Internal pressure type sleeve compensator provided with composite external safety casing pipe

A technology of sleeve compensator and internal pressure type, which is applied in expansion compensating devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., which can solve the problems of safety production accidents, bellows leakage, and bellows with many waves and other issues, to achieve the effect of safe and reliable work, enhanced sealing performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

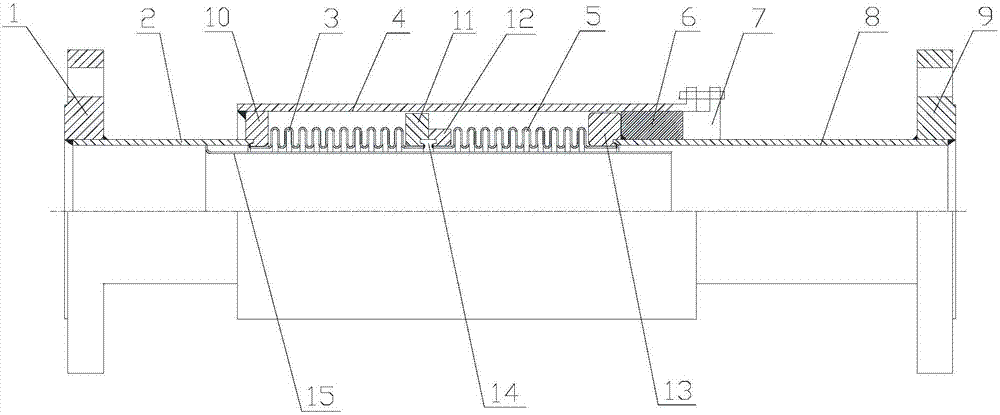

[0016] Such as figure 1 As shown, the internal pressure sleeve compensator of the composite external insurance sleeve includes left core tube 2, right core tube 8, left bellows 3, right bellows 5 and diversion tube 15, and the left end of left core tube 2 A left flange 1 is provided, and a right flange 9 is provided at the right end of the right core tube 8 . The left core tube 2 is connected to the left corrugated tube 3, the right core tube 8 is connected to the right corrugated tube 5, the left corrugated tube 3 is connected to the right corrugated tube 5, and the guide tube 15 is arranged on the left core tube 2 to the right core tube 8 In the inner cavity of the guide tube 15, the left end of the guide tube 15 is connected and fixed with the inner wall of the left core tube 2, the right end of the guide tube 15 extends into the right core tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com