Recycled ester, preparation method thereof and application of recycled ester in preparation of HZY3 brake fluid

A technology for brake fluid and recyclate, applied in the field of preparing HZY3 brake fluid, recovering ester and its preparation, can solve the problem of not involving the recycling of high-vacuum recyclate, not mentioning the treatment scheme of the recyclate after esterification, not involving Recyclables treatment and other issues, to achieve good low temperature kinematic viscosity, high dry and wet boiling point, and reduce production and processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First prepare reclaimed ester, preparation steps are as follows:

[0024] (1) Low vacuum esterification stage: Add 100kg of boric acid with a purity ≥ 99.9%, 0.05kg of analytically pure phosphorous acid, and 1,800kg of high-vacuum recyclate into the reactor. Carry out the dehydration reaction at -165°C, control the heating rate ≤ 5°C / h, and the reaction time ≥ 24h. When the reaction temperature reaches 160°C ~ 165°C, heat slowly, then keep it at 165°C for 1h, and cool down after no moisture slips out to room temperature;

[0025] (2) High-vacuum esterification stage: Under the conditions of vacuum degree ≥ 0.096Mpa and temperature 155-180 ℃, carry out micro-dehydration reaction, control the reaction time ≥ 24h, and recover the ester after the reaction is completed.

[0026] Next, prepare HZY3 brake fluid, its preparation steps are as follows: in the reaction kettle of 1.5T, add polyethylene glycol methyl ether 250kg successively; Trihydroxypolyoxypropylene ether: 35kg;...

Embodiment 2

[0031] Using the recycled ester prepared in Example 1 to prepare HZY3 brake fluid, the preparation steps are as follows: in a 1.5T reactor, add 200 kg of polyglycol methyl ether; trihydroxypolyoxypropylene ether: 25 kg; recycled ester: 300 kg ; Diethylene glycol: 100kg; Triethylene glycol monobutyl ether 180kg; Tetraethylene glycol dimethyl ether: 100kg; Tolyl benzotriazole: 6kg; 4-hydroxyphenyl) propane (bisphenol A): 8kg parts; tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: 6kg parts; polypropylene glycol 2000: 0.12 kg; sodium nitrite: 1.5kg, then add diisopropanolamine to adjust the pH value to above 7.5, then continue to stir for 4 hours, filter through a 0.1um filter and pack separately to obtain HZY3 brake fluid.

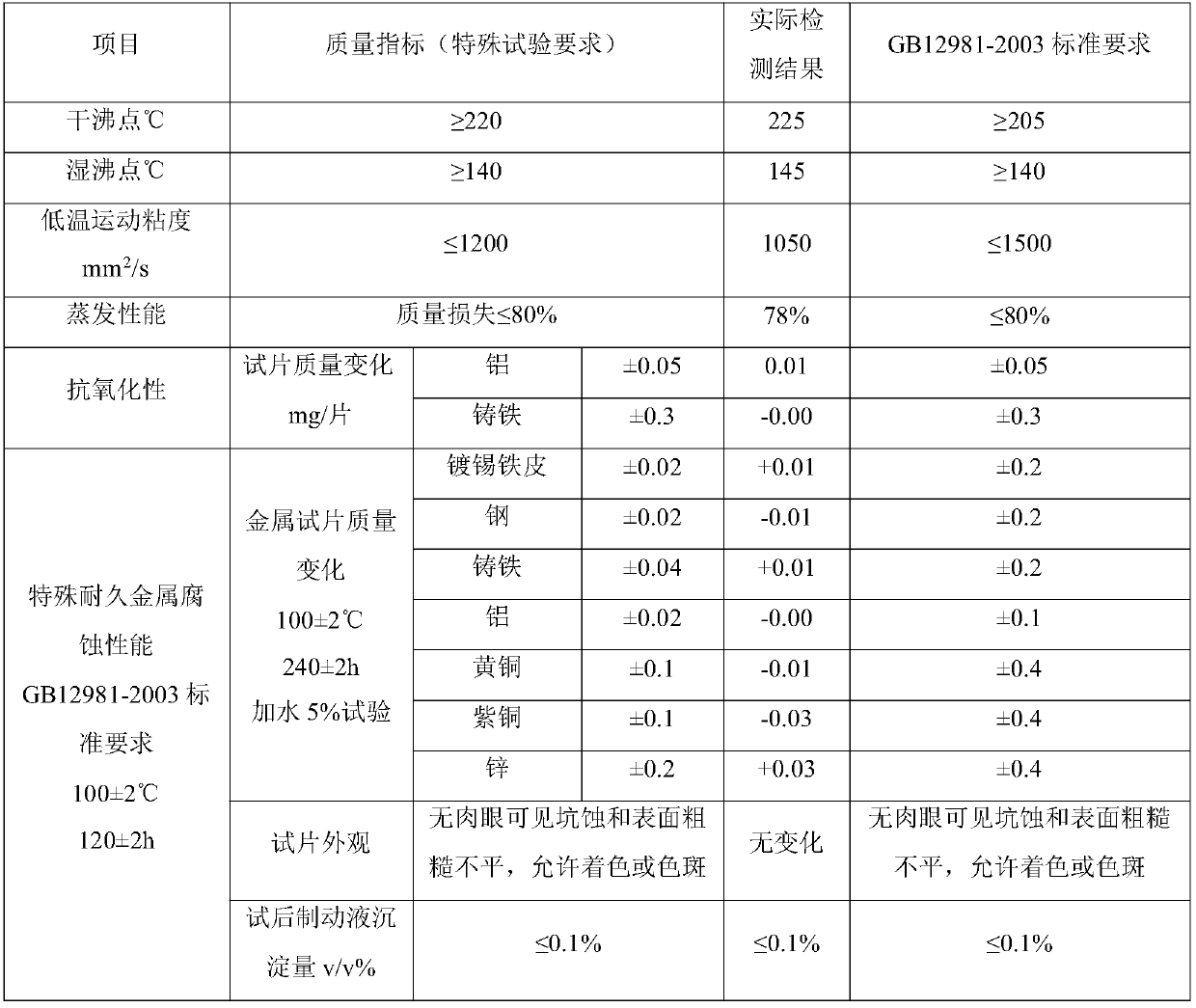

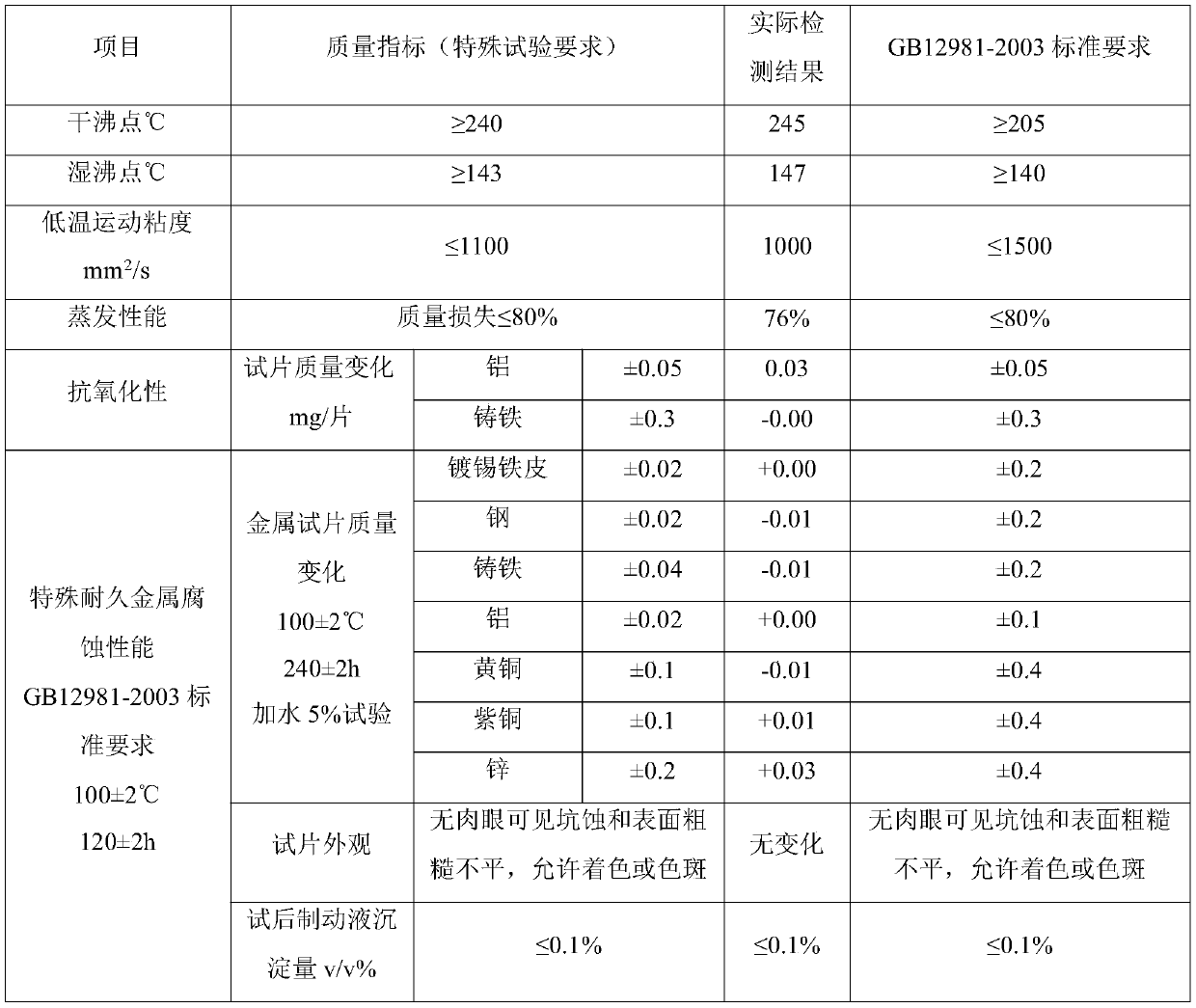

[0032] According to the requirements of the special durable metal corrosion experiment, the technical indicators of the HZY3 brake fluid prepared in Example 1 were tested, and the test results are shown in Table 2 below.

...

Embodiment 3

[0036] Using the recycled ester prepared in Example 1 to prepare HZY3 brake fluid, the preparation steps are as follows: in a 1.5T reactor, add polyglycol methyl ether: 150kg; trihydroxypolyoxypropylene ether: 20kg; recycled ester: 450kg; diethylene glycol: 100kg; triethylene glycol monobutyl ether: 200kg; tetraethylene glycol dimethyl ether: 50kg; methyl benzotriazole: 8kg; dioctylaniline: 10kg; 2,2- Bis(4-hydroxyphenyl)propane (bisphenol A): 10kg; tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: 5kg; polypropylene glycol 2000: 0.2 kg; sodium nitrite: 0.5kg, then add diisopropanolamine to adjust the pH value to above 7.5, then continue to stir for 4 hours, filter through a 0.1um filter and pack separately to obtain HZY3 brake fluid.

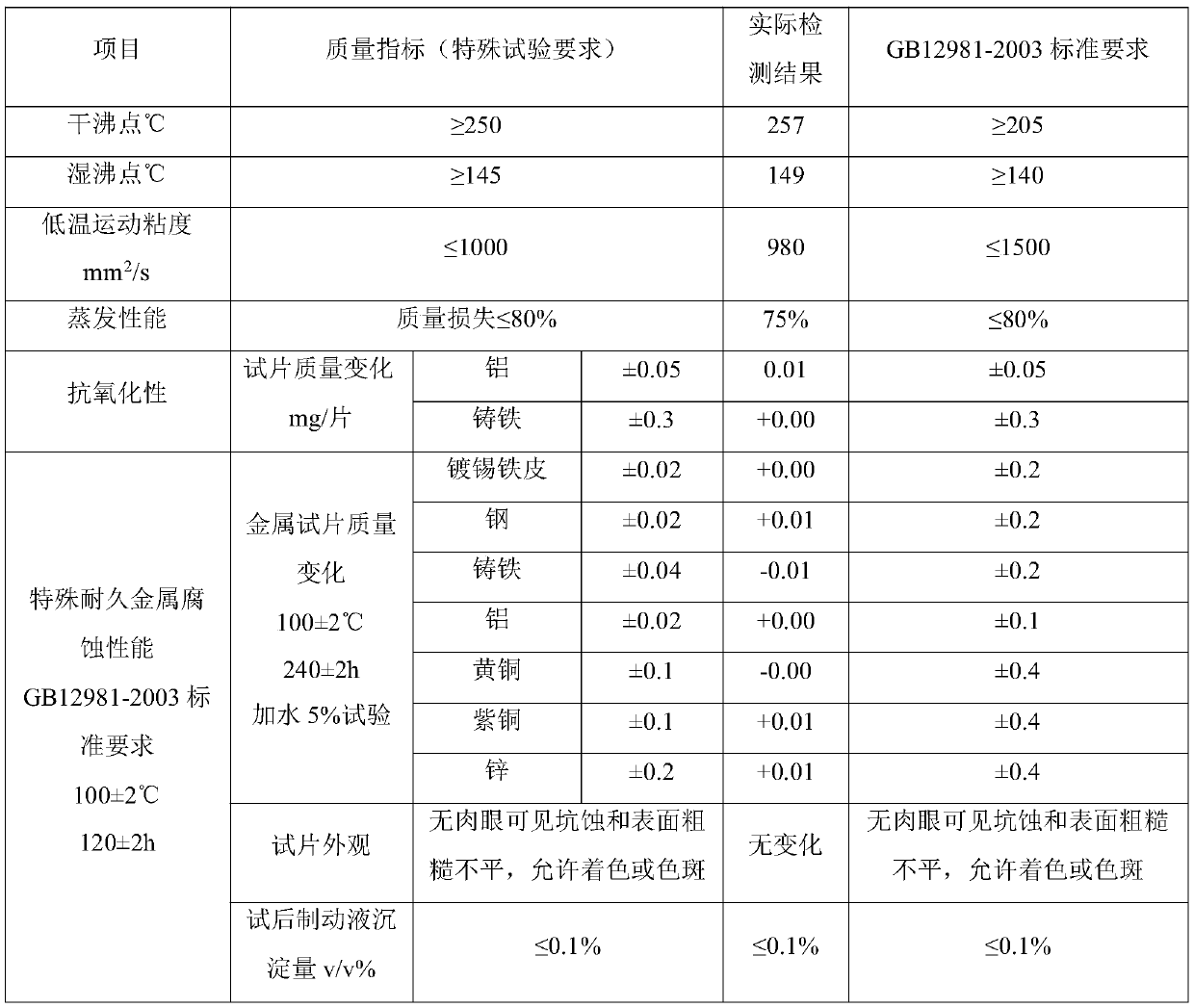

[0037] According to the requirements of the special durable metal corrosion experiment, the technical indicators of the HZY3 brake fluid prepared in Example 1 were tested, and the test results are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com