Multifunctional Scaffolding for Construction Engineering

A construction engineering, multi-functional technology, applied in the connection of scaffolding, construction, building structure, etc., can solve the problems of repeated use, hidden dangers, broken fasteners, etc., and achieve the effect of avoiding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

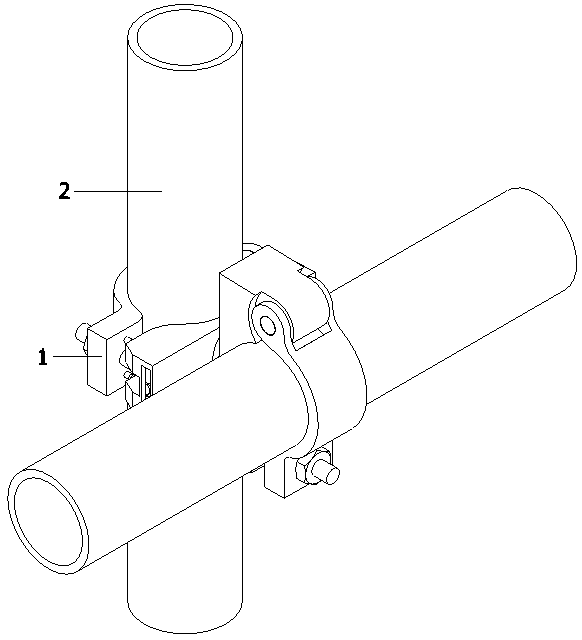

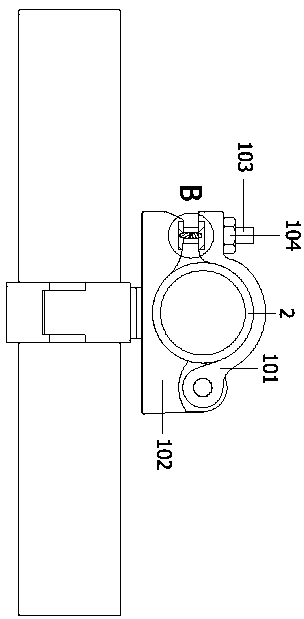

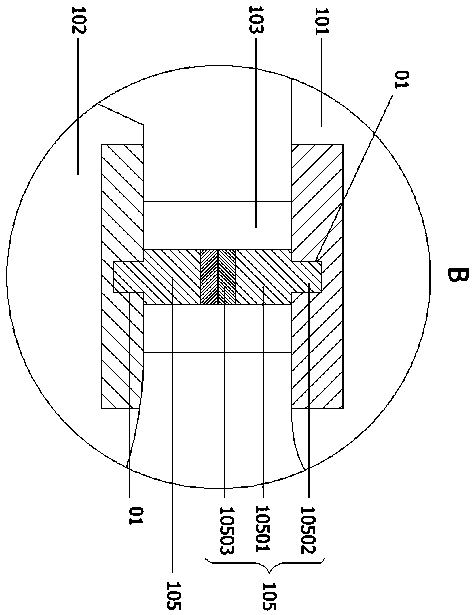

[0028] as attached figure 1 To attach Figure 7 Shown:

[0029] The present invention provides a multifunctional scaffold for construction engineering, comprising a steering fastener 1, an upper fastener block 101, a first annular groove 10101, a lower fastener block 102, an arched groove 10201, a screw rod 103, a nut 104, and a second annular groove 10401, limit device 105, cylindrical block 10501, threaded column 10502, rubber cushion 10503, blister parallel instrument 106, thread groove 01, bearing 02, ring block 03, nylon wire 04 and steel pipe 2; the steering fastener 1 One end is composed of the upper fastener block 101 and the lower fastener block 102 which are rotatably connected; the screw rod 103 connected to the left end of the lower fastener block 102 passes through the through hole provided at the left end of the upper fastener block 101 , and a set of nuts 104 are threaded on the screw 103; the bottom surface of the nut 104 is provided with a second annular gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com