Multiposition printing production line for balloons

A production line and balloon technology, used in printing, printing presses, rotary printing presses, etc., can solve the problems of low work efficiency, easy to explode, shift position, etc., and achieve the effect of improving printing quality, improving printing efficiency and avoiding printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

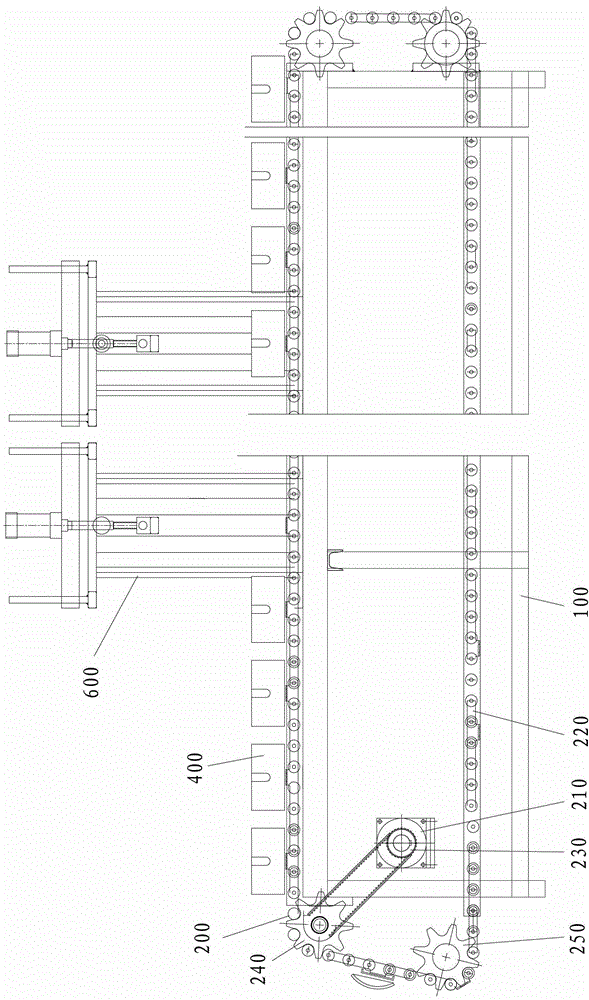

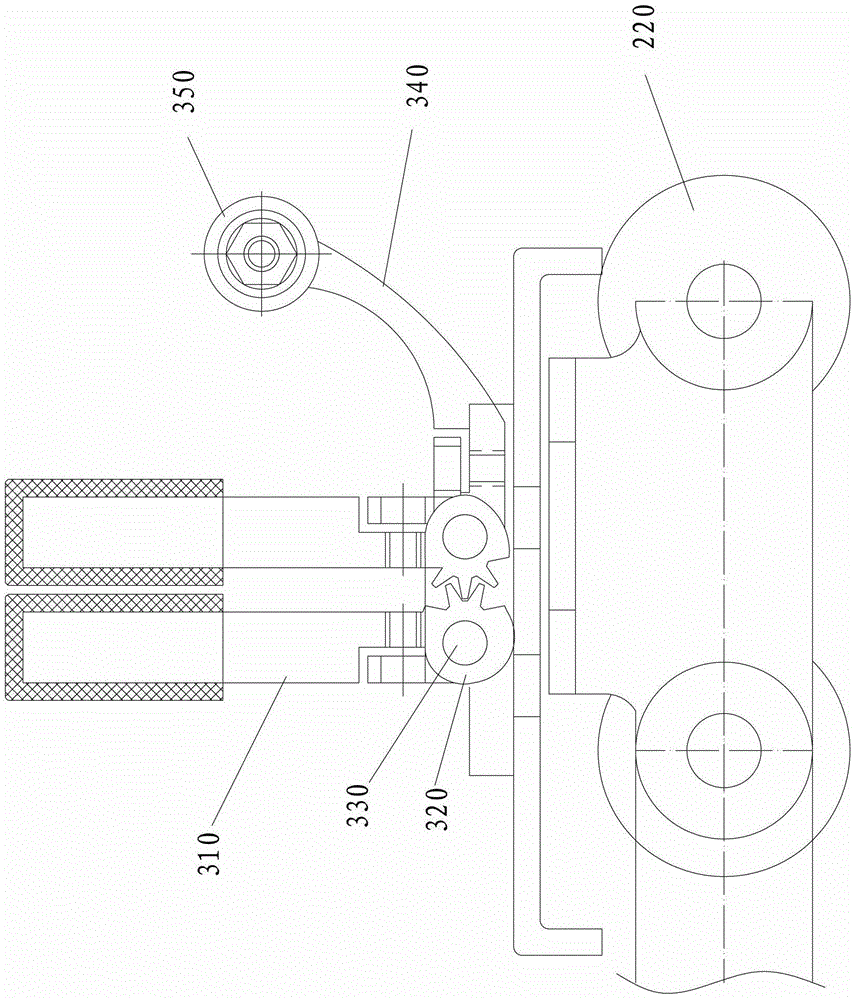

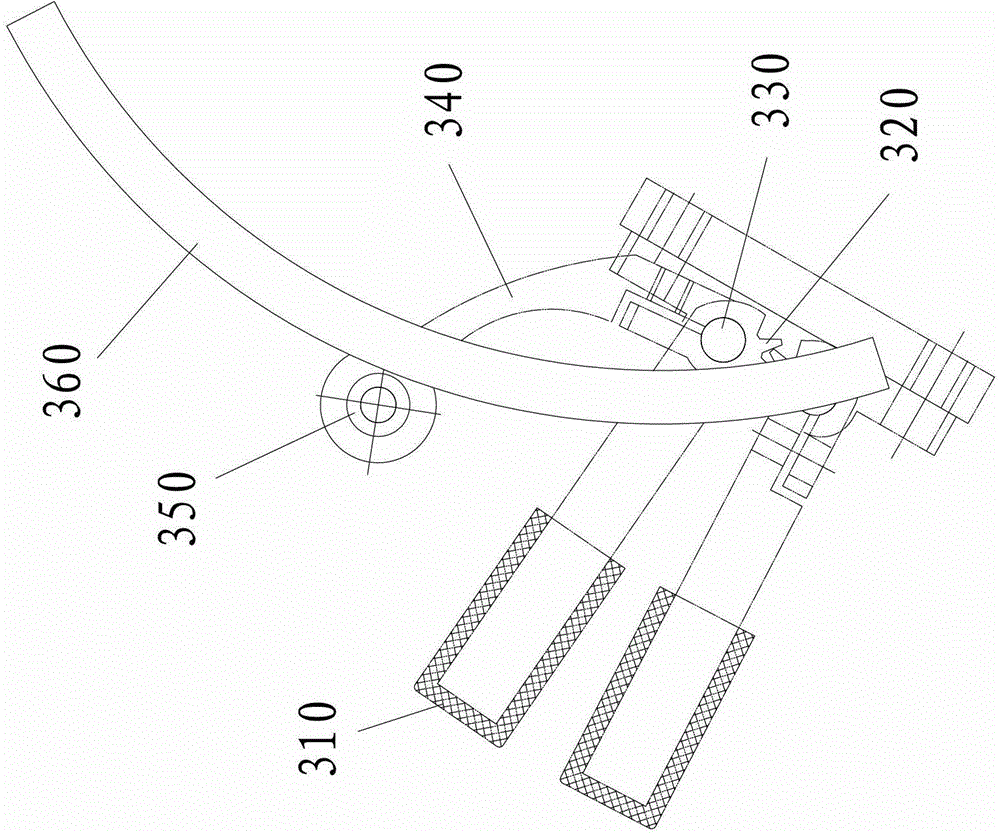

[0052] like Figures 1 to 16 As shown, a multi-position balloon printing production line of the present invention includes a frame 100, a conveying device 200, a balloon clamping and unloading device 300, a balloon positioning sleeve 400, an air blowing device 500, a printing device 600 and a numerical control system.

[0053] The frame 100 adopts a frame structure and is mainly used for installing the conveying device 200 , the balloon clamping and unloading device 300 , the balloon positioning sleeve 400 , the blowing device 500 and the printing device 600 .

[0054] The conveying device 200 includes a conveying motor 210 , a chain 220 , a driving wheel 230 , a tensioning wheel 250 and a mounting plate 260 . The conveying motor 210 adopts a three-phase asynchronous motor, and the three-phase asynchronous mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com