Friction roller suitable for conical bobbin

A friction roller and conical cylinder technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of rotation and slippage, affecting production efficiency, uneven force, etc., and achieves stable work and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

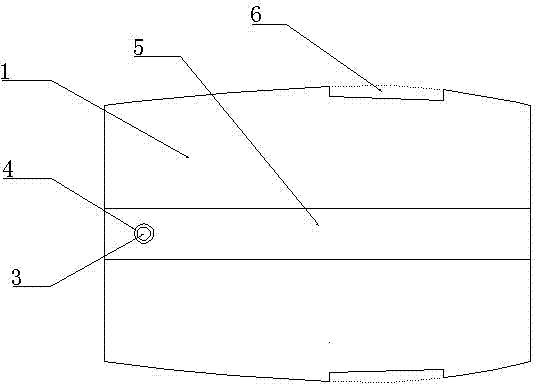

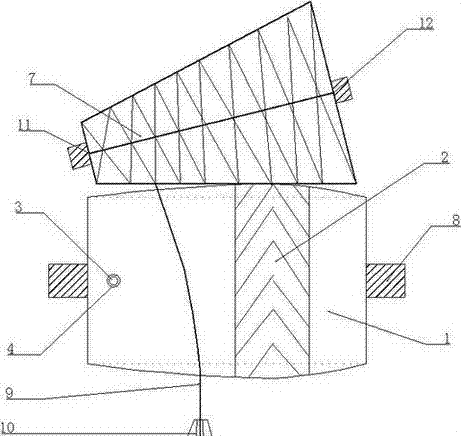

[0016] like figure 1 As shown, a friction roller suitable for tapered bobbins of the present invention includes a friction roller body (1), a rubber (2) and a top wire (3), and a cylindrical friction roller body (1) with slightly bulging sides. A shallow rubber groove (6) is provided on the side where the side deviates from the middle. After the rubber (2) with the same size as the shallow rubber groove (6) is embedded in the shallow rubber groove (6), the side of the friction roller body (1) and the rubber (2) The outer surface is smooth and consistent. The top wire (3) is screwed into the top wire hole (4) perpendicular to the center shaft hole (5), contacts with the center shaft (8) of the fixed friction roller, and tightens the top wire (3), so that the friction roller is tightly fixed in the center on the shaft (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com