Borate type automobile brake fluid

A technology of automobile brakes and borates, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of increasing the steric hindrance of borates, reducing the temperature rise of brake fluid, and volatile moisture, etc., and achieves good Effect of Low Temperature Kinematic Viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

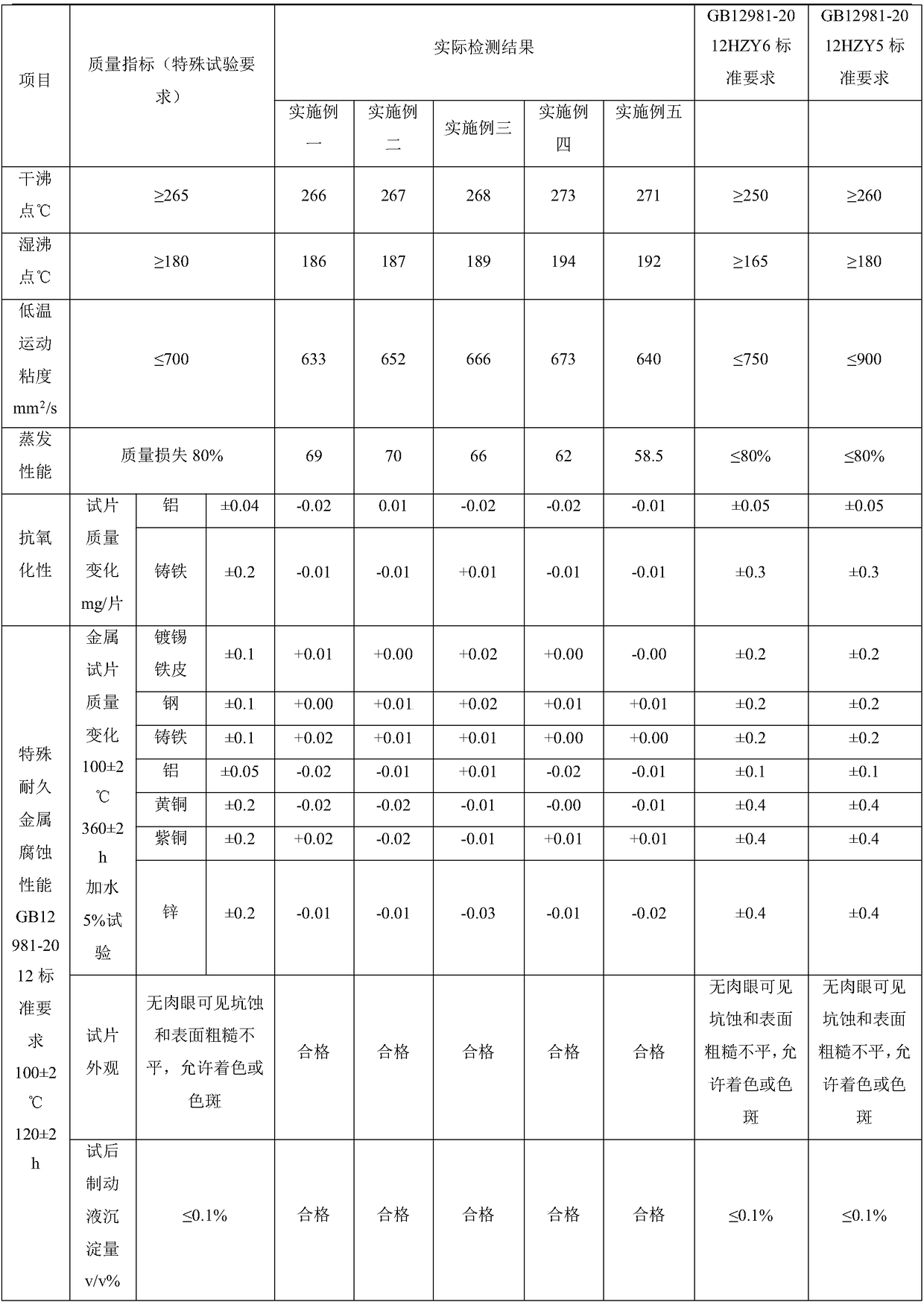

Examples

Embodiment 1

[0022] Into a 1.5T reactor, add polyethylene glycol butyl ether composition: 80kg; polyethylene glycol methyl ether composition: 78kg; triethylene glycol methyl ether borate: 834kg; start adding additives after stirring for 5 minutes, Each additive is added at an interval of 5 minutes and then the next adjuvant is added in order, 6-methyl-2-mercaptobenzothiazole: 0.3kg; methylbenzotriazole: 0.35kg; antioxidant BHT: 0.6kg ; 2-ethylhexyl acrylate: 0.15kg; 4,4′-butylene bis(6-tert-butyl m-cresol): 0.12kg; 2,2-【【(methyl-1H-benzotri Azol-1-yl)methyl]imino]Diethanol: 1.1kg; methylparaben: 0.02kg; dodecahydrodiphenylamine: the rest; each material is added at an interval of 5min, and after stirring for 6h, it can pass 0.1 The um filter is filtered and sub-packed to obtain borate type automobile brake fluid.

Embodiment 2

[0024] In a 1.5T reactor, add polyethylene glycol butyl ether composition: 54kg; polyethylene glycol methyl ether composition: 54kg; triethylene glycol methyl ether borate: 884kg; start adding additives after stirring for 5 minutes, Each additive is added at an interval of 5 minutes and then the next adjuvant is added in order, 6-methyl-2-mercaptobenzothiazole: 0.4kg; methylbenzotriazole: 0.45kg; antioxidant BHT: 0.7kg ; 2-ethylhexyl acrylate: 0.16kg; 4,4'-butylene bis(6-tert-butyl m-cresol): 0.15kg; 2,2-【【(methyl-1H-benzotri Azol-1-yl)methyl]imino]Diethanol: 1.0kg; ethyl paraben: 0.01kg; dodecahydrodiphenylamine: the rest; each material is added at an interval of 5min, and after stirring for 6h, it can pass 0.1 The um filter is filtered and sub-packed to obtain borate type automobile brake fluid.

Embodiment 3

[0026] Add polyethylene glycol butyl ether composition: 62kg; triethylene glycol methyl ether borate: 930kg into a 1.5T reaction kettle; start adding additives after stirring for 5 minutes, and add each additive in sequence after 5 minutes. The next adjuvant, 6-methyl-2-mercaptobenzothiazole: 0.25kg; methyl benzotriazole: 0.25kg; antioxidant BHT: 0.7kg; 2-ethylhexyl acrylate: 0.3 kg; 4,4'-butylene bis(6-tert-butyl m-cresol): 0.2kg; 2,2-[[(methyl-1H-benzotriazol-1-yl)methyl] imino 】Diethanol: 1.5kg; methyl paraben: 0.015kg; tri-n-butylamine: the rest; each material is added at an interval of 5 minutes, and after stirring for 6 hours, it can be filtered and packed through a 0.1um filter to obtain borate Type car brake fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com