Multi-stage diversion SSMBBR sewage treatment system and treatment method

A sewage treatment system and deflector technology, which is applied in biological water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc. and other problems, to achieve the effect of reducing construction investment, long time, and enhancing the removal of total nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

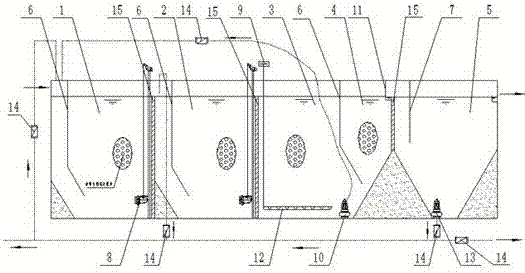

[0042] 1. A multi-stage diversion type SSMBBR sewage treatment system

[0043] Such as figure 1 As shown, a multi-stage diversion type SSMBBR sewage treatment system includes anaerobic section 1, denitrification section 2, aerobic section 3, filtration section 4, sedimentation section 5, deflector A6, deflector B7, Stirrer 8, fan 9, mixed liquid return pump 10, screen 11, microporous aerator 12, sludge pump 13, control valve 14 and partition 15, anaerobic section 1 and denitrification section 2, denitrification section 2 and the aerobic section 3, the filtration section 4 and the precipitation section 5 are all provided with a partition 15, and the lower part of the partition 15 is fixed on the bottom of the reactor, and the reaction section on both sides of the partition 15 is in overflow communication, and the anaerobic section The inlet end of the anaerobic section 1 is parallel to the wall surface of the anaerobic section 1, and a deflector A6 is arranged. The inlet end o...

Embodiment 2

[0058] One, a kind of multistage diversion type SSMBBR sewage treatment system (same as embodiment 1)

[0059] 2. Sewage treatment process

[0060] The concentration of sewage COD is 320mg / L, BOD 5 The concentration of SS is 170mg / L, the concentration of SS is 180mg / L, the concentration of TN is 35mg / L, the concentration of ammonia nitrogen is 25mg / L, the concentration of total phosphorus is 4mg / L, and the rural domestic sewage with a pH value of 6-9 , after the grid treatment, the large particle suspended matter and floating matter are intercepted, the sewage enters the regulating tank, and after staying in the regulating pond, the sewage is sent to the above-mentioned multi-stage diversion type SSMBBR sewage treatment system, and anaerobic treatment is carried out in turn. Treatment, denitrification treatment, aerobic treatment, filtration section treatment and sedimentation section treatment, to obtain sewage with various physical, chemical, and biochemical indicators qual...

Embodiment 3

[0062] One, a kind of multistage diversion type SSMBBR sewage treatment system (same as embodiment 1)

[0063] 2. Sewage treatment process

[0064] The concentration of sewage COD is 280mg / L, BOD 5 Rural domestic sewage with a concentration of 150mg / L, a concentration of SS of 180mg / L, a concentration of TN of 35mg / L, a concentration of ammonia nitrogen of 25mg / L, a concentration of total phosphorus of 4mg / L, and a pH value of 6-9 , after the grid treatment, the large particle suspended matter and floating matter are intercepted, the sewage enters the regulating tank, and after staying in the regulating pond, the sewage is sent to the above-mentioned multi-stage diversion type SSMBBR sewage treatment system, and anaerobic treatment is carried out in turn. Treatment, denitrification treatment, aerobic treatment, filtration section treatment and sedimentation section treatment, to obtain sewage with various physical, chemical, and biochemical indicators qualified, and finally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com