Light anti-sliding fabricated comprehensive pipeline support and hanger and assembly method thereof

A comprehensive pipeline, anti-slip technology, applied in the direction of pipeline support, pipe/pipe joint/pipe fitting, rod connection, etc., can solve the failure of the connection between the fixed support and the vertical boom, the cross arm connection can not bear the pressure load, Problems such as loose bolt connections can shorten the assembly time, simplify the assembly process, and reduce the use of assembly equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

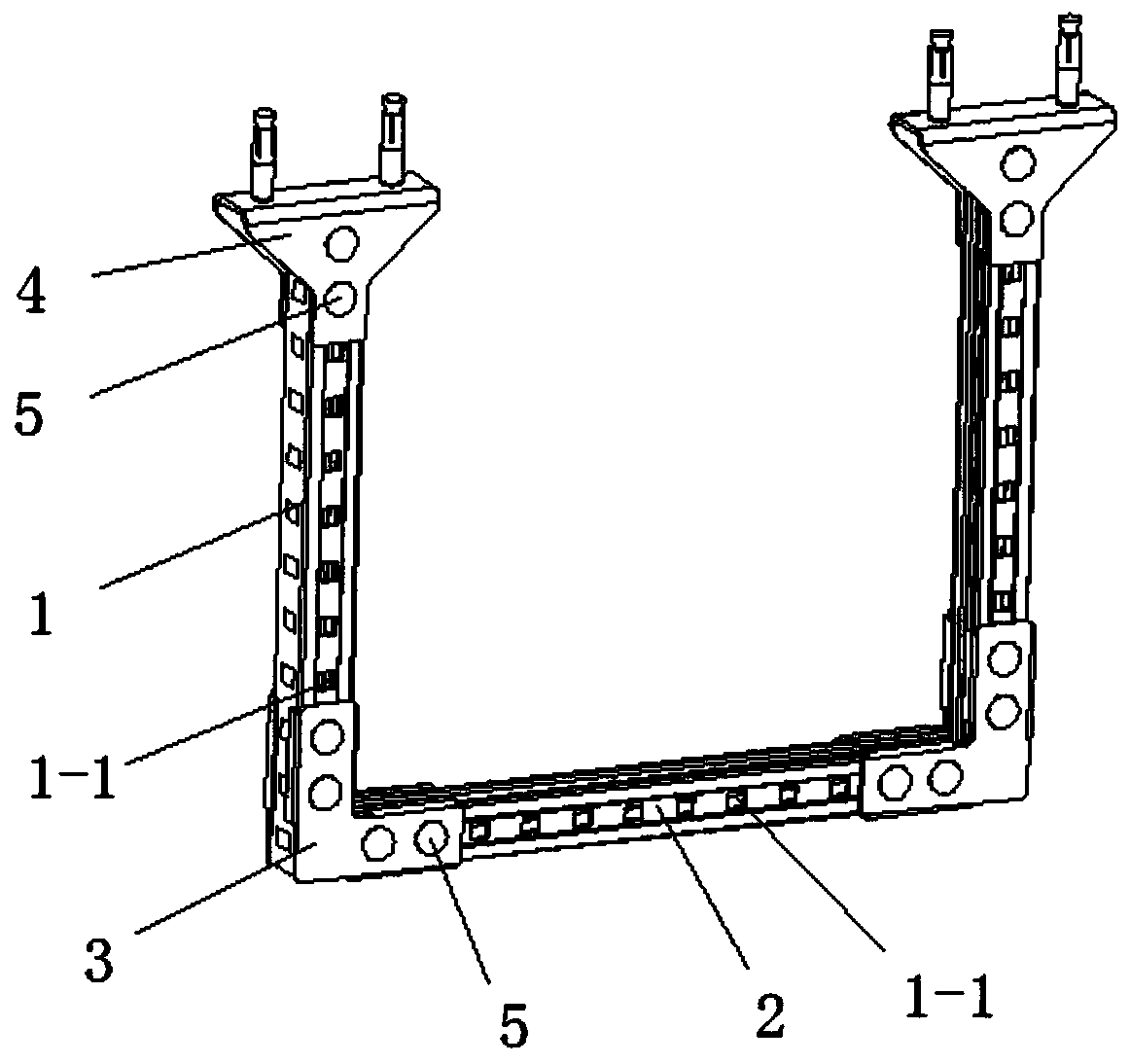

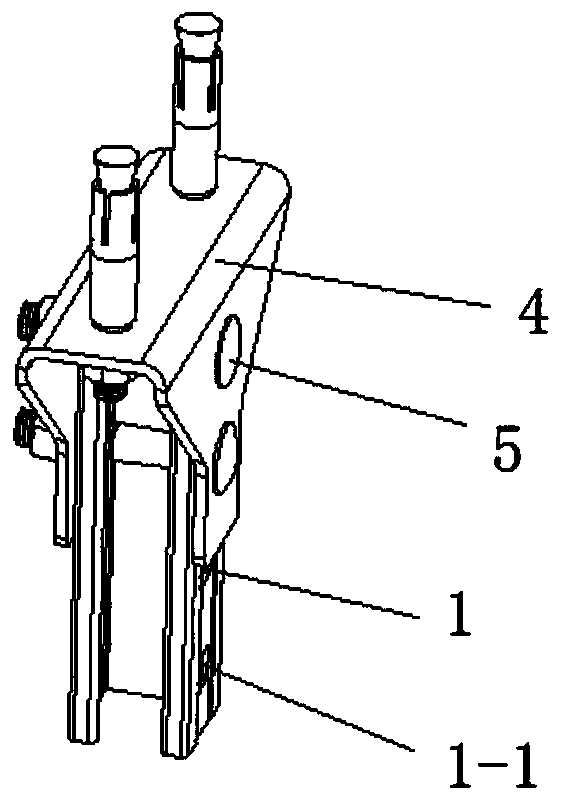

[0080] It can be seen from the accompanying drawings that it includes a column 1, a cross arm 2, a first corner connector 3, and a first base 4;

[0081] The number of the uprights 1 is two, and each upright 1 is arranged vertically at both ends of the cross arm 2 in a symmetrical arrangement; the three side walls of the uprights 1 and the cross arm 2 are provided with profile mounting holes 1-1; the first corner connector 3 is attached to the side wall of the column 1 and the cross arm 2, and one end of the column 1 on each side and the cross arm 2 is connected by a pair of the first corners The first base 4 is arranged on the top of the column 1 on each side, and is matched with the fastener 5 to realize locking and fixing.

[0082] Further, both the column 1 and the cross arm 2 are made of C-shaped inner angled channel steel.

[0083] Further, the profile mounting holes 1-1 provided on each of the uprights 1 and the cross arms 2 are arranged in an array, and each profile m...

Embodiment 2

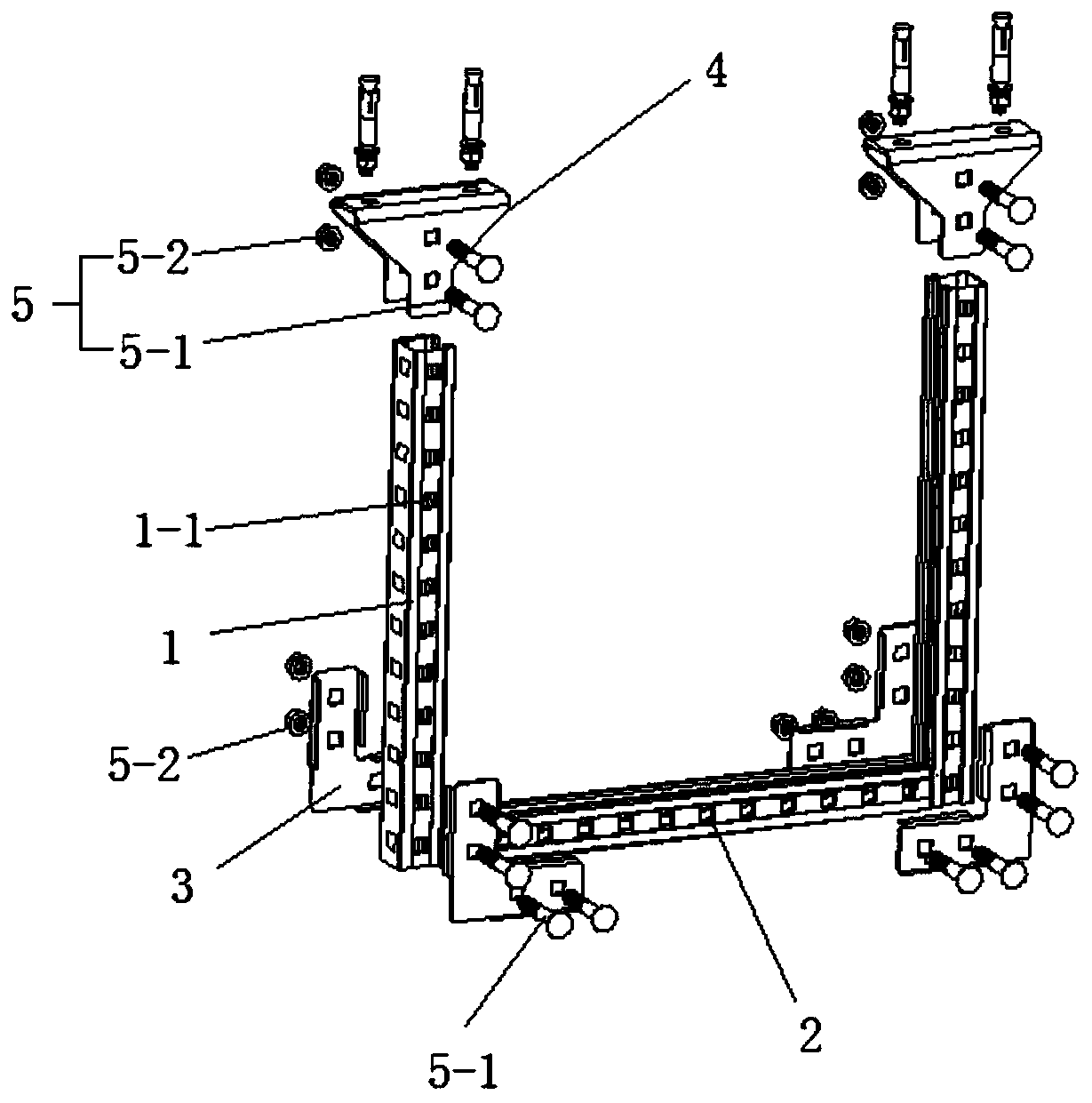

[0097] It can be seen in conjunction with the accompanying drawings that the difference between embodiment 2 and embodiment 1 lies in the bolt 5-1, and the bolt 5-1 adopts a square neck bolt 5-1 of common length;

[0098] The number of fasteners 5 used in each of the first corner connectors 3 is four groups; the bolts 5-1 of each two groups of fasteners 5 pass through the first corner connection holes and a column of the first corner connector 3 respectively. 1 The mounting hole 1-1 of the profile on the single side wall is screwed with two sets of bolts 5-1 through two sets of nuts 5-2; the bolts 5-1 of each set of fasteners 5 penetrate through the first corner connector The first angle connection hole of 3, the profile installation hole 1-1 of the single side wall at one end of the cross arm 2, and are respectively threaded with two sets of bolts 5-1 by two sets of nuts 5-2;

[0099] The number of fasteners 5 used in each of the first bases 4 is four groups; the bolts 5-1 of...

Embodiment 3

[0101] It can be seen from the accompanying drawings that the difference between embodiment 3 and embodiment 1 lies in the first base 4, and embodiment 3 uses the second base 6 instead of the first base 4;

[0102] The second base 6 includes a second base cylinder 6-1 and a second base fin 6-2; the cross section of the second base cylinder 6-1 is in the shape of "匚", and the second base cylinder 6-1 The two sides of the wall are provided with a second base cylinder hole 6-1-1, and the number of the second base cylinder hole 6-1-1 on each side is two, in a square structure; the second base fin 6-1- 2. It is arranged on both sides of the end of the second base tube 6-1. The second base fins 6-2 are formed by mechanical bending and form an integral structure with the first base tube 4. The second base The surface of the second base fin 6-2 is provided with a second base fin hole 6-2-1;

[0103] The number of fasteners 5 used in each of the second base 6 is two groups; the bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com