Novel steel wooden door frame

A steel-wood door, a new type of technology, applied in the direction of window/door frame, etc., can solve the problems of shortening the service life of solid wood furniture, lack of flame retardancy, safety hazards, etc., and achieve the effect of material saving, convenient processing and low maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

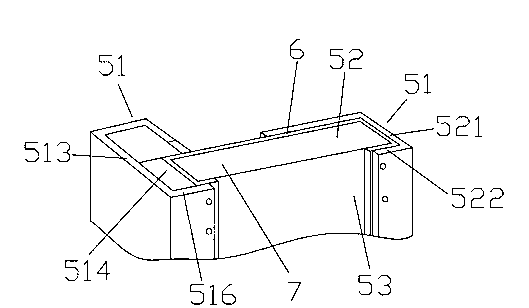

[0028] As shown in the accompanying drawings, a new type of steel-wood door frame includes a door panel step 51 and a door frame base 52 arranged perpendicular to each other; a steel plate frame 6 is arranged inside the door frame base 52 . The door frame base 52 is connected to the door panel step 51 through the steel plate frame 6 .

[0029] The door panel step 51 includes an integrally formed step outer frame 513 and a fireproof block arranged in the step outer frame 513. The fireproof block includes two vertically connected pieces, and the two fireproof blocks include a horizontal fireproof block 514 and the vertical fire block 515, the upper surface of the horizontal fire block 514 and one side surface of the vertical fire block 515 are arranged in close contact with the inner wall surface of the outer frame 513 of the step, and the lower surface of the horizontal fire block 514 is in contact with the The other side surface of the vertical fire block 515 is respectively c...

Embodiment 2

[0035] The difference from Embodiment 1 is that the steel plate frame 6 is filled with inorganic fireproof material cores 7 before the wall is installed, which reduces the step of pouring the inorganic fireproof material after the wall is installed.

[0036] In the present invention, the steel plate frame 6 is directly arranged in the door frame 5. The steel material not only increases the overall strength and flame retardancy of the door frame, but also improves the weather resistance of the door frame 5 because the thermal expansion and contraction rate of the steel plate is extremely small, and it does not have water absorption. , so that it shrinks and expands smaller with the change of solar terms, so as to ensure that the painted surface will not crack or warp. The utility model has the advantages of simple structure, convenient processing and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com