A kind of steel arch construction method

A construction method and technology for steel arches, which are applied to the field of steel arches of arch bridges, can solve problems such as the inability of various span arch bridges to meet construction needs, the inability to adapt to the construction needs of various linear arch bridges, and the inability to arbitrarily adjust the linearity of the arch axis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

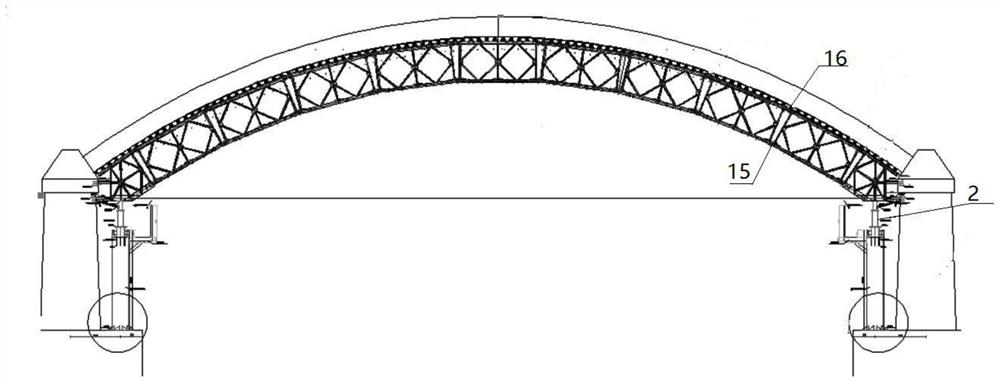

[0029] Such as Figure 1-4 As shown, a steel arch construction method at least includes the following steps:

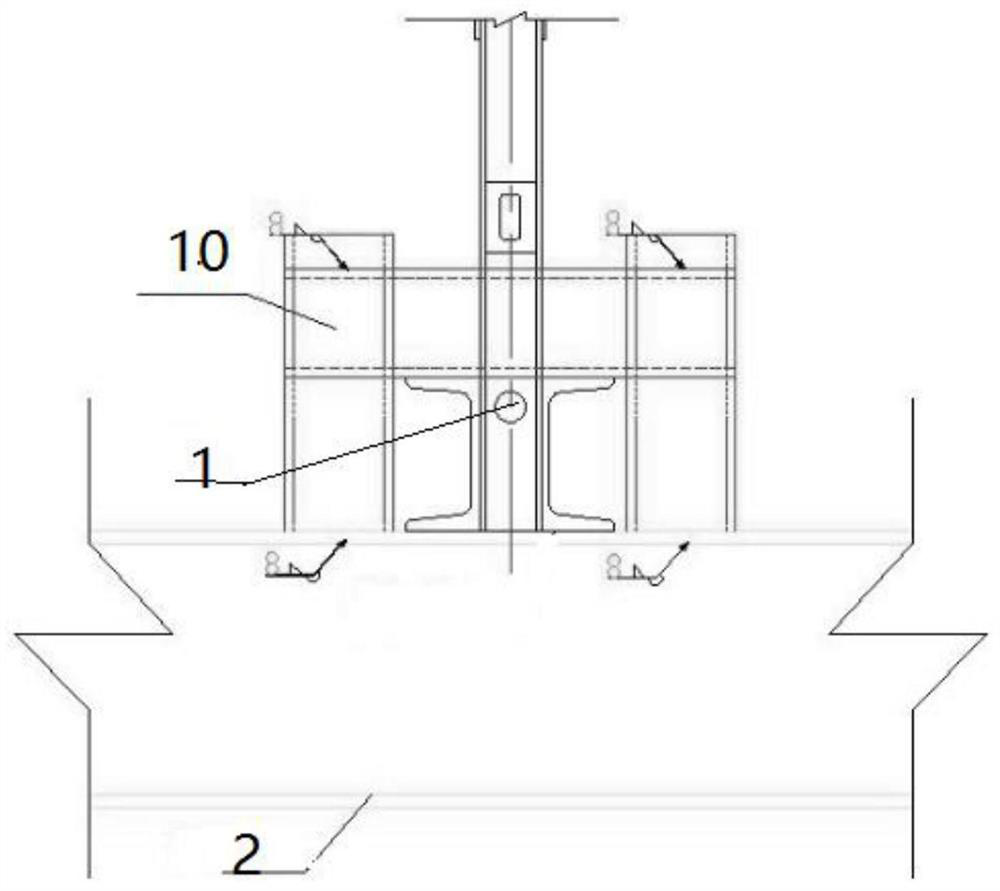

[0030] 1) Assembling the steel arch frame at least includes the following steps: first, horizontally assemble the horizontal bridge of the steel arch frame in groups; secondly, hoist and erect the horizontally assembled steel arch frame; Install rebar 1 and distribution beam 2 on the arch foot of the frame to complete the assembly;

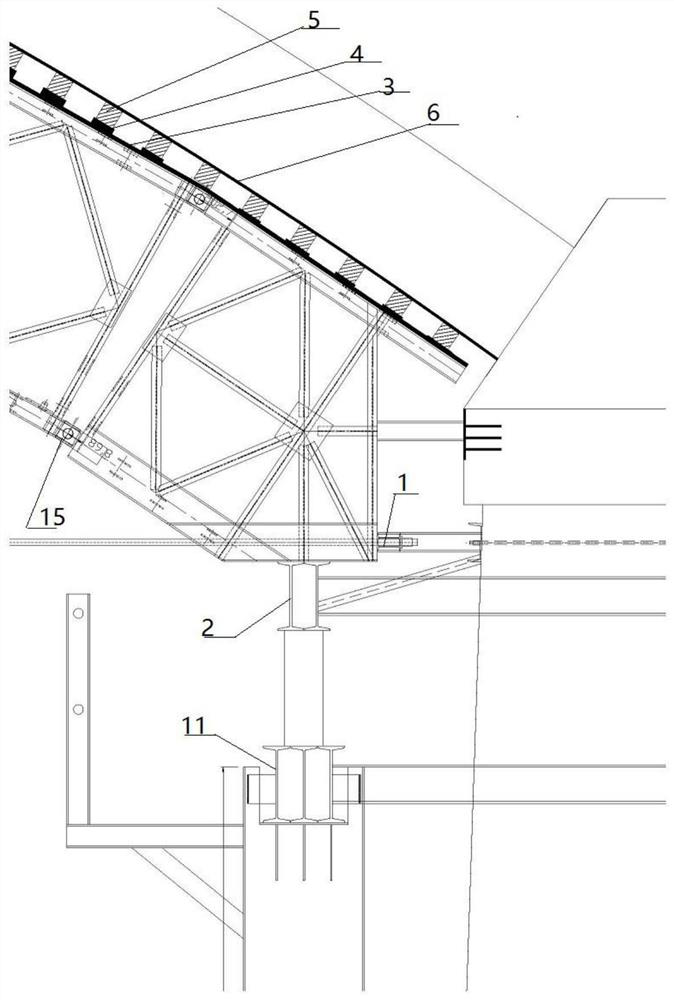

[0031] 2) Installing the steel arches assembled in step 1) at least includes the following steps: first, install and position the steel arches group by group; secondly, fix the arch feet of the positioned steel arches; On the top of the steel arch frame, lay steel strips 3, wedge-shaped steel plates 4, horizontal beams 5 and bottom mold 6 in sequence from bottom to top, and install side molds on one side of the bottom mold to complete the installation;

[0032] 3) pouring concrete on the main arch ring of the steel arch frame installed ...

Embodiment 2

[0036] On the basis of embodiment 1, a kind of steel arch construction method at least comprises the following steps:

[0037] 1) Assembling the steel arch frame at least includes the following steps: first, horizontally assemble the horizontal bridge of the steel arch frame in groups; secondly, hoist and erect the horizontally assembled steel arch frame; Rebar 1 and distribution beam 2 are installed on the arch foot of the frame to complete the assembly; said step 1) The specific steps of horizontal assembly are: first release the large sample in proportion according to the level of the catenary line of the arch shaft, and determine the size according to the large sample. The position and rotation angle of each Bailey sheet are made with positioning cards to form an assembled tire frame; secondly, the assembly is carried out from the arch foot at one end of the steel arch to the arch foot at the other end. When assembling, the lower chord between the standard segments of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com