Twin-screw oil press with cooling device

A double-screw oil press and cooling device technology, applied to presses, manufacturing tools, etc., can solve problems such as non-use, loss of beneficial components of peanut protein, etc., to ensure quality, avoid denaturation and loss of trace beneficial components, Guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

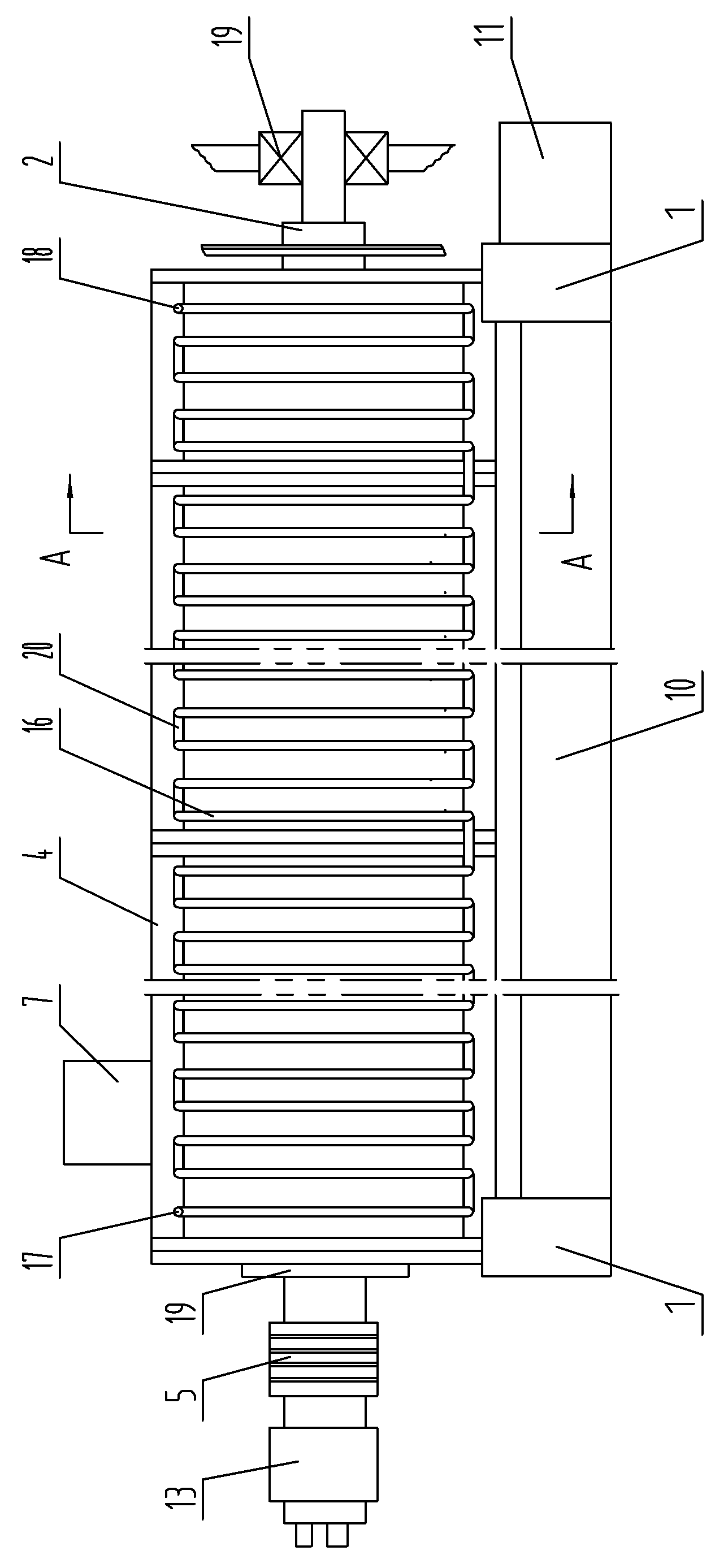

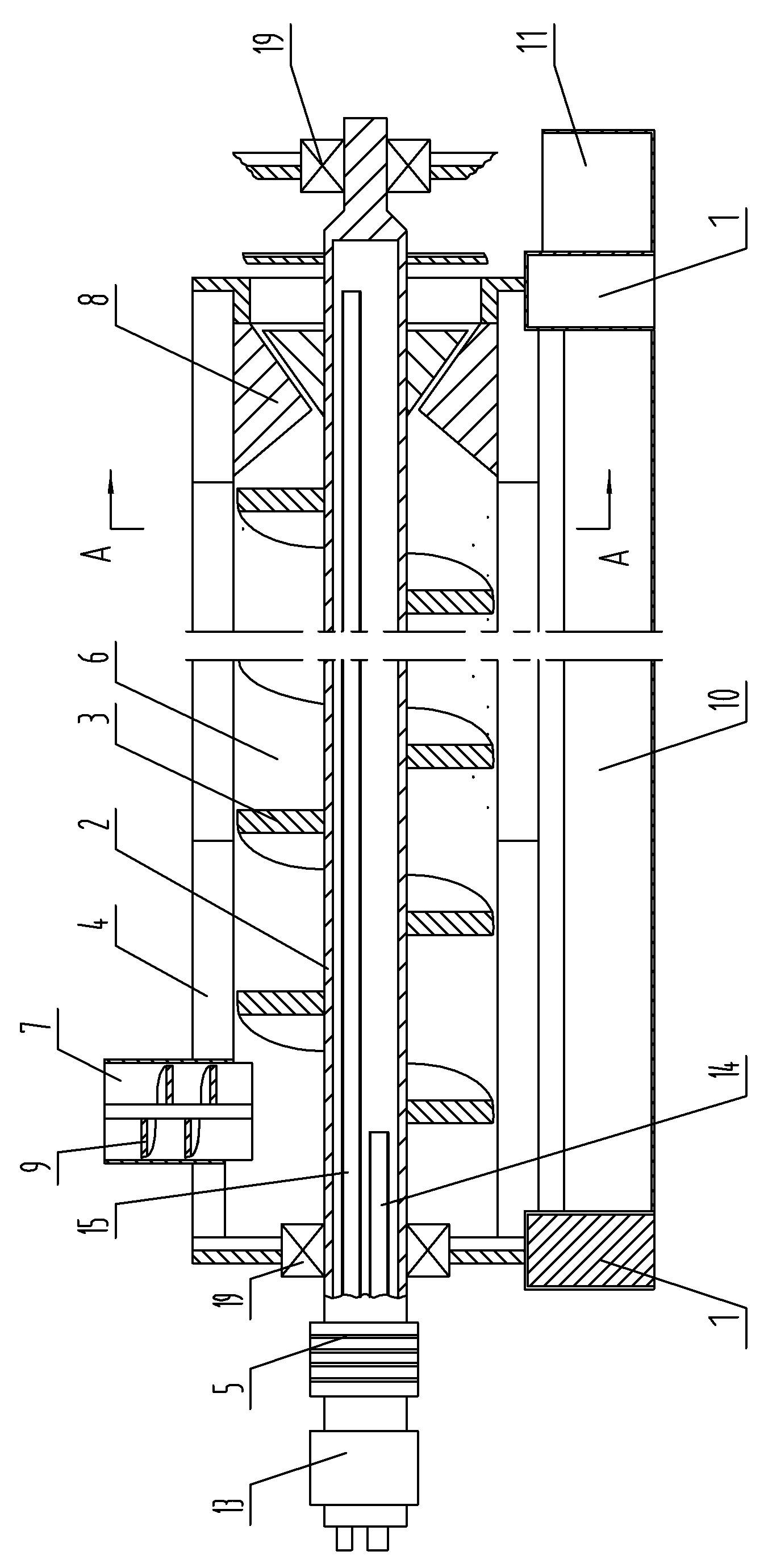

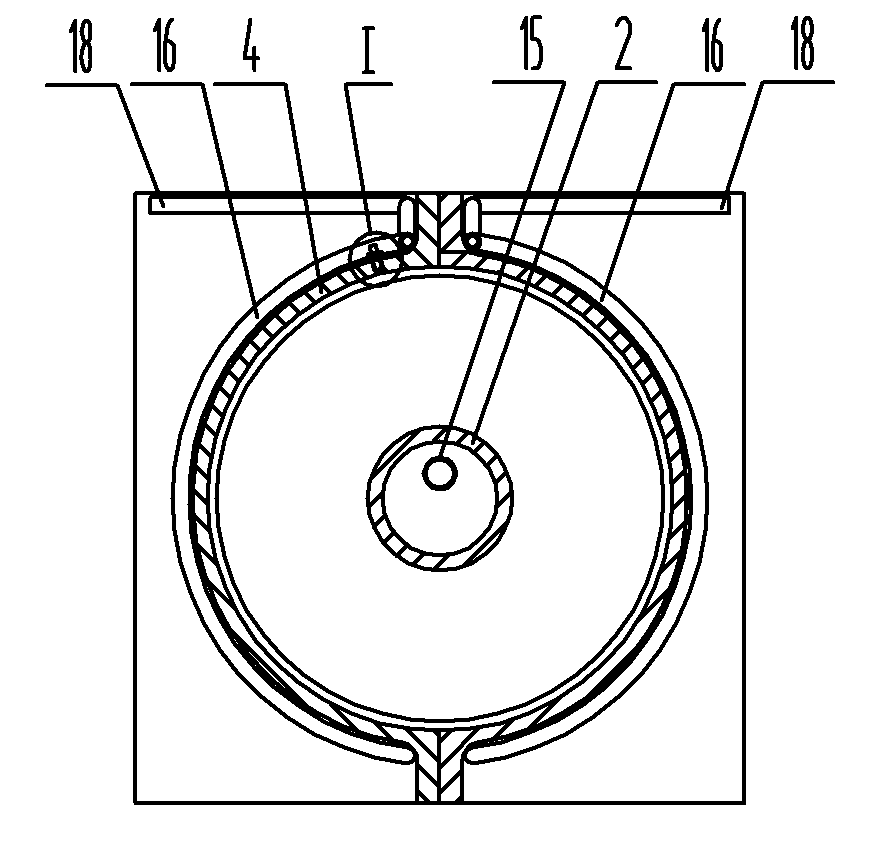

[0033] see Figure 1 to Figure 4 , in the figure, the double-screw oil press with cooling device of the present invention includes a frame 1, and the top of the frame 1 is provided with a hollow pressing shaft 2 installed on the frame through supports at both ends, and the pressing shaft 2 is fixed A spiral blade 3 is installed, and the blade 3 is covered with a squeeze row 4, which is composed of two half cylinders. One end of the squeeze shaft 2 is provided with a transmission mechanism 5. Squeeze cavity 6, one end of the squeeze cavity 6 communicates with the material inlet 7 located above, the other end is provided with a cake output regulating mechanism 8, the material inlet 7 is provided with a screw feeding mechanism 9, the frame An oil collecting tank 10 is provided in the middle part of 1 and below the press row 4, and a cake collecting tank 11 is provided on the side of the frame 1 corresponding to the cake output adjustment mechanism 8, and also includes a press sha...

Embodiment 2

[0035] see Figure 5 , in the figure, the meanings of the same numbered parts in this embodiment and the first embodiment are the same and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com