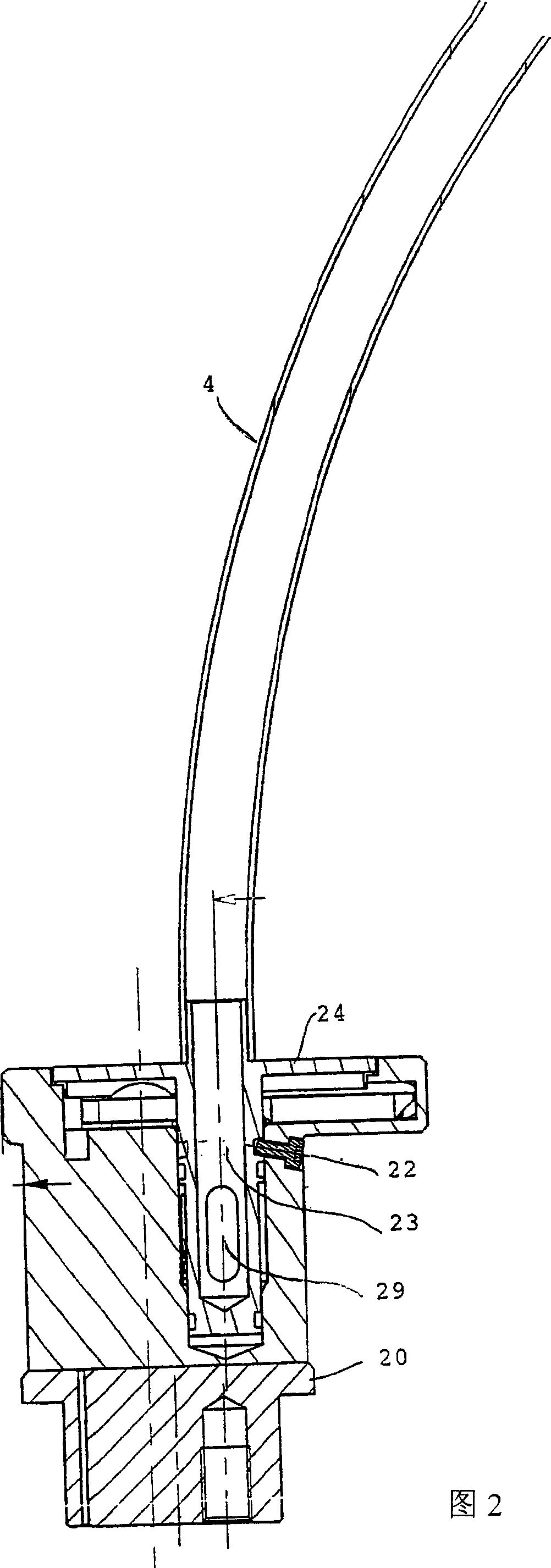

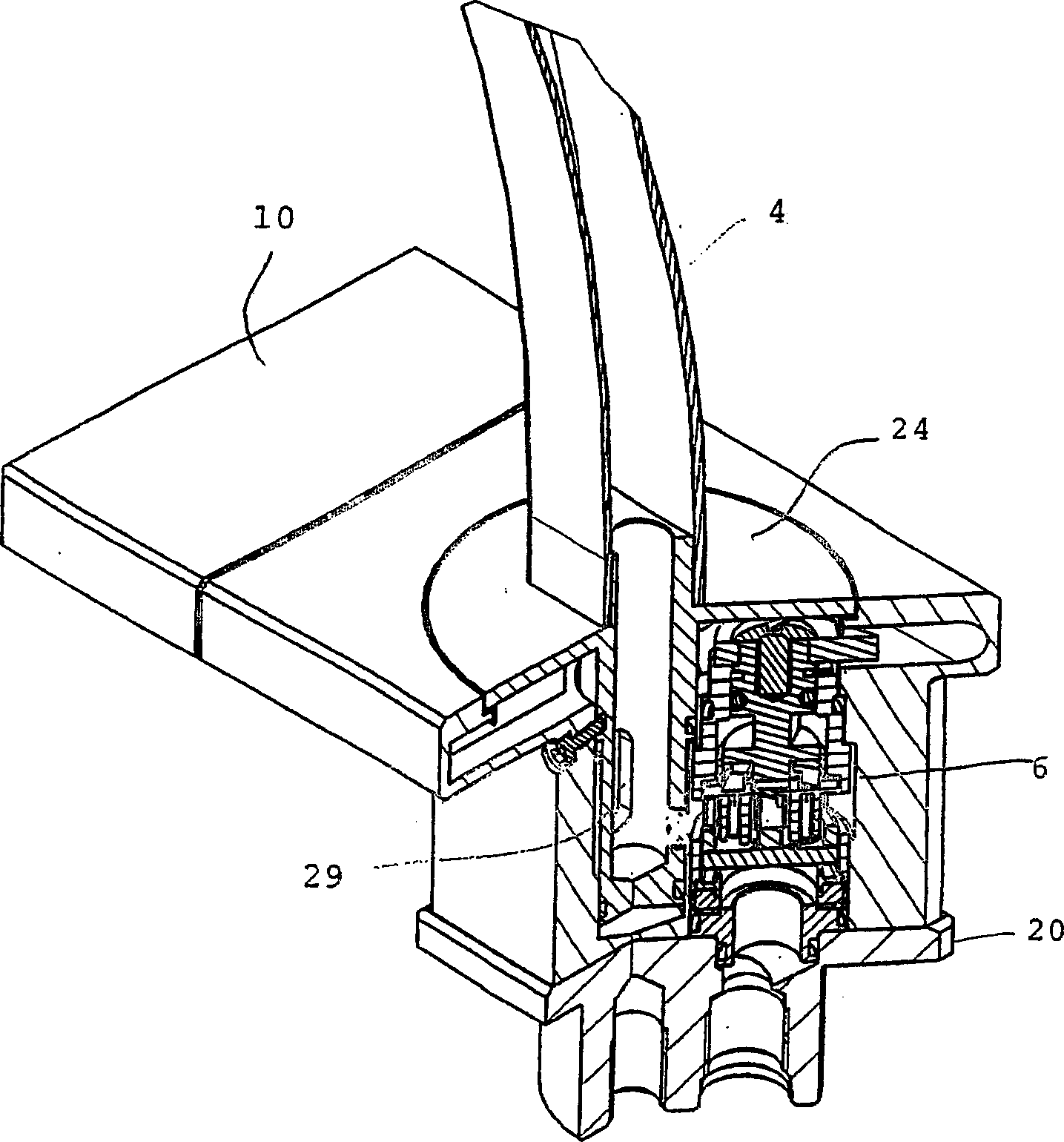

A mixing faucet

InactiveCN1723356AWon't twistOperating means/releasing devices for valvesDomestic plumbingEngineeringMechanical engineering

A mixing faucet includes a body part, where a rotatable swivel tap is mounted on said body part, and where a rotatable valve spindle is mounted in said body part for an adjustment of the feeding of cold and hot water, respectively. The rotatable valve spindle is according to the invention equipped with a projecting arm engaging a groove in a slide on the side of the body part. The resulting mixing faucet is much easier to handle than hitherto known.

Owner:DAMIXA AS

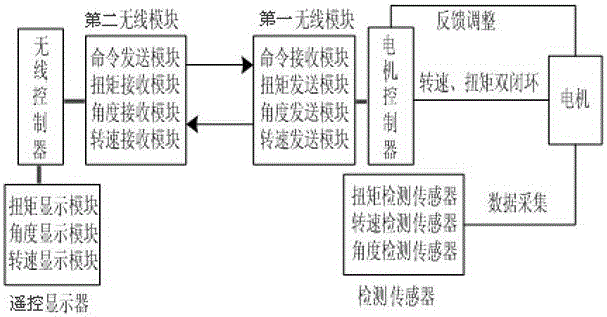

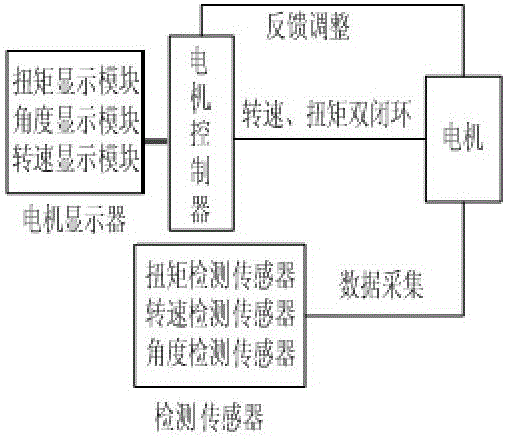

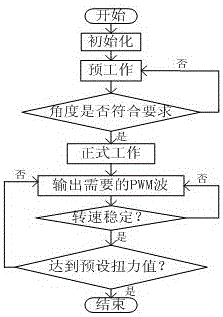

Control device of intelligent bolt fastener and control method thereof

InactiveCN105911894AGood control effectImprove accuracyProgramme control in sequence/logic controllersWireless controlRemote control

The invention discloses a control device of an intelligent bolt fastener and a control method thereof. The device comprises a motor, a detection sensor, a wireless communication module, a handheld control module and a wireless control module. The handheld control module comprises a motor controller and a motor display. The wireless control module comprises a wireless controller and a remote control display. The motor is connected to the detection sensor and the motor controller. The motor controller is connected to the motor display. The motor controller is connected to the wireless controller through the wireless communication module. The wireless controller is also connected to the remote control display. Control of the bolt fastener is subdivided into hand-held control module work and remote control wireless control module work. According to different conditions of a scene, such as a space size, an operation angle size, a construction height and the like, an appropriate control method is selected and an optimal control effect is reached.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD MAINTENANCE BRANCH +3

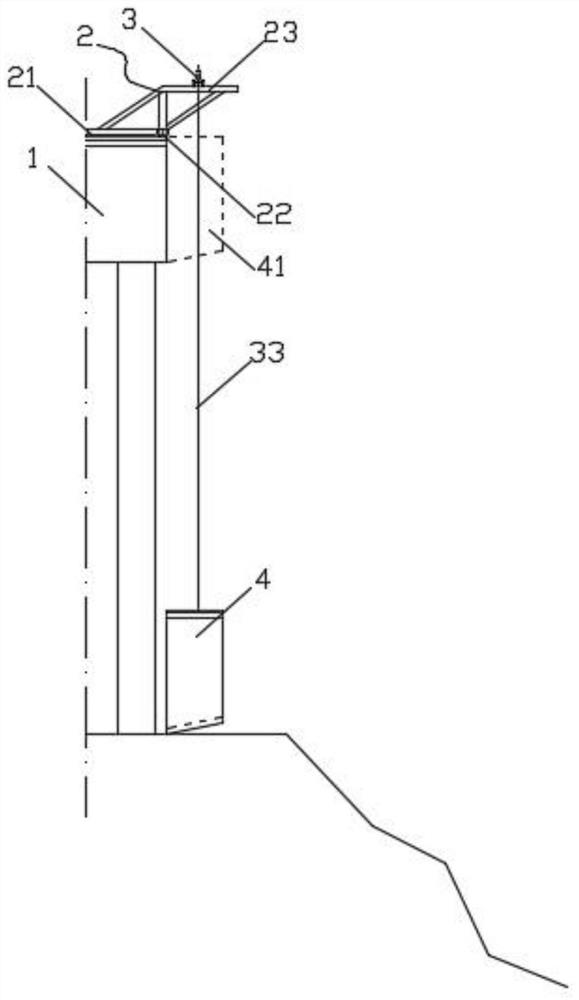

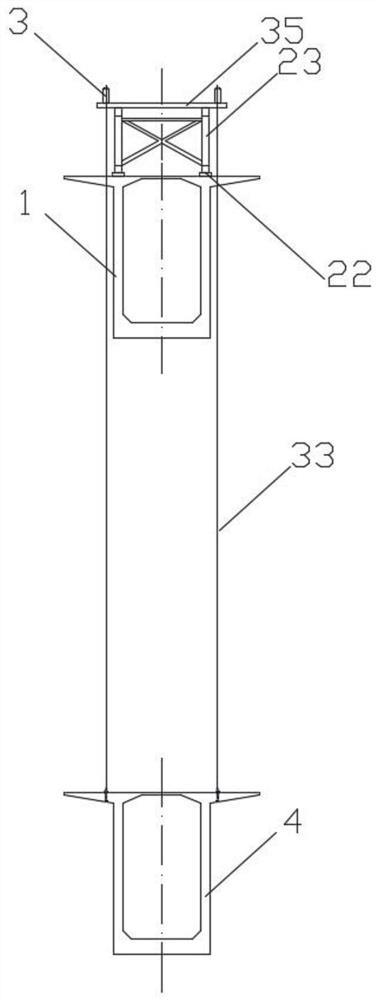

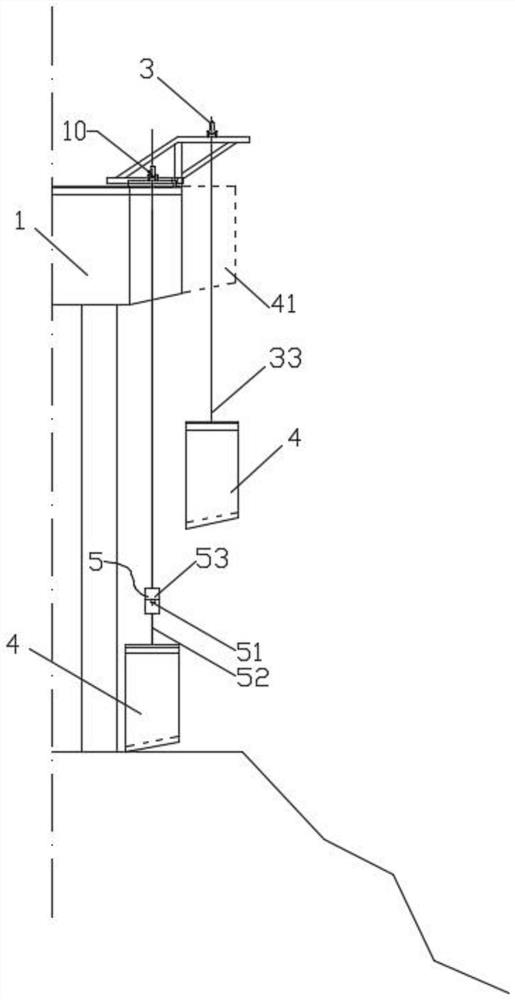

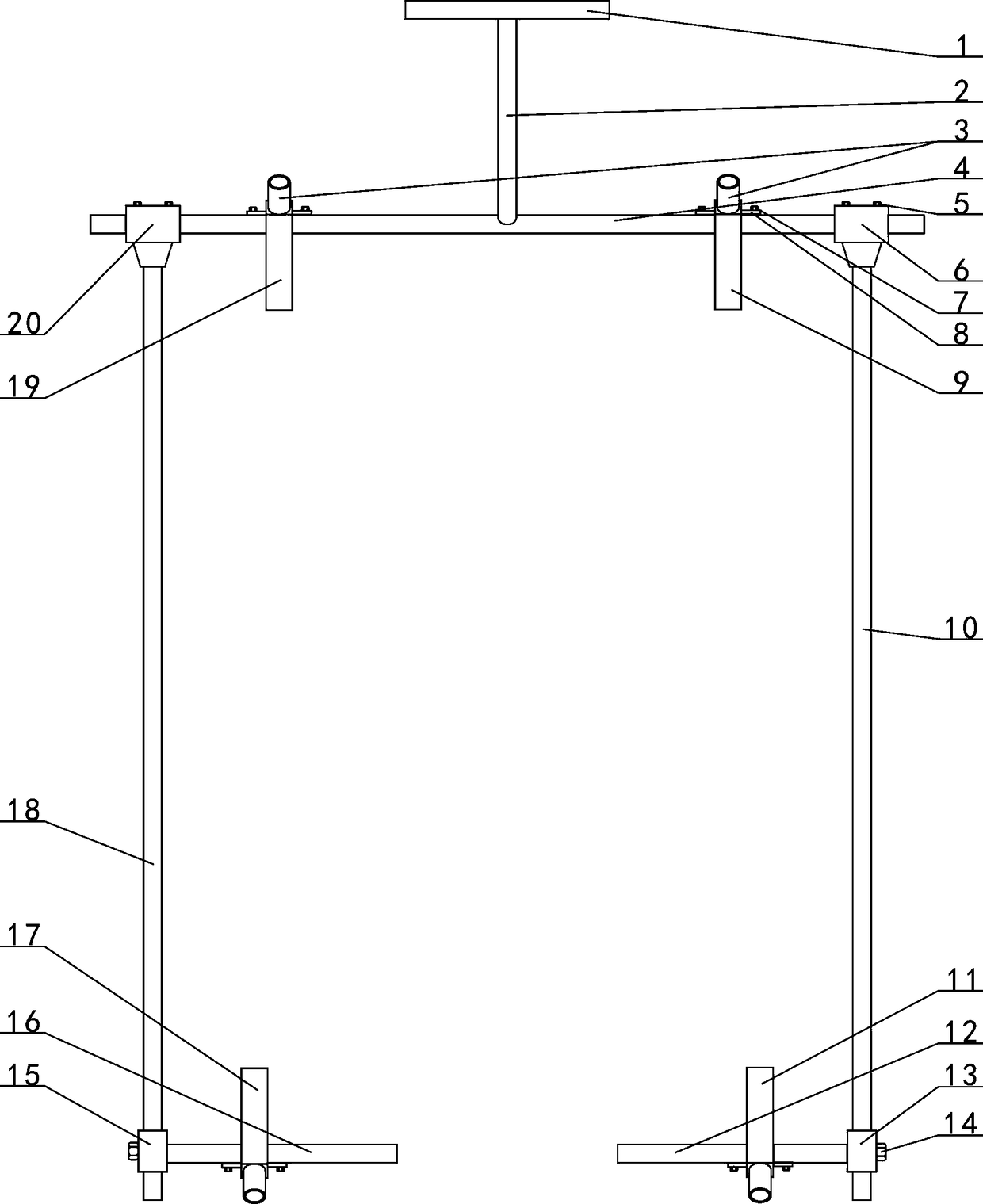

Multifunctional scaffold for construction engineering

The invention provides a multifunctional scaffold for construction engineering. The multifunctional scaffold comprises a turning fastener and steel pipes. One end of the turning fastener is composed of an upper fastener block and a lower fastener block which are rotationally connected. A screw axially connected to the left end of the lower fastener block penetrates through a through hole formed inthe left end of the upper fastener block, and a nut is connected to the screw in a threaded mode; each limiting device is jointly composed of a cylindrical block, a threaded column and a rubber cushion layer; each threaded column is connected to the center of the tail end of the corresponding cylindrical block in a welded mode, and the threaded columns are connected in threaded grooves in a threaded mode; and each rubber cushion layer adheres to the head end of the corresponding cylindrical block. By arranging four nylon wires, the nut is not separated from the upper fastener piece, so that losing of the nut is avoided; and by arranging bearings and circular ring blocks, the situation that when the nut is twisted, the four nylon wires drill a hole along with the nut is facilitated, and thus twisting of the nut is not hindered.

Owner:江苏新苏阳建设有限公司

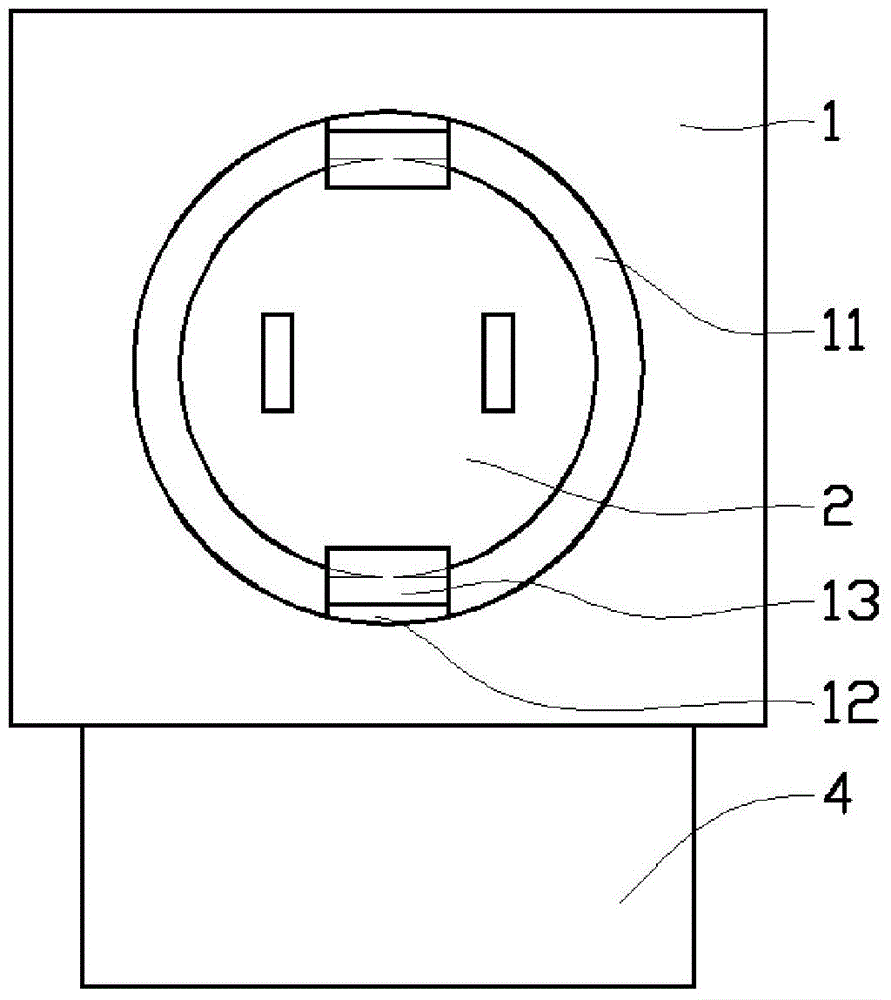

Drawable fixed electric socket

The invention provides a drawable fixed electric socket. The drawable fixed electric socket comprises a fixed shell, a cylindrical socket body, an electric wire and a wire winding shell. The fixed shell is embedded in the wall surface. A tubular socket barrel extending outwardly is designed on the outer side of the fixed shell. The socket body is assembled in the socket barrel. Jacks are formed in the socket body and connected with the electric wire through metal connecting pieces. The wire winding shell is fixed on the inner side of the fixed shell and positioned inside the wall surface when the socket is assembled. The electric wire is stored in the wire winding shell. The drawable fixed electric socket is mainly applied to the wall surface and can be used as a fixed socket directly; when the socket body is drawn out from the socket barrel directly, the electric wire is taken out from the wire winding shell, and the socket body can be used as a connected movable socket directly, so that convenience in use is achieved.

Owner:SUZHOU SLAITE ELECTRONICS TECH

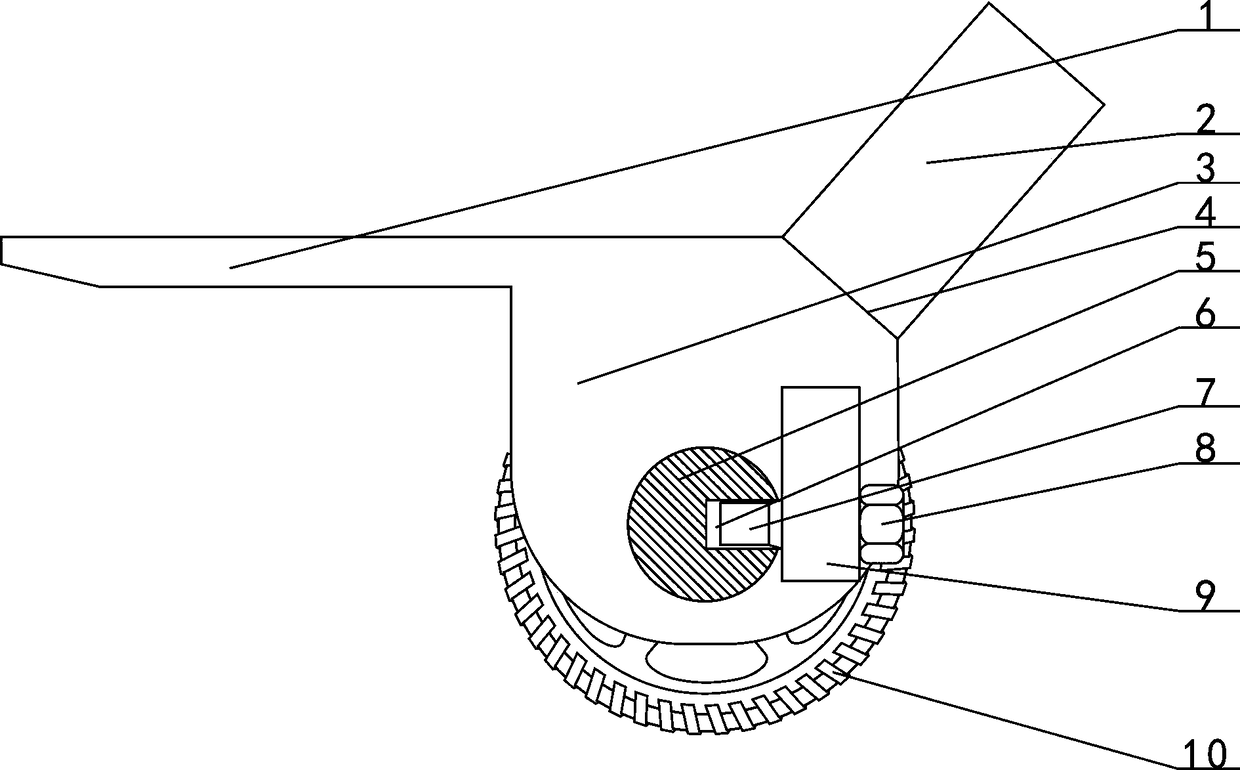

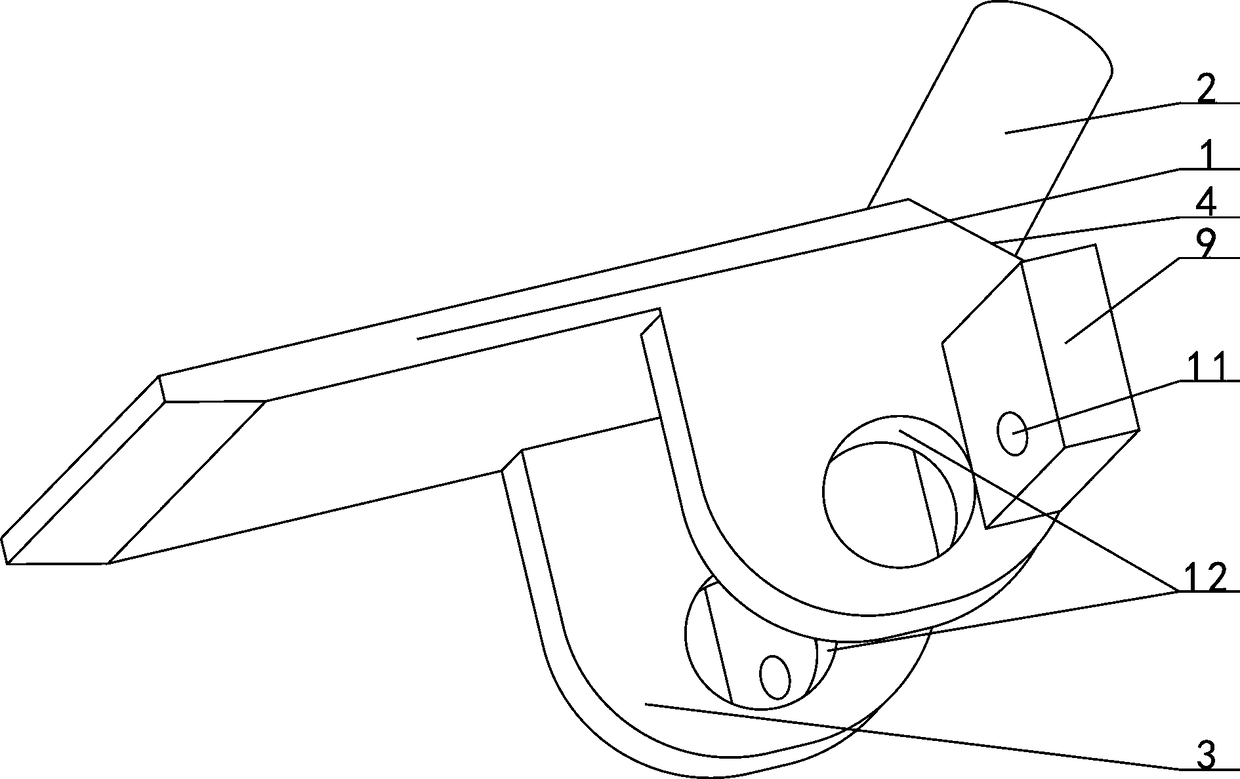

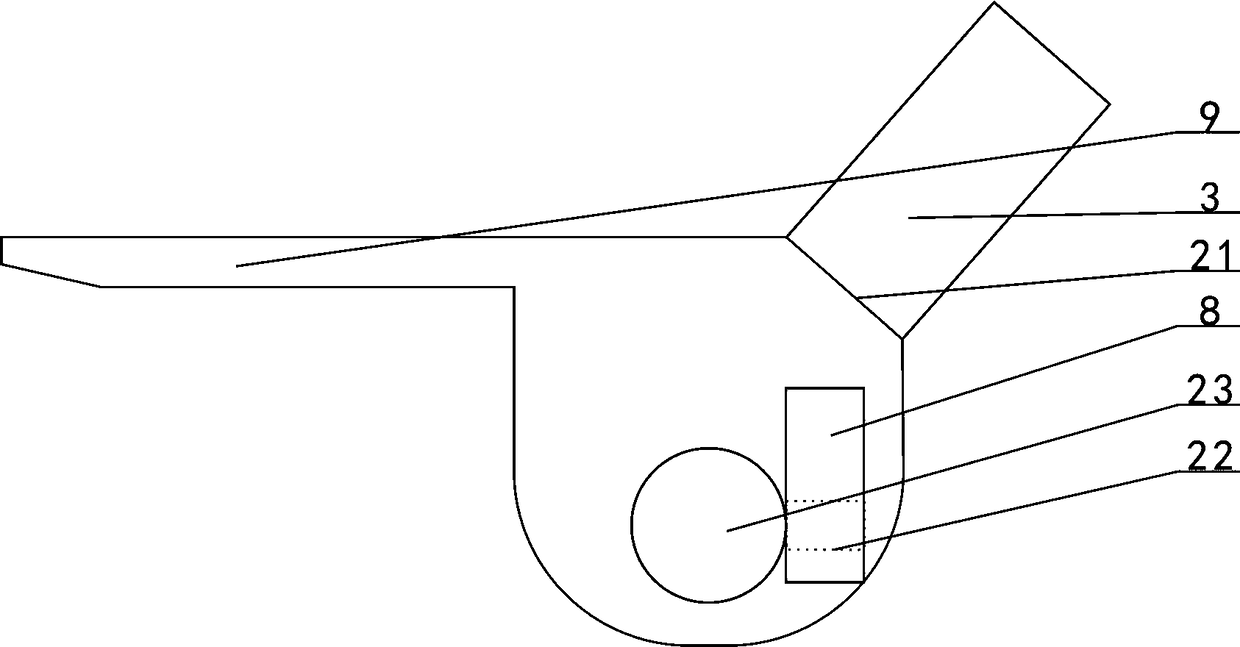

A shovel wheel of an overhaul trolley and an application thereof

ActiveCN109050613AReduce investmentLow costSledge wheelsHand carts with multiple axesAgricultural engineeringMaterial Perforation

The invention relates to a shovel wheel of an overhaul trolley and an application thereof, the invention relates to an application of a shovel wheel, A low end of that pry bar insertion pipe (2) is fixedly connected to a tilt plate (4) arrange at one end of the shovel plate, the upper ends of the two upright plates (3) are fixedly connected to the middle part of the shovel plate to the lower sidesof one end, A low part of an inclined plate on one side of that perforation (12) on the outside of the two vertical plates is respectively provided with a positioning plate (9), the two positioning plates are respectively provided with screw holes A (11), the middle part of the hub (27) of the wheel is provided with a sleeve (25), the sleeve is arranged between the two vertical plates to form a shovel wheel, the frame rod of the overhaul trolley is pierced in the perforation of the two vertical plates and the middle hole of the sleeve, and the two fixing screws (8) fix the two positioning plates on the frame rod respectively; The shovel plate of the shovel wheel of the invention shovels up the equipment, and the small space equipment is rapidly replaced by a combination of an elongated and widened front rod, a connecting rod and a rear rod.

Owner:HENAN ZT LEAGUE CHEM

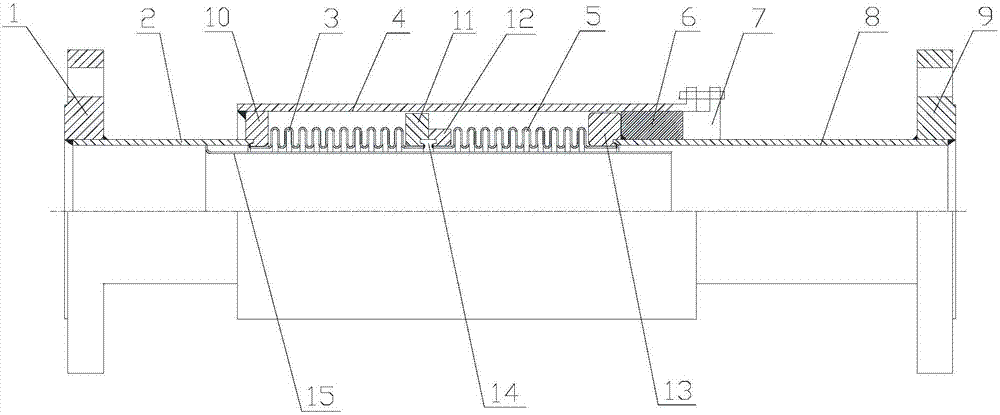

Composite sleeve compensator with warning device and intelligent management system thereof

PendingCN107559527AWon't twistIncreased axial stabilityPipeline expansion-compensationPipeline systemsLine tubingControl engineering

The invention relates to a composite sleeve compensator with a warning device and an intelligent management system thereof. The composite sleeve compensator with the warning device comprises core tubes, corrugated pipes and a flow guide pipe, wherein the flow guide pipe is arranged in an inner cavity formed in the part from the left core tube to the right core tube; an outer sleeve pipe is arranged on the peripheries of the left corrugated pipe and the right corrugated pipe; the left end of the outer sleeve pipe is connected with the left core tube; the right end of the outer sleeve pipe is connected with the right core tube through a sealing device; the sealing device comprises a packing ring, a gland packing and a packing gland flange; the management system comprises a plurality of compensators, a signal transmission device and a central control unit; and all the compensators are in circuit connection with the signal transmission device and the central control unit. According to thecomposite sleeve compensator with the warning device and the intelligent management system thereof, the compensator is improved in sealing performance and not liable to leakage, and can maintain reliable sealing for a long time; besides, the service life is long, the maintenance cost is low, the operation is safe and reliable, and meanwhile the real-time management and safety monitoring level of the pipeline is greatly improved.

Owner:JIANGSU YONGLI PIPELINE CO LTD

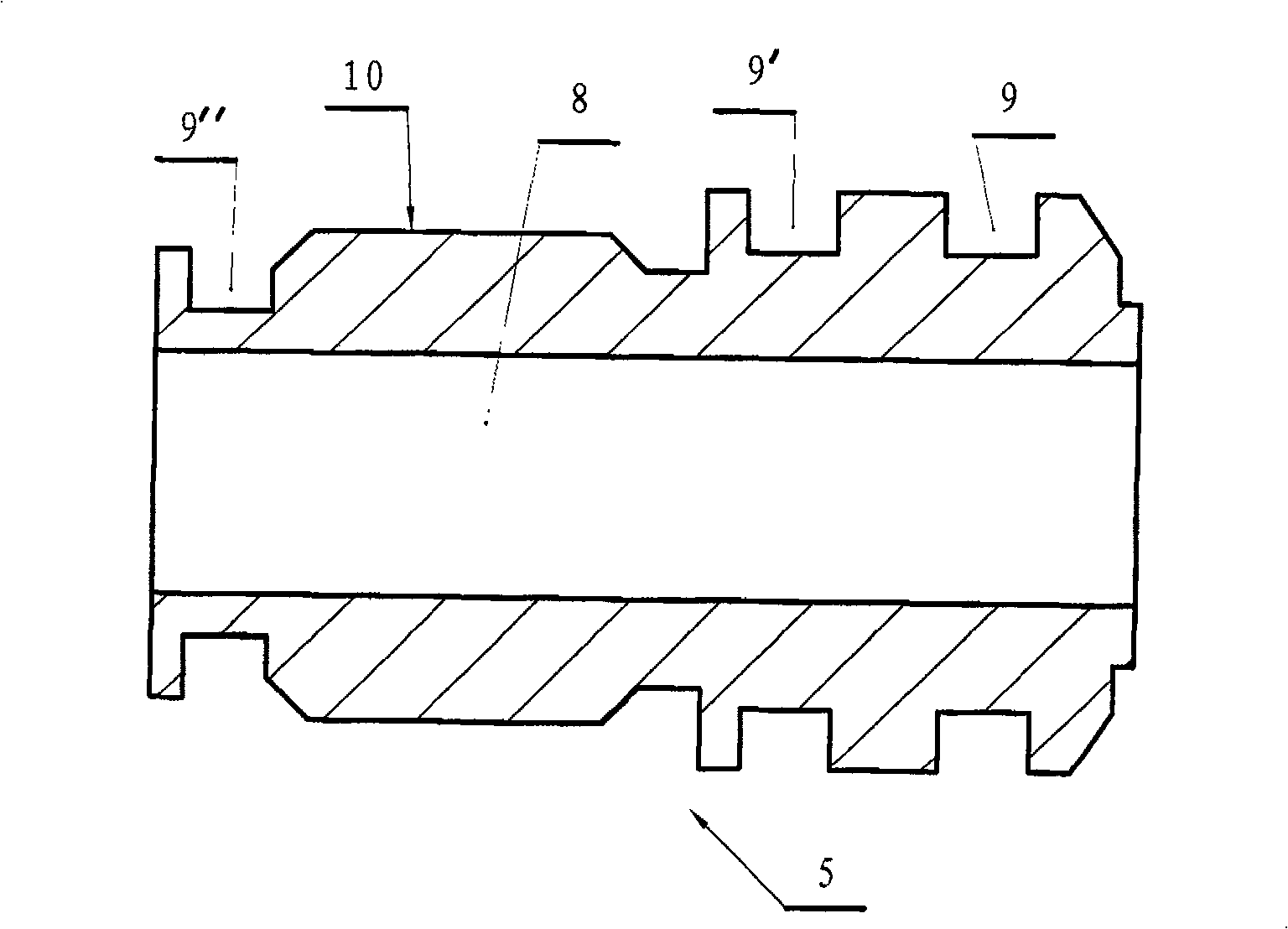

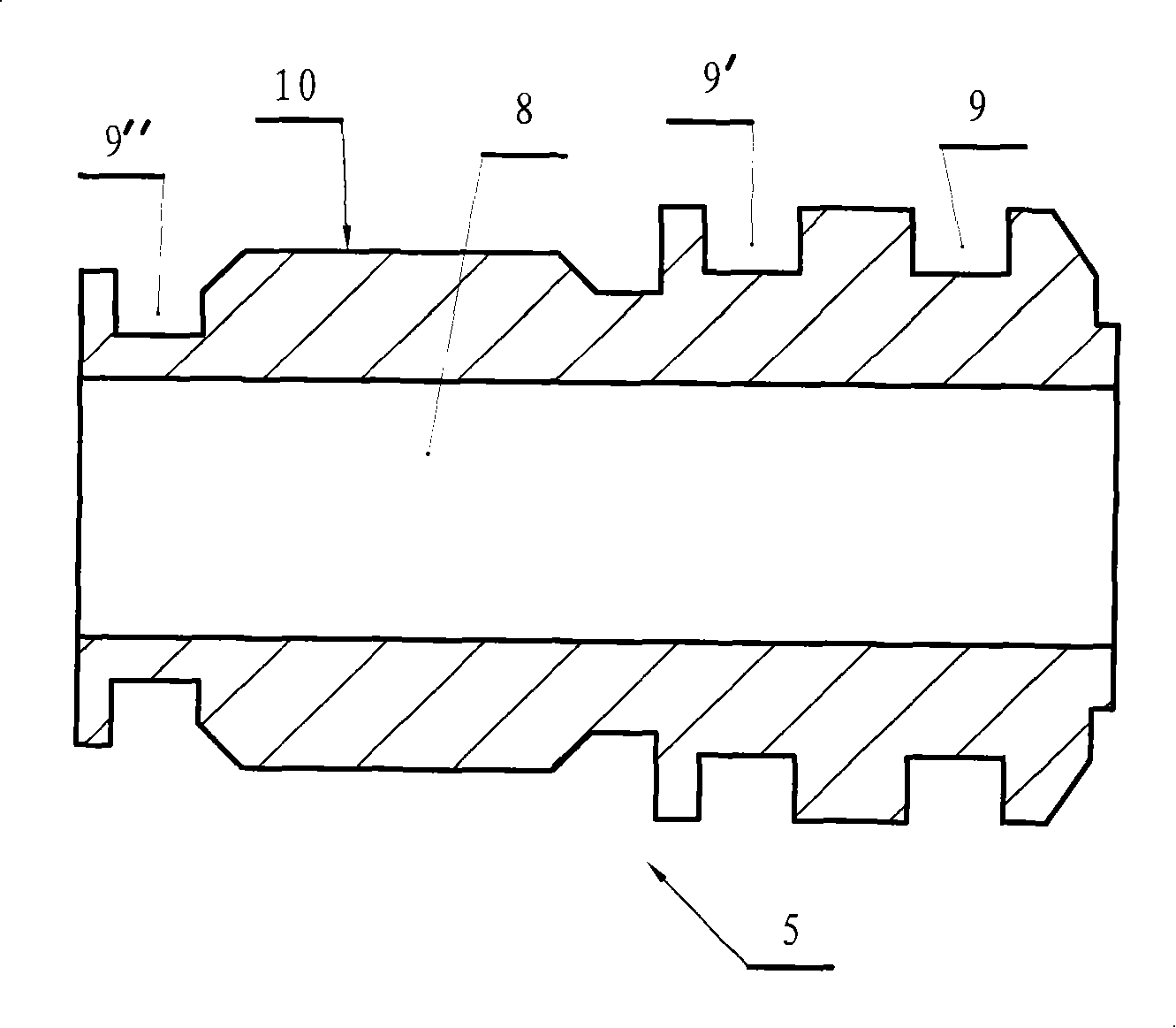

Water faucet with connecting joint, pipes connecting joint and pipes connecting method

The invention has a water tap with a connecting joint, a pipe connecting joint and a pipe connecting method, including a water inlet pipe, a spout and a handle, and a connecting joint including a joint body, a snap ring and a sealing ring. The joint body is a cylinder with a central through hole. The rear end of the joint body is connected to the water outlet position of the water inlet pipe. A section of straight hobbing teeth is arranged on the outer periphery of the joint body. The inner diameter of the mating section of the straight hob is slightly smaller than the outer diameter of the straight hob, and there are at least two grooves on the outer periphery of the joint body for fitting snap rings and sealing rings. Since the connection between the water inlet pipe and the water outlet of the faucet of the present invention is provided with a connecting joint with straight hobbing teeth, when installed, it is squeezed into the water outlet, so that the connection between the water inlet pipe and the water outlet is firm and will not be loosened. Twisting, the connection port is smooth and smooth, and the appearance is beautiful.

Owner:开平市美逸卫浴实业有限公司 +1

Novel steel wooden door frame

The invention belongs to the field of wooden doors and in particular relates to a steel wooden door frame in which a steel plate is additionally arranged so that the door frame has higher strength. The steel wooden door frame comprises a door plate block step and a door frame base, which are vertical to each other, wherein a steel plate frame is arranged in the door frame base; and the door frame base is connected with the door plate block step by the steel plate frame. The steel wooden door frame has the beneficial effects that the steel plate frame is directly arranged in the door frame, the steel improves the overall strength and fire retardance of the door frame, and as the steel plate has very low expansion and contraction rate and does not have water absorption, the weather resistance of the door frame 5 is improved and contraction and expansion, with solar term change, of the door frame become slight, thus ensuring that the coated paint can not crack or warp; and the steel wooden door frame has a simple structure and is convenient to process and low in cost.

Owner:HUZHOU TIEFO REFRACTORIES

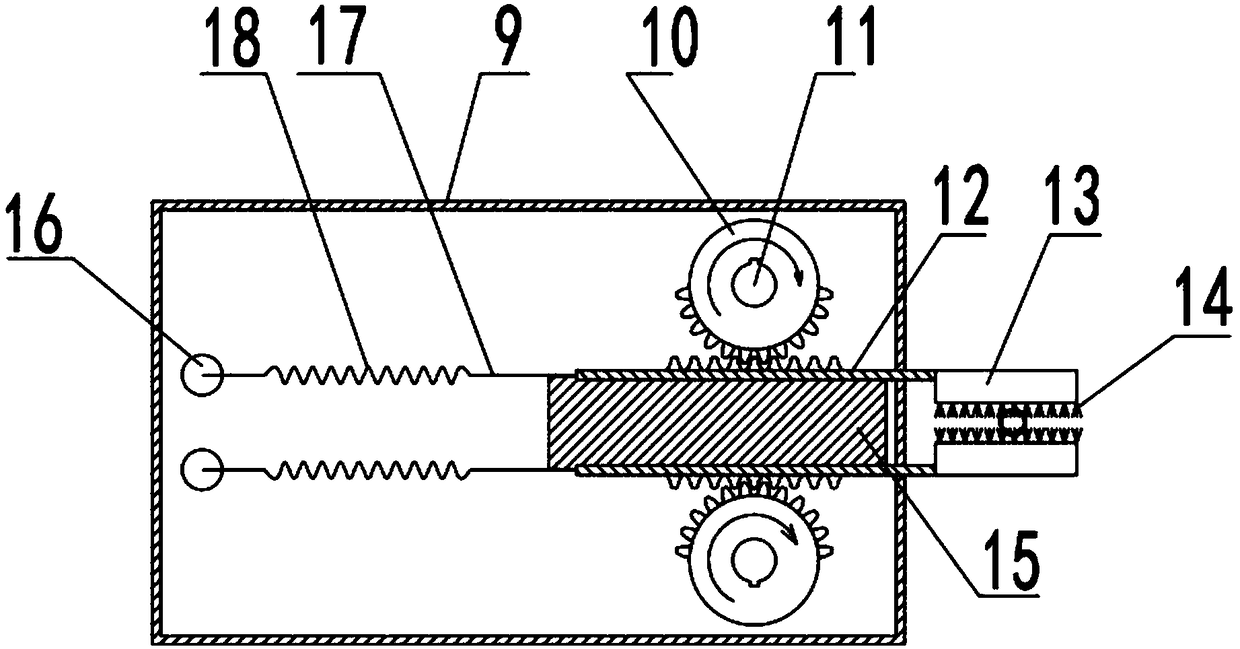

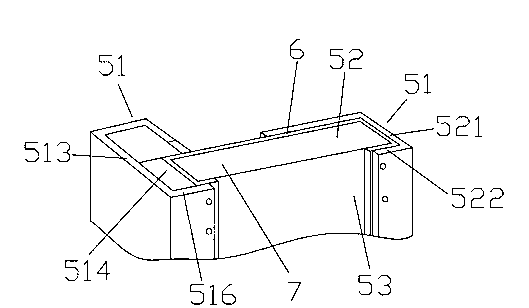

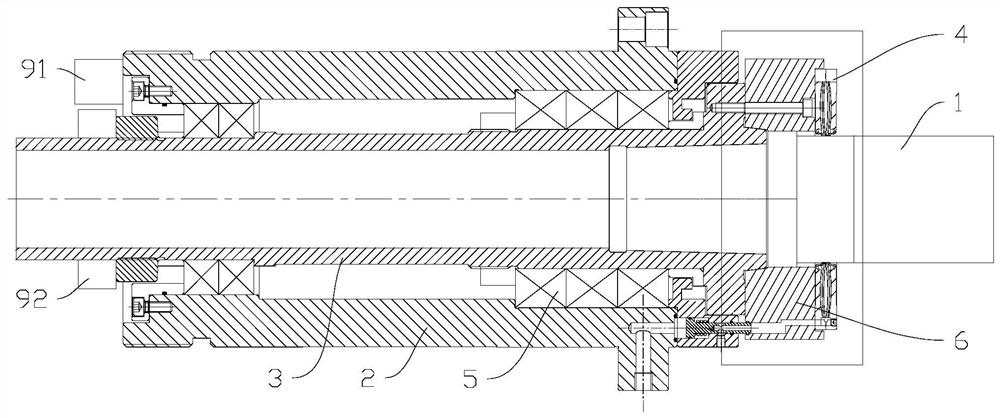

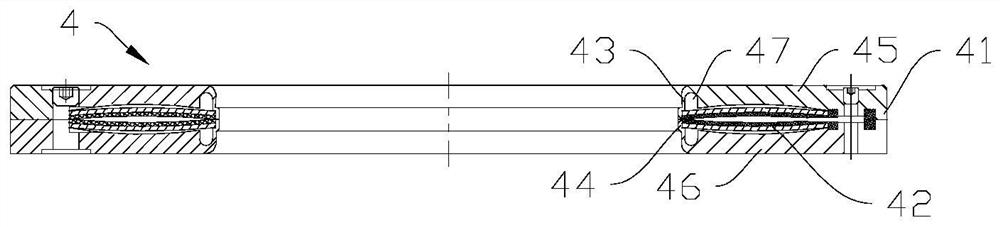

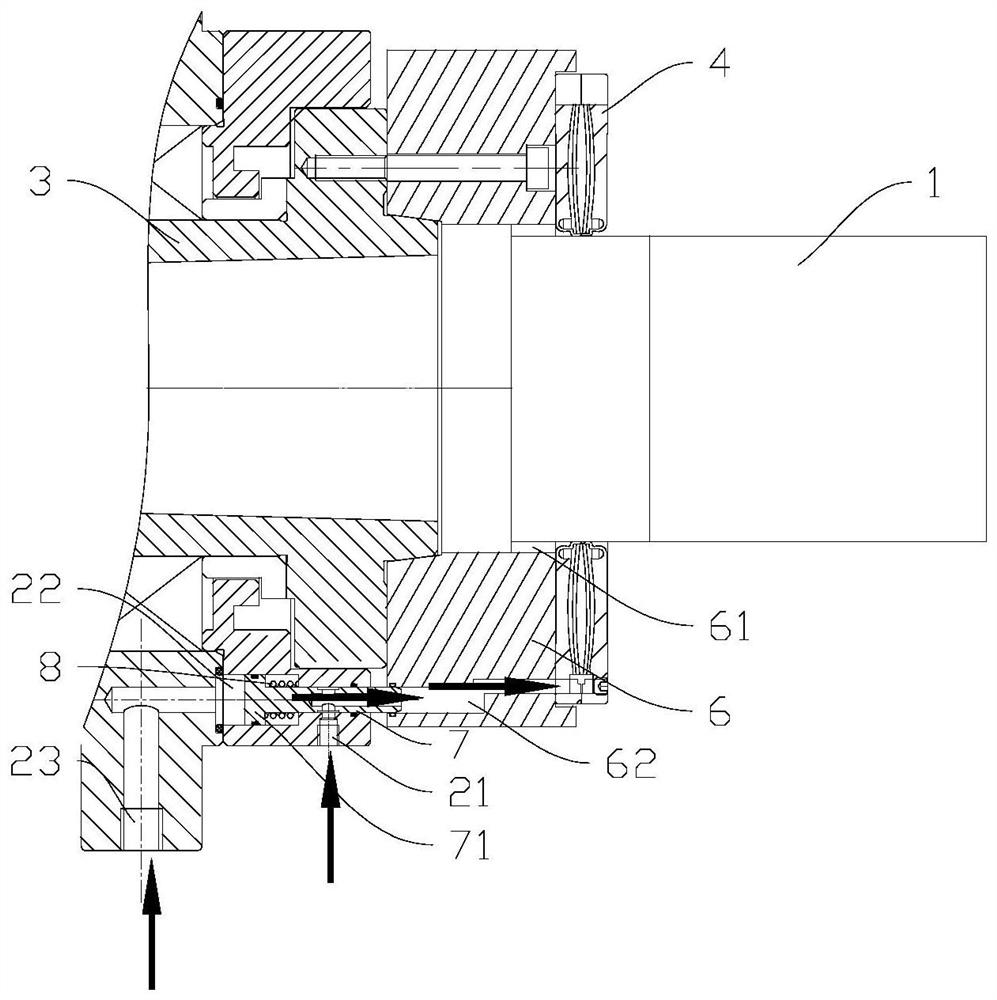

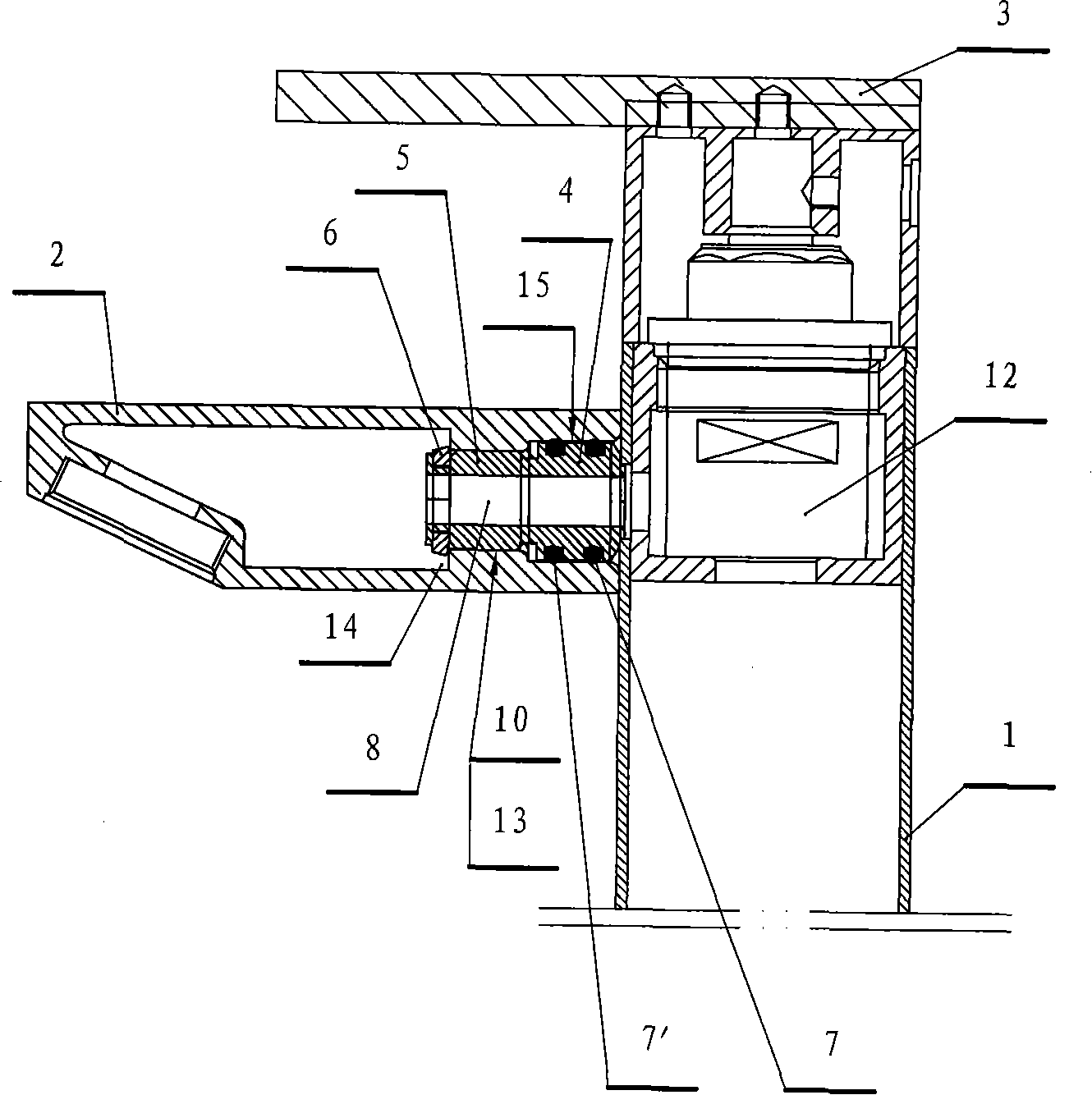

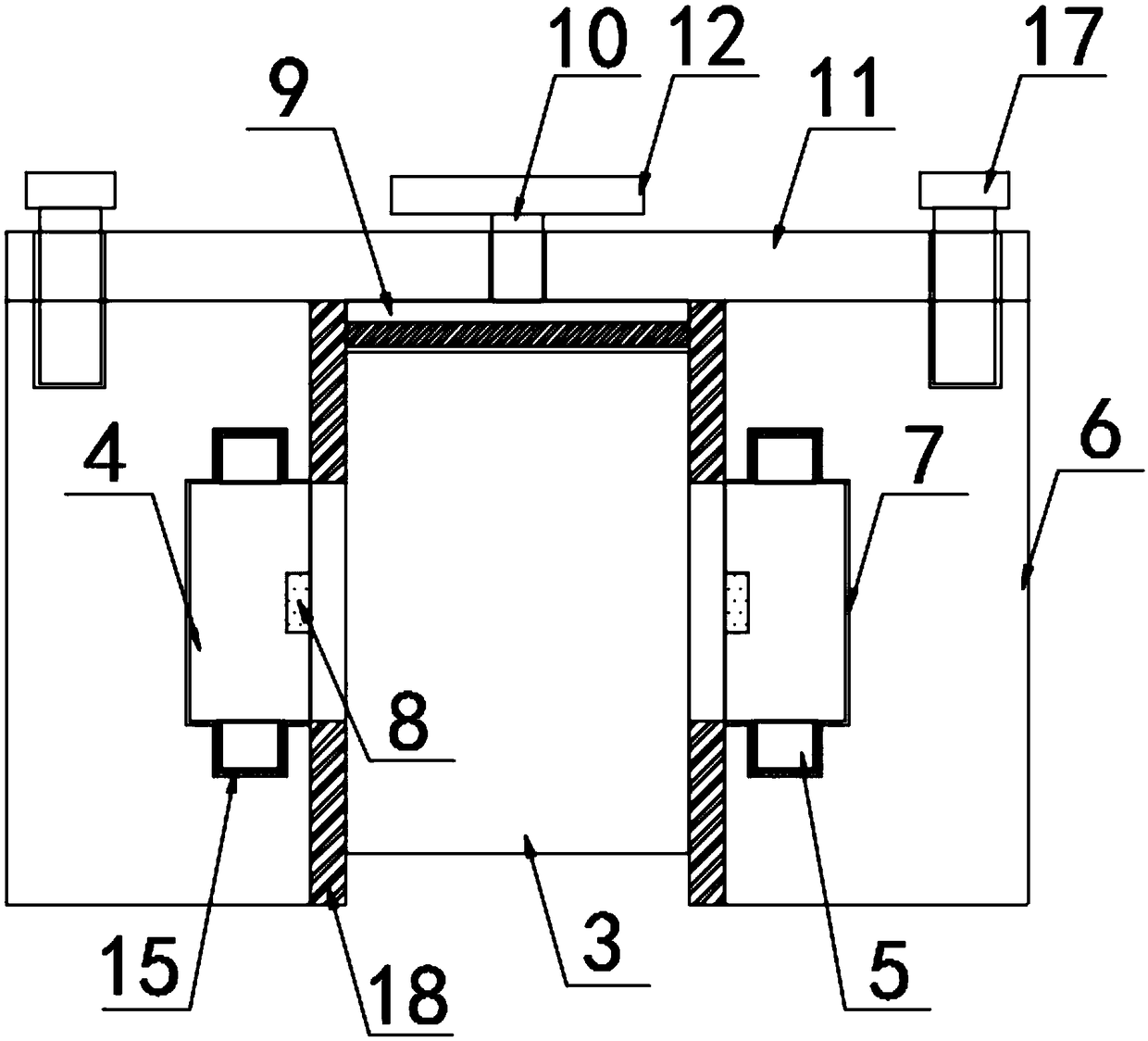

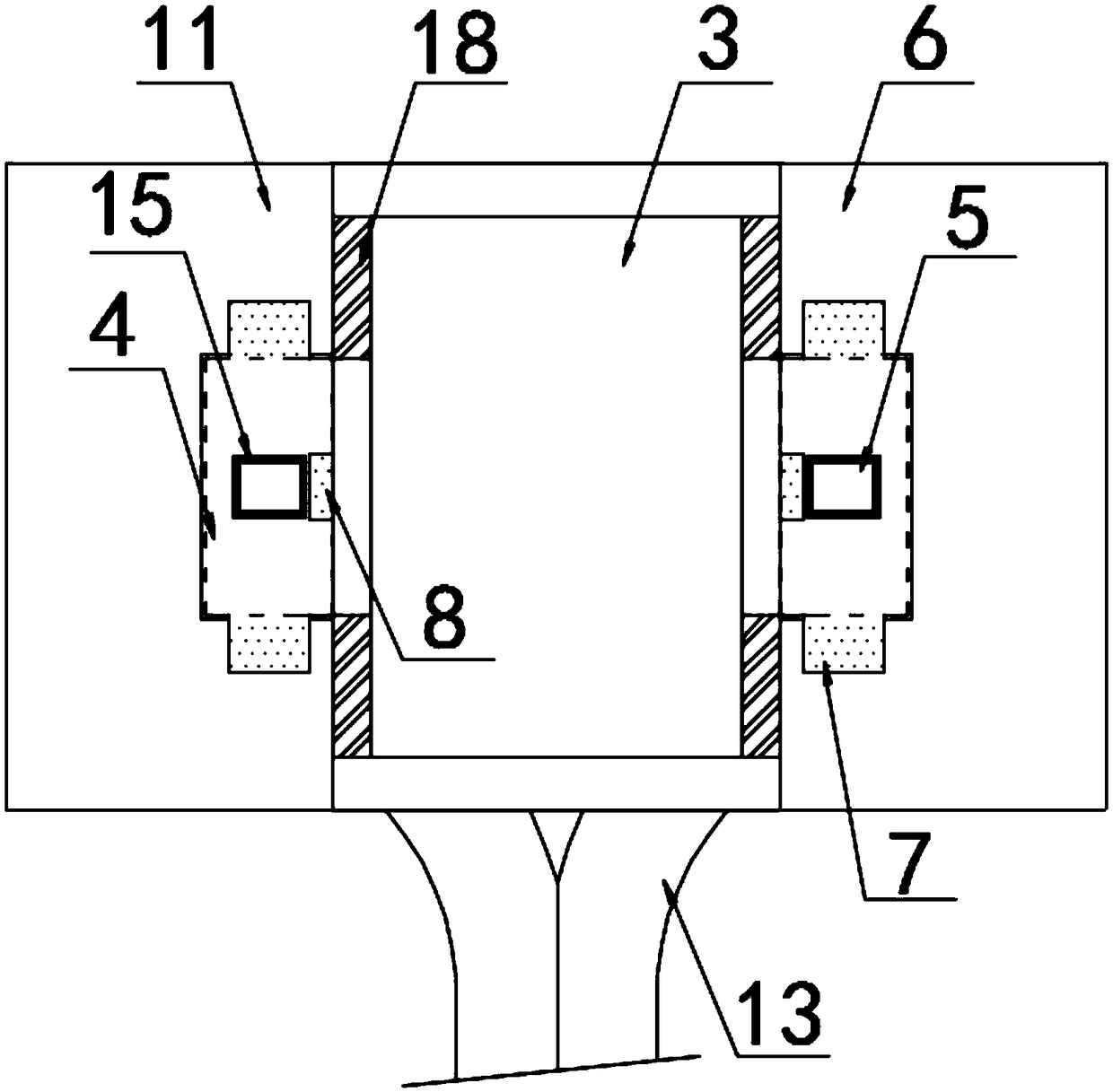

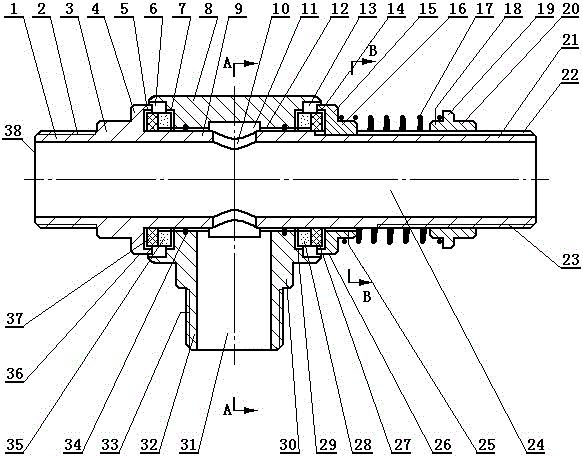

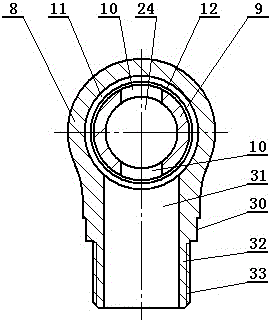

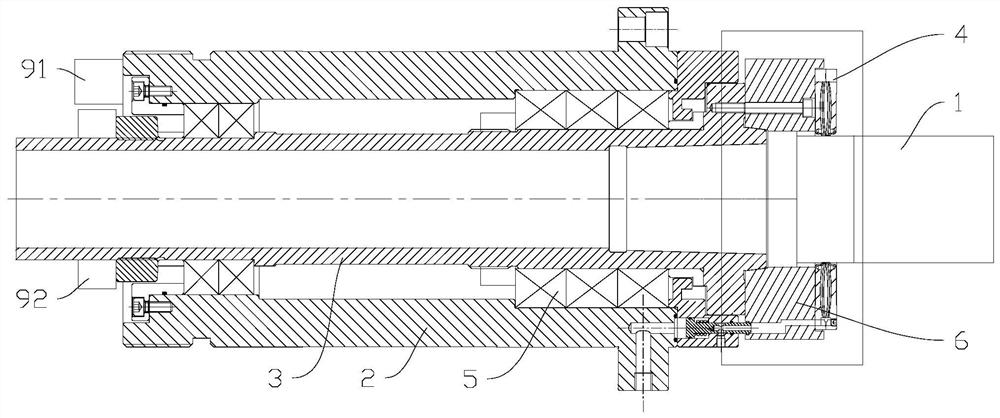

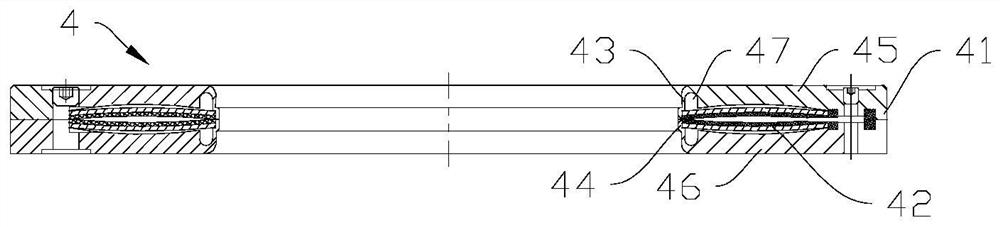

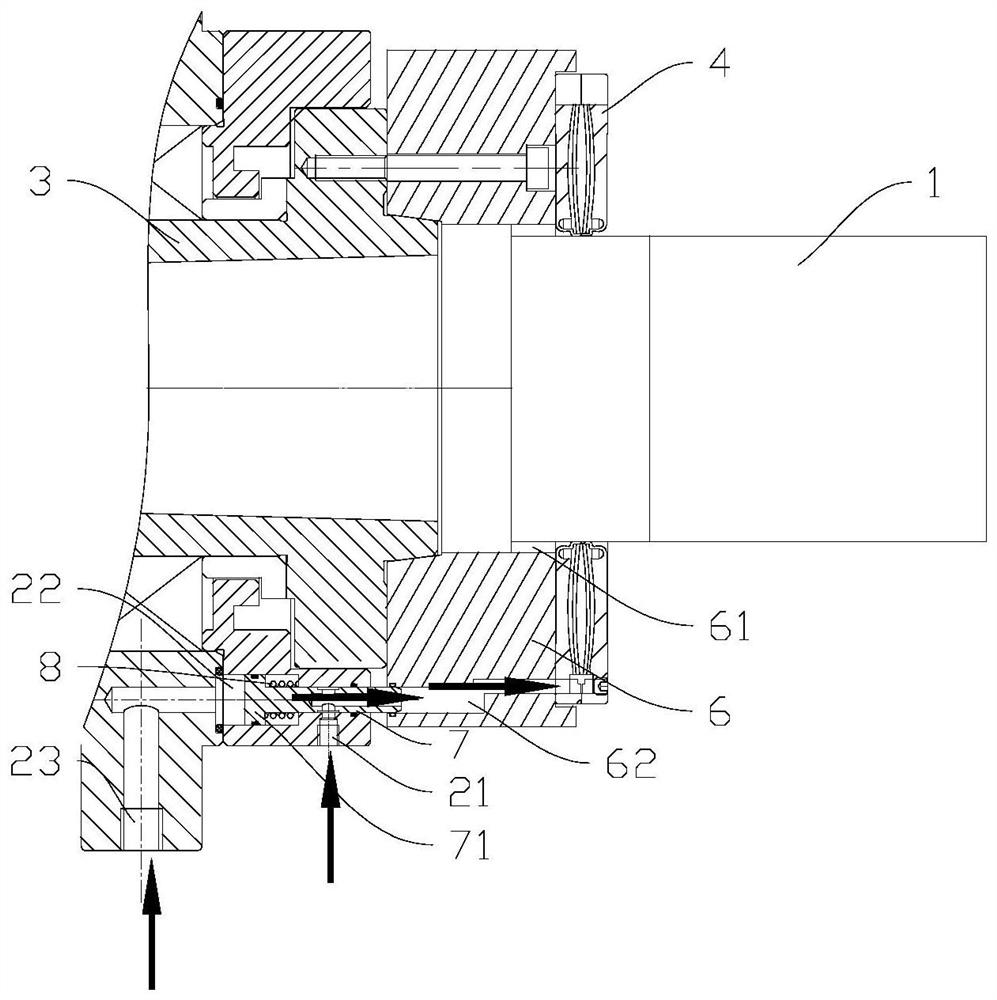

Workpiece clamping device and machine tool

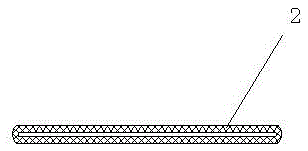

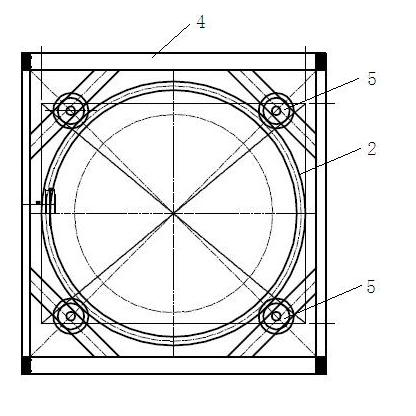

ActiveCN113118799AAchieve clamping and fixingHigh clamping torquePositioning apparatusMetal-working holdersEngineeringCylinder block

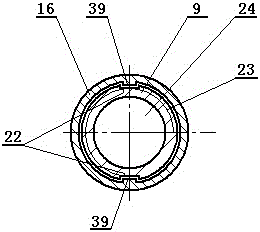

The invention discloses a workpiece clamping device and a machine tool. The workpiece clamping device comprises a box body, a workpiece shaft and a pneumatic band-type brake; the pneumatic band-type brake comprises a band-type brake cylinder body and a spring bellow, wherein the band-type brake cylinder body is annular and is connected to the workpiece shaft, an inner cavity is formed in the band-type brake cylinder body, the inner cavity is provided with an inner ring cavity wall for locking a workpiece, and the inner ring cavity wall has elastic deformation capacity; the spring bellow is formed in the inner cavity, the outer edge of the spring bellow is connected with the band-type brake cylinder body in a fastened mode, and the inner edge of the spring bellow abuts against the inner ring cavity wall; after the spring bellow is deflated, the spring bellow stretches in the radial direction and applies acting force to the inner ring cavity wall, and the inner ring cavity wall holds the workpiece; and after the spring bellow is inflated, the spring bellow expands in the axial direction, and the inner ring cavity wall rebounds and is separated from the workpiece. According to the scheme, the clamping and loosening effects are achieved by contracting and expanding the radial size. By the adoption of the clamping structure, large-torque and high-rigidity positioning clamping can be achieved; and meanwhile, due to the fact that the structure is compact and ingenious, compared with a traditional hydraulic piston type clamping mechanism, the device is smaller.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Prefabricated segment swing shifting method for bridge cantilever assembly

ActiveCN113235460AVarious structural formsMany optionsBridge erection/assemblyButt jointArchitectural engineering

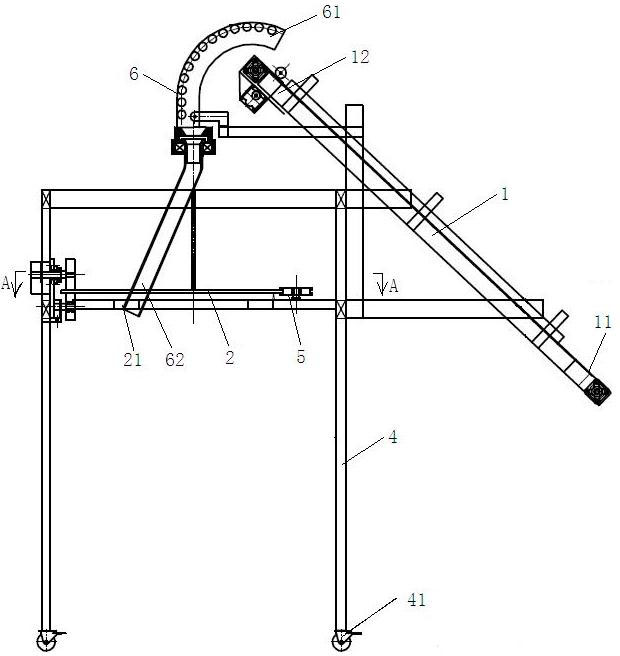

The invention relates to a prefabricated section swing shifting method for bridge cantilever assembly, which comprises the following steps that S1, a pier top cast-in-place section and a plurality of prefabricated sections are manufactured before construction; s2, a bridge floor support is installed on the pier top cast-in-place section, a pair of A hinge bearing lifters is installed at the front end of the bridge floor support, the first prefabricated section is lifted to the height of the pier top cast-in-place section through the A hinge bearing lifters, and the first prefabricated section and the pier top cast-in-place section are in butt joint and anchored; and S3, the remaining multiple prefabricated segments are lifted and transferred through the prefabricated segment auxiliary transfer device in sequence so as to be in butt joint with the A hinge bearing lifter, and the multiple prefabricated segments are spliced to form the bridge. According to the prefabricated segment swinging and moving method for bridge cantilever assembly, the multiple prefabricated segments are moved and transported to the cantilever end from the bridge pier in the air to be in butt joint, and the prefabricated section swing shifting method can be used for moving and hoisting the prefabricated segments during cantilever assembly under the bridge without the transportation condition.

Owner:张志新

Water faucet with connecting joint, pipes connecting joint and pipes connecting method

The invention provides a water tap with a connection joint, a pipe connector and a pipe connection method, comprising a water inlet pipe, a water outlet nozzle and a handle. Furthermore, the invention is provided with a connector comprising a joint body, a clamp ring and a sealing ring. The joint body is a cylinder with a central perforation; the rear end of the joint body is connected with a water outlet position of the water inlet pipe; the external periphery of the joint body is provided with a section of straight gear hobbing; the internal diameter of the section where the water outlet nozzle and the joint body is matched is slightly less than the external diameter of the straight gear hobbing; the circumference of the joint body is provided with at least two concave troughs used for sleeving the clamp ring and the sealing ring. As the connection between the water inlet pipe and the water outlet nozzle of the invention is provided with the connector with the straight gear hobbing, when in installation, the connector enters the water outlet nozzle by extrusion, leading the connection between the water inlet pipe and the water outlet nozzle to be firm, not loosened or twisted, and leading the connection to be slippery and smooth with beautiful appearance.

Owner:开平市美逸卫浴实业有限公司 +1

Damping type computer display device and adjusting method

PendingCN109296889AGood damping effectEasy to useStands/trestlesEnergy efficient computingDisplay deviceComputer engineering

The invention discloses a damping type computer display device and an adjusting method. The damping type computer display device comprises a displayer. A connecting rod is fixedly arranged on the rearside of the displayer. A rotating block is fixedly arranged at the end of the connecting rod. Rotating rods are fixedly arranged on the two sides of the rotating block. A damping ring gasket fixedlyconnected with the rotating block is arranged on the outer portion of each rotating rod in a sleeving manner. Limiting blocks are arranged at the top and the bottom of each rotating rod. A damping sleeve is arranged on the outer portion of each limiting block in a sleeving manner. A clamp plate is arranged on the outer side of each rotating rod. A limiting groove is arranged on the inner side wallof each clamp plate. According to the damping type computer display device, the rotating block rotates and drives the rotating rods and the limiting blocks to be in sliding connection in the limitinggrooves; through the arranged damping sleeves, when the rotating block rotates, damping of the longitudinal annular face is generated between the damping ring gaskets on the two sides of the rotatingblock and the clamp plates, damping of the transverse annular face is generated by the outer walls of the limiting blocks and the inner walls of the limiting grooves, and therefore the damping effectis better; and when the displayer rotates, greater stability is achieved, and any angle can be adjusted.

Owner:大连景竣科技有限公司

T-tube connector capable of being rotated by 360 degrees

The invention discloses a T-tube connector capable of being rotated by 360 degrees. The T-tube connector capable of being rotated by 360 degrees is characterized in that an upper circular hole and a lower circular hole which are symmetric to each other are formed in the upper wall and the lower wall of a hollow tube in the middle of a fixed connector, wherein the circular holes communicate with an inner hole in the fixed connector; a rotating connector capable of being rotated by 360 degrees is arranged on the outside diameter of the hollow tube; an integral third-way connector is arranged at the lower end of the rotating connector; a first annular concave hole which communicates with the circular holes in the upper wall and the lower wall of the hollow tube is formed in the middle part, in the length direction, of a first through hole in a horizontal center line of the rotating connector; the lower end of the first annular concave hole communicates with a water draining hole of a third-way connector; a first ceramic sealing ring and a second ceramic sealing ring, which are correspondingly sealed to a first graphite sealing ring and a second graphite sealing ring in a precision fitting manner, are correspondingly arranged in a first left concave hole and a first right concave hole in the left end and the right end of a first through hole; a compressing spring is arranged at the right end of a compressing plate; adjusting nuts are arranged at the right ends of the compressing springs. The T-tube connector capable of being rotated by 360 degrees is simple, convenient and easy to connect.

Owner:詹桥生

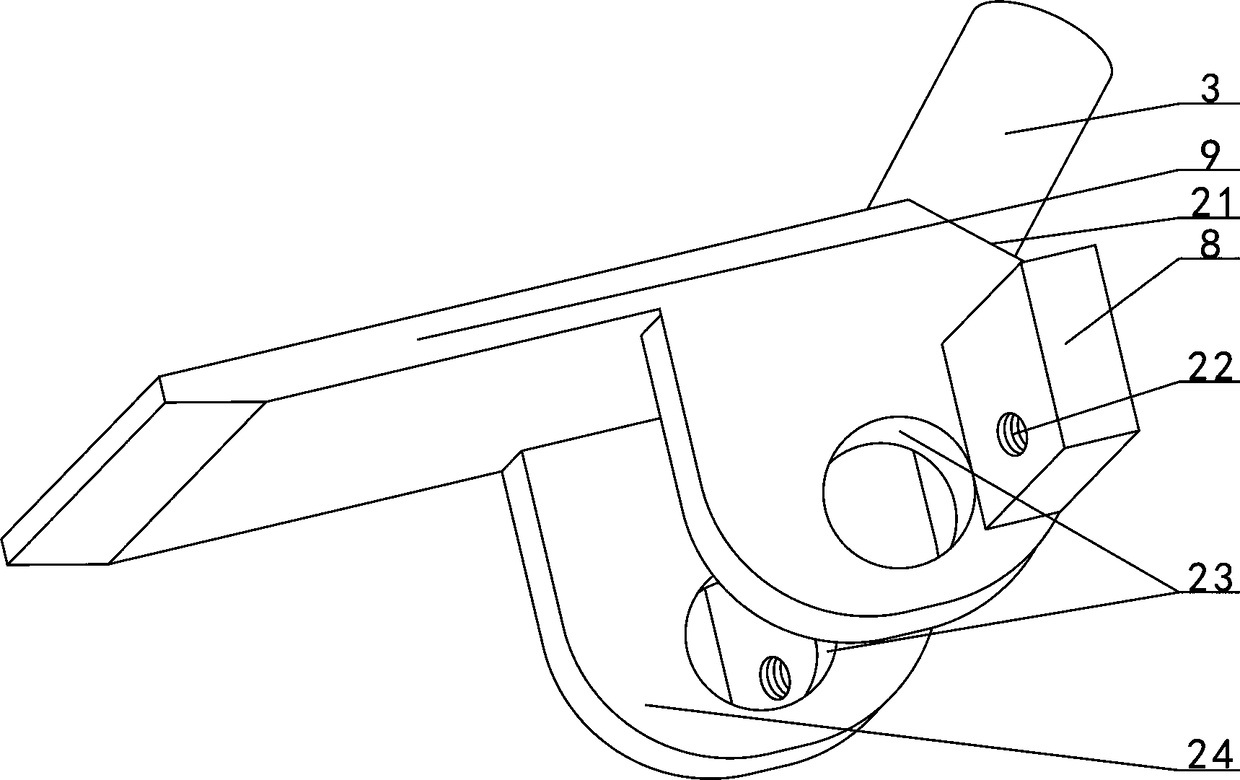

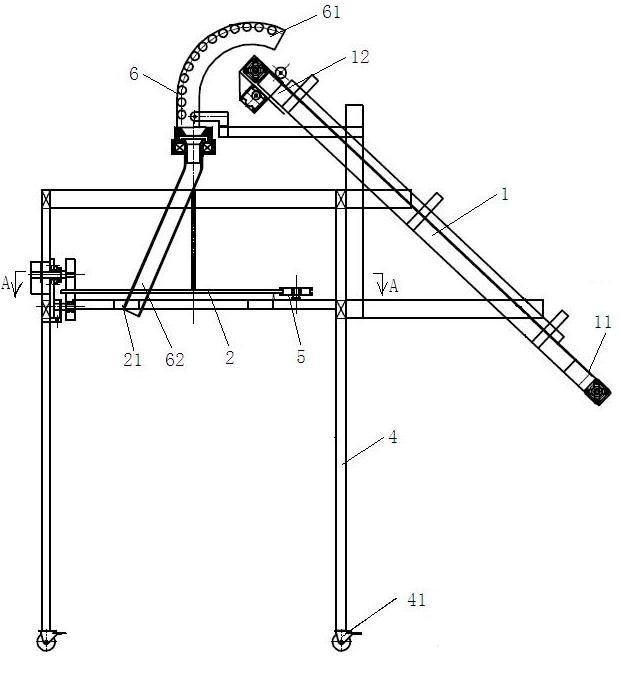

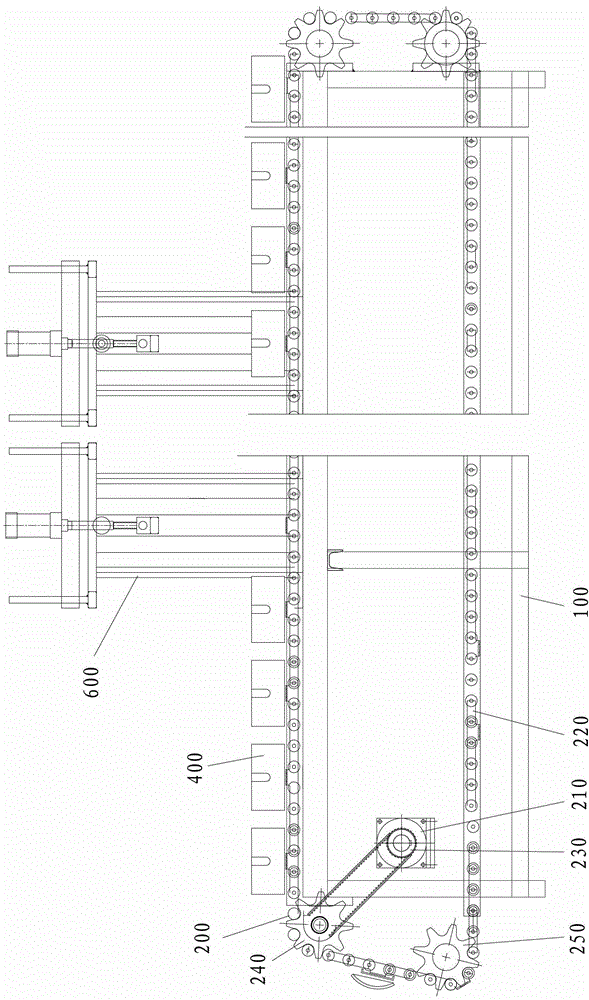

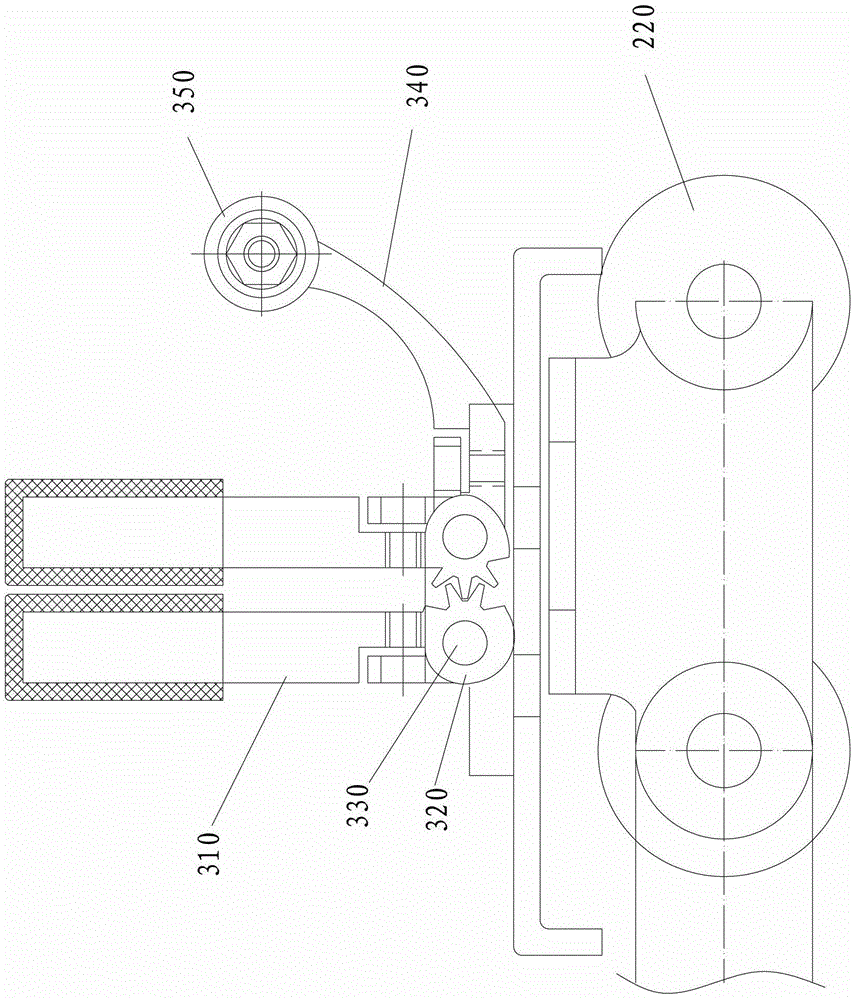

A chemical inspection and repair equipment trolley

ActiveCN109050612AWon't twistReduce investmentHand carts with multiple axesHand cart accessoriesEngineeringShovel

A chemical inspection and repair equipment trolley relates to a trolley. A rear end of the tie rod (2) is fixedly connected to the middle of the front rod (4), A shovel plate have wheels is arrange onboth sides of that front rod, the rear and upper parts of the two shovel plates are respectively provided with pry bar cannulas (3), The front ends of the connecting rod A (10) and the connecting rodB (18) are respectively connected to the proximal ends of the front rods, A length adjusting sleeve A (13) and a length adjusting sleeve B (15) are respectively arranged at the proximal rear ends ofthe connecting rod A and the connecting rod B, the opposite faces of the length adjusting sleeve A and the length adjusting sleeve B are respectively connected with the outer ends of the rear lever A(12) and the rear lever B (16), the rear lever A and the rear lever B are respectively provided with another two shovel plates with wheels, and the rear upper parts of the other two shovel plates arerespectively provided with a pry bar insertion tube; The invention realizes the quick replacement of the small space equipment through the combination of the elongated and widened front rod, the connecting rod and the rear rod, and the cooperation of the shovel plate and the pry bar cannula.

Owner:HENAN ZT LEAGUE CHEM

Multifunctional Scaffolding for Construction Engineering

Owner:江苏新苏阳建设有限公司

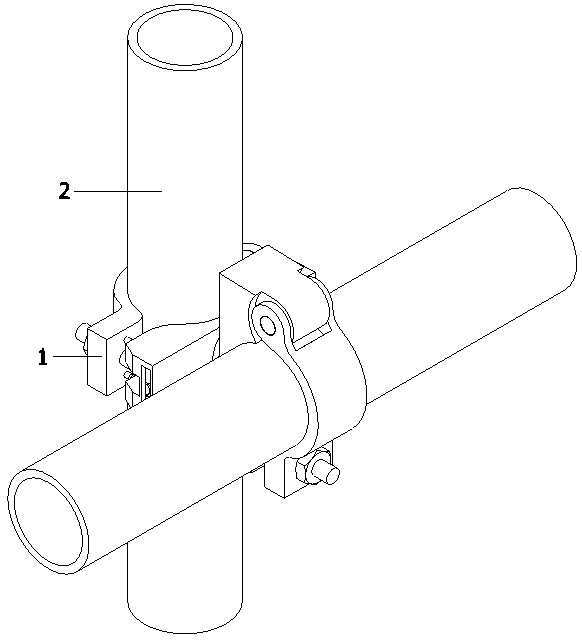

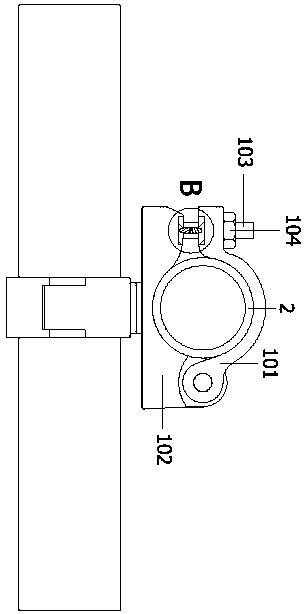

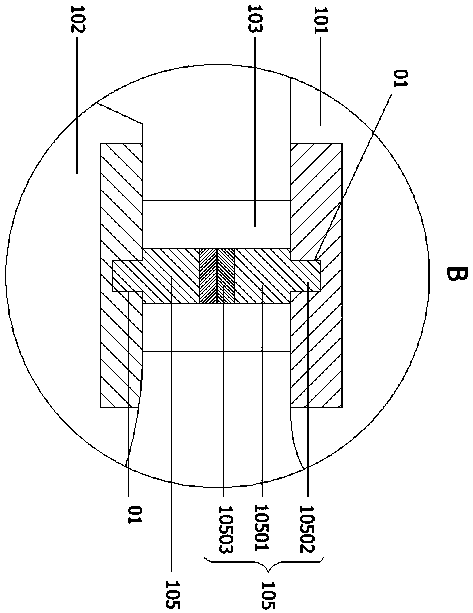

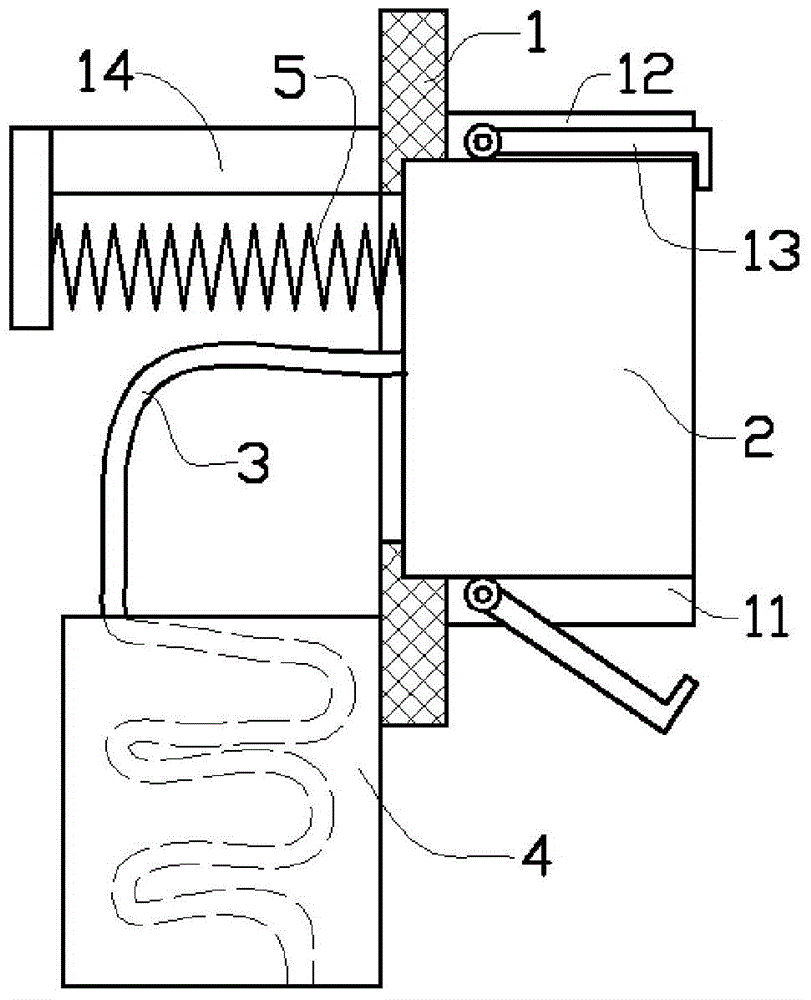

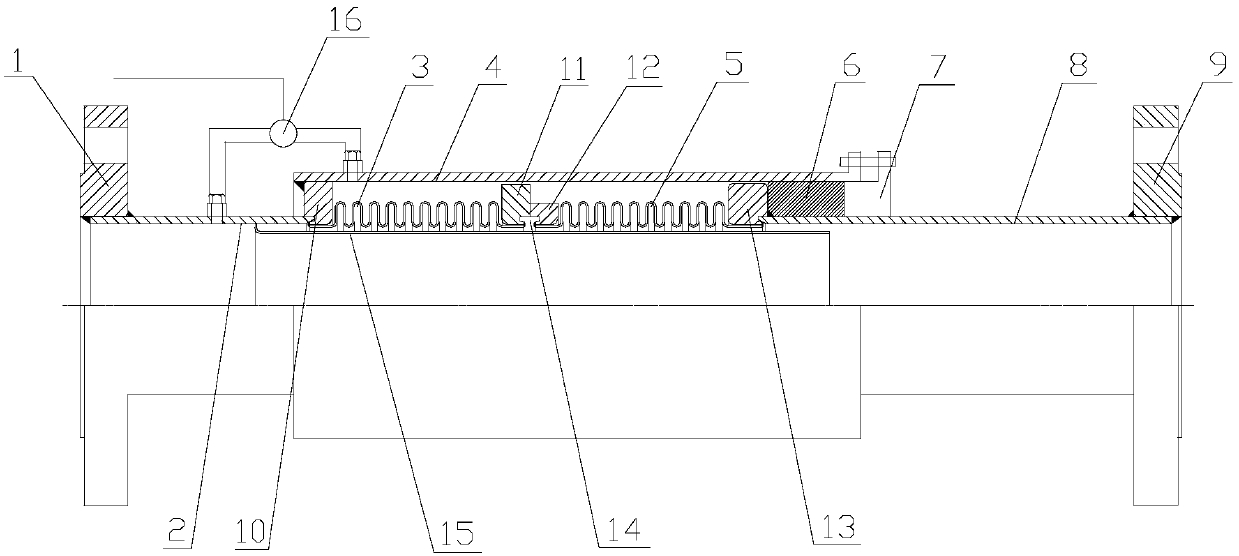

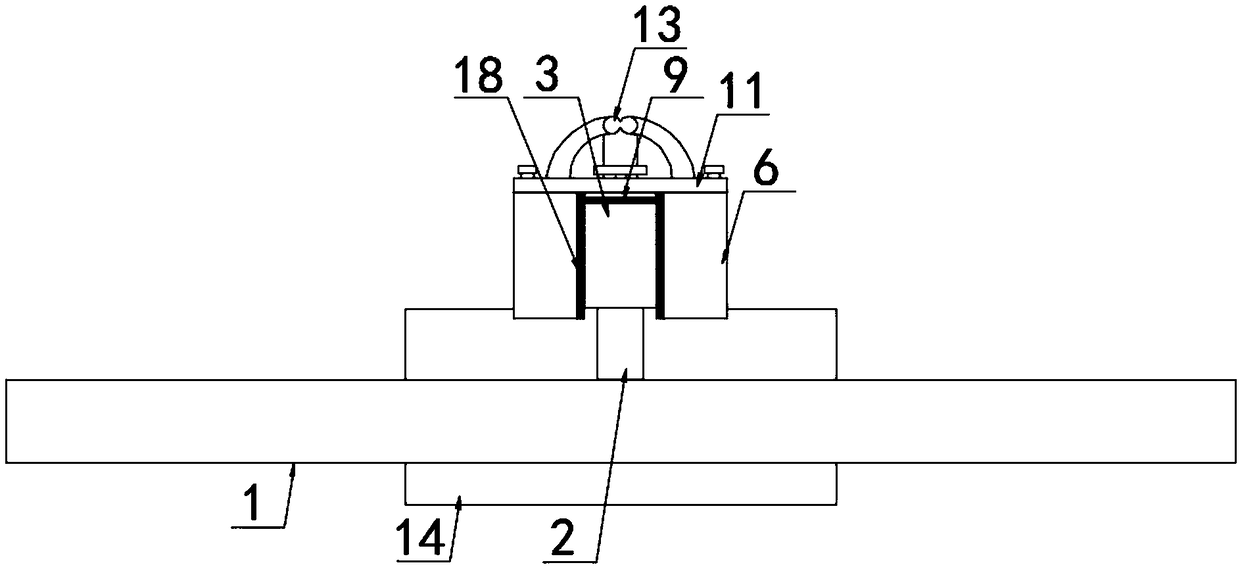

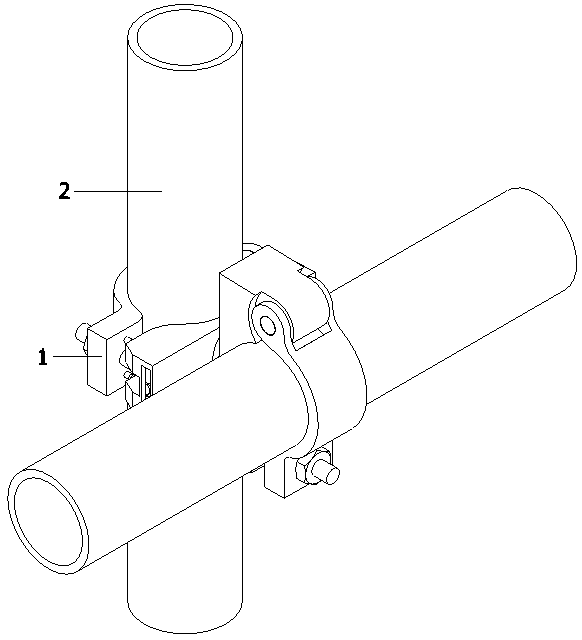

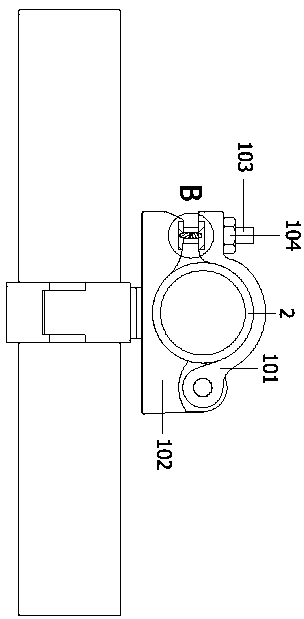

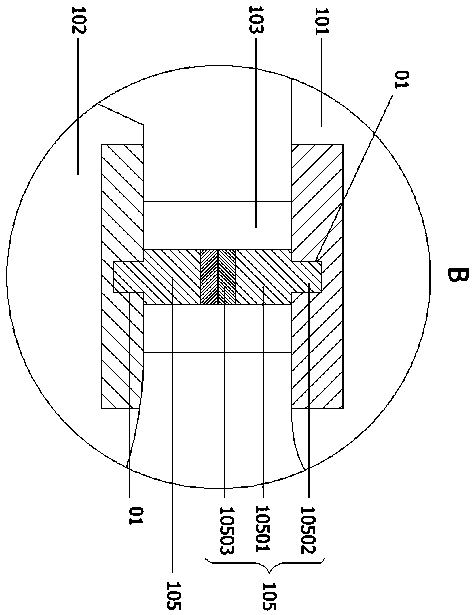

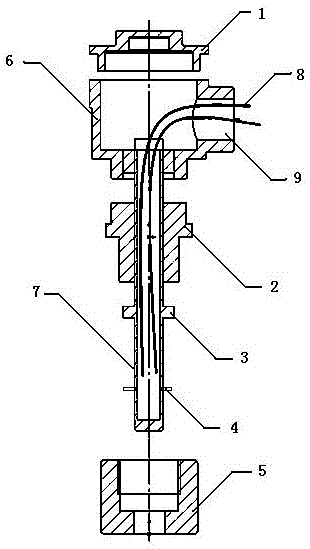

Ultrasonic heat meter temperature sensor anti-wire-twisting device

InactiveCN105784204ASimple structureEasy and quick installationCalorimeterHeat meterIndustrial engineering

The invention relates to an ultrasonic heat meter temperature sensor anti-wire-twisting device and belongs to the field of an ultrasonic heat meter. The device is provided with a sensor cavity. The device is characterized in that a sensor cover is mounted on the upper end of the sensor cavity; one side of the sensor cavity is provided with a wire outlet; the lower end of the sensor cavity is connected with a tubular sensor guide rod; the inner cavity of the sensor guide rod is communicated with the sensor cavity; the sensor guide rod is fixedly provided with a baffle piece; the sensor guide rod between the baffle piece and the sensor cavity is sleeved by a movable nut; the lower end of the sensor guide rod is inserted into a through hole in a base; the base is internally equipped with a sensor; the movable nut and the base are screwed together through a thread; the lower ends of wires are connected with the sensor; and the upper ends of the wires pass through the wire outlet through the sensor guide rod inner cavity and the sensor cavity.

Owner:WEIHAI BOYANG ELECTRONICS

A quick emergency fire hose belt

Owner:QUANZHOU SANXING FIRE FIGHTING EQUIP

Internal pressure type sleeve compensator provided with composite external safety casing pipe

PendingCN107575687AWon't twistIncreased axial stabilityPipeline expansion-compensationInternal pressureOuter Cannula

The invention relates to an internal pressure type sleeve compensator provided with a composite external safety casing pipe. The internal pressure type sleeve compensator comprises a left core pipe, aright core pipe, a left corrugated pipe, a right corrugated pipe and a flow guide pipe. The left core pipe is connected with the left corrugated pipe. The right core pipe is connected with the rightcorrugated pipe. The left corrugated pipe is connected with the right corrugated pipe. The flow guide pipe is arranged in an inner cavity from the left core pipe and the right core pipe. The peripheries of the left corrugated pipe and the right corrugated pipe are provided with the outer casing pipe. The left end of the outer casing pipe is connected with the left core pipe, and the right end of the outer casing pipe is connected with the right core pipe through a sealing device. The sealing device comprises a padding ring, sealing padding and a padding gland flange. The outer casing pipe of the compensator is good in axial stability, the compensator cannot be twisted, and even if the corrugated pipes fail due to fatigue and leakage happens, the outer casing pipe of the compensator can achieve a good sealing effect. By means of the internal pressure type sleeve compensator provided with the composite external safety casing pipe, the sealing performance of the compensator is improved, reliable sealing of the compensator can be maintained for a long time, and the maintenance-free purpose is achieved. By means of the internal pressure type sleeve compensator provided with the composite external safety casing pipe, leakage is not likely to happen, the service life is long, the maintenance cost is low, and work is safe and reliable.

Owner:JIANGSU YONGLI PIPELINE CO LTD

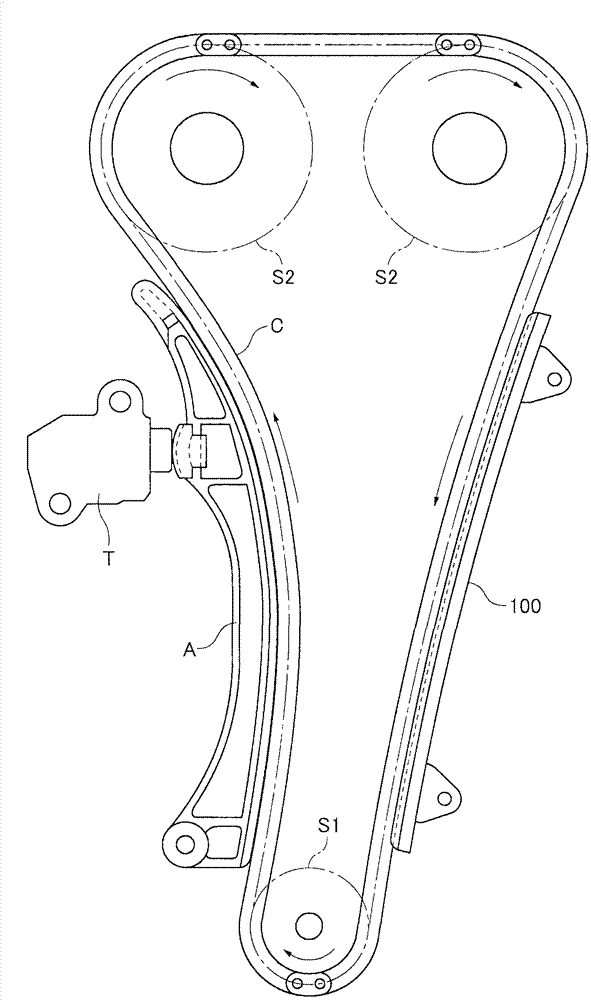

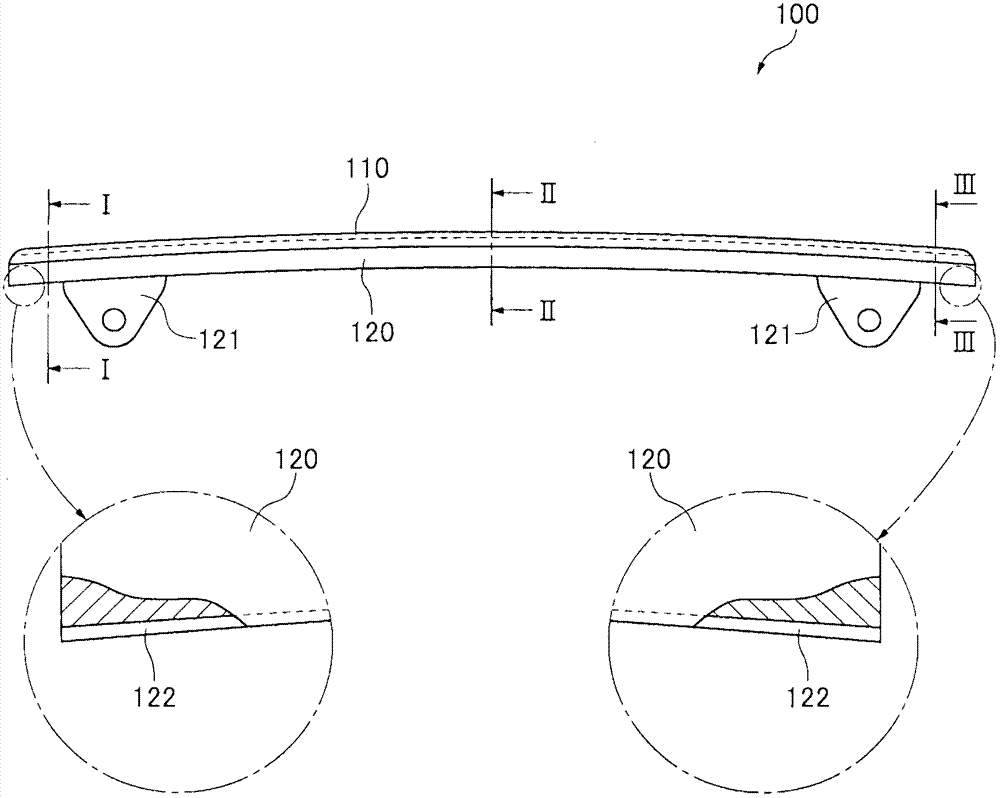

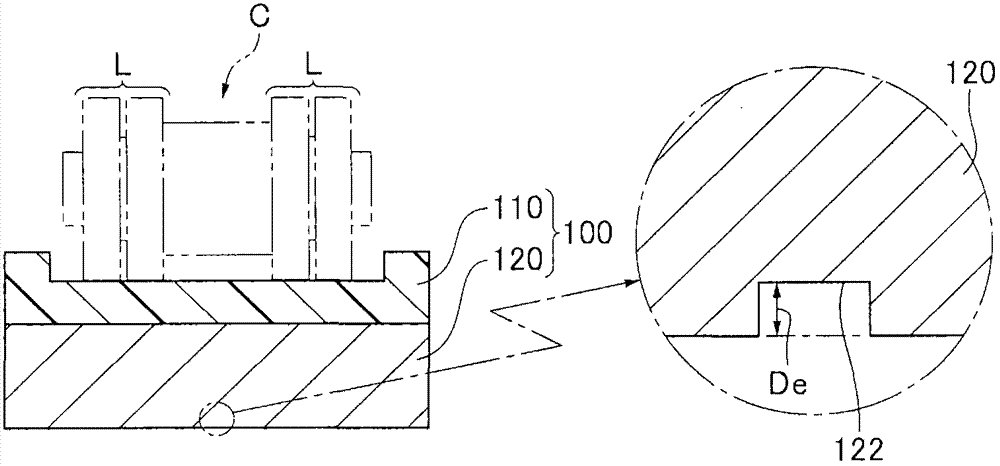

Stationary chain guide

Owner:TSUBAKIMOTO CHAIN CO

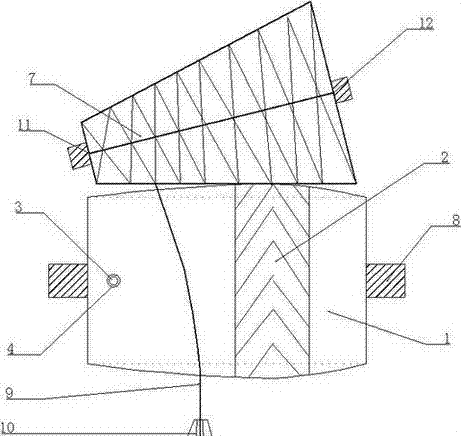

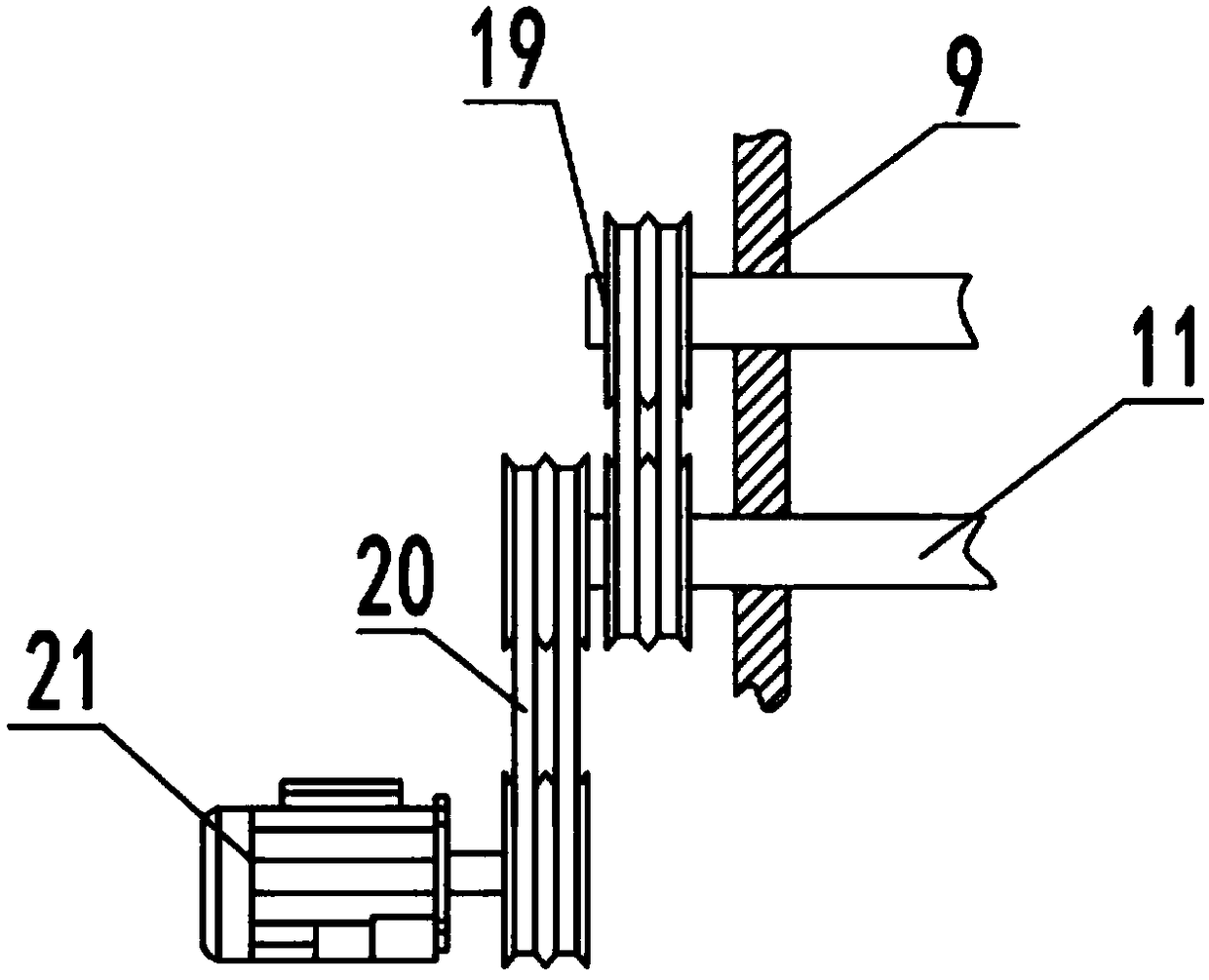

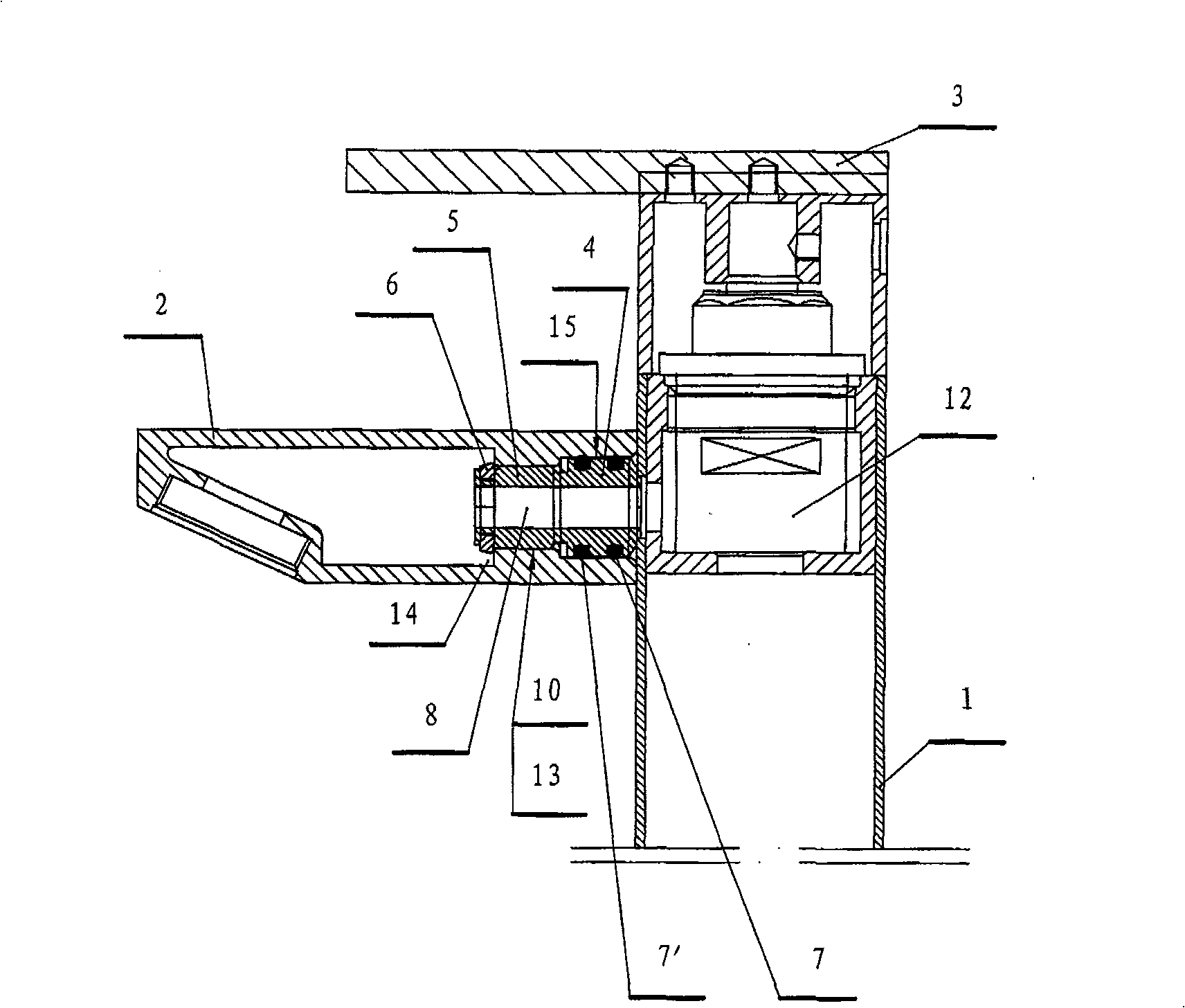

Sealing strip coiling device

InactiveCN102320495AWon't twistBeautiful appearanceFilament handlingMechanical engineeringEngineering

The invention discloses a sealing strip coiling device. The device comprises a conveyer belt, a rotating disk and a strip basket, wherein the conveyer belt is used for conveying a sealing strip, the rotating disk can be driven by a driving device to rotate around an axle center and is provided with an outlet allowing the sealing strip to pass through, and the strip basket is arranged under the rotating disk and can accept the sealing strips passing through the outlet. The sealing strip coiling device provided by the invention can realize automatic strip coiling, thereby replacing the conventional manual strip coiling work and improving the strip coiling efficiency. Coiling the sealing strip by the sealing strip coiling device provided by the invention, the sealing strip cannot be twisted tightly, and the coiled sealing strip is tidy and regular and has elegant appearance. By measuring the sealing strip conveying speed, the length of the coiled strip can be accurately measured based onthe strip coiling time and the sealing strip conveying speed, the strip coiling time is set according to the needed length of the sealing strip, and the sealing strip is automatically cut off when the set strip coiling time is out, so that the measurement is accurate.

Owner:COOPER STANDARD AUTOMOTIVE KUNSHAN CO LTD

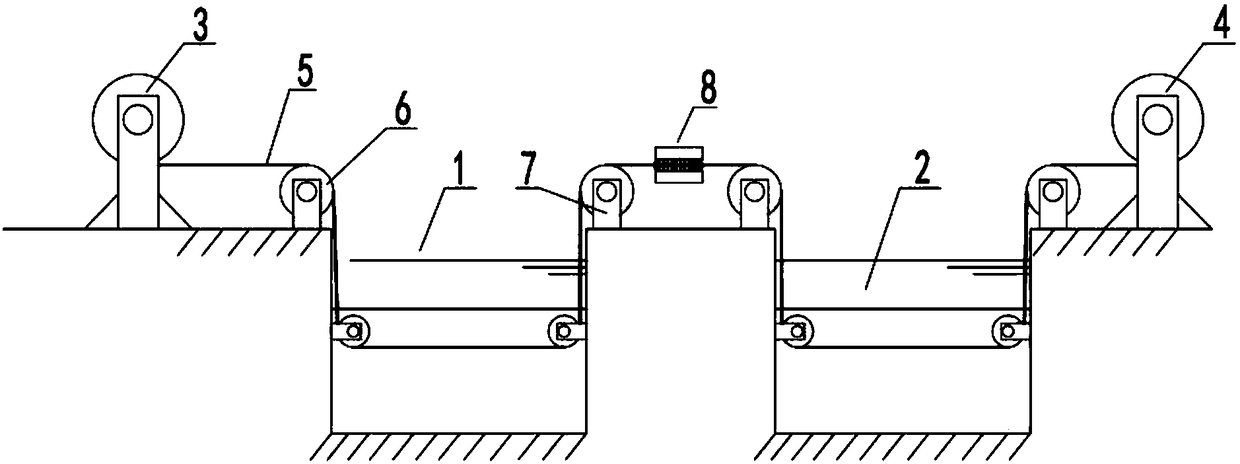

Multiposition printing production line for balloons

InactiveCN103144423BImprove printing efficiencyImprove printing qualityRotary pressesProduction lineNumerical control system

The invention discloses a multiposition printing production line for balloons, which comprises a rack, a conveying device and a plurality of printing devices that are mounted on the rack, a plurality of balloon clamping and dismounting devices, a plurality of balloon positioning sleeves, air blowing devices and a numerical control system, wherein the balloon clamping and dismounting devices and the balloon positioning sleeves are mounted on the conveying device, and arranged in a one-to-one correspondence manner; the air blowing devices and the printing devices sequentially correspond to the balloon clamping and dismounting devices; the air blowing devices correspond to air taps of the clamped balloons in the balloon clamping and dismounting devices; and the printing devices correspond to balloon printing surfaces of the inflated balloons, which are exposed out of the balloon positioning sleeves. According to the multiposition printing production line for the balloons, the production line is connected by the conveying device in a balloon printing process; the printing efficiency can be improved greatly; in addition, as the balloons can be positioned by the balloon positioning sleeves, in this case, the inflated balloons cannot twist in the printing process; patterns are clear; misprinting and position changing are avoided; and the printing quality is improved.

Owner:QUANZHOU FENGZE FUFAN MECHANICAL

A workpiece clamping device and machine tool

ActiveCN113118799BAchieve clamping and fixingHigh clamping torquePositioning apparatusMetal-working holdersBrakeEngineering

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

a hospital bed

The invention provides a hospital bed. The hospital bed comprises a bed body (100), a supporting frame (200), a guide platform (300) and a locking part (500), and the bed body comprises at least threebed plates (101), a bed sheet (102), a bed frame (103) and a limiting plate (104); the supporting frame is arranged on the bed plates (101); the guide platform comprises an annular guide rail (301),a ball (302) and a supporting block (303). Compared with the prior art, the hospital bed has the advantages that through the structure, when a patient lays on the bed and his / her four limbs are hung,he can turn over arbitrarily, and the hung joint cannot be twisted.

Owner:路万虹

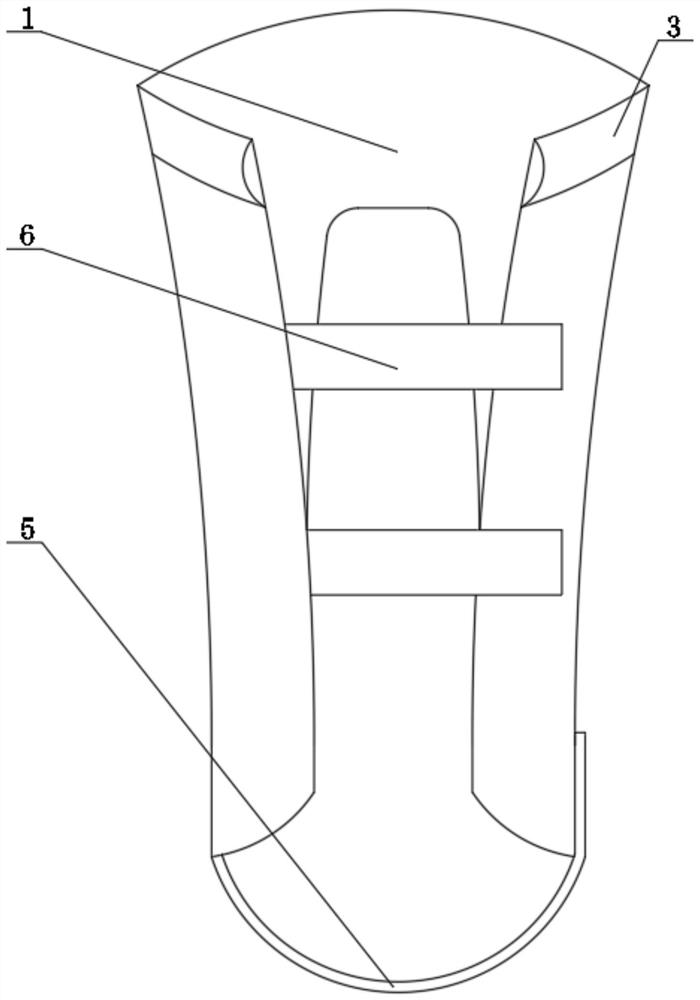

Inflatable parachuting special ankle guard and using method

InactiveCN112619112AAnti-slip and wear-resistantDurableSport apparatusMedial malleolusPhysical medicine and rehabilitation

The invention relates to an inflatable parachuting special ankle guard and a using method, wherein the inflatable parachuting special ankle guard comprises an ankle guard sleeve and an air column bag arranged in the ankle guard sleeve, the shape of the air column bag is matched with the ankle guard sleeve, and the ankle guard sleeve is provided with a heel fixing band and a binding band which play a role in fixing. The ankle protecting sleeve comprises two sheet bodies corresponding to the medial malleolus and the lateral malleolus respectively and a surrounding sheet connected with the two sheet bodies, wherein the surrounding sheet is located at the tops of the sheet bodies, a containing opening used for containing the air column bag is formed in the surrounding sheet, and a foldable hook-and-loop fastener is arranged at the containing opening. According to the invention, an ankle is fixed through the ankle protecting sleeve, wherein the ankle protecting sleeve is a special cloth sleeve and has the advantages of skid resistance, wear resistance, firmness and durability; after the ankle protecting sleeve is bound to the ankle, the twisting range of the ankle is limited, and the ankle is protected and fixed; after the air column bag located in the ankle guard sleeve is inflated, external force can be effectively buffered, the ankle joint is protected, and the ankle joint cannot be twisted and injured under the condition that the ankle joint is impacted by the external force.

Owner:WUXI TAYLOR PACKAGING ENG CO LTD

An orthopedic medical bed

InactiveCN107789135BChange ups and downsWon't twistDiagnosticsNursing bedsOrthopedic departmentBiomedical engineering

Owner:THE SIXTH AFFILIATED HOSPITAL OF XINJIANG MEDICAL UNIV

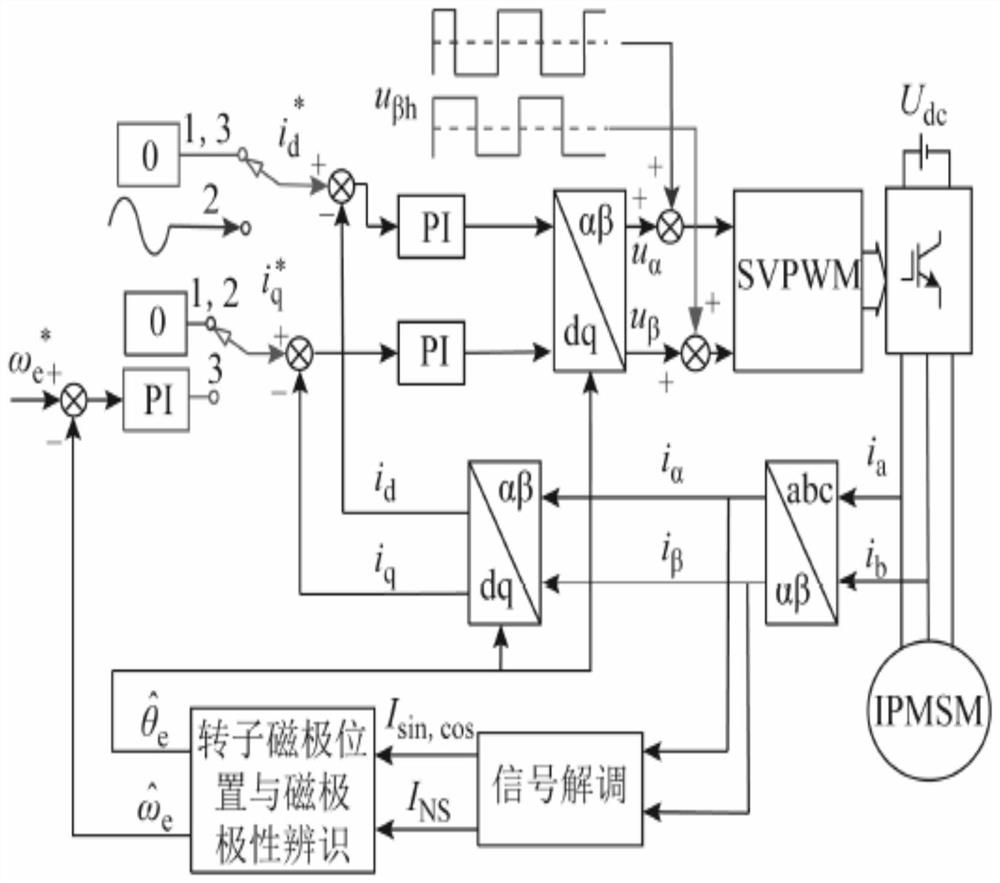

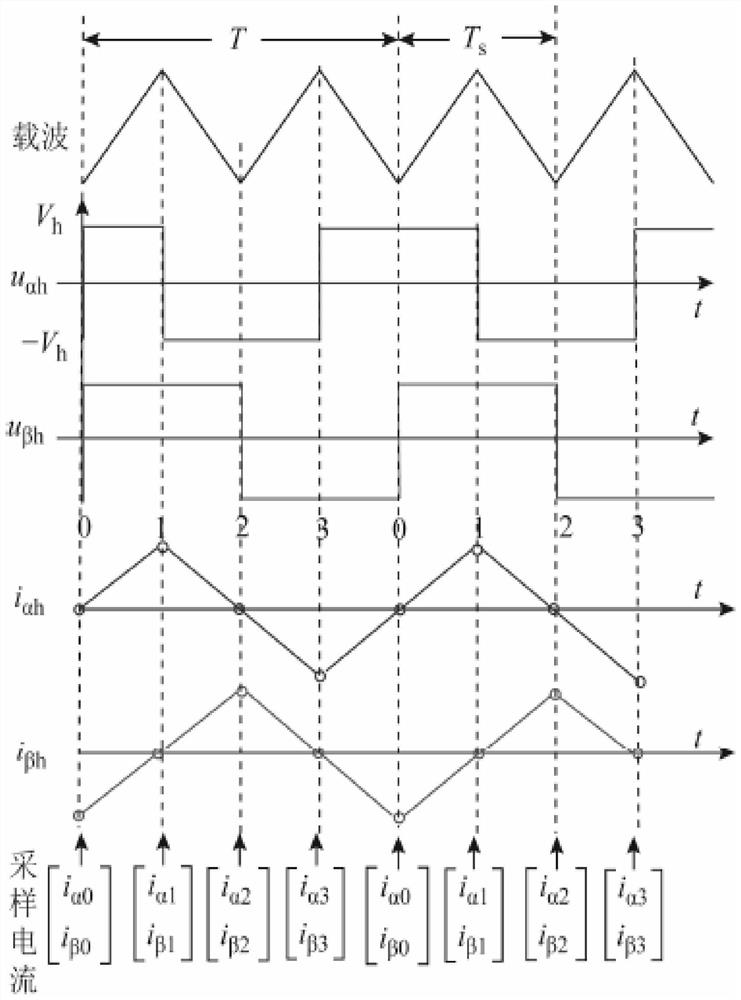

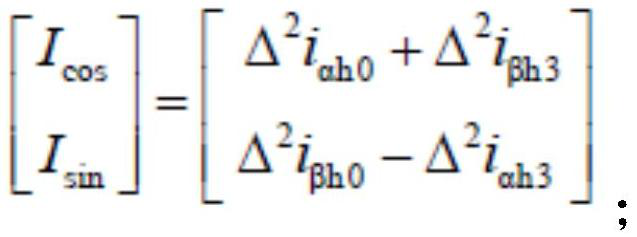

Permanent magnet motor magnetic pole position detection method

PendingCN112491317AWon't twistAccurate detectionElectronic commutation motor controlVector control systemsSignal onMagnetic poles

The invention discloses a method for detecting the position of a magnetic pole of a permanent magnet motor. The method comprises the following steps: 101) identifying the position of the magnetic pole: respectively injecting two orthogonal high-frequency square wave voltage signals into an alpha axis and a beta axis, demodulating the high-frequency response current signals on the alpha axis and the beta axis, and identifying the position of a rotor pole; 102) magnetic pole polarity identification: after magnetic pole position identification is completed, keeping high-frequency square wave voltage signal injection unchanged, and injecting a low-frequency sinusoidal current signal of a period into a d axis, so the magnitude of high-frequency response current is changed. The polarity of the magnetic pole is identified by comparing the positive and negative peak values of the low-frequency sinusoidal current signal and the high-frequency response current signal at the positive and negativepeak values. According to the detection method, the rotor is not twisted, the detection is accurate, and the response speed is high.

Owner:深圳库马克科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com