T-tube connector capable of being rotated by 360 degrees

A technology of rotating joints and through joints, applied in the direction of pipes/pipe joints/pipes, pipes, branch pipelines, etc., can solve the problems of troublesome connection, narrow space, hard work, etc., and achieve the effect of simple and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

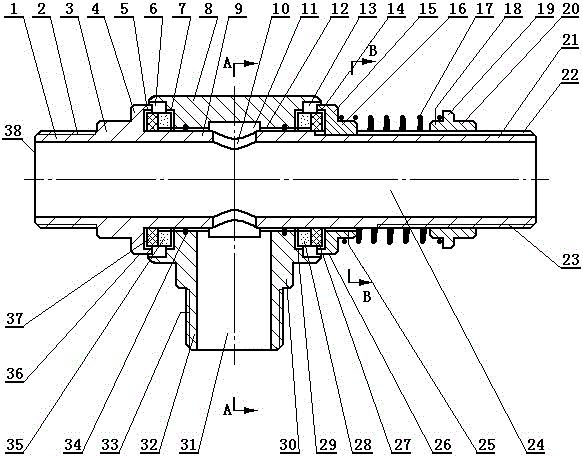

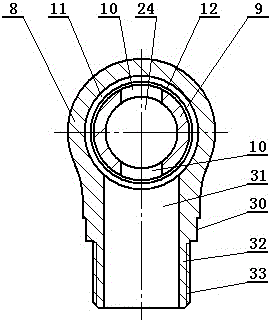

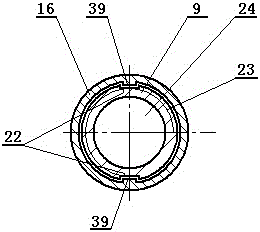

[0032] Embodiment: As shown in the accompanying drawings, the rotary joint 8, the pressing plate 15, the compression spring 17, the adjusting nut 19, the second graphite sealing ring 27, the second ceramic sealing ring 28, the silicone sealing ring 34, the first ceramic sealing ring Ring 35, the first graphite sealing ring 37 and the three-way pipe joint that can be rotated 360 degrees formed by the fixed joint 38, the upper and lower wall thicknesses of the hollow tube 9 in the middle of the fixed joint 38 are provided with upper and lower symmetrical round holes 10 , the circular hole 10 communicates with the inner hole 24 of the fixed joint 38, the outer diameter of the hollow tube 9 is provided with a rotary joint 8 capable of rotating 360 degrees, and the lower end of the rotary joint 8 is provided with a third joint 32 of an integral structure, the third The outer diameter of the joint 32 is provided with a third external thread 33 , and the upper end of the third externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com