Prefabricated segment swing shifting method for bridge cantilever assembly

A technology for segments and bridges, applied in the field of prefabricated segment swing method, can solve the problems of unusable, cantilever ends of prefabricated segments butted in place, and the lifting point is inside the support point, etc., and achieves diversified structural forms and simple structure. , the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

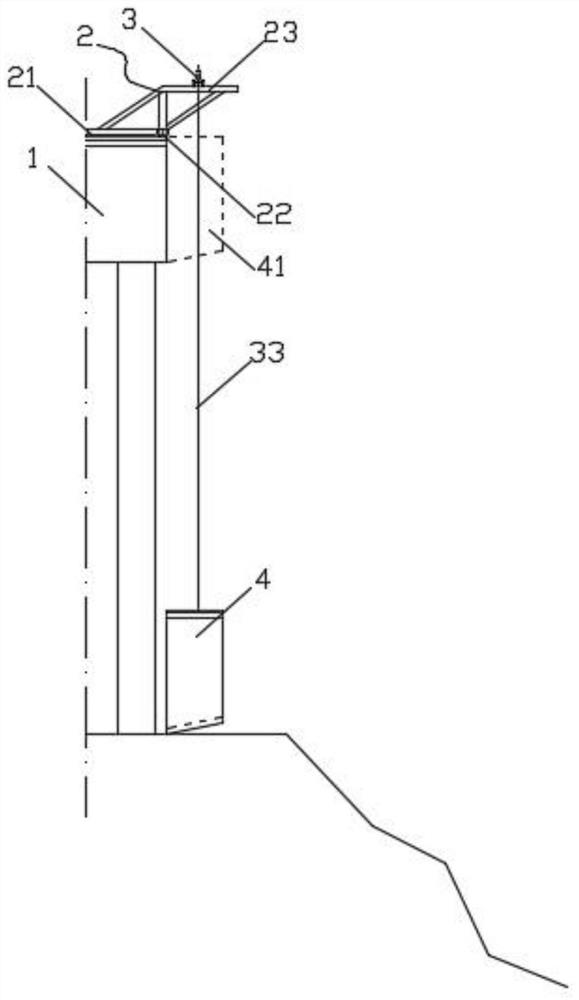

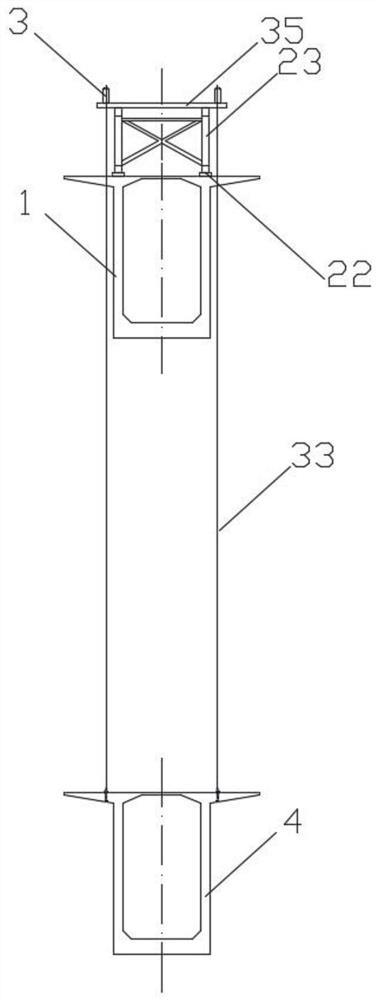

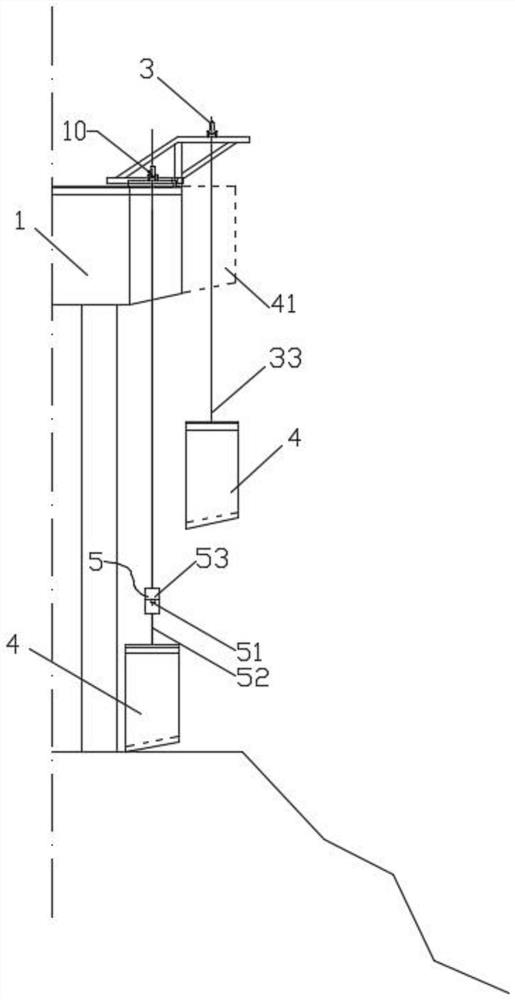

[0069] Such as Figure 1-18 As shown, according to an embodiment of the prefabricated section swinging method for bridge cantilever assembly provided by the present invention, it includes the following steps,

[0070] S1, the cast-in-place section 1 on the top of the pier and the multi-block prefabricated sections 4 are manufactured before construction, and when the cast-in-place section 1 on the top of the pier is poured, the embedded parts of the bracket are set on it to fix the bridge deck support 2. Set hoisting embedded parts 74 on section 4 for subsequent hoisting; complete the beam transportation channel from the prefabricated section 4 storage site to the pier;

[0071] S2, install the bridge deck support 2 on the cast-in-place section 1 at the top of the pier, install a pair of A-hinge support lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com