Ultrasonic heat meter temperature sensor anti-wire-twisting device

A temperature sensor and sensor technology, applied in measuring devices, calorimeters, measuring heat, etc., can solve the problems of reducing the service life of wires and temperature sensors, and achieve the effect of simple structure and simple and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

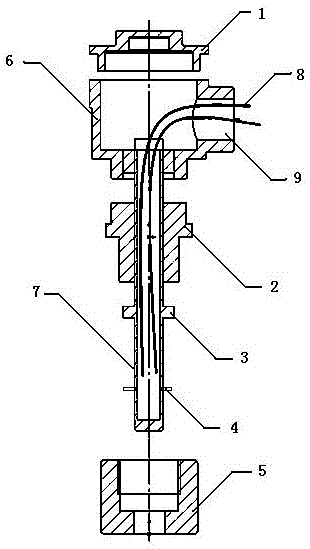

[0010] Such as figure 1 As shown, a sensor cavity 6 is provided, a sensor cover 1 is installed on the upper end of the sensor cavity 6, a wire outlet 9 is processed on one side of the sensor cavity 6, a tubular sensor guide rod 7 is connected to the lower end of the sensor cavity 6, and the sensor guide The inner cavity of the rod 7 communicates with the sensor cavity 6, the sensor guide rod 7 is fixed with a stopper 3, the sensor guide rod 7 at the lower end of the stopper 3 is covered with a gasket 4, and the gap between the stopper 3 and the sensor cavity 6 The sensor guide rod 7 is covered with a live nut 2, the lower end of the sensor guide rod 7 is inserted into the through hole of the base 5, the sensor is installed in the base 5, the live nut 2 and the base 5 are threaded together, and the lower end of the wire 8 Connected with the sensor, the upper end of the wire 8 passes through the inner cavity of the sensor guide rod 7 and the sensor cavity 6 from the wire outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com